-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Techtonic

-

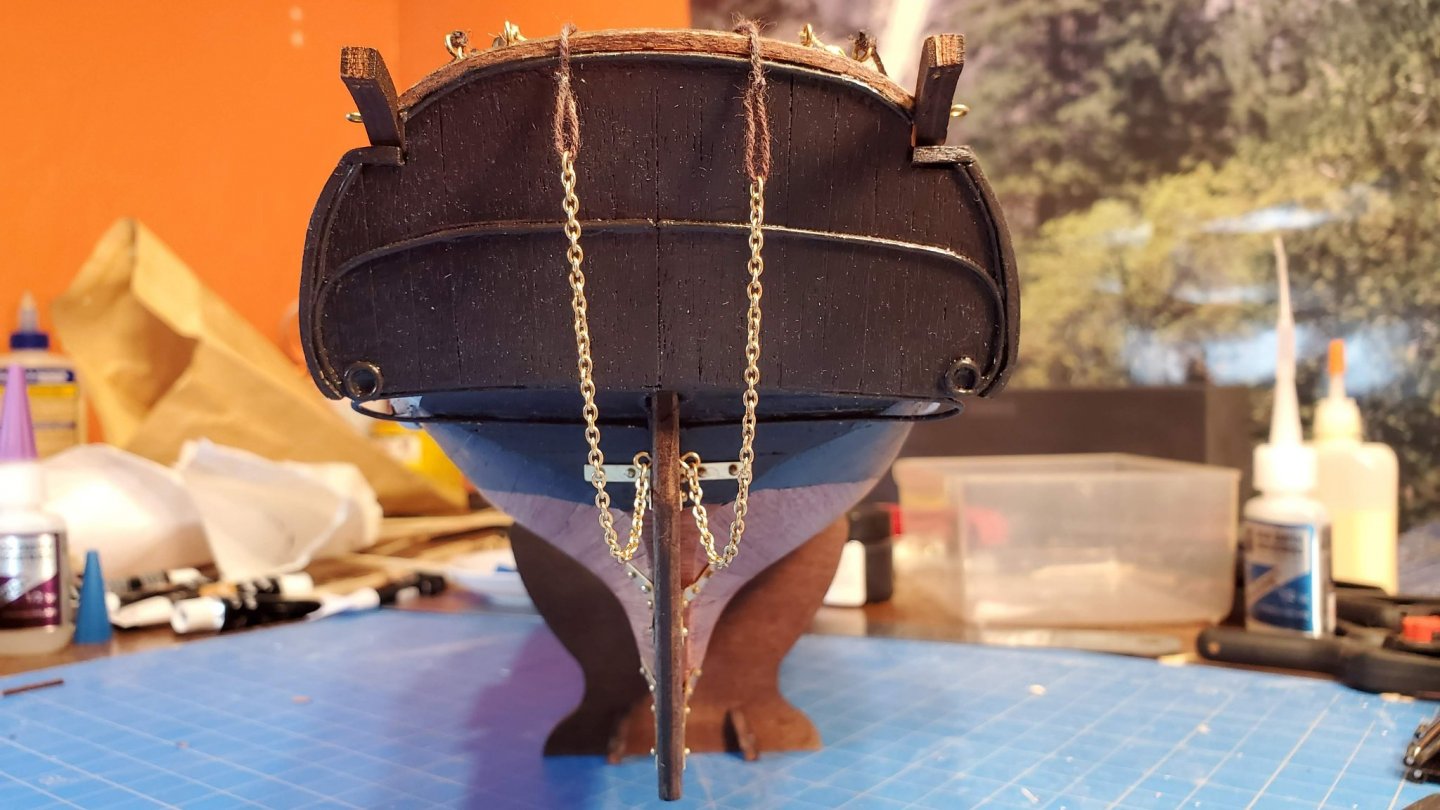

One final thought for the day. I think the guy that created the model for the instructions messed up when installing part H20. I believe it is installed upside down which is why you end up with the odd splaying of the chains around the gun port. So I believe the group of three deadeyes should be fore of the gun port and the group of two should be aft, with the gap being inline with the gun port. It's too late for me to fix on mine but if I were to build again I would definitely correct this.

