-

Posts

323 -

Joined

-

Last visited

About JKC27

- Birthday 03/04/1973

Profile Information

-

Location

Windsor, ON

-

Interests

shipwatching (Great Lakes), hockey, golf, model building (of course), F1 racing, science, history

Recent Profile Visitors

-

Resin ice effects

JKC27 replied to JKC27's topic in Painting, finishing and weathering products and techniques

@wefalck Nice! Well done. -

JKC27 reacted to a post in a topic:

Resin ice effects

JKC27 reacted to a post in a topic:

Resin ice effects

-

Keith Black reacted to a post in a topic:

Resin ice effects

Keith Black reacted to a post in a topic:

Resin ice effects

-

JKC27 reacted to a post in a topic:

Resin ice effects

JKC27 reacted to a post in a topic:

Resin ice effects

-

Thukydides reacted to a post in a topic:

Resin ice effects

Thukydides reacted to a post in a topic:

Resin ice effects

-

Paul Le Wol reacted to a post in a topic:

Resin ice effects

Paul Le Wol reacted to a post in a topic:

Resin ice effects

-

Kenchington reacted to a post in a topic:

Resin ice effects

Kenchington reacted to a post in a topic:

Resin ice effects

-

Resin ice effects

JKC27 posted a topic in Painting, finishing and weathering products and techniques

I know AK Interactive makes a resin ice kit and it is rather expensive, so not sure if I want to spend the money just to experiment with so I figured I'd throw this on here and see what you all think. Here is what I am contemplating doing.... I scratch build steel hull ships that sail the great lakes, and are generally built at 1/200 or 1/192 scale. I mount them on a wood base, slightly raised off the wood of course using 1/4" square lifts (I guess you could call them). Thinking how I can up my game, I was thinking how cool it would be to surround my ship model with ice, as it would be if sailing at this time of year (January) on the lakes. I would use a styrofoam base for this and do the ice effect on top. Has anyone on here used this, or a similar product? What are your thoughts on it, or any other suggestions???? Here is the look I am going for: -

Good job on this! I built the 1/72 Tamiya Spitfire kit a couple years back and it turned out OK. I like building at a bigger scale, and basically used it as practice for the next Spitfires build - the beer run kit from ICM. This kit had quite a few issues, and I never did finish it, found the plastic soft and had some fit and gap issues. I still have to open and get started on my Eduard 1/48 Mk IXc kit..... it has the option to build the place as flown by Canadian ace Jerry Billing who happens to be from my area - and our local junior hockey team's logo is based off a Mk IX Spitfire too. I find the 1/72 too small for my liking, but your build is looking great.

-

I highly suggest people look up the US Coast Guard radio transmissions with the ship (Captain Bernie Cooper on the Arthur M Anderson) that was tracking the Fitzgerald. It's really worth a listen.

-

If this is better suited for different section, mods can feel free to move it. I was just curious as us here in the Great Lakes have seen ships from all over the world trade here, and I know like everywhere companies come and go, loads/contracts as well. What I am curious to know, and maybe some of our Scandinavian users might be able to shed some light on is the smaller cargo ships from Finland that used to trade here back in the late 1980s/early 1990's. I have attached a pic or 2 for reference.... What ever happens to F-Ships? They were regular traders here, and I would see them quite often back in the 80s/90s. Did the company fold? Did they get out of the international trade business?

-

It was quite the tragic end to this classic laker. A couple fires within months - one at sea not far from me in Lake Erie, and then again in winter layup (this one did major damage) in Ohio. Interestingly..... this ship's unloading system was still the old bucket style unloading system, as opposed to the modern loop belt systems. @realworkingsailor would be able to shed more light this likely. As for the age of the ships...... a lot of ships, especially on the American side of the great lakes are at least 40 years old if not more. Sailing exclusively in fresh water sure helps, and the US fleet sails a much smaller region. Whereas a good portion of the ships for Canadian great lakes shipping companies will transit the entire seaway and use many more of the locks, which must play at least some part in the shorter life spans on top of visiting the brackish/saltwater parts of the St. Lawrence River. I will defer to @realworkingsailor again for better insight on this. Sorry Andy!

-

I just stumbled upon this build log. First of all...good luck on your first build. I got started thanks to the pandemic of all things, and now I recently completed my 5th scratch build. The ships I do are similar to this, but have not ventured into the RC world (yet), nor fibreglass. As others have stated already, keep at it and you will learn as you go. Plus there are many very knowledgeable builders on here, so keep asking questions, posting your progress. As an aside. I remember Jugolinija's ships often sailing here in the Great Lakes - many times I remember watching their ships transit the Detroit River back in probably the 1980's, maybe early 1990's. In fact one of them is now sailing as a Canadian bulk carrier. Originally named Omisalj, now knows as Algoma Guardian https://boatnerd.com/algoma-guardian/ https://www.shiphotos.com/Ship/?ID=1945 You might enjoy these links.

