-

Posts

1,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Papa

-

Most of the brass fittings are in place. I think I will leave the tall stanchions until after I have fitted the masts.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

I checked the photos in your build log and lt looks as if you did not use the tiny nail pads (part 23) under the oarlocks.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

I took the attached photo to ask how Master Korabel expected one to insert the square peg (of the oarlock)in the tiny round hole in the nail pad. But in the photo I can see the outline of an oarlock inside the etching. Were we expected to file these down to this outline? The post might go into the hole if it were filed down and rounded. I saw nothing in the instructions to suggest this and in any case that would be way way beyond my ability. I plan to use them as is and without the tiny pad.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

A bit of an understatement! And very difficult to snip off of the sheet.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

Current status. The long rails along the deck were difficult to glue down as the glue surface is very narrow and there is nothing to clamp to. I was eventually able to get a clamp from the rail down to the bar in the keel vise. It was unstable but held long enough for the glue to set. See photo (I used 3 clamps per side)

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

Planking is done. I installed the sternpost binding. I found that I could not do the nails as described by MK; they were too tiny and went flying around the room. Instead I drilled out the holes about 0.001 larger than the wire, held a small section of wire with needle nosed pliers and pushed the wire into the hole after dabbing the end in some superglue. I then snipped the wire flush with the binding plate. Some needed a bit of filing to get flush.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

Velcro

-

Planking is done. Started sanding. The planking was quite easy with pre-shaped planks. I did find it easier to align and glue the planks to the reference frame (15) first. And then glue forward and aft rather than starting at the bow or stern as recommended.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

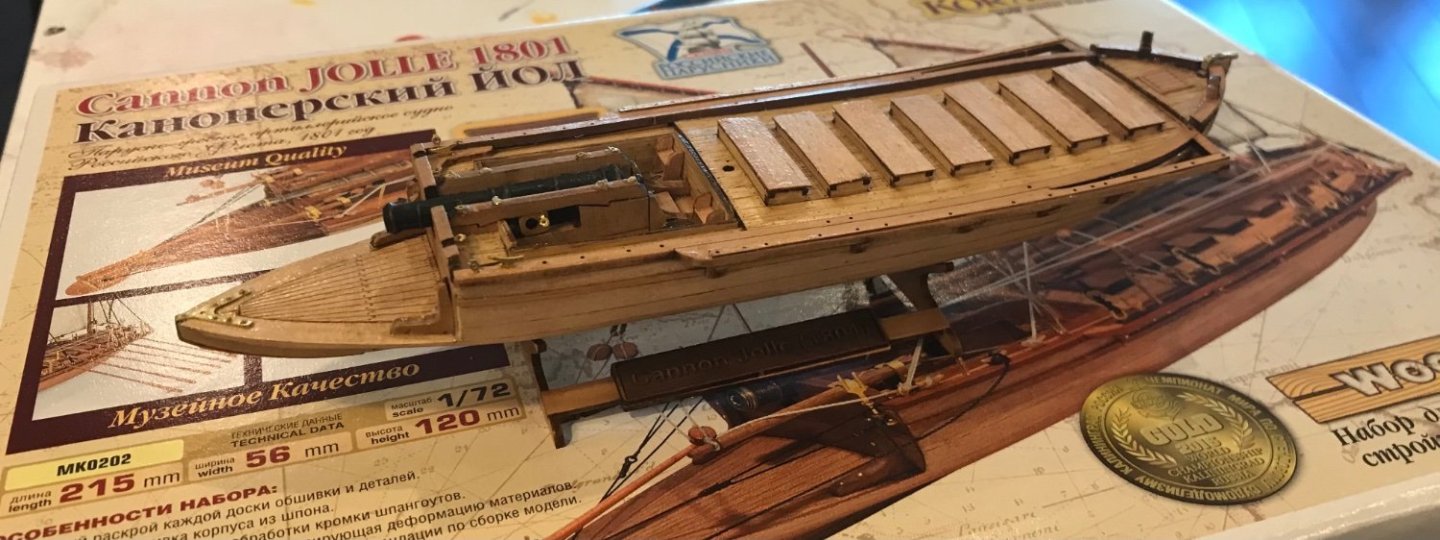

Back from the lake and spend the morning reviewing build logs for this kit.I would have saved myself a lot of trouble and expense had I done this before starting! Never to old to learn a valuable lesson. I was wondering if i should keep the PE parts bright as shown on the box art. Looks like all the builders painted the PE black. I am also looking at how the kits were finished (i.e., painted or stained etc.).

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

Yes, I know. Thanks for the reminder anyway. I wanted to make sure the keel fit before planking and the instructions suggested this step in fact. It took a lot of sanding but now the keel pieces fit perfectly without excessive force. I also now have 3 rows of planks in place. It is nice having the planks shaped to fit. The shipyard will be closed for a week as we are taking our granddaughter to a nearby lake for a week.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

I just started fitting the keel. I see what you mean about a tight fit.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

I have the seat supports (D10) in place and decks D5 L/R, D2 and D3. These pieces are very thin and fragile and the protrusions of D10 broke in many places places and 2 of the cross pieces of D2 broke as well . I wonder how anyone could install these without some breakage. It was certainly way beyond my skill level. In any case I think it will all look ok when finished. This kit is not nearly as easy as I had expected! After posting and looking at the photo I think the two forward deck cross pieces look wonky. They were the parts that broke. Since I have an extra kit I may just replace those two, cutting the replacements from the extra D sheet.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