-

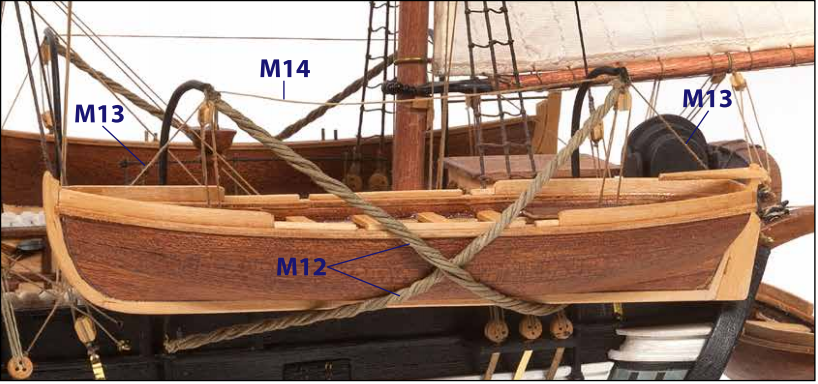

Another thing I noticed in the pictures in the instructions - You can tell by the plank widths and grain it definitely looks like they have double planked the boats that hang over the side with the sapelli veneer, though they don't mention doing this anywhere. I might consider doing this depending on how good my first planking looks.

-

Hmm... looking ahead in the instructions it looks like there's more of the 1mm brass wire required than I anticipated. I didn't realize there is a fair bit used in the masts. I must be missing a good 4 or 5 rods of this material. I wish I had known earlier in the build as I would have made the transom decorations out of the 1mm steel wire I have as that all gets painted so the wire color doesn't matter. I don't want to have to wait for shipping from OcCre in Italy, so I just went ahead and ordered a spool of 18 gauge brass jewelry wire off Amazon. Hope it works as required.

-

Looking great! I like the way you painted the figurehead. Looks like you're just a little ahead of me, I'm just about to start on the dinghy and long boats. It's a bit late but I also just started a build log on this kit yesterday if anyone is interested. https://modelshipworld.com/topic/28420-hms-beagle-by-techtonic-occre-160/