-

Decals for draft markings

JKC27 replied to g8rfan's topic in Painting, finishing and weathering products and techniques

I don't mind Woodland Scenics dry rub for maybe putting the name of the ship but I cant imagine doing depth markings...that would be a test of patience I am not interested in tackling. -

Decals for draft markings

JKC27 replied to g8rfan's topic in Painting, finishing and weathering products and techniques

BECC makes depth markings in all sorts of scales, variations....... I have ordered and used their depth markings for my big laker models. Might be worth checking out.... http://www.becc.co.uk/contents/en-uk/d22.html#p260 -

Thank you......... I have really been starting to think that making hollow decks could be wasting time on my builds. You are correct though - styrene does a really good job representing steel. I have been experimenting with running micro LED lights to the p & s lights and top of the masts, etc. and it looks really nice with one positioned inside the bridge, but I am sure I could make the lighting work either way if I do more builds with the LEDs. re: your comments on scale - for me, I don't care about wall thickness at scale vs real world, nobody would ever care or even notice, it's just finding the right material especially for the top deck where there are essentially windows surrounding that deck of course.

-

The scale I use is 1/192 or 1/200, and these are ships that are generally 740ft or slightly shorter in the real word, so parts tend to get quite small. Even the windows. My first build I tried using vinyl that was cut into small squares, but again......it is hard to replicate the sizes and make everything looks "square". I've yet to find a punch set with the correct size/shape as well, or I'd consider using that.

