-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Smittybear

-

-

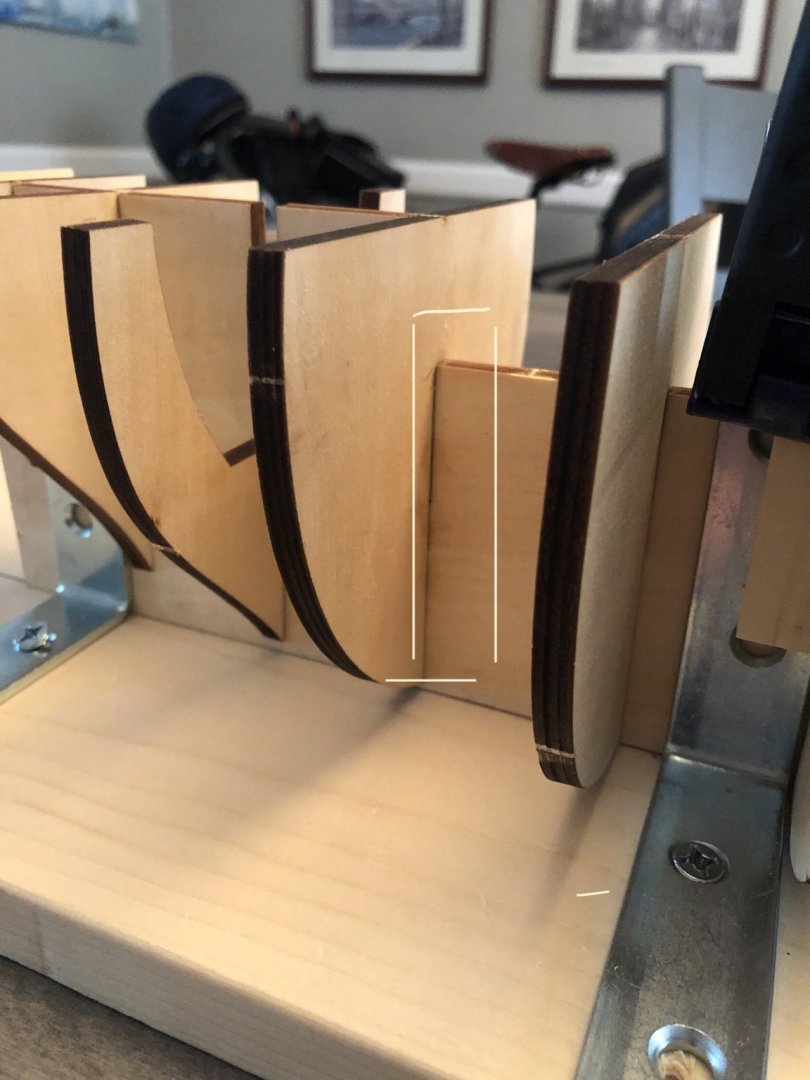

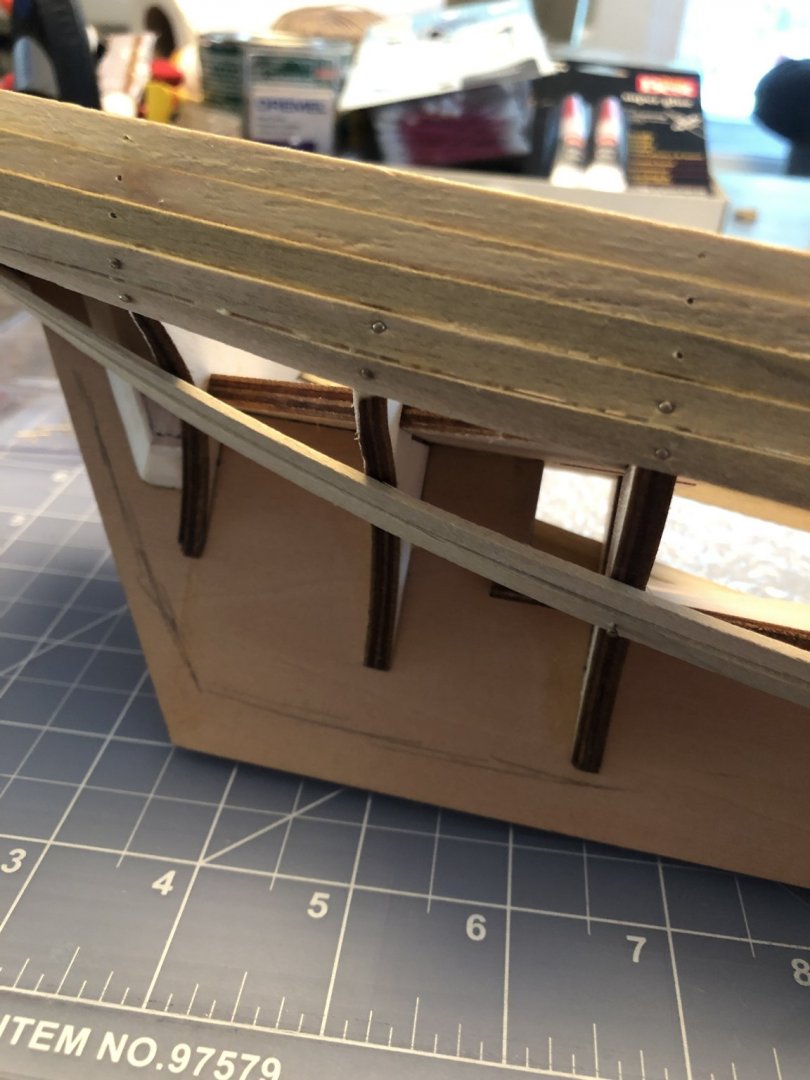

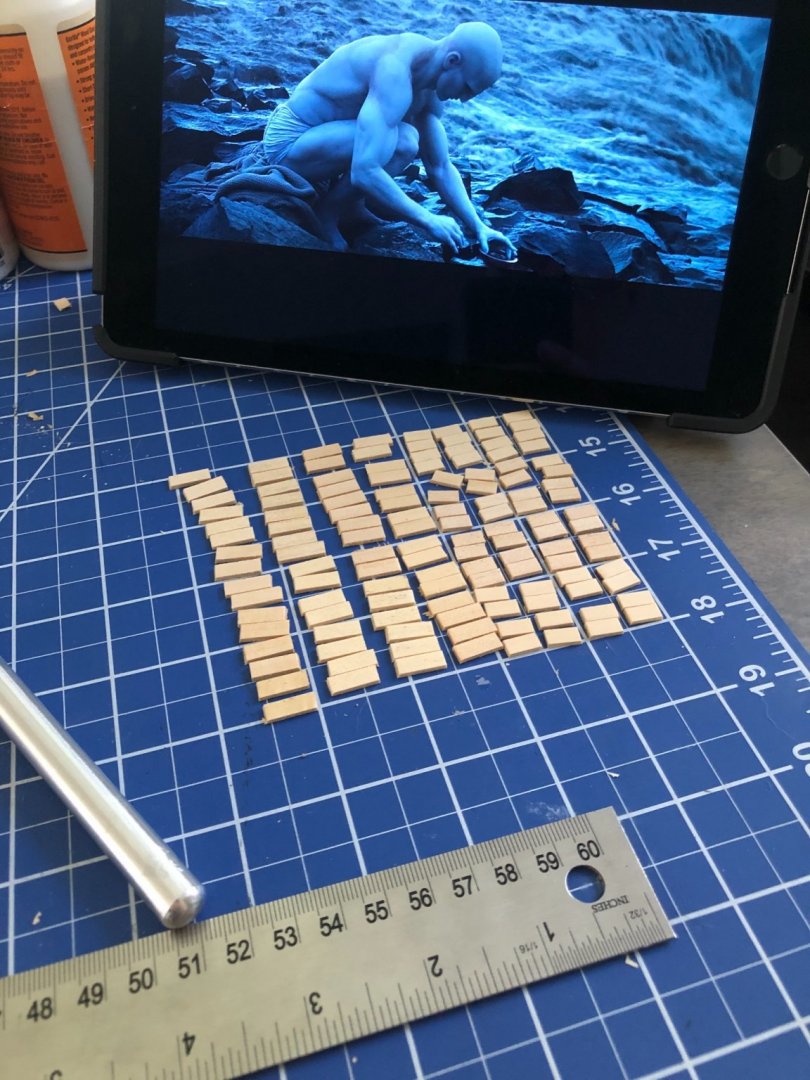

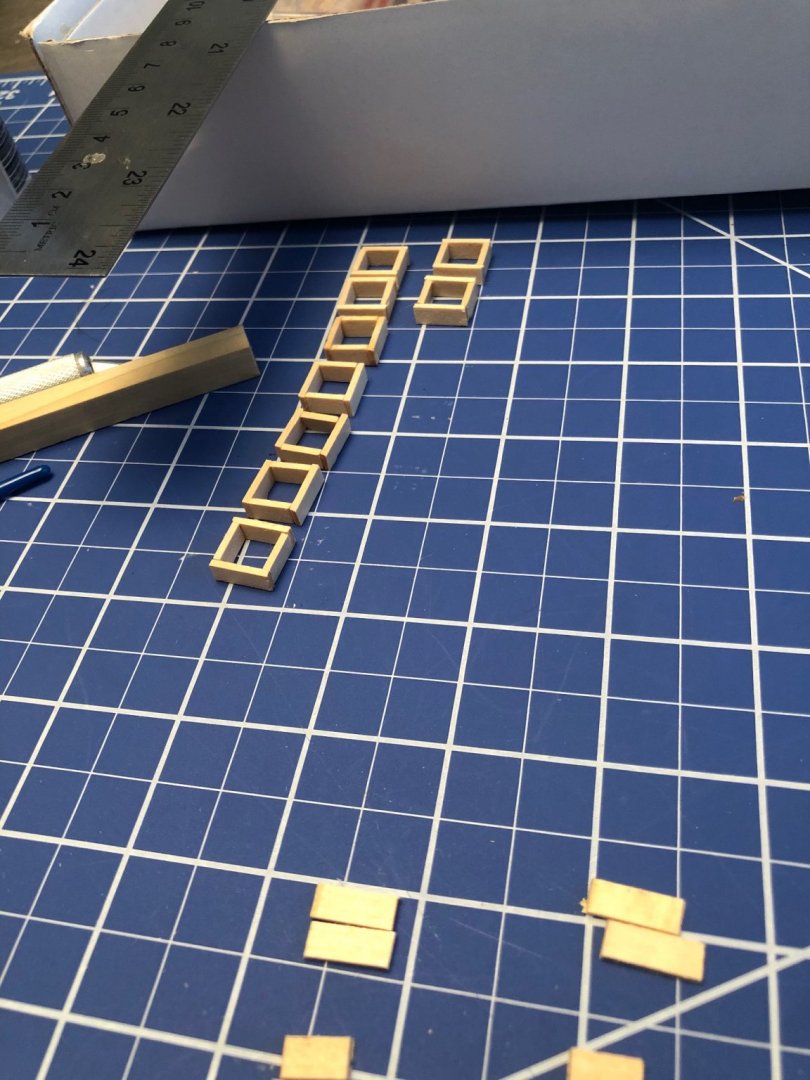

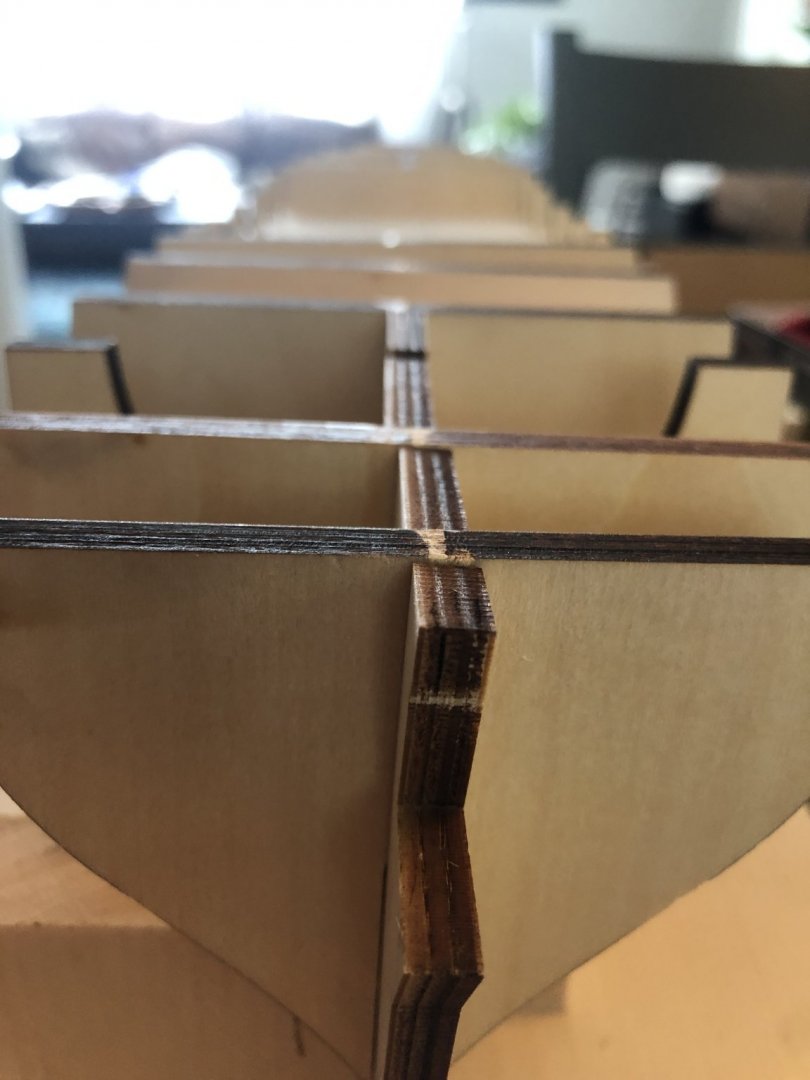

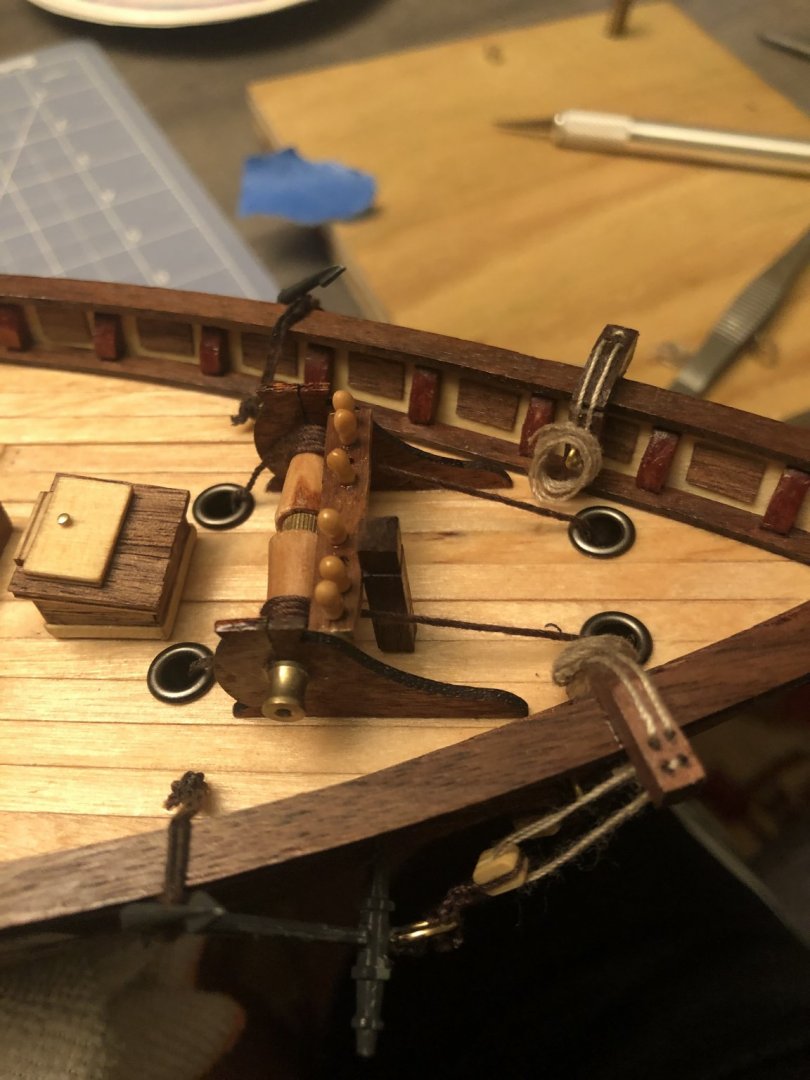

Took a hiatus out of frustration and in general life busy-ness. I’m back at it now that it’s cold out again. Cut out gun ports and put in the frames. See pic. I was dry fitting the bulwarks and one snapped. I don’t have an electric plank bender so plan on soaking and then using a hand iron to bend. If that doesn’t work I’ll use a clamp bender and sand down. Should be ok since it will be planked on both sides. For the frames of the gun ports I built them prior. Put primer on and then painted black. They will need a final touch up.

