-

Posts

249 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Salt Lake City, UT

-

Interests

Travel, Hiking, Skiing, Golf, History (Civil War), Wood and plastic models

Recent Profile Visitors

-

Geordie Tyne reacted to a post in a topic:

New to wooden ship modeling

Geordie Tyne reacted to a post in a topic:

New to wooden ship modeling

-

WWR4 reacted to a post in a topic:

New to wooden ship modeling

WWR4 reacted to a post in a topic:

New to wooden ship modeling

-

Keith Black reacted to a post in a topic:

New to wooden ship modeling

Keith Black reacted to a post in a topic:

New to wooden ship modeling

-

Welcome @WWR4 I tried years ago to get into wood ship modeling, but my first one was very frustrating, and I finally gave up on it. A few years ago, when I retired, I thought I would try it again. Thankfully I started like you did with the GB Dory, then moved on to the other two Model Shipways Shipwright learning trio, the Norwegian Sailing Pram and the Muscongus Bay Lobster Smack. I learned a lot from these that have given me the confidance and skills to try more difficult models. I hope you enjoy building these model ships. There will be times you want to quit as you build more complicated ships, but take a break and then resume. Have fun. SkiBee

-

robert952 reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

robert952 reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

-

RVB reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

RVB reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

-

Geordie Tyne reacted to a post in a topic:

Getting Started: From Dollhouses to the USS Constitution

Geordie Tyne reacted to a post in a topic:

Getting Started: From Dollhouses to the USS Constitution

-

Ryland Craze reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

Ryland Craze reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

-

Keith Black reacted to a post in a topic:

Getting Started: From Dollhouses to the USS Constitution

Keith Black reacted to a post in a topic:

Getting Started: From Dollhouses to the USS Constitution

-

Taken Aback reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

Taken Aback reacted to a post in a topic:

The latest to begin the Model Shipways 3 kit set

-

Getting Started: From Dollhouses to the USS Constitution

SkiBee replied to Jasennord's topic in New member Introductions

@Jasennord welcome and you will learn a lot and gain skills that will help in your future builds. -

The latest to begin the Model Shipways 3 kit set

SkiBee replied to Taken Aback's topic in New member Introductions

@Taken Aback you will learn a lot and gain great experience in these 3 ships. I had built the MS 18th Century Long boat first and had a lot of problems that would have been prevented if I had built the MS Shipwright series first. Good luck and welcome, you will enjoy this hobby. -

Ryland Craze reacted to a post in a topic:

New Member Bob Roeder

Ryland Craze reacted to a post in a topic:

New Member Bob Roeder

-

Bob I'm in the middle of building the AVS too. I have found that I get a lot of great information from @CiscoH AVS build log, I have found him very responsive to messages via this web site. He is ahead of me in the build, since I have taken a break from the build. Also, I've found great detail instructions from Luck St Shipyards, https://lauckstreetshipyard.com/ the instructions do cost but I have found them indispensable. Also, I'm also building the MS Phantom, but it is on hold while I focus on the AVS. Please do post some pictures of your Phantom.

-

SkiBee reacted to a post in a topic:

Speedwell Battle Station Kit 1752 by CiscoH - Syren Ship Model Company - 3/8" or 1:32

SkiBee reacted to a post in a topic:

Speedwell Battle Station Kit 1752 by CiscoH - Syren Ship Model Company - 3/8" or 1:32

