-

Posts

1,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Papa

-

Lotus Honda 100T by Papa - Tameo - 1/43 - METAL

Papa replied to Papa's topic in Completed non-ship models

Looks great. -

I had always wanted to try one of these metal F1 kits, so a few months back I purchased one on sale at Model Expo. One is enough! At 1/43 some of the PE pieces are about the diameter of a human hair. If you have fantastic eye sight and access to that mysterious place where so many small parts end up then perhaps one of these kits is for you. The instructions are 1 page with an exploded image numbering the parts and suggestions as to where they go. Some obvious, others not so. Page two identifies the photo etched parts and where to place the decals. The decals are excellent. They released quickly and didn’t tear. There are videos on YouTube that show how to build the Tameo kits, but I didn’t find one specific to this one. They are helpful.

-

I am currently attempting to build the "14Bis". This is not an easy kit. I have had to re glue the wing frames multiple times. Butt joints do not hold up well. Right now I have the 3 right wing frames in the assembly jig with the longitudinal pieces glued. I don't have the patience to simulate the bamboo,so I am considering covering the frame with tissue or some appropriate covering when it is completed, like the classic stick and tissue models I built as a child. Has any builder done this? Should I do it? Recommended material? Ron Gove, AKA Papa

-

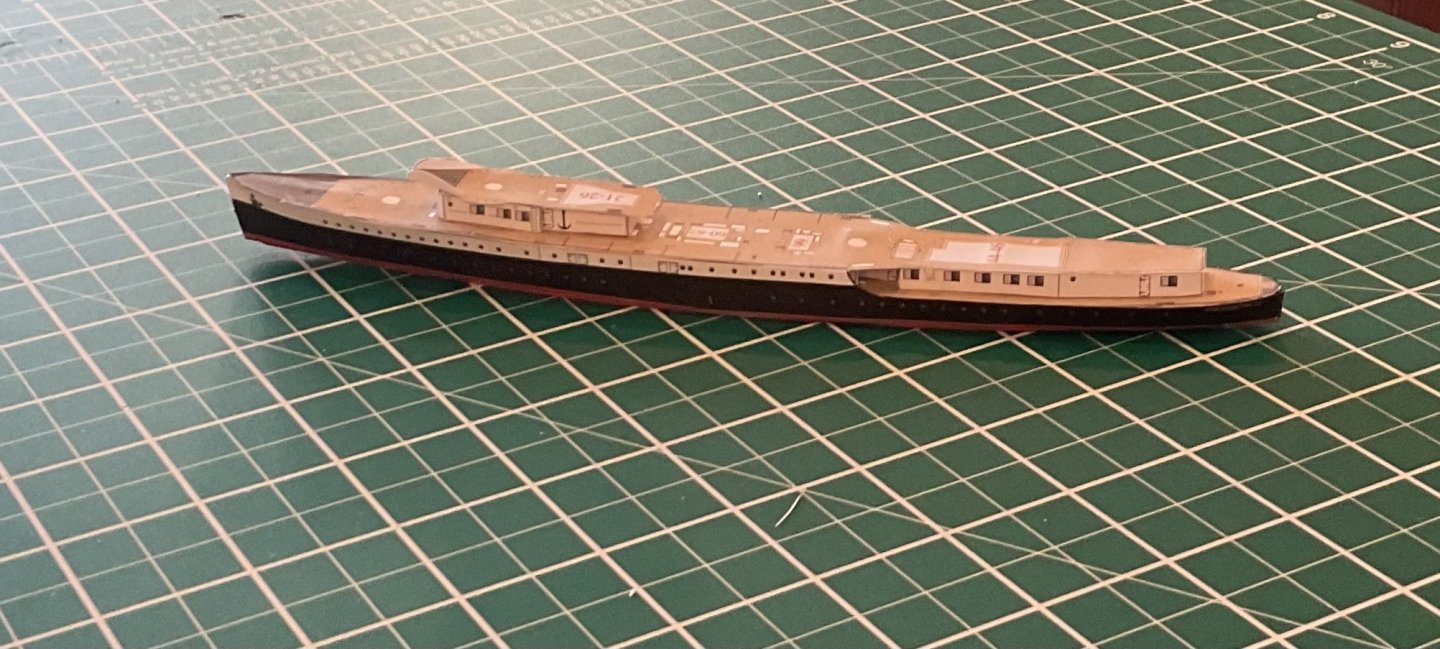

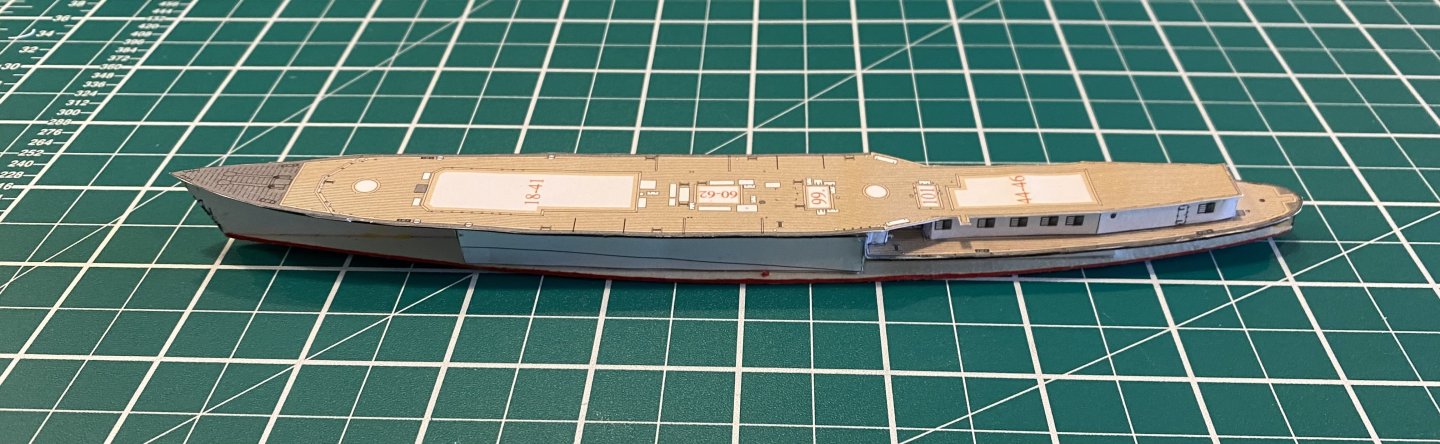

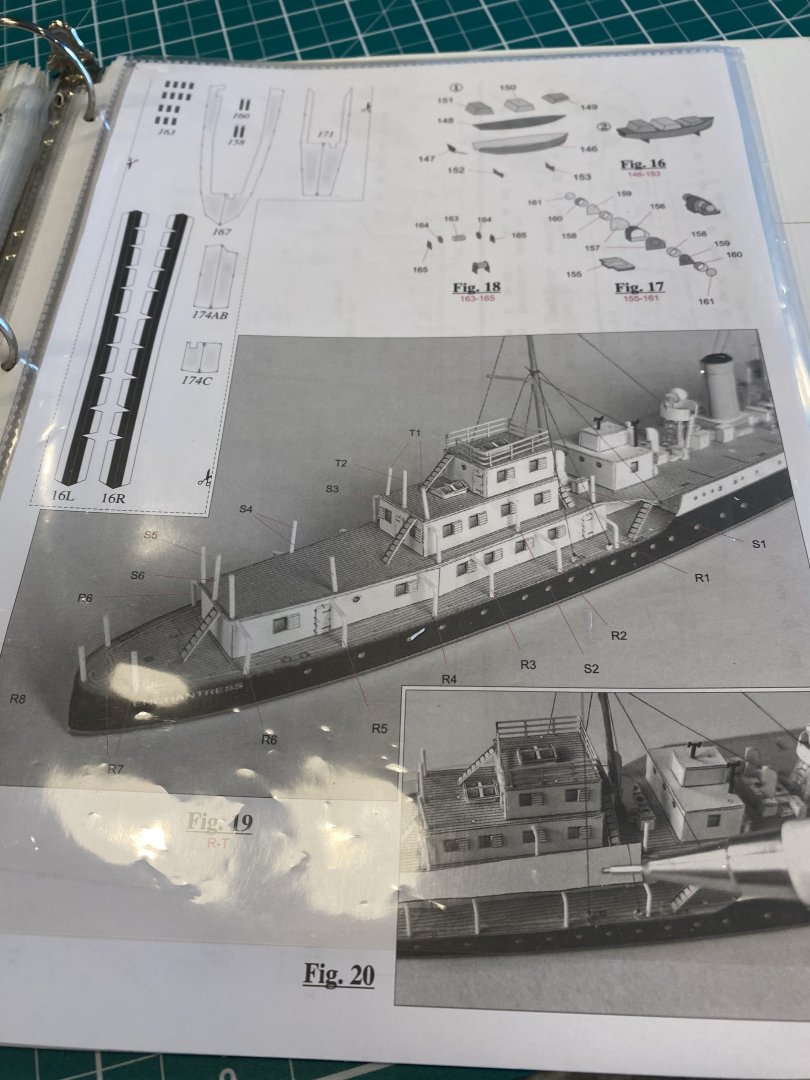

The Enchantress is finished as I can achieve except for railings, which are on order from JSC. There are a few deck fittings that are just too tiny for me to assemble so she’ll go without. A very challenging build. And I doubt I would try another card ship at 1/400 scale.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