- Jack12477, mtaylor and GrandpaPhil

-

3

3

-

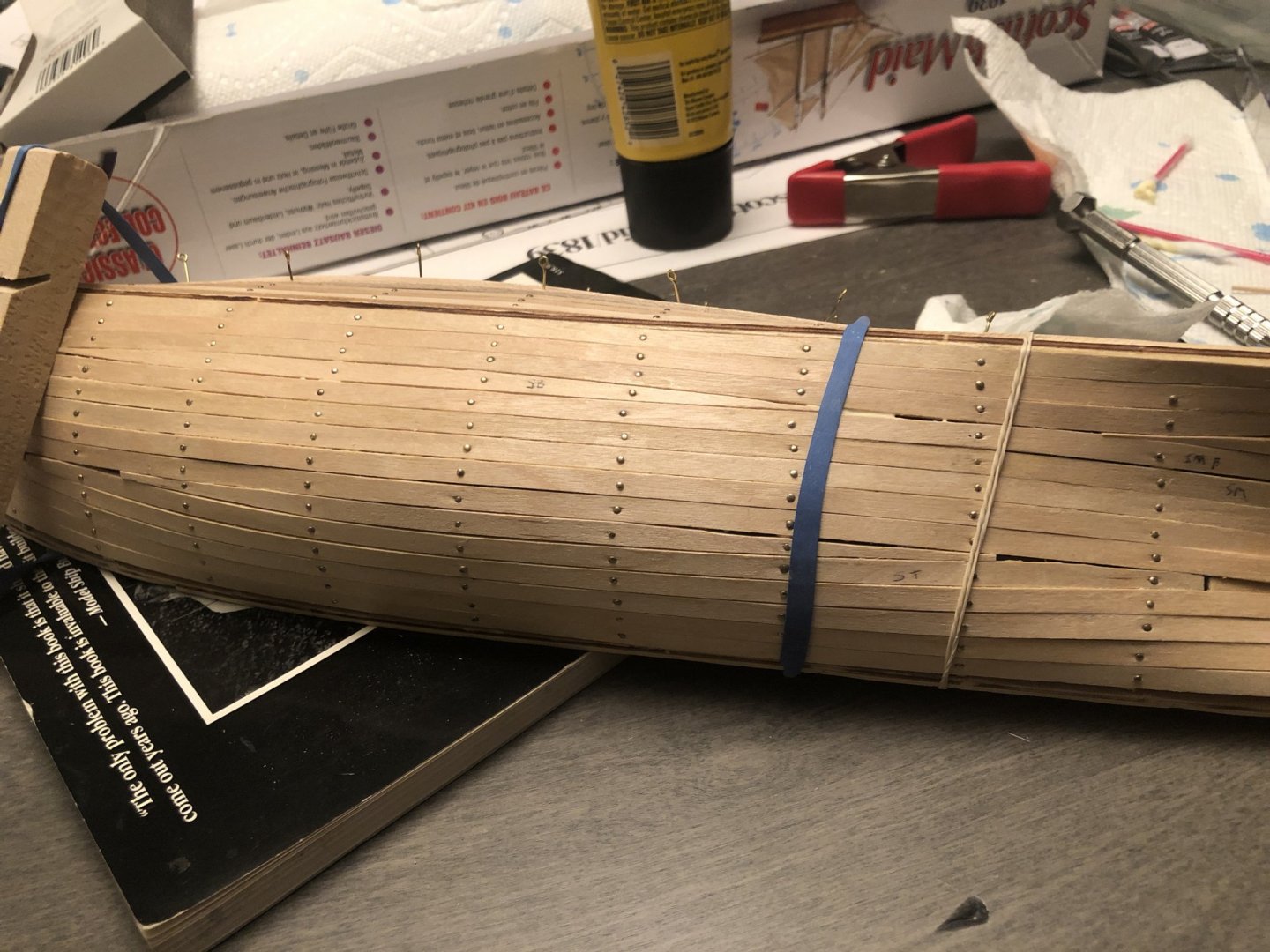

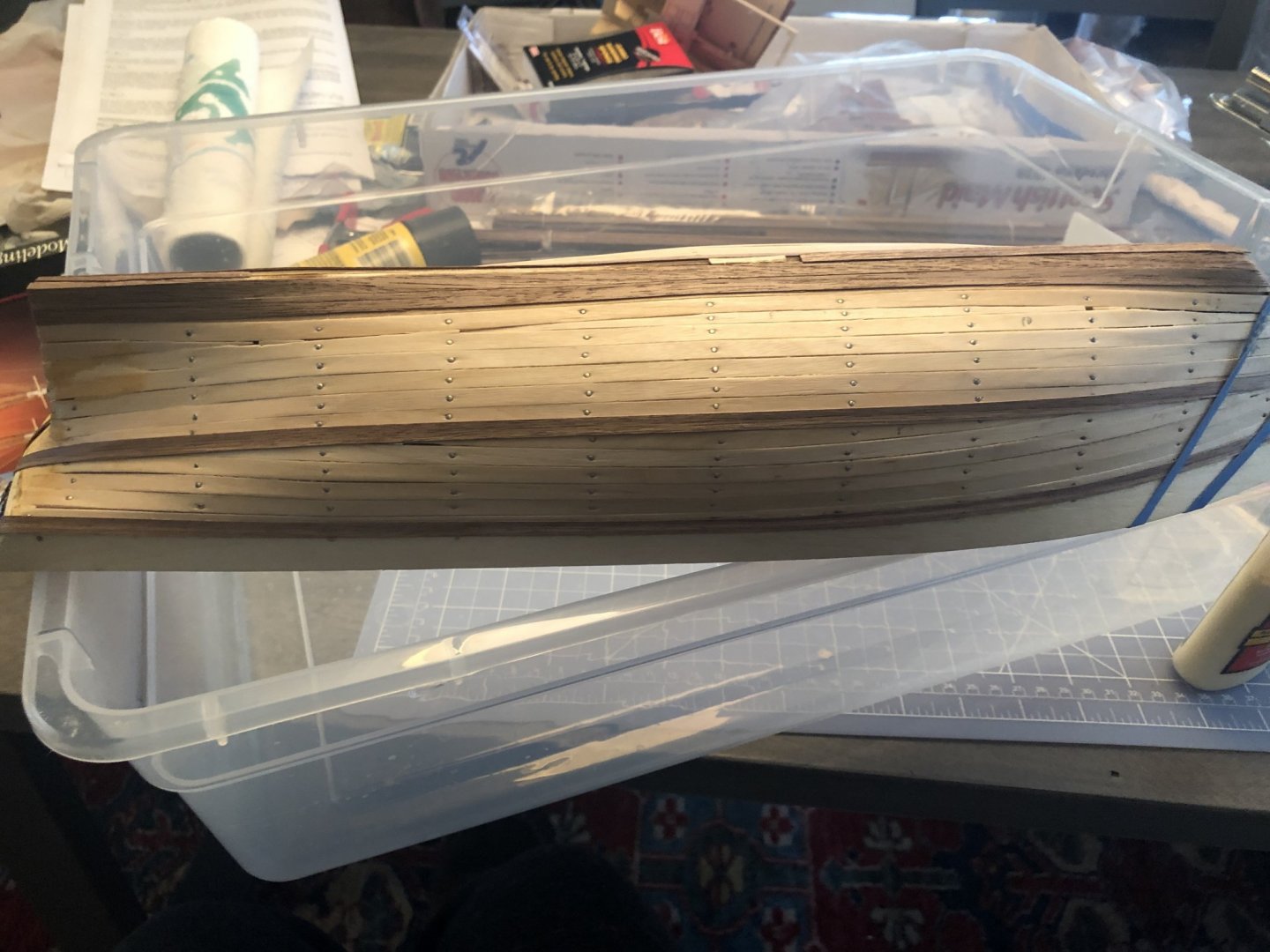

Have had quite a bit going on the last 2 months. Recovering from a hip surgery last week and can finally sit and work on the boat again. Because it’s been 2 months I’ve lost some of my train of thought. I’ve finished the first layer of planking and decided I want to cut out the gunports before using wood filler, sanding, and applying the second layer. I like JD’s idea of making the interior 9.5 vs 8 because a square wooden dowel of 9.5 mm (0.375in) is available at Lowe’s To use as a square guide. However it’ll be a few days before I’m out of crutches or wanting to run errands, so it’ll just have to wait. I’m having some trouble getting the bough keel cut out sufficiently. I’ve been using a razor blade but was wondering if you guys thought a Dremel router or cutter would be more useful? Also reference sketching on the gunports... any tips for accuracy? I’ve spent a lot of time searching the forums and referencing other build logs so look forward to your inputs. I have lots of other things to keep me busy with this build until moving forward with the gunports.

Have had quite a bit going on the last 2 months. Recovering from a hip surgery last week and can finally sit and work on the boat again. Because it’s been 2 months I’ve lost some of my train of thought. I’ve finished the first layer of planking and decided I want to cut out the gunports before using wood filler, sanding, and applying the second layer. I like JD’s idea of making the interior 9.5 vs 8 because a square wooden dowel of 9.5 mm (0.375in) is available at Lowe’s To use as a square guide. However it’ll be a few days before I’m out of crutches or wanting to run errands, so it’ll just have to wait. I’m having some trouble getting the bough keel cut out sufficiently. I’ve been using a razor blade but was wondering if you guys thought a Dremel router or cutter would be more useful? Also reference sketching on the gunports... any tips for accuracy? I’ve spent a lot of time searching the forums and referencing other build logs so look forward to your inputs. I have lots of other things to keep me busy with this build until moving forward with the gunports.