-

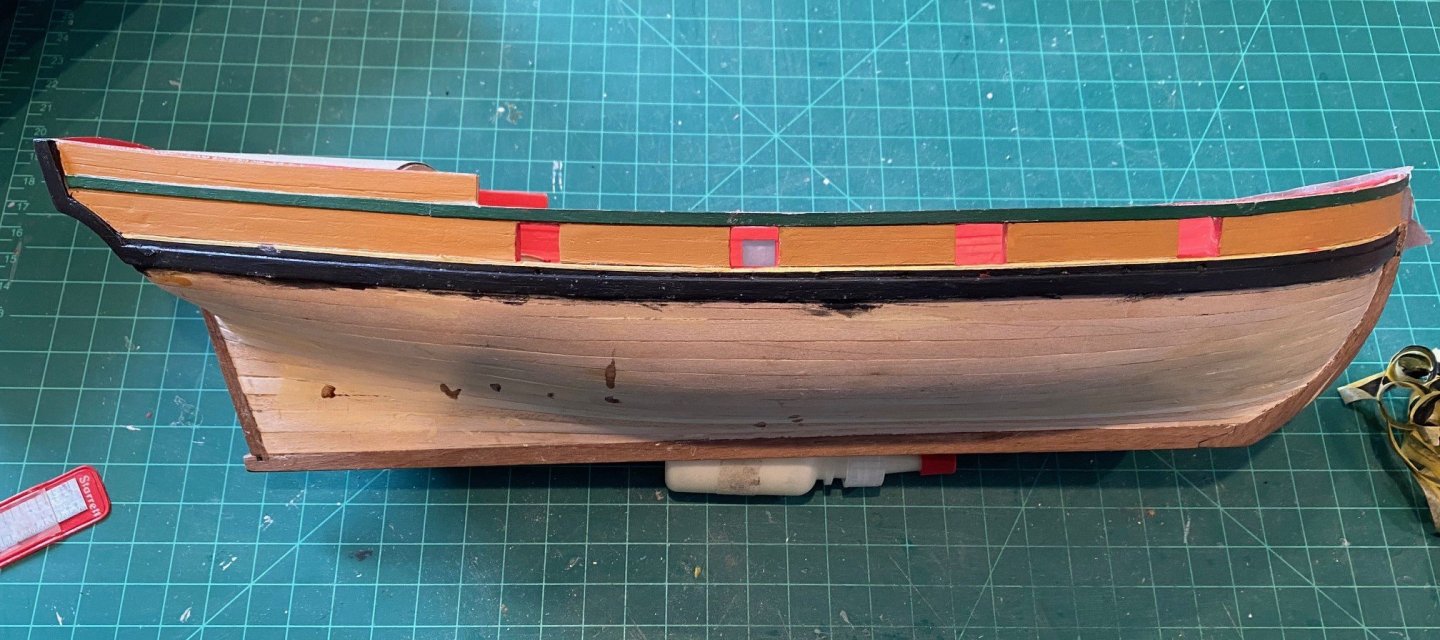

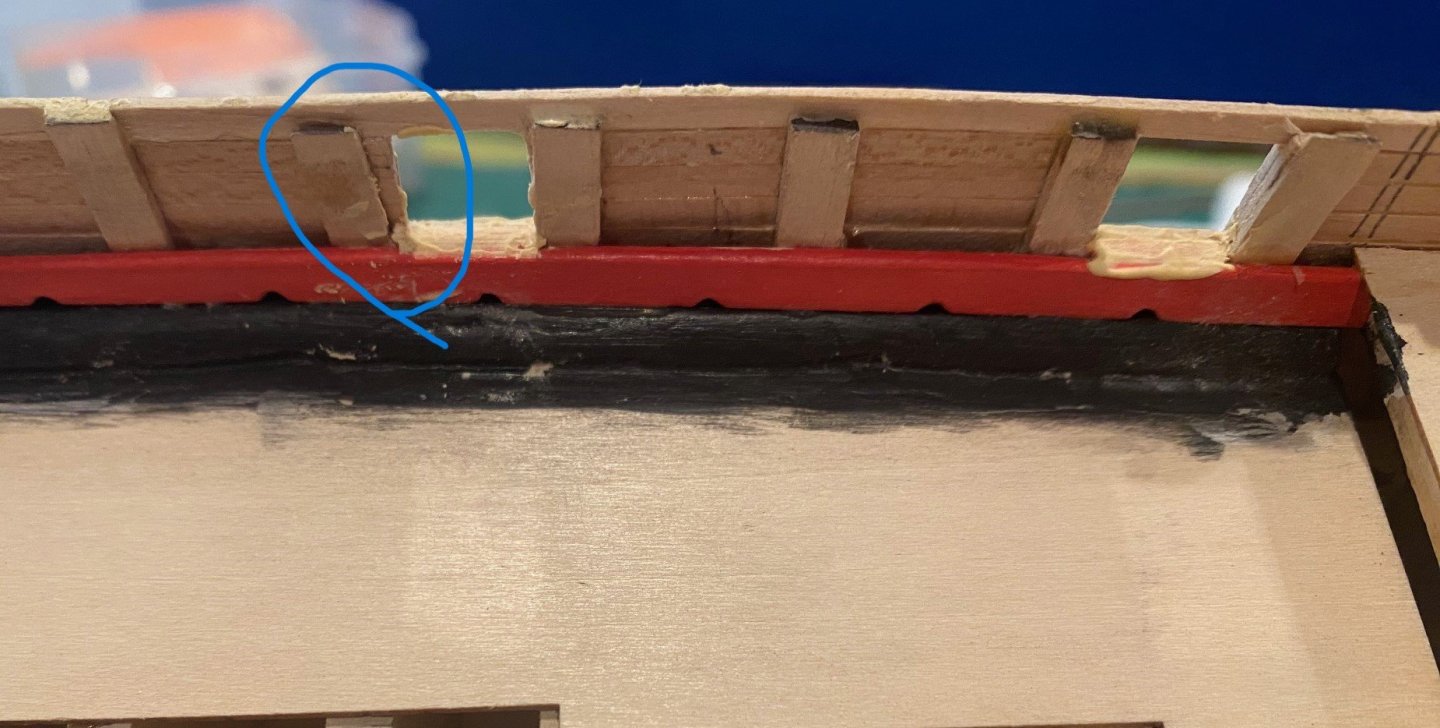

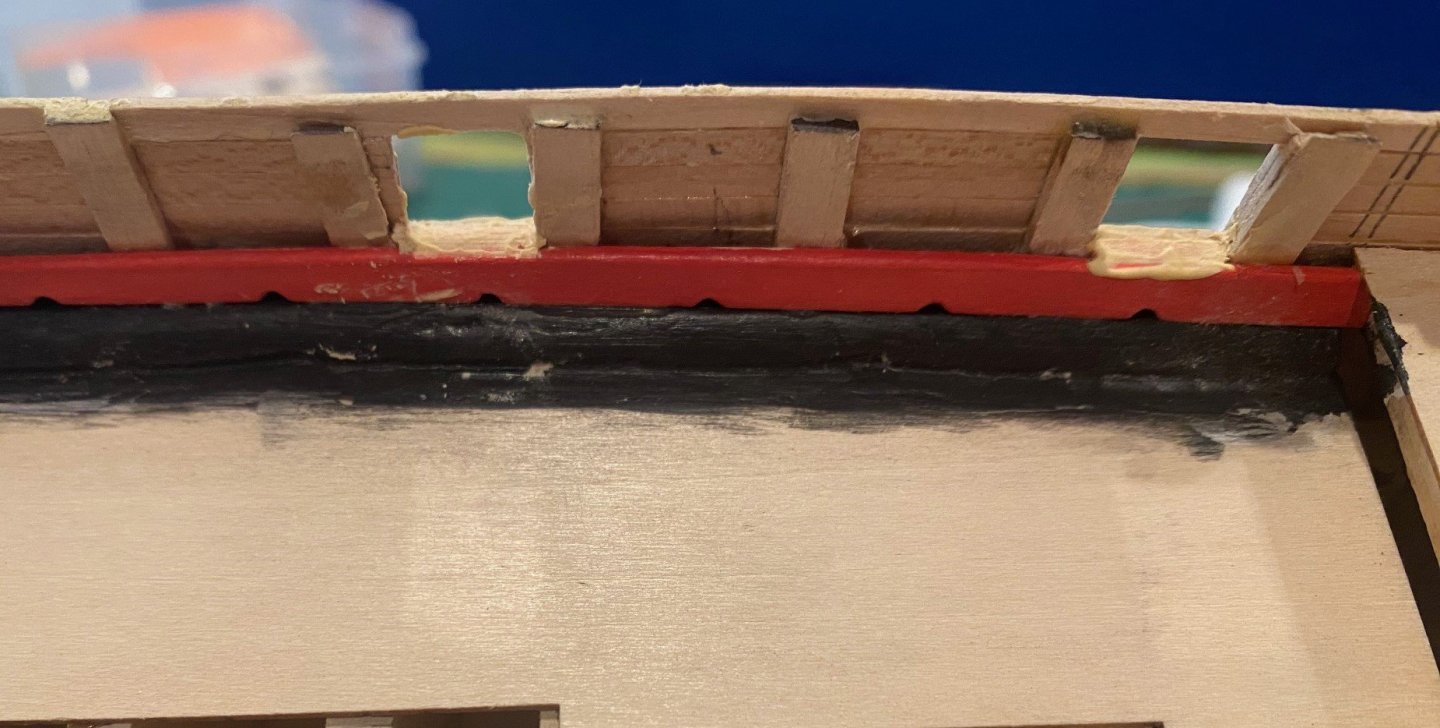

Added the aft deck bulkhead planking and finished the interior and exterior painting. Not the happiest with the finish of the interior, hopefully whey I get everything installed it won’t’ be as noticeable. I ended up with a gap at the fantail and aft ceiling plank, see circled pic below. I’m going to wait until after I plank the decks to see if I need to fix. Now on to the lower planking, a lot of reading of build logs, especially CISCOs, and R Lunt’s practicum from Luck Shipyard; as well as determining the layout and marking up the hull.

-

Hello! New to the forum, happy to be here :)

SkiBee replied to BuckyBoo's topic in New member Introductions

@BuckyBoo welcome. This is a great web site to learn about and ask for help on everything that is model ship building. Also, please update your build on your own build log, you get a lot of great help by doing that. -

NOTE: I strongly recommend that if you don’t have a micrometer to buy one now. One of my biggest problems on this build was determining the thickness of the very thin planks. It was hard to use a rule to distinguish between 1/32-inch plank and 3/64-inch planks, as there is only 1/64 between them. Sometimes hard to distinguish even a 1/16 in plank from them. I’m afraid I used some 1/32 in the wrong place. Save yourself some trouble later on, buy one now. NOTE: I should have drilled a small pilot hole through the spirketting scuppers so you can align the black strake suppers to match the elevation of the spirketting scuppers. The scuppers pilot holes will also provide an upper alignment line for the wales plank. Installed the wales and black strake planks, after I filled the scuppers in the black strake. There was a about a 1/16-inch difference in some areas between the scuppers on the spirketting and black strake planks, I don’t think it will matter much unless someone looks real closely. Then painted the top of the black strake gold. Even though you normally paint dark colors after the lighter colors, I wish I would have painted the black first as it bled through the masking tape a little and now, I have to go back and fix that.