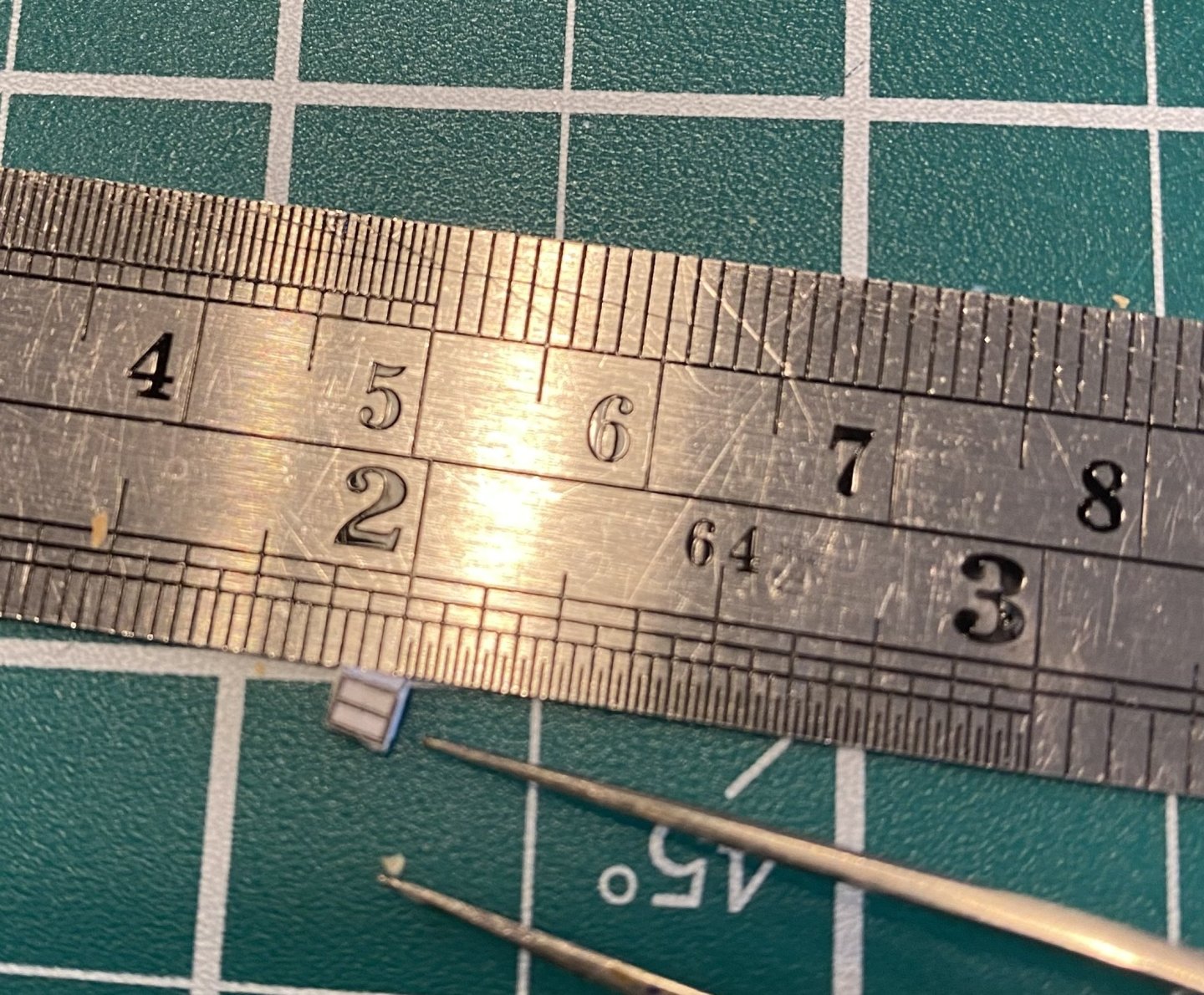

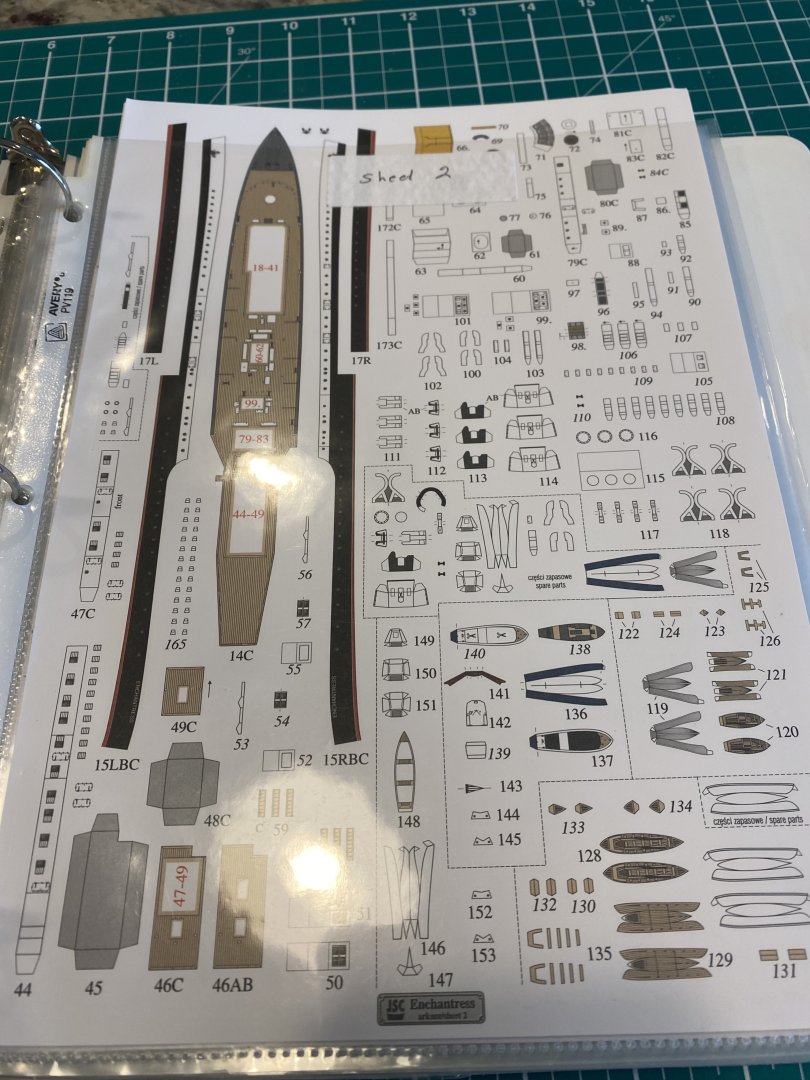

I have 4 of the ship’s boats built and installed. 2 dinghies and 2 whalers. JSC provides some tiny pieces to build the interior of each one and I tired to do that but it was just too small for me to get looking good. I used their alternative method that consisted of a flat piece with the interior of the boat printed on. The dinghies are on the deck under the whalers. In the photo on the green mat there is a tiny laser cut detail of 3 seats for the dinghy. I think one would have to work under a microscope to assemble these.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

Working on masts and rigging. The masts ended up a tad wonky. It must have been the heavy seas in the channel during Churchill’s last trip.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

I just looked at their site and didn’t see them. Update 6/24: JSC advised me on the proper rails and I ordered a set. Also thought I would try a paper aircraft and ordered their Spitfire.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