- GrandpaPhil, JDDouglass, ccoyle and 1 other

-

4

4

-

-

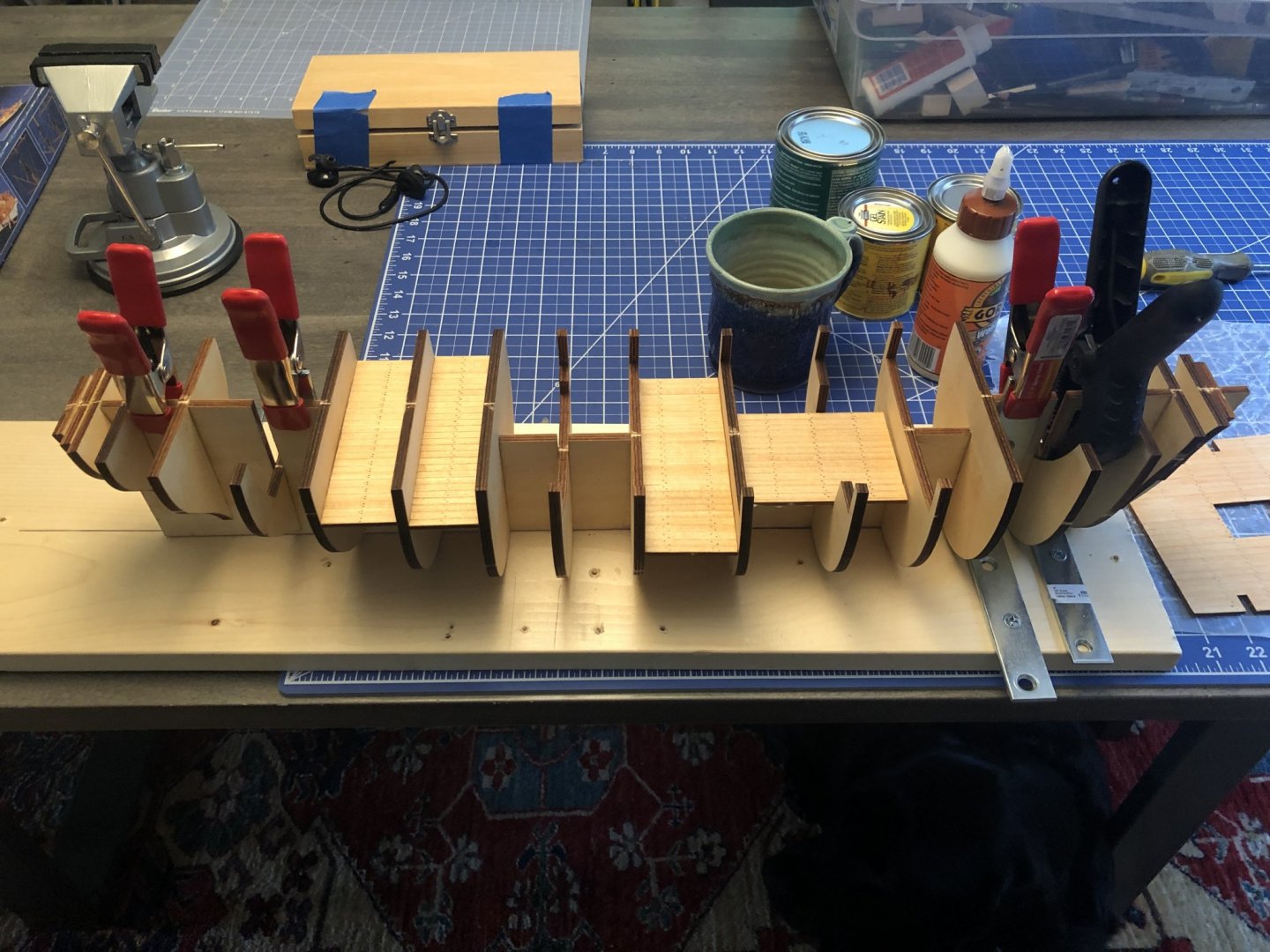

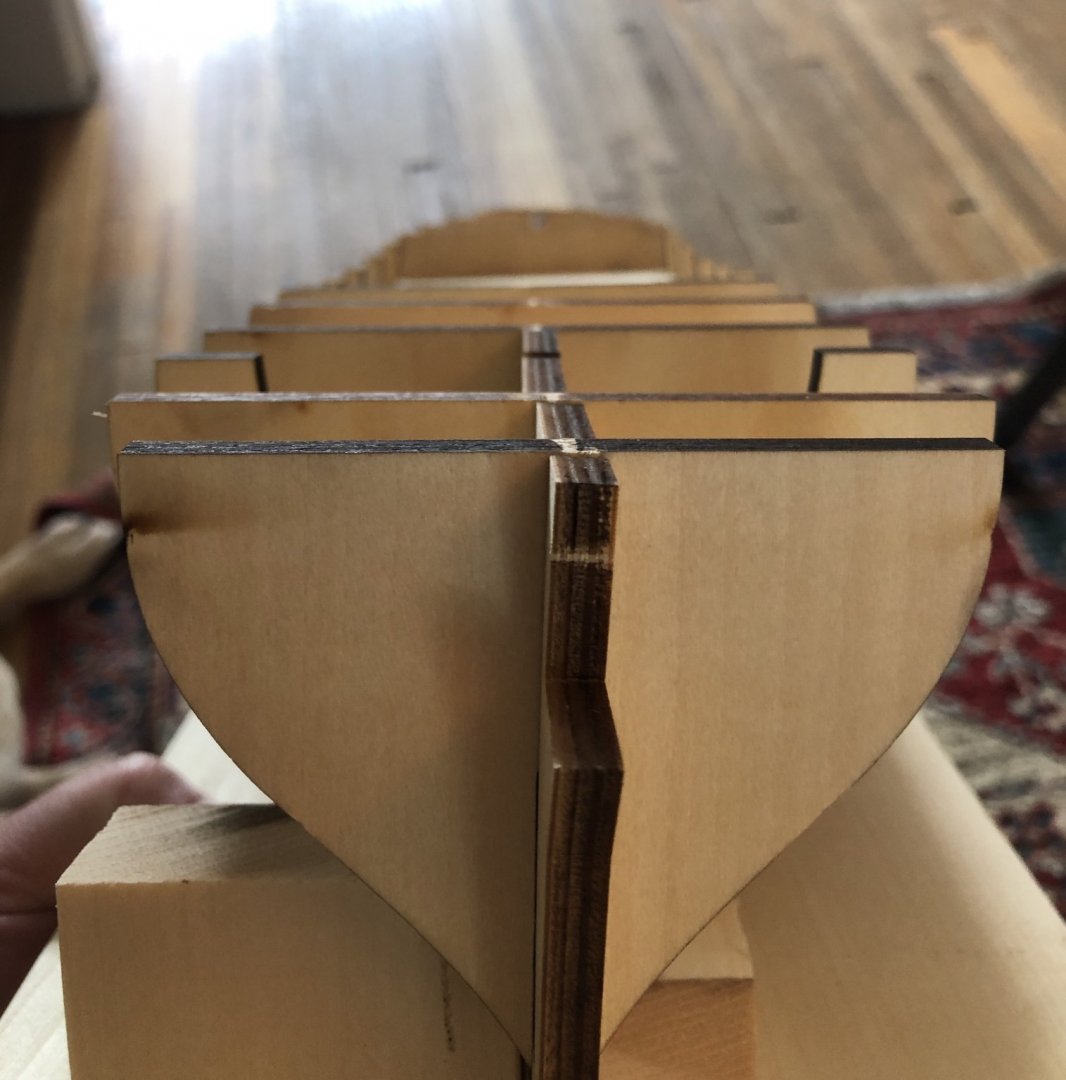

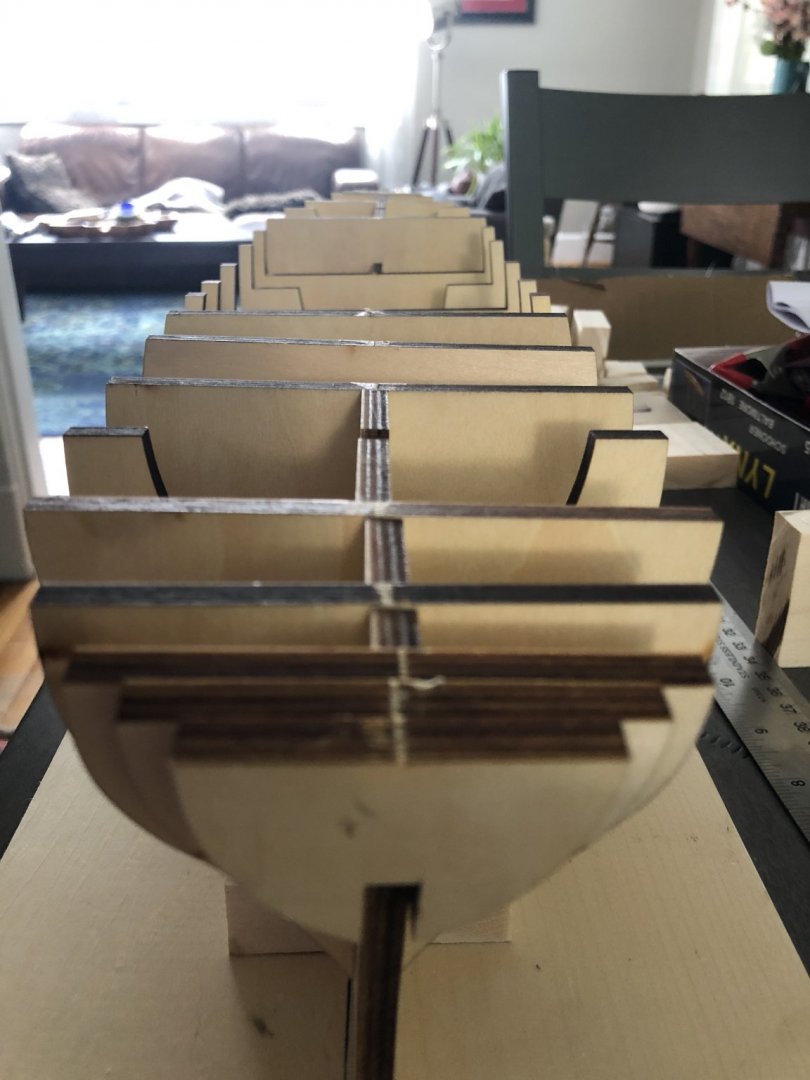

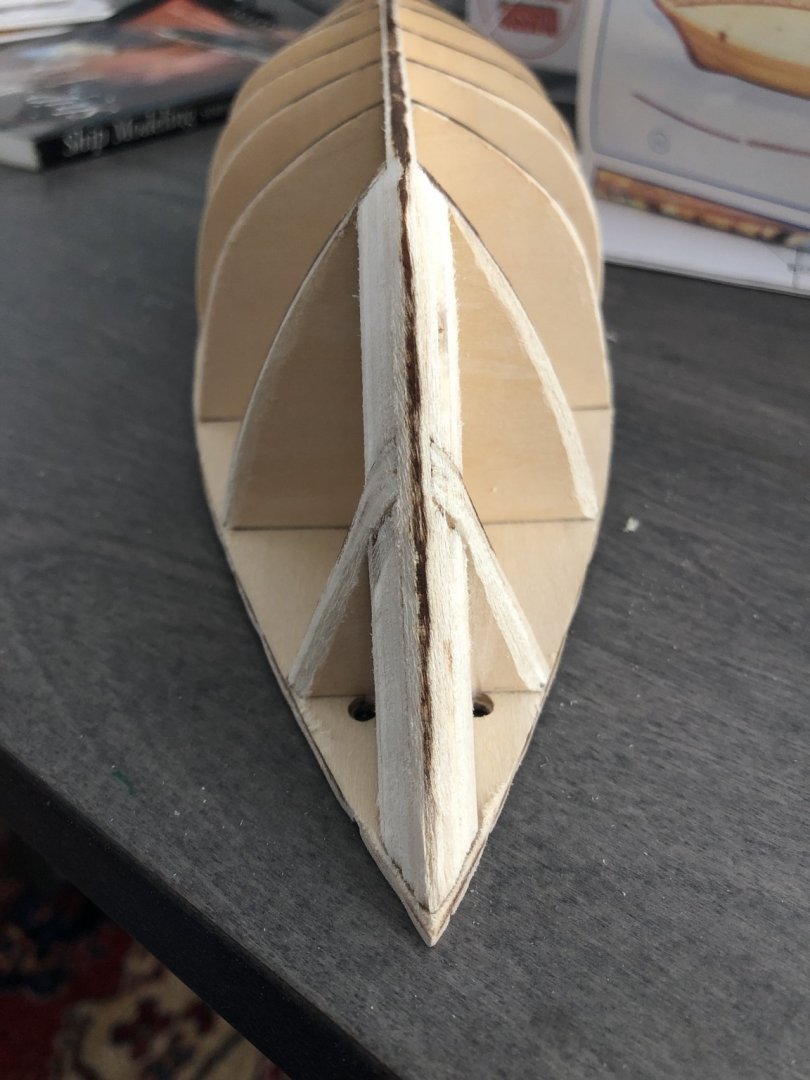

Finally finished putting the bulkheads in and still had significant warpage. Putting some of the inner decks in while still keeping it clamped straight has helped straighten everything out.

The bow is still somewhat warped. I tacked on the upper decks temporarily which hold the bow where it is supposed to be. If it’s a little off I’ll just have to shape it by sanding it down a little more in some spots. I am planning on adding a few rows of planks and then I should be able to remove the upper deck and work from there.

this isn’t the best shot and this isn’t tacked on to every bulkhead, but everything appears to be lined up. Lots of sanding to do today. -

-

-

I will try this in the problem areas before moving forward. Hopefully, by weighing it down with multiple bricks glue and the wood it will straighten out twisting in the front especially. Also hopefully if anyone has an issue with this in the future they can reference this log. I also emailed micro mark and told them about the issue, haven’t heard anything back. For the price of this kit and the skeleton be so warped, I’m pretty disappointed in that distributor to not even follow up.

-

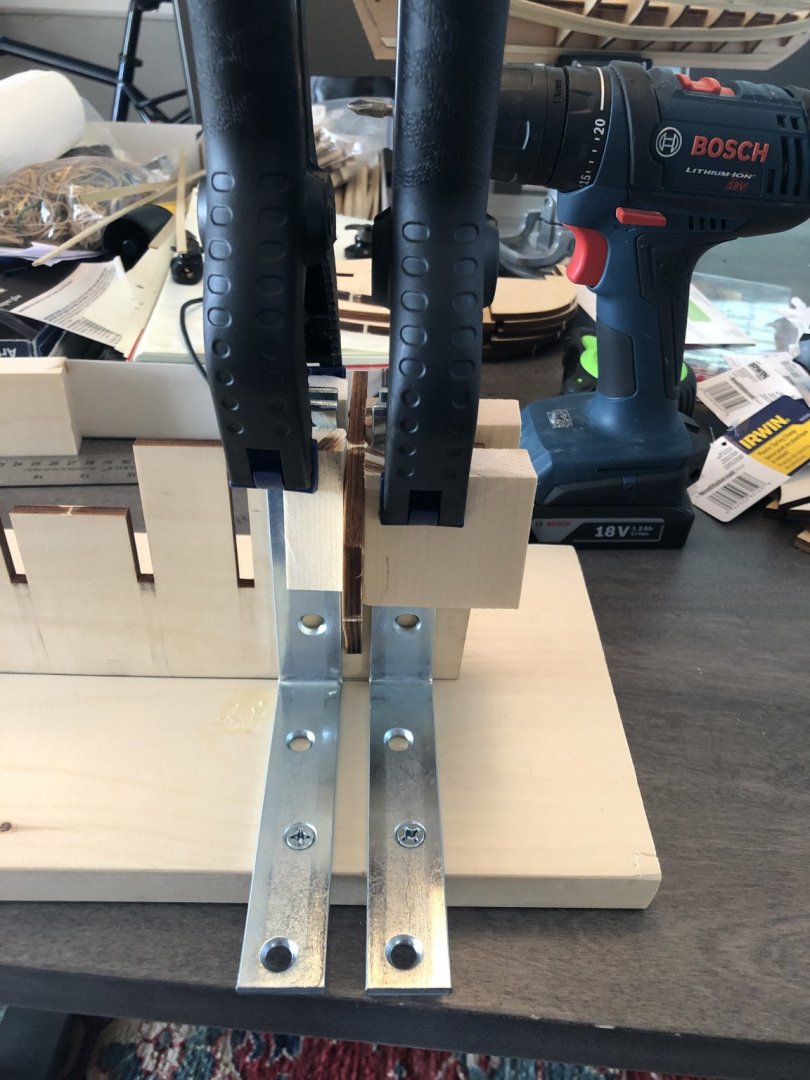