-

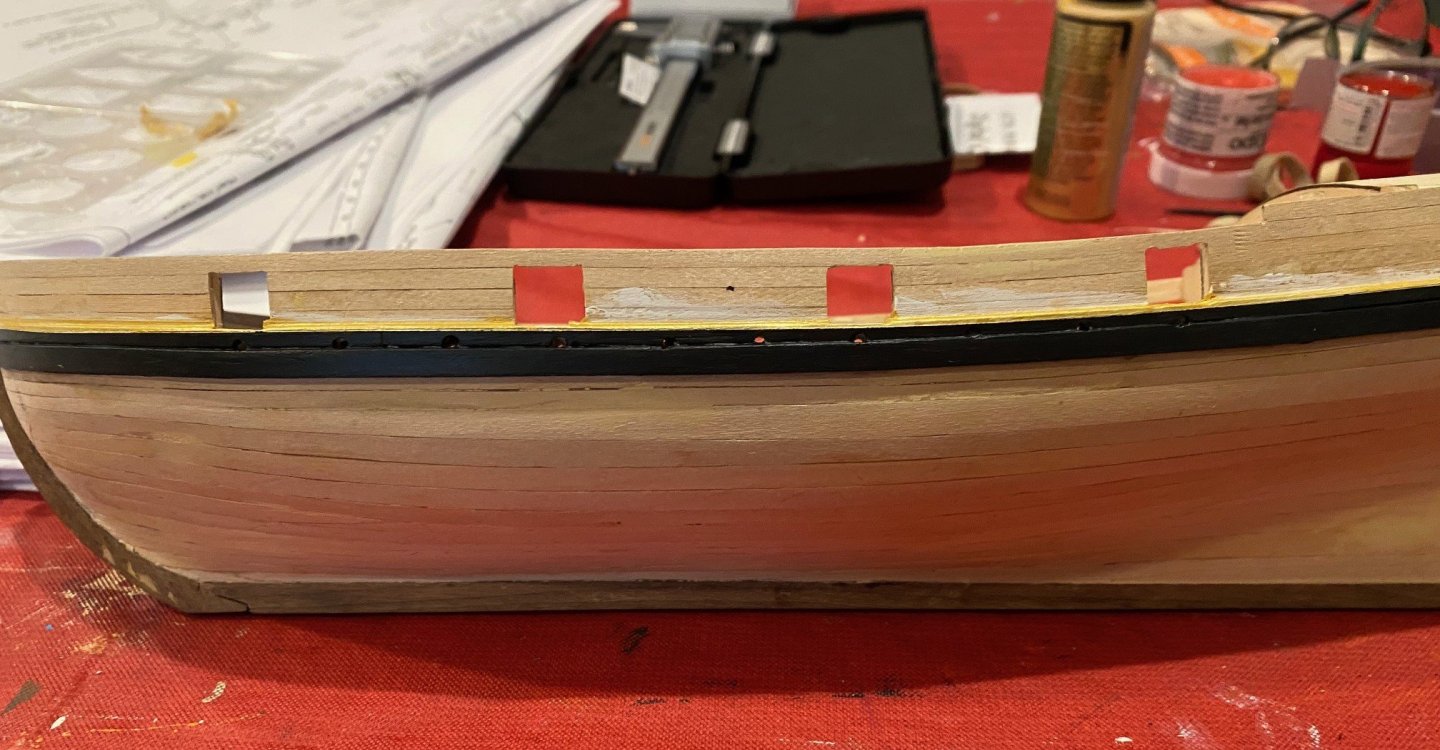

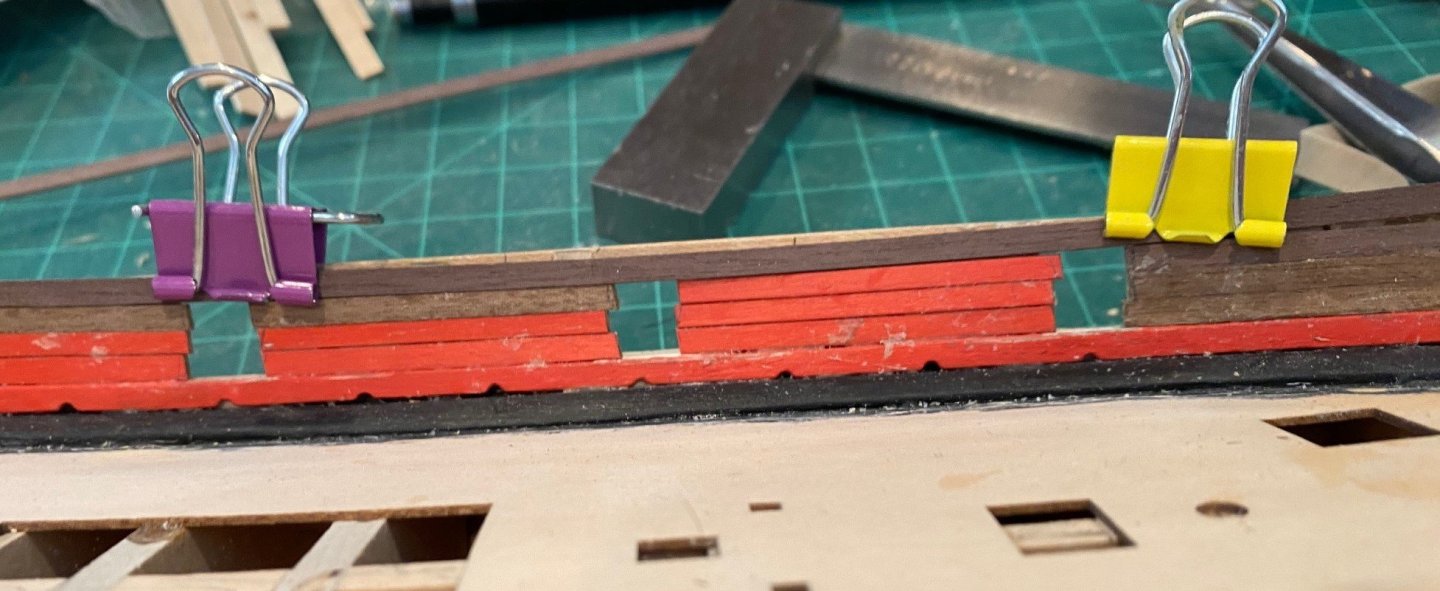

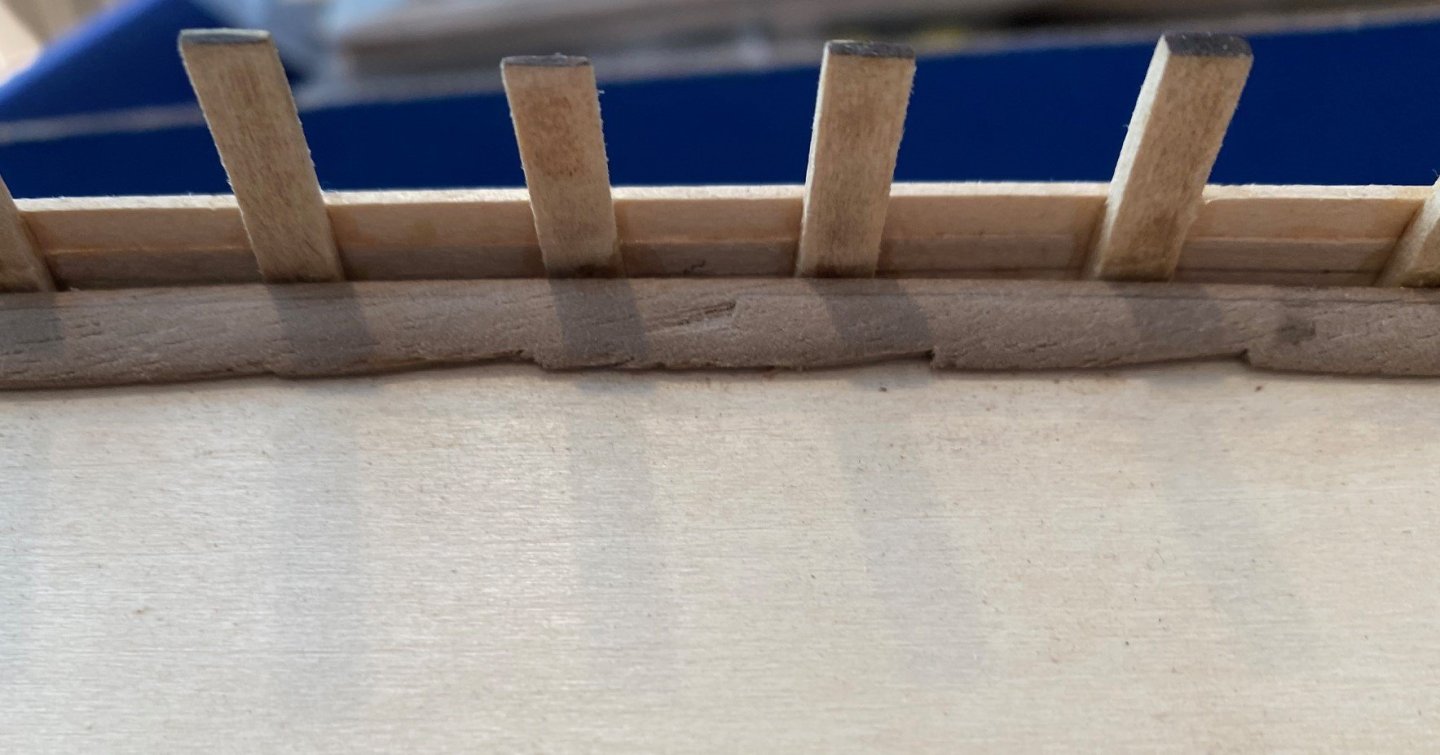

Installed the inner bulwark planks. When I trimmed the planks around the gunports, the walnut splinted a lot, should have cut them to fit better when installing them so I would just have to sand them around the gunport When I went to install the upper plank, noticed that on the port side there was a area mid-ship that was not covered by the plank. Not sure if I should cut the area out or add a sliver of plank to fill in the gap. But I’m going to wait until I install the upper external planks to see if there is a problem there. When you look at that area without the plank, you can see an upward bulge compared to the starboard side. Suggestions welcomed. Port Side Starboard Side

-

NOTE: you need to make sure you measure twice cut once. Also, the walnut is really hard to cut length wise with a knife and plane due to the strong grain wanting to drag you off line when your using your xacto, or end up with chunks. I wasted a fair amount of walnut planks with splitting, braking and such, to the point I had to use multiple pieces to get the length I wanted without wasting wood. I decided to do the internal planking before I did the Wales plank. Started to prep the Spirketting Plank, I picked the wrong walnut plank, to thick, to thin. Then I used the right planks and cut them down to 1/8” per the practicum. However, I found that doing that I ended up with a spirketting