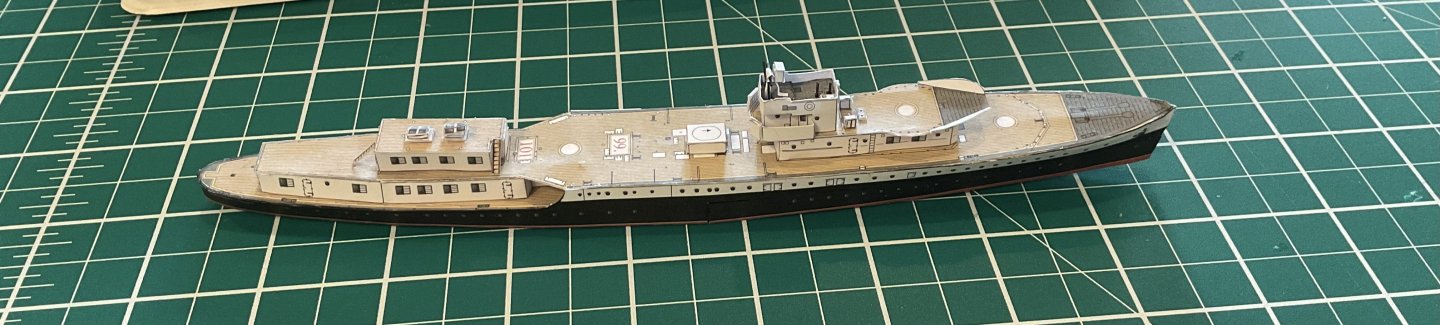

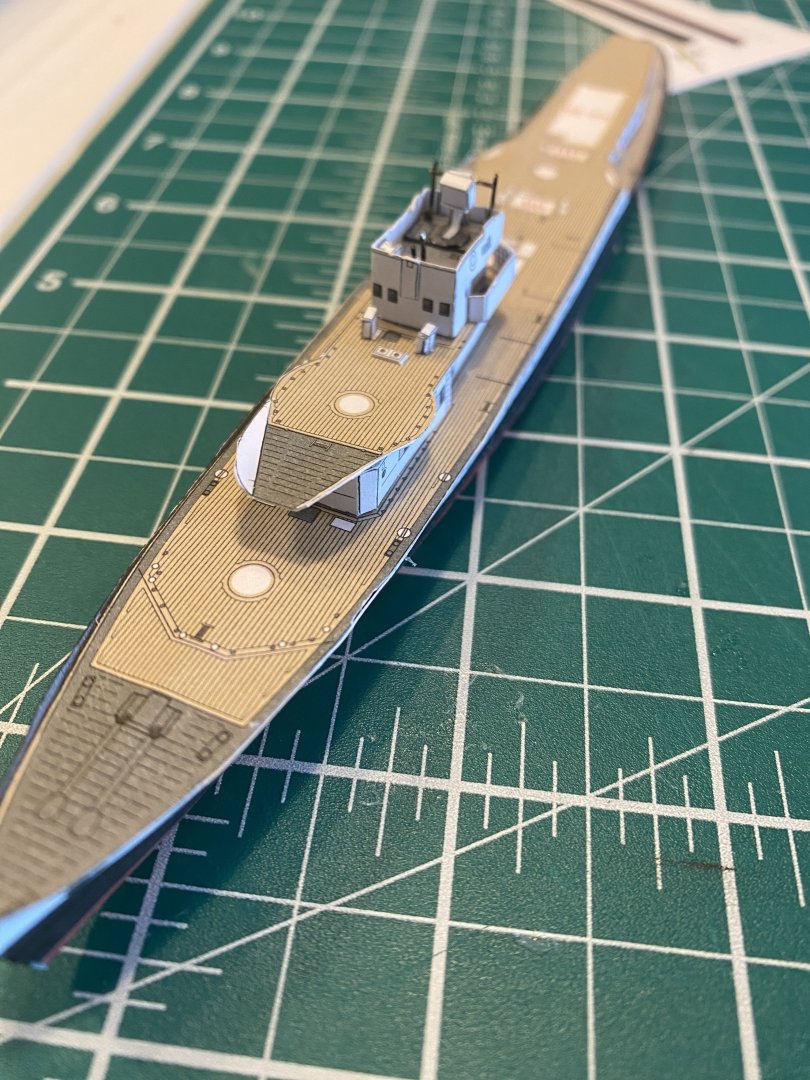

She is getting close to the end. Need to add the saluting guns, masts, boats and davits, and some remaining deck equipment. The kit didn’t come with railings and I am wondering if I should find some 1/400 photo etched railings for her.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

A lot of tiny boxes on this ship. Also, the instructions with the detail set stated that the main instructions indicated which parts had laser cut versions. If they did I missed them and missed a few ladders. I replaced the card ladders and marked all the part numbers that had laser cut details. The only part I can’t fix is the search light tower. The card tower is not coming off without damaging the deck.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

To be honest I didn't pay any attention to the scale. I seemed like an interesting ship. If I thought about what 1/400 really meant I might have hesitated. The details are at the limit of my vision!