I’ve been plugging away once a day trying to get this warped keel straightened out. I’ve increased the brackets from 4 to 10. Do one, lift, slide, remeasure and level, measure again, glue, adjust, and measure one more time.

Today I discovered some bulkheads (the ones on the same sheet as the keel) to be a bit warped. Compounding the issue of trying to get everything squared up. The keel, even with all of these brackets still wants to twist and turn too, so this has been a pretty frustrating endeavor. In hindsight I wish I would have just had the keel remade. I don’t think there’s a way to 100% salvage this project, but I’m still going to try.

Today I discovered some bulkheads (the ones on the same sheet as the keel) to be a bit warped. Compounding the issue of trying to get everything squared up. The keel, even with all of these brackets still wants to twist and turn too, so this has been a pretty frustrating endeavor. In hindsight I wish I would have just had the keel remade. I don’t think there’s a way to 100% salvage this project, but I’m still going to try.

My question is, typically I see people put supports between bulkheads. Would it be better to try and ward off twisting by adding 90 degree supports to this location? It’s still twisting even after gluing the bulkheads in. Or just add wood pretty much everywhere?

I’ll be out of town for a bit, so in a few weeks I’m going to have to tackle this issue at the bow. The keel has limited space to put angle supports. Any helpful suggestions would be much appreciated.