-

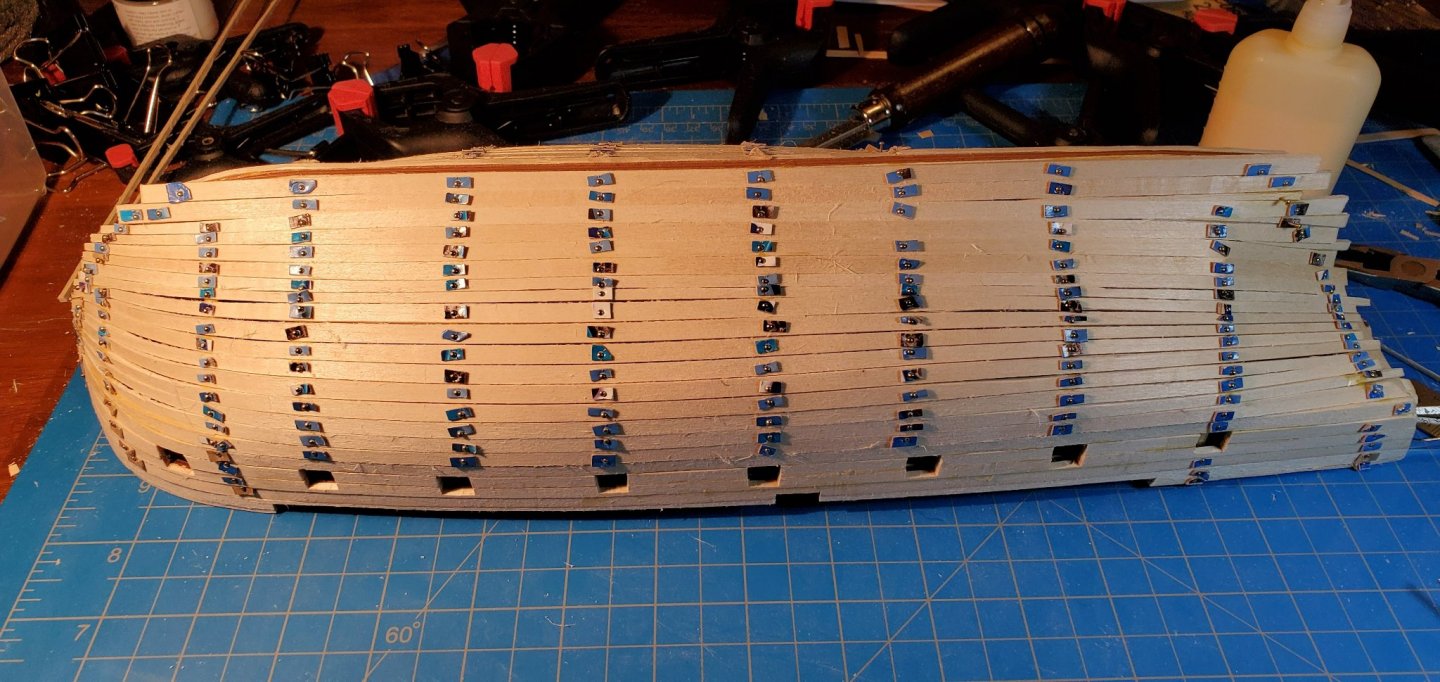

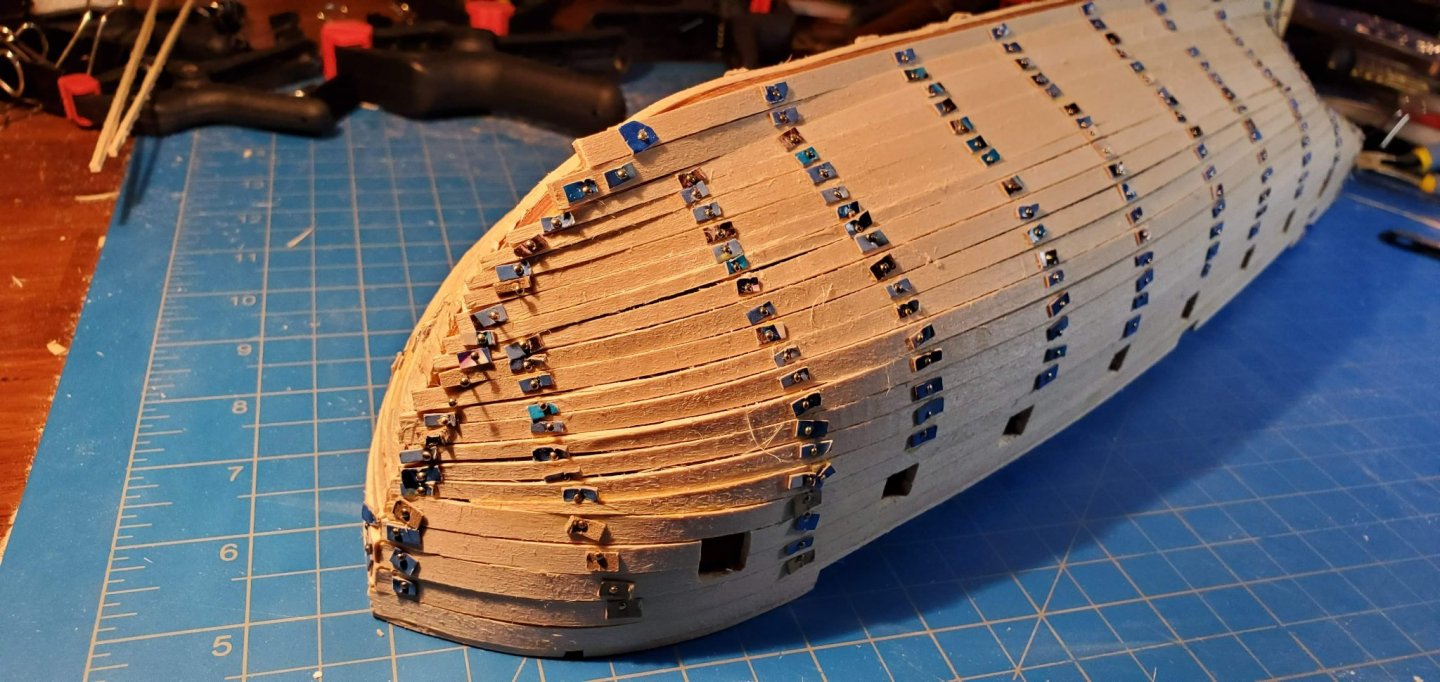