plank below the gun ports. The right height for my one plank was 3/16” or slightly under that and the other a little wider than the 1/8 inch. So, recommend checking the space between your final waterway and the bottom of your gun ports before you cut anything. I used a 3/16” round file to make the scuppers to the required dimension. The other problem I noticed was my bulkhead extensions were not the same thickness, especially by the waterway. So, I tried to reduce the thick ones and I’m not sure I’m going to need to shim the thin ones. This became very noticeable when I glued the spirketting plank in, it was at a slight angle instead of vertical. I painted the waterway flat black, and the spirketting plank a flat red. I painted a scrap piece of walnut with the kit’s bulkhead red and a Tamiya flat red to see which one I liked. The flat red was redder than the bulkhead red, but I decided to try the bulkhead red since I can topcoat with the flat red later. I did use white primer on both the waterway and spirketting plank which gave a truer color to the final coats of color. I installed the lower sills on the gunports, had to use a little putty to fill in some small gaps. Also, I noticed that some of the gunports have a gap between the gunport and bulwark extensions. This would leave a noticeable gap in the finished model. So, I’m going to have to fill them like the gunport sills.

-

SkiBee reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

SkiBee reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

SkiBee reacted to a post in a topic:

Muscongus Bay Lobster Smack by SkiBee - FINISHED - Model Shipways - 1:24 Scale

SkiBee reacted to a post in a topic:

Muscongus Bay Lobster Smack by SkiBee - FINISHED - Model Shipways - 1:24 Scale

-

SkiBee reacted to a post in a topic:

Muscongus Bay Lobster Smack by SkiBee - FINISHED - Model Shipways - 1:24 Scale

SkiBee reacted to a post in a topic:

Muscongus Bay Lobster Smack by SkiBee - FINISHED - Model Shipways - 1:24 Scale

-

SkiBee reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

SkiBee reacted to a post in a topic:

18th Century Armed Longboat by TheFace - Model Shipways - 1/24 Scale - First Build

-

SkiBee reacted to a post in a topic:

Armed Virginia Sloop (AVS) by SkiBee - Model Shipways - 1:48

SkiBee reacted to a post in a topic:

Armed Virginia Sloop (AVS) by SkiBee - Model Shipways - 1:48

-

SkiBee reacted to a post in a topic:

Armed Virginia Sloop (AVS) by SkiBee - Model Shipways - 1:48

SkiBee reacted to a post in a topic:

Armed Virginia Sloop (AVS) by SkiBee - Model Shipways - 1:48

-

Jig for planing planks?

SkiBee replied to Pitts2112's topic in Building, Framing, Planking and plating a ships hull and deck

I to use a Xacto and steel rule, but I do draw a line first witch gives a little indent, then I use the back edge of the Xacto to deepen the indent once or twice then cut. I'm going to try the sandpaper on the rule since it seems to slip a lot.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.