-

20 minutes ago, ccoyle said:

This is an old kit design, and that was pretty much industry standard back in the day.

Good to know! Are their newer kits more user friendly?

-

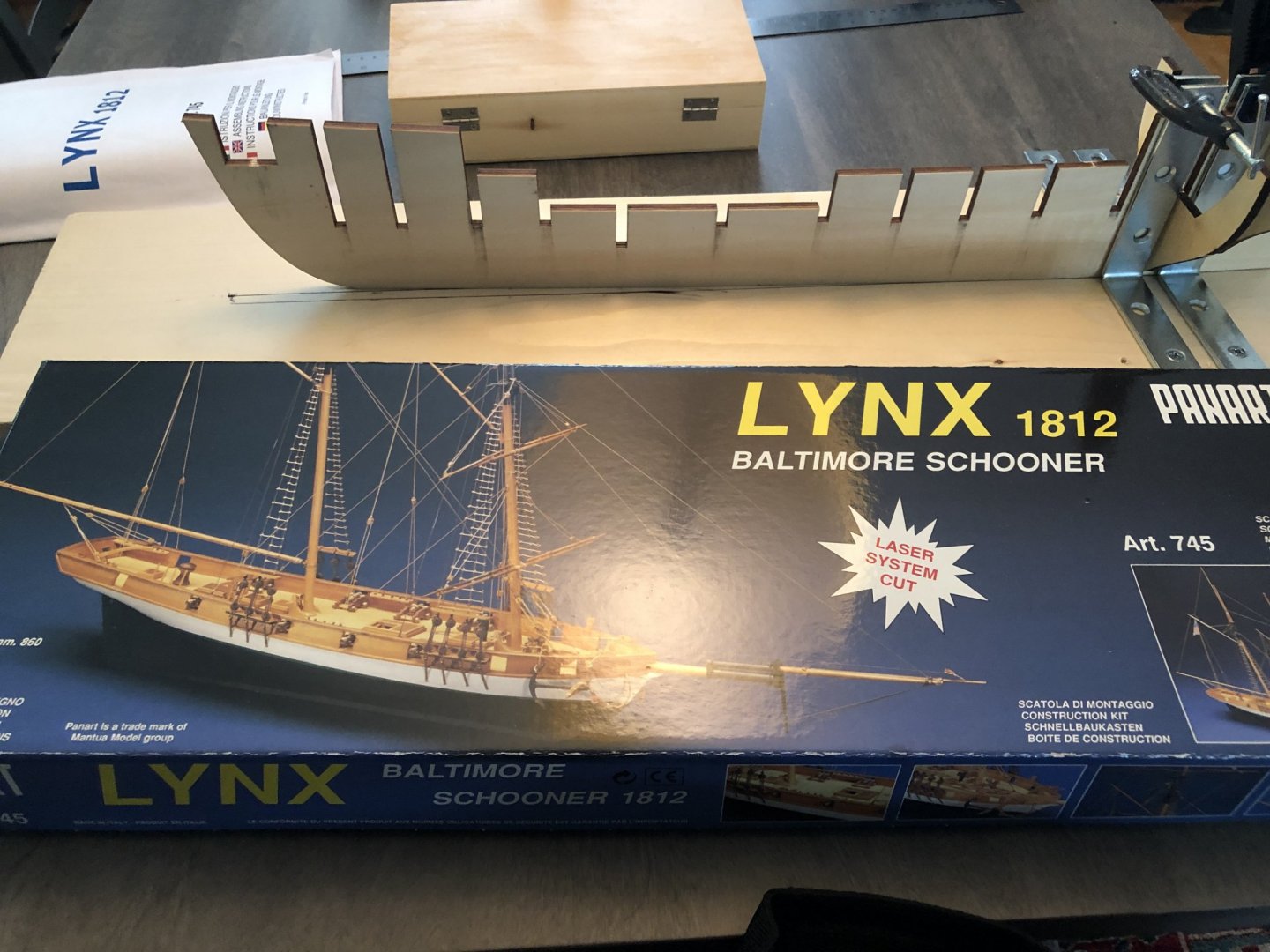

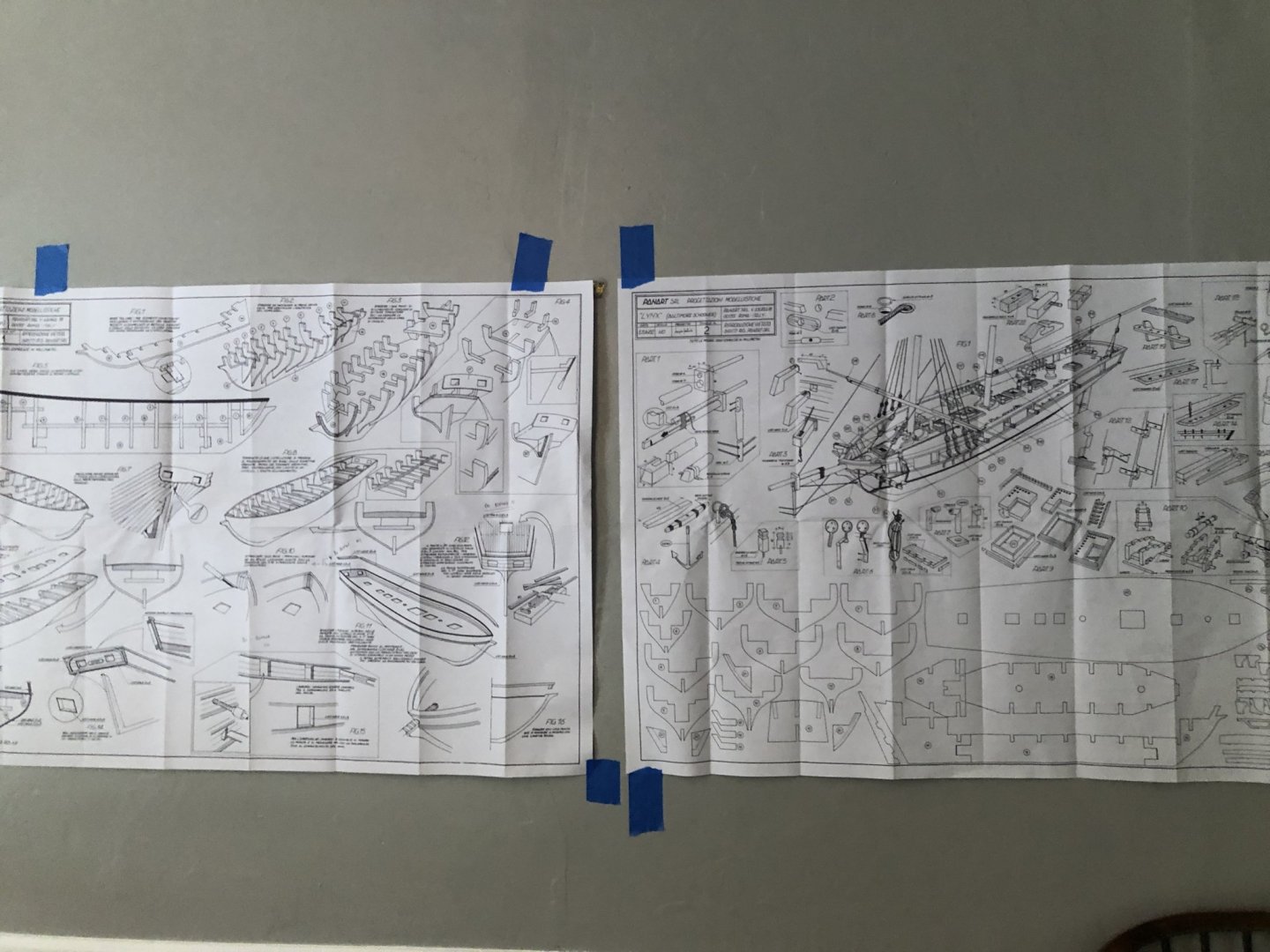

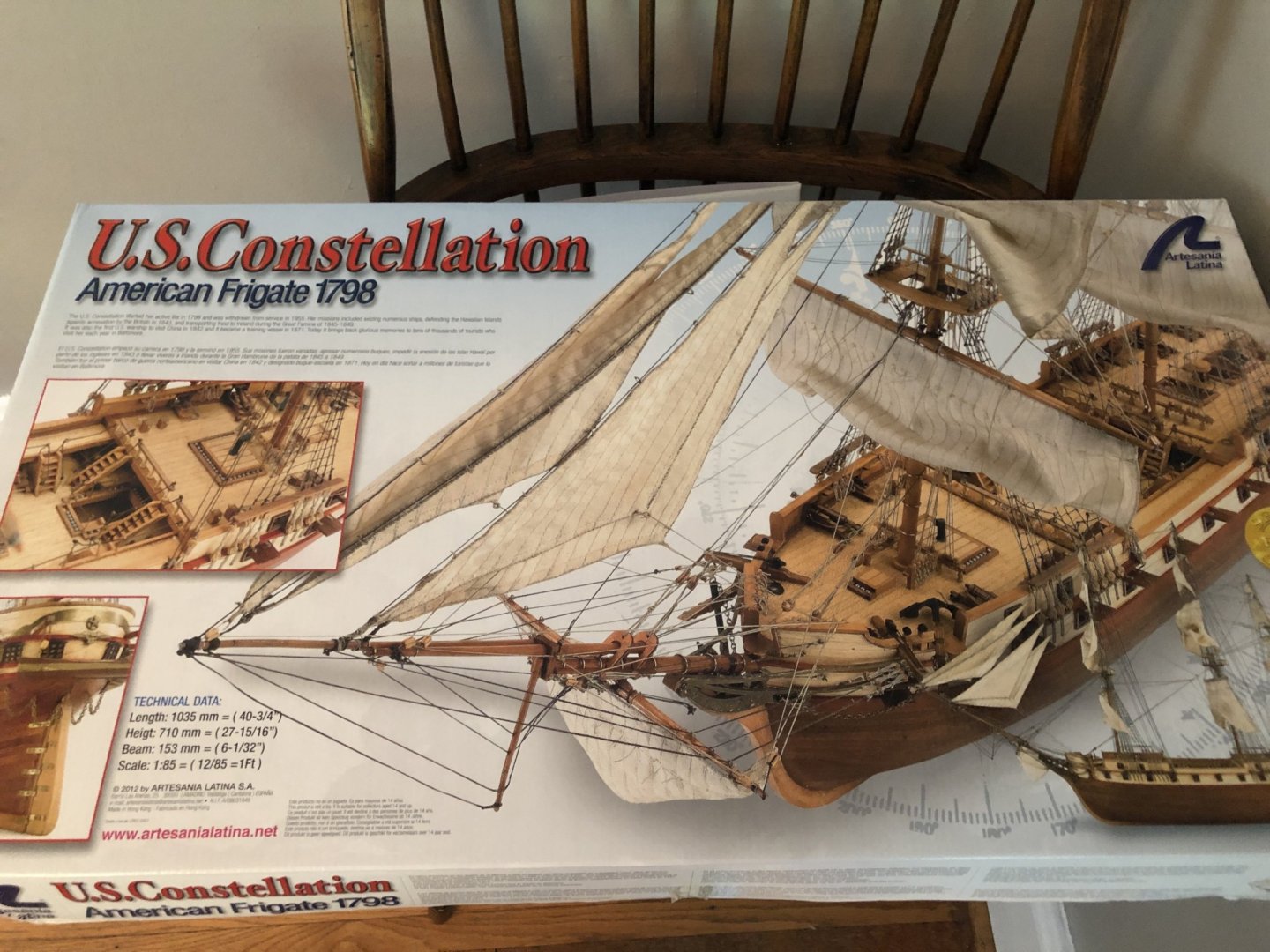

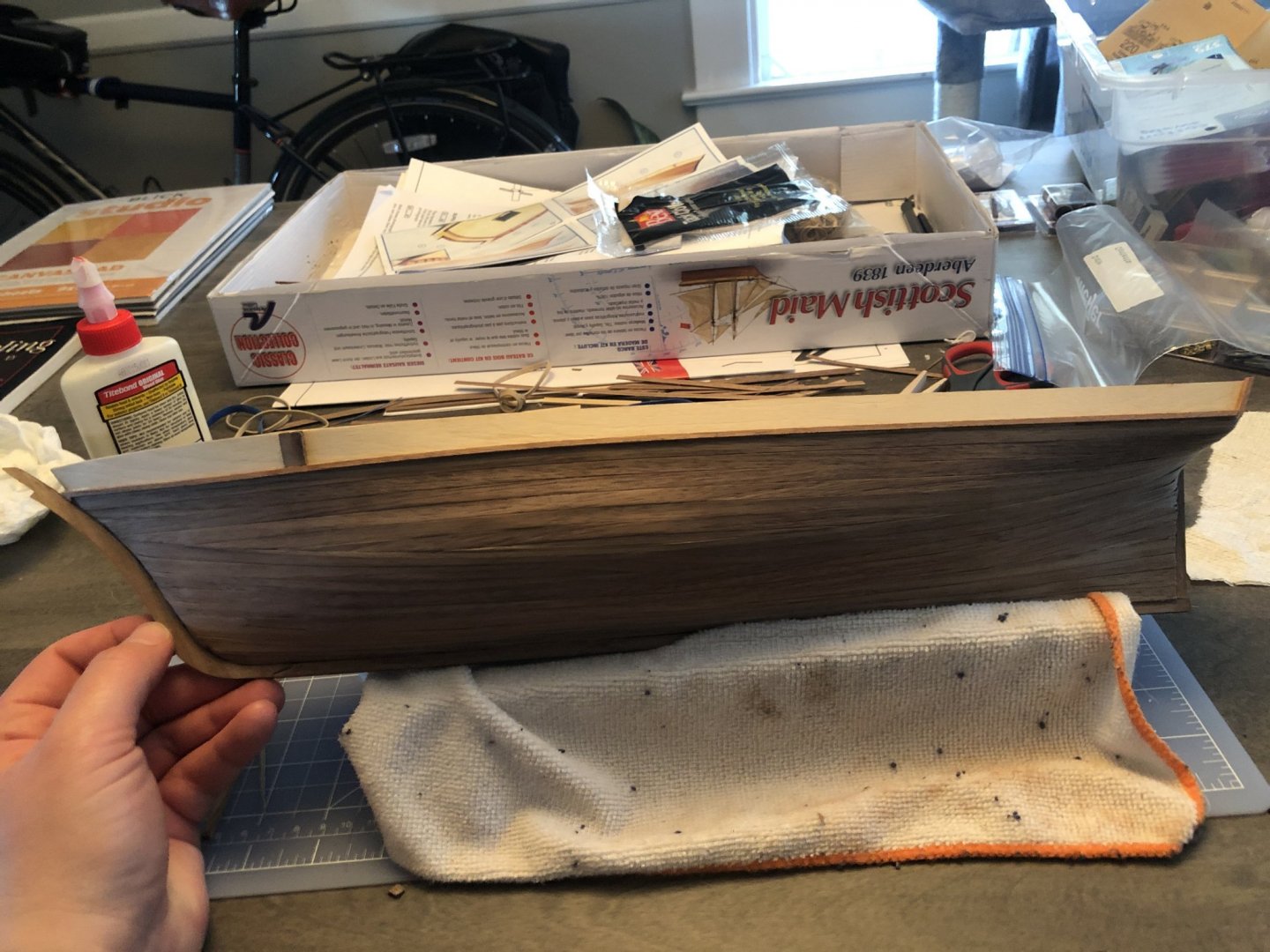

I started working on this model about a month ago. My dad and I FaceTime when we find a few hours to work on our respective models. I don’t have too many pics of it from the beginning and have finished the first planking. This is my second kit/build, my first being the AL Scottish maid. Mantua seems to not use as high of quality materials and I didn’t think that there could be any possibly worse instructions than AL, but here we are. I’ll be filling both sides in with wood filler today and sanding the hull down to start second planking this week.

I’ll be filling both sides in with wood filler today and sanding the hull down to start second planking this week.

-

I definitely plan on referencing a few builds of the Constellation I found on this site. So much useful information. Since I’m only doing a bulkhead a day, I’ll have plenty of time to catch up on the rest before planking.

- mtaylor and Ryland Craze

-

2

2

-

Your kit unboxing looked a little different than mine also, 4 plastic parts bins where mine had 3. I only had 3 spools of thread, the olive thread had already been woven in to the sails. Yours was definitely stored better. Mine must have been in a wet basement next to a giant register in a climate that swung from 105 to -10 degrees. Probably on it’s side. And upside down. I’ve looked all over the internet and haven’t been able to find a keel in this bad of shape. Anyway, finalized a bulkhead with your suggestions, looks lined up so far.

- Jack12477, Ryland Craze and mtaylor

-

3

3

-

-

-

I put it on a board and added a few supports which really do nothing except hold it upright. The blocks I use to keep the bulkheads square don’t do much either. I’ve been thinking about this all day and came home from work thinking i would just glue the bulkheads using my 90 degree blocks as an aid and then stick supports between them. After poking around and dry fitting some things I am back to square one. Soooo... I have a few questions. 1. Should I go through each bulkhead individually and hold it with my hands for 30 minutes to an hour each to make sure it all lines up? I don’t think any clamps will be of use and I’ll attach pictures to show why, hoping I’m wrong. 2. If I add supports would this be of any use at all in straightening it out? The keel seems more twisted than bent to me. 3. Should I just have a new keel made and bypass all of this nonsense?

-

- Ryland Craze, Edwardkenway and mtaylor

-

3

3

-

-

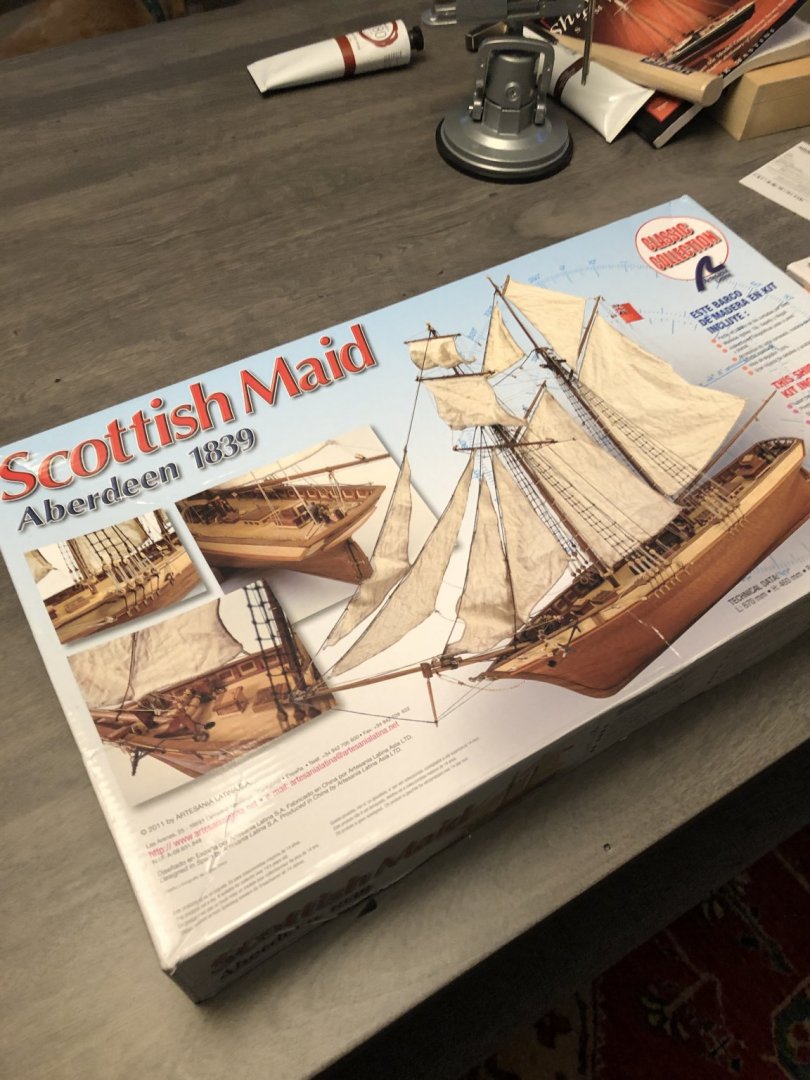

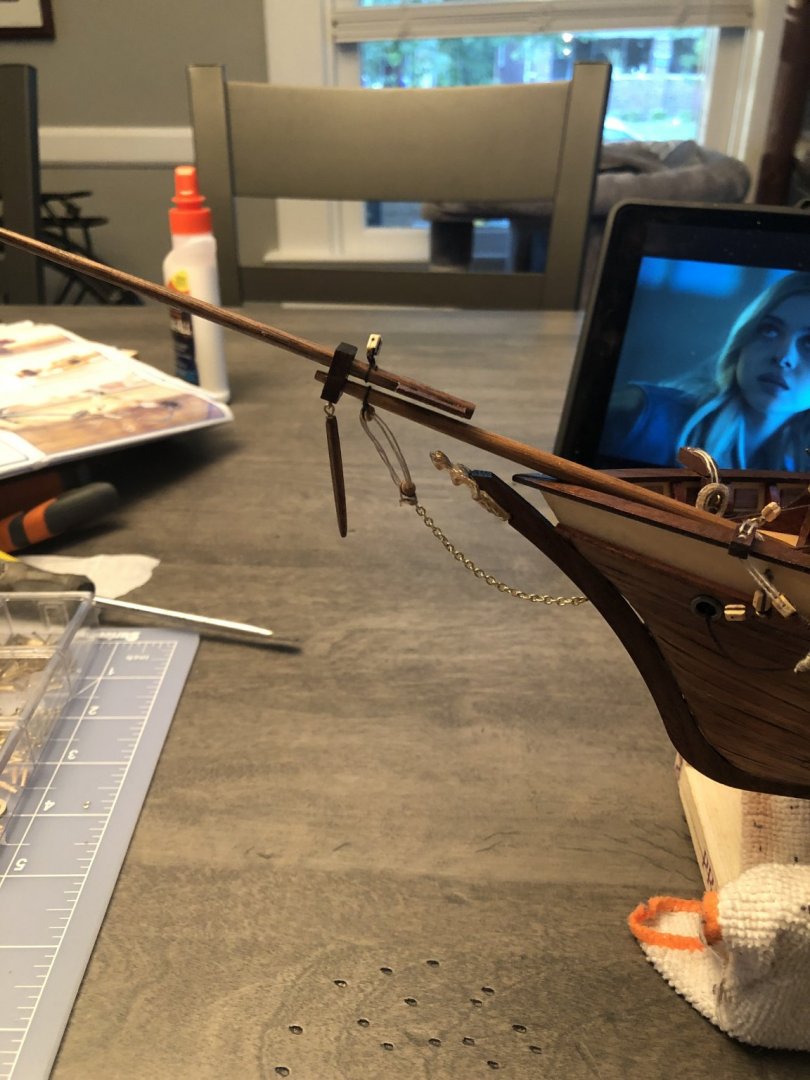

This was my first build ever and it’s completed. I started in March of 2020 and finished in June. Lots of free time with it being pandemic times. I did my best to trouble shoot on my own and got some help through YouTube videos. I’ll have lots of questions about rigging on the other two I’m currently building. Comments and suggestions are welcome.

-

Thanks for having me, I could spend a week or a month going through all of these tutorials and content. I finished my first ship, an artesania Latina Scottish maid model, a few months ago. When I have some time I’ll update build photos. I learned a lot and mostly trouble shooted on my own. Currently working on a Mantua Lynx. My dad and I FaceTime and work on it together. Will be starting a build log for that and also an Artesania Latina Constellation. Anyway, thanks again for having me and I’m looking forward to learning from you guys.

Constellation by Smittybear - Artesania Latina - 1:85

in - Kit build logs for subjects built from 1751 - 1800

Posted

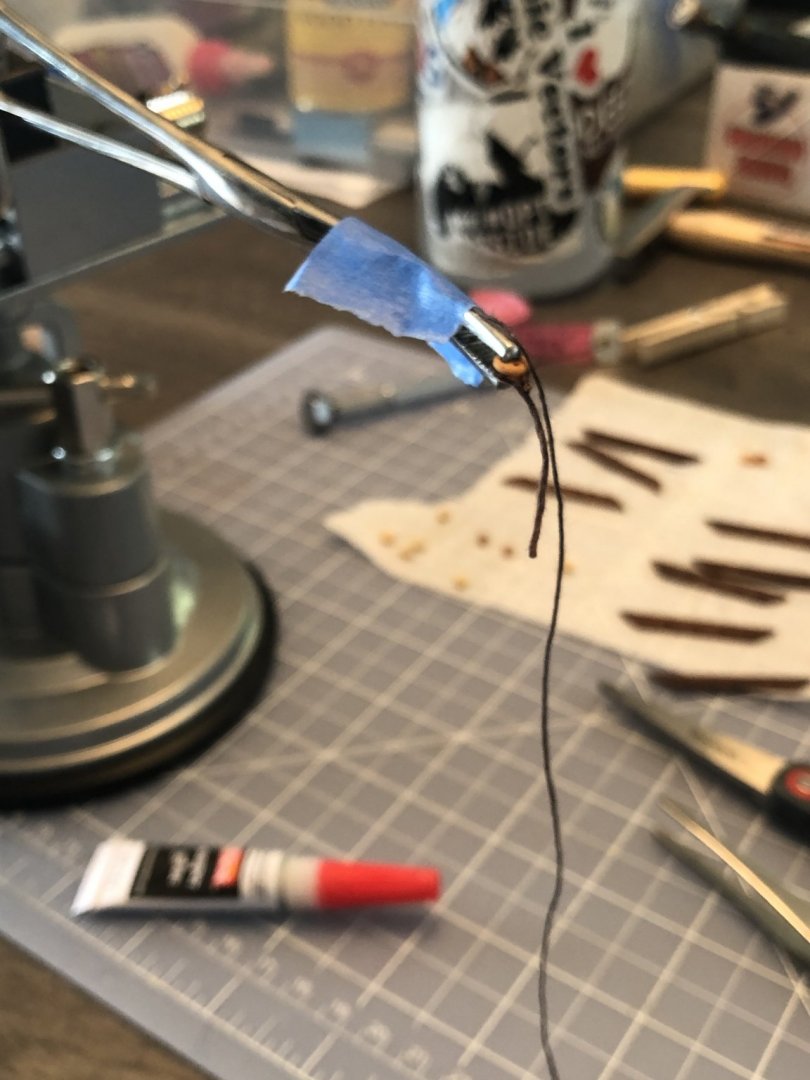

Also apologies, I like to be auditorily distracted while I work and was “watching” Prometheus while working this day. I didn’t realize there were half naked aliens and severed Android heads in the backgrounds until I reviewed the post.