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

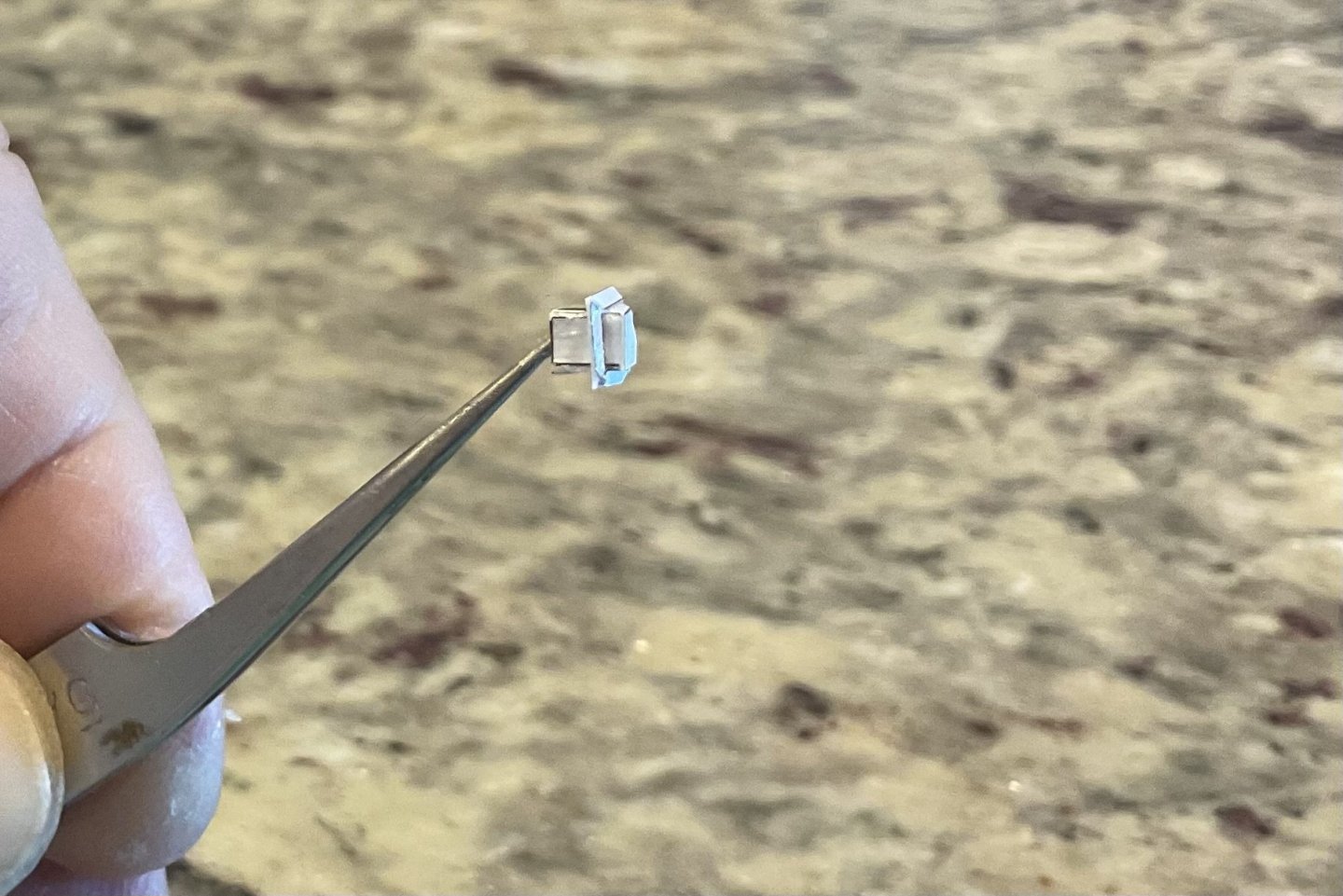

A lot of the work now has to be done with tweezers! The little deckhouse in the tweezers went under the overhang forward of the funnel.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

I am sure that space is awash with tiny blocks, deadeyes, and other bits

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

I now have the front superstructure in place. This involved some very tiny structures. One card piece snapped out of my tweezers and ended up in the 4th dimension apparently. Fortunately its absence isn’t noticeable.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

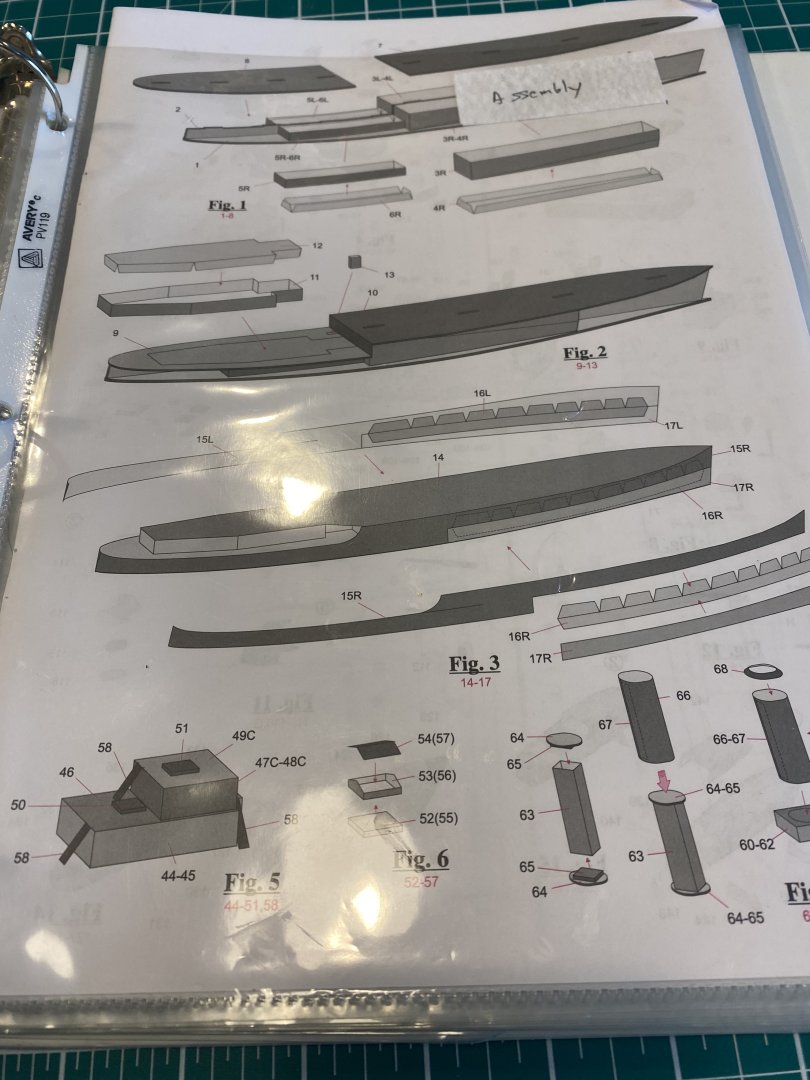

The instructions say to apply the hull sides starting at the stern. When I did that the curve at the step in the deck didn’t line up. I had to remove the side, and ruined it in the process. Fortunately there are parts for different versions and I was able to switch to the B version (middle years, I was doing A, as launched). This time I started the sides at the step.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