-

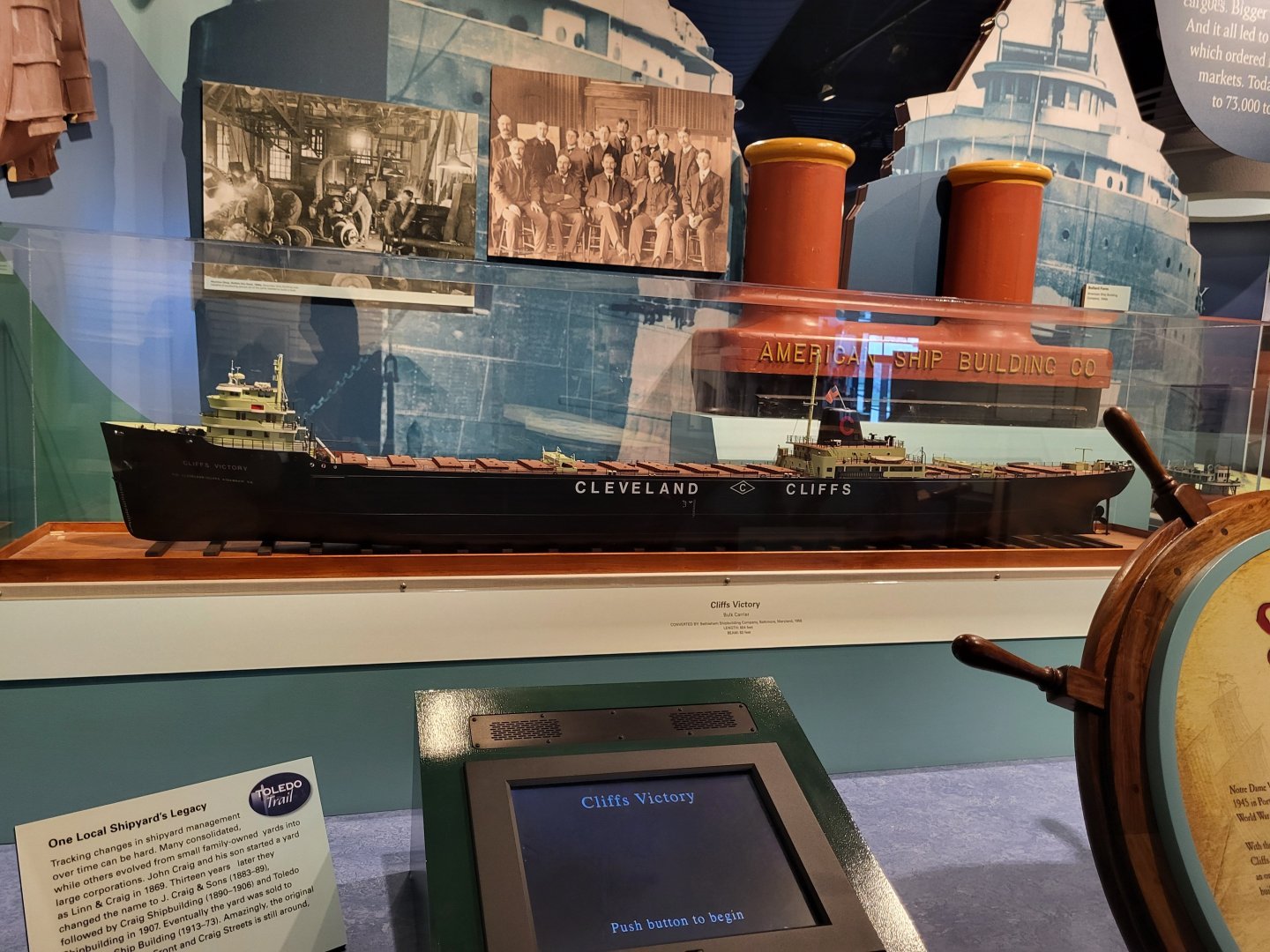

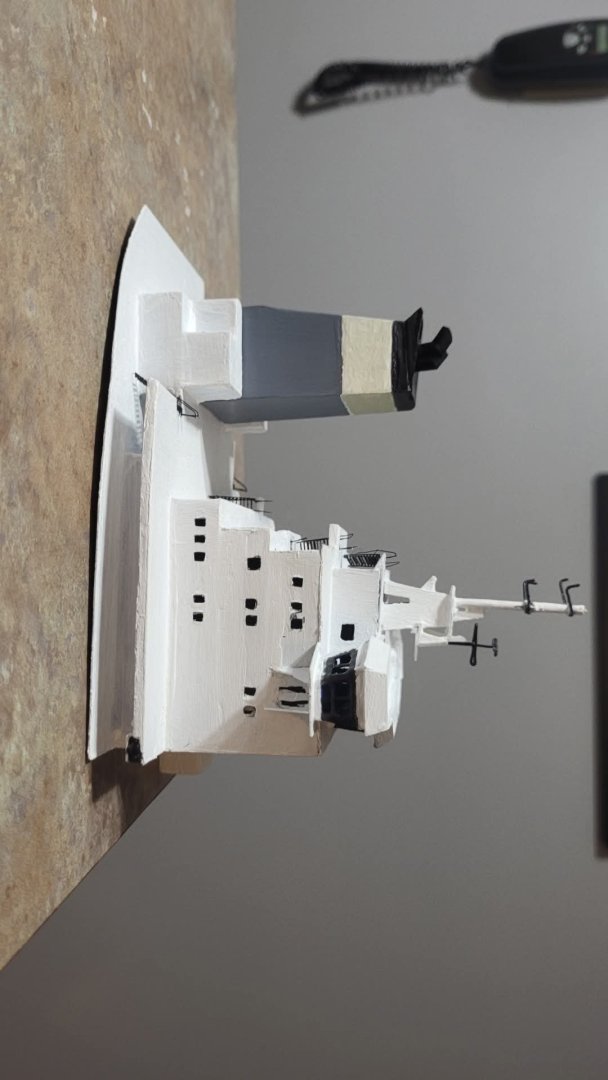

As the ships I model are the large ships that service the Great Lakes, these are all steel construction. No big deal on the hull - it's a wood model of a steel ship, so that's not an issue. When it comes to building the various decks (most are now all at the rear of the ship, while some older ships have both fore and aft) I have used card stock with pretty good success, but prefer using styrene sheets cut to the proper sizes to build the walls of each deck, then stack them together accordingly. My frustration with using either material is cutting out the windows.... I've been using a #11 exacto, but even with drawing out the proper lines, etc. it can be a real test of patience to cut the windows out and have all the edges like right. Card stock gets a little flimsy pretty quick, styrene I find can bend inwards a bit, but you can also make the cut too large with both mediums. I've been using .020 styrene. I know the thicker you go, that harder it would be to cut, but there might be a better way for me to perfect this part of my skill set....... Any thoughts or suggestions would be appreciated! See attached pics to see what the cream of the crop looks like..... this is what I strive for, as I only have been at this for about 5 years now, and it's only when I have time after work, or on weekends when I have time between other things in life like errands, housework, spending time with my wife, etc..... First 2 pics are in the museum in Toledo, OH - the next couple are some of my recent builds - both were card stock. Last one, my current build is styrene.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.