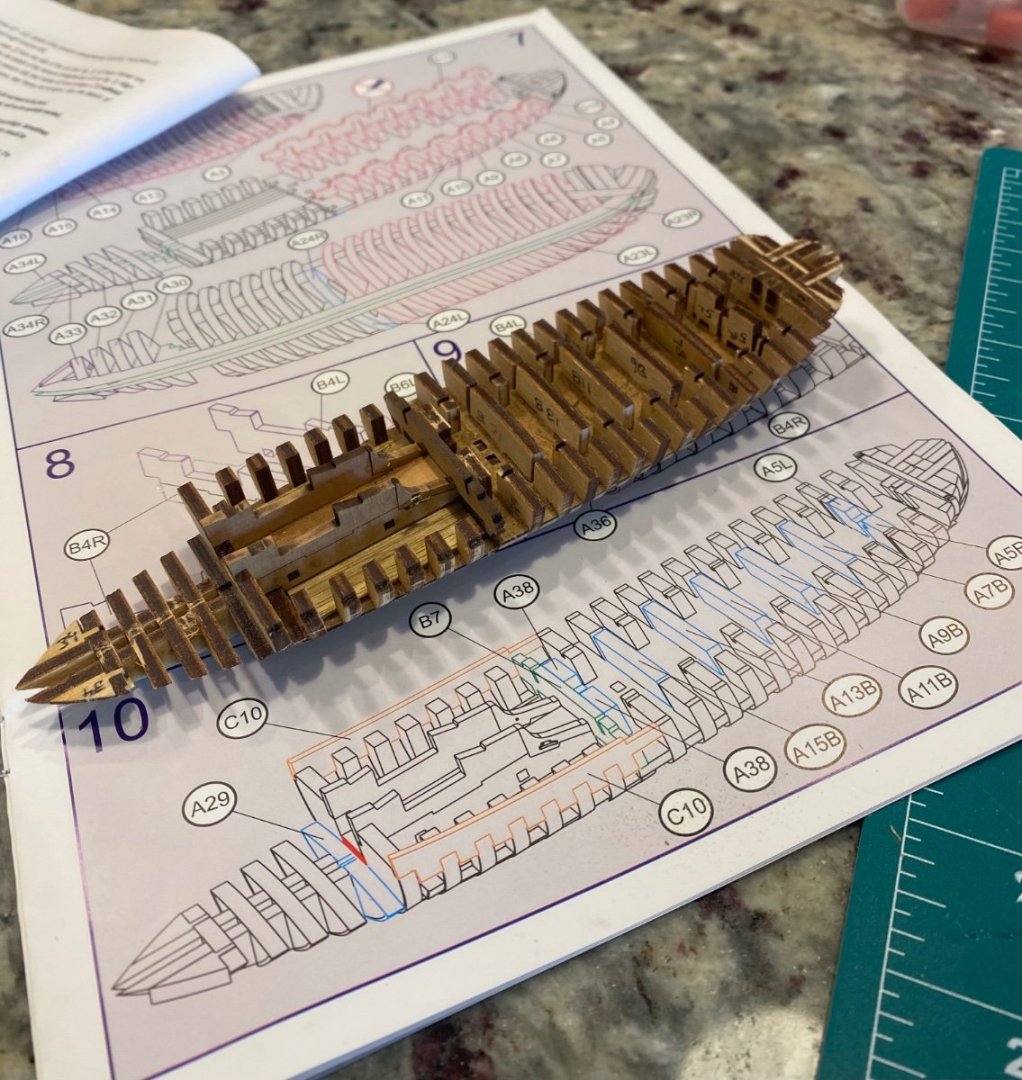

She is ready to get sanding and final shaping done. If I may offer a word of advice. There is no room for error in this kit. Everything is designed to fit snugly and perfectly in position. So check and check and check. I discovered when I was attaching the stringers C10 that the rough transom was not pushed all the way into its slot. Fortunately I was able to loosen the joint enough to tap it down into its correct position. I should have noticed that it was not correct when I attached it but somehow missed it.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

It took hours of sanding and dry fitting but I finally was able to assemble the frames and keel pieces.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

I finally looked up a translation for Korabel. It is “shipbuilder” . I had a year of Russian when i was a freshman in college in 1961 but I don’t remember ever seeing that word! I think the first vocabulary word in the text was the word for postman pochtalon. Very useful word, hey.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

No problem. I appreciate all the advice i can get. I now am dry fitting everything and light sanding so i am not forcing pieces together.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

I received my replacement kit and I have taken your advice. Previously I could not get the keel parts to fit over the frames. A bit of sanding in all the notches and they went in perfectly. The close fit on the parts in this kit is quite amazing!

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

It would take several days to see all of the exhibits.

-

If you are ever in the St Michaels, Maryland area I would recommend a visit to the CBMM (cbmm.org). There are loads of Chesapeake water craft from Bugeyes to log canoes to examine. There also are several interactive areas that entertained our 11 year old granddaughter.

-

I may as well confess. I managed to reverse the forward and aft directions on the first subassembly. By the time i got to step 7 or so things wouldn’t fit and I discovered the problem. I then tried to disassemble what i had done with disastrous consequences. Progress will resume when my replacement kit arrives. With 2 kits i expect I will have many parts left over. So in the future if one of you out there needs a replacement part for the Jolle, let me know and i might have it. Unless i make many more terrible mistakes. Read and read and read and check and double check and check again. My 80 year old brain does have a tendency to get confused easily. 😖

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

Sub assemblies and the main set of frames ready to be glued. I am sanding the bevels after the frames are glued in place.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

-

-

Reading your build log encouraged me to purchase this kit. And I definitely plan to purchase quality rigging line.

- 42 replies

-

- Cannon Jolle

- Master Korabel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.