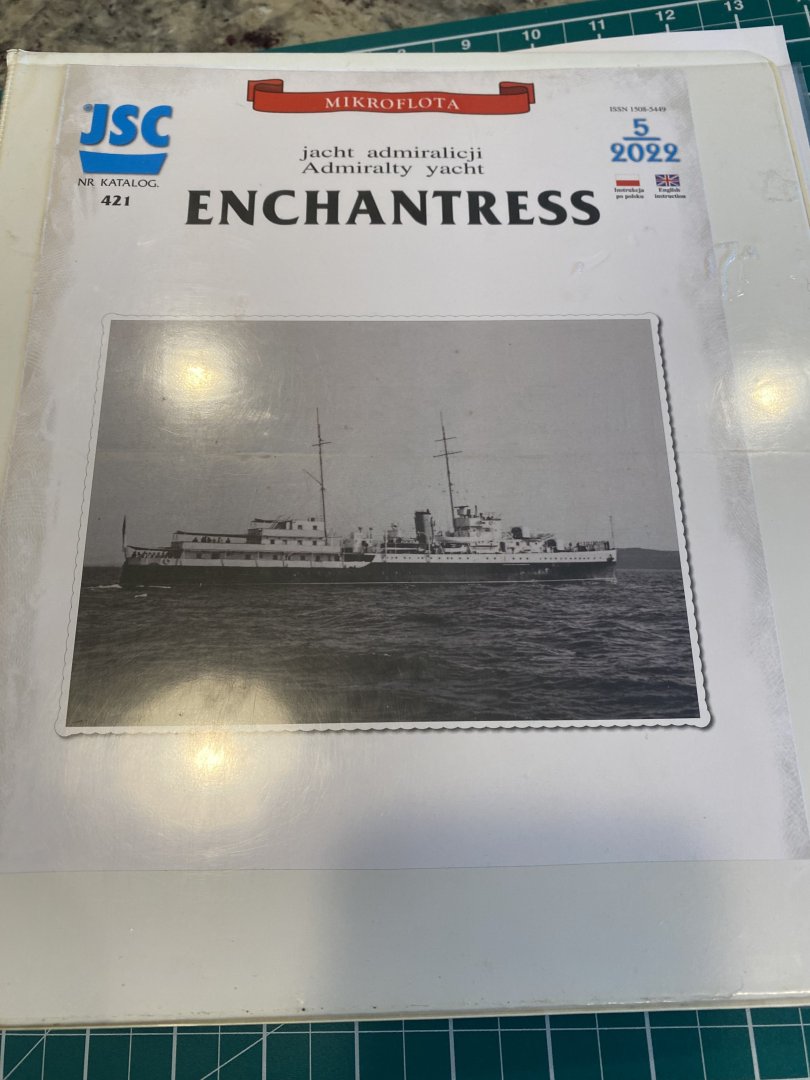

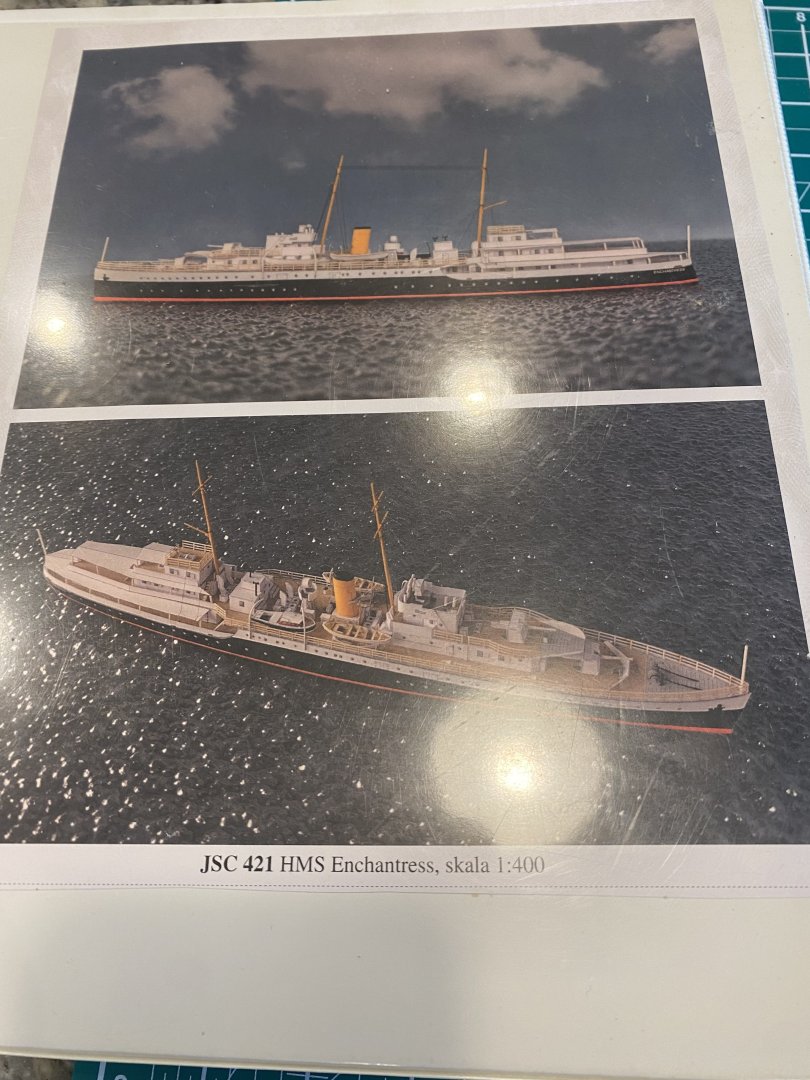

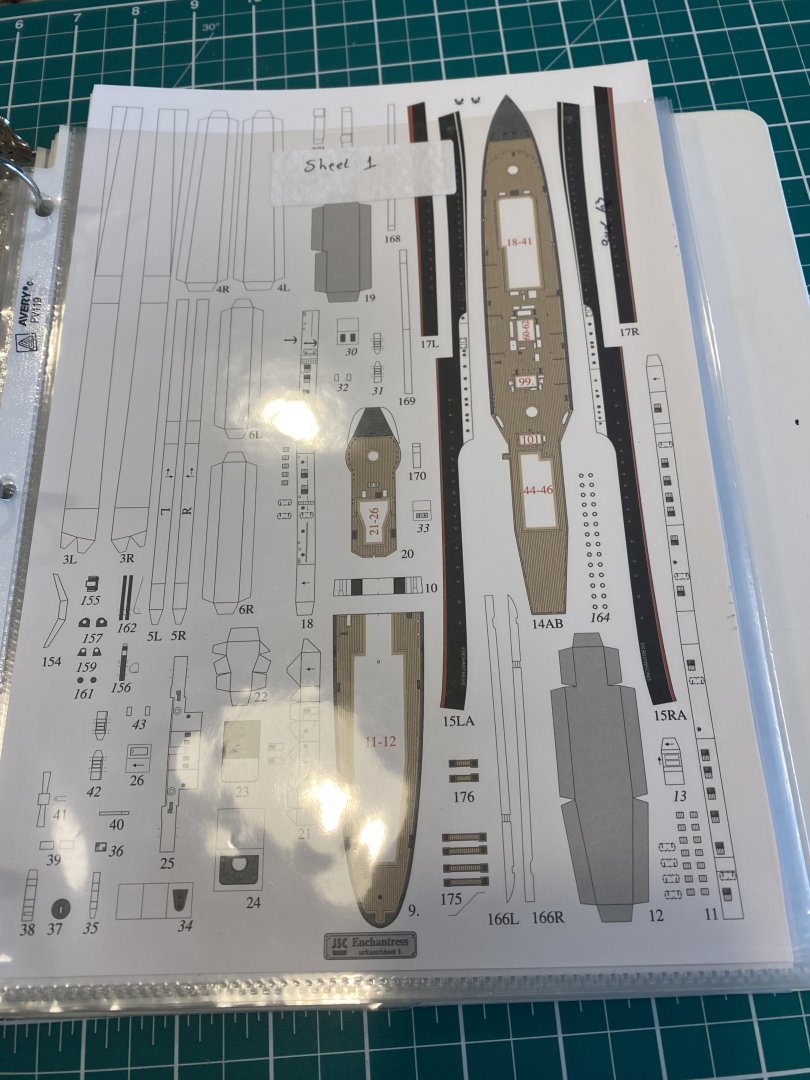

The Enchantress was built at the J. Brown shipyard in Great Britain. Originally designed to be a convoy escort named Bittern, her purpose was changed during construction to an Admiralty Yacht and her name changed to Enchantress. She was launched December 21, 1934 and entered service on April 8, 1935. This is a card model from JSC and comes in booklet form. The basic kit has laser cut parts to form the hull and I also purchased a laser cut detail set. I separated the pages and put them with the instructions in plastic sleeves. This keeps everything neat makes it more difficult to misplace parts.

- 22 replies

-

- Enchantress

- JSC

-

(and 1 more)

Tagged with:

-

She is finished. I chose not to install the railings as I think they spoil the look and I don’t recall Verne mentioning them. I also remade the stand using basswood and applying the card pieces onto the basswood.

- 40 replies

-

- Nautilus

- Heinkel Models

-

(and 2 more)

Tagged with:

-

Kit review Belle Poule - Occre - 1/90 - review by kevin

Papa replied to Kevin's topic in REVIEWS: Model kits

Would the camber even be noticeable at this scale? -

- 40 replies

-

- Nautilus

- Heinkel Models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.