Avi

Members-

Posts

323 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Avi

-

Ok now I completely understand what you are saying. I see it in the pictures as well. I also have the glued up planking (as well as the scribed that comes with the kit), and just checked the order, it is indeed 1/16”. If anyone comes across this in the future, here are useful links: - 1/16” glued up decking - 3/32” glued up decking - ⅛” glued up decking - 3/16” glued up decking I will take them out and look at them against the ship, see if the 1/16 vs 3/32 is visible enough for me to want the other planking. I also have various bits of planking around, so I can get some feel for it. It is frustrating, like the gudgeons and pintles, there are too many places in the model or book where the information is wrong, leading you to make mistakes or order the wrong parts. The book itself is in serious need of review, revision and modernization (cc @MrBlueJacket). thanks for going into the detail @KurtH; it really helps

-

@KurtH I don’t understand. The glued up planking comes as sheets. They just are used as the deck. What did you mean by you would use 3/32” rather than 1/16”? it sound like you mean actual planking strips, but how do those fit into that? You also reference the photos in Arnot’s book. Where were you able to see the deck plank width in there?

-

About that gundeck. I’ve got the glued up planking, which is four sheets. Each deck (gun and spar) is two sheets side by side. My plan is to cut the sheets for the spardeck but not quite snug, just a bit too big, 1-2 mm around. Then I’ll take one of the cannon and glue it together with glue that comes apart easily, as I’m not planning on painting yet, just using it for measuring. I’ll probably use Elmer’s glue, which I hear can be removed with vinegar. Open to suggestions. Either way, I’ll use the cannon to determine what the correct deck height should be at each point, by placing it on the deck planking at the gunport. Where the deck needs to be higher, extra hull planking under the deck planking will provide the boost. Since it is so very thin, I can get tiny gradations. I expect to start around mid to late August.

-

Rudder shipped. The gudgeons and pintles aren’t permanently attached to each other, in case I need to remove them for work. But they are glued to the hull and rudder, respectively. I had them primed and painted, then attached them. And when I did, most of the paint came right off. I had to do another coat or two. And I suspect more in the future. But good for now.

-

Redid the rudder. Used an iron to heat up the copper, removed all the plates, cut my finger (optional), sanded it down, then sanded a curve, primed, painted, and applied new copper. Giving it a day, then will wax and varnish. Bluejacket is sending me replacement gudgeons and pintles of the correct width, but they will not arrive for a few weeks.

-

That’s a fair point, unless there were a large enough gap between rudder and sternpost, which would not be great for the fluid mechanics. The picture from the museum shows it. Even rounding it won’t help much, without some serious tapering. Those gudgeons and pintles are ⅛”, the wood stock for the rudder is 5/32”, add the copper and it’s up to 7/32”. I’m somewhat perturbed that the guide didn’t say anything about rounding. It’s obvious once someone smart like @Gregory says it, but not before that 🤦♂️ I would like to get that rounding in anyways. But even if I do, I need gudgeons and pintles with wider spacing in the gap. I’ll have to get from bluejacket. As for the rounding, I could remove the leading edge copper plates, and then either add material or sand it down. Anyone remember how to remove contact cement? 😁

-

I probably read that at some point or another, as I read every build log that might help. I must have forgotten. I’ll just have to get those. Thanks @JSGerson if anyone comes across this in the future, here’s the link https://www.bluejacketinc.com/shop/fittings/under-water/gudgeons-and-pintles/f0852-1-4-to-fit-rudder-thickness/ item F0852

-

Ok I primed them and will paint soon. Never a boring moment. Despite the promises of the book, the gudgeons are too narrow to fit over the coppered sternpost and hull, and same for the pintles over the coppered rudder. Oops. I’m not quite sure what to do here. The metal is soft, so I try to shape it, but I’m more concerned I’ll snap the pieces off.

-

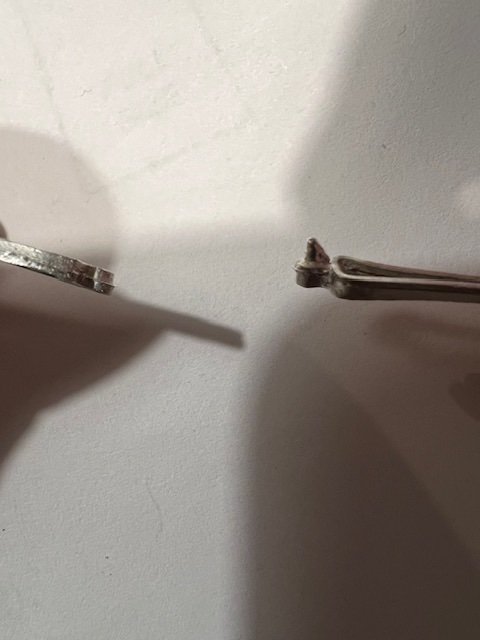

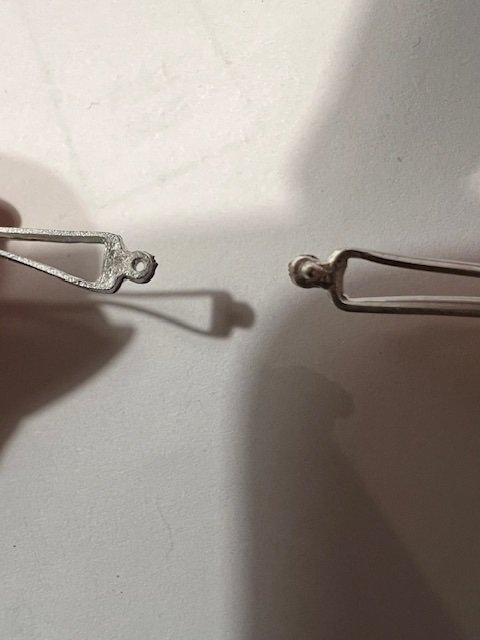

Hard to believe it has been two months since I posted. Life has been a wee bit busy here. Before I start on the gundeck, I’m going to place the gudgeons and pintles (my phone keeps trying to auto correct those 😂) The book recommends not shipping the rudder permanently yet, but to wait until some of the harder work on decks and masts is done, since the rudder is fragile, which makes sense. I ran I into two issues. First, the gudgeons and pintles are of that metal. Should they be finished or painted in some way? Second, I don’t understand how you attach the rudder to the sternpost, or more correctly, the pintles to the gudgeons. There are holes in the pintles, which the guide suggest running a stiff wire through for alignment. But the gudgeons have more a triangle than a post on them. It isn’t something you can set the holes from the pintles onto. I could put the gudgeons in with them facing down, and then just glue the pintles to the gudgeons, but then it would have no motion. I guess I also could carefully trim down the triangles to a post with a file? Not sure. Pictures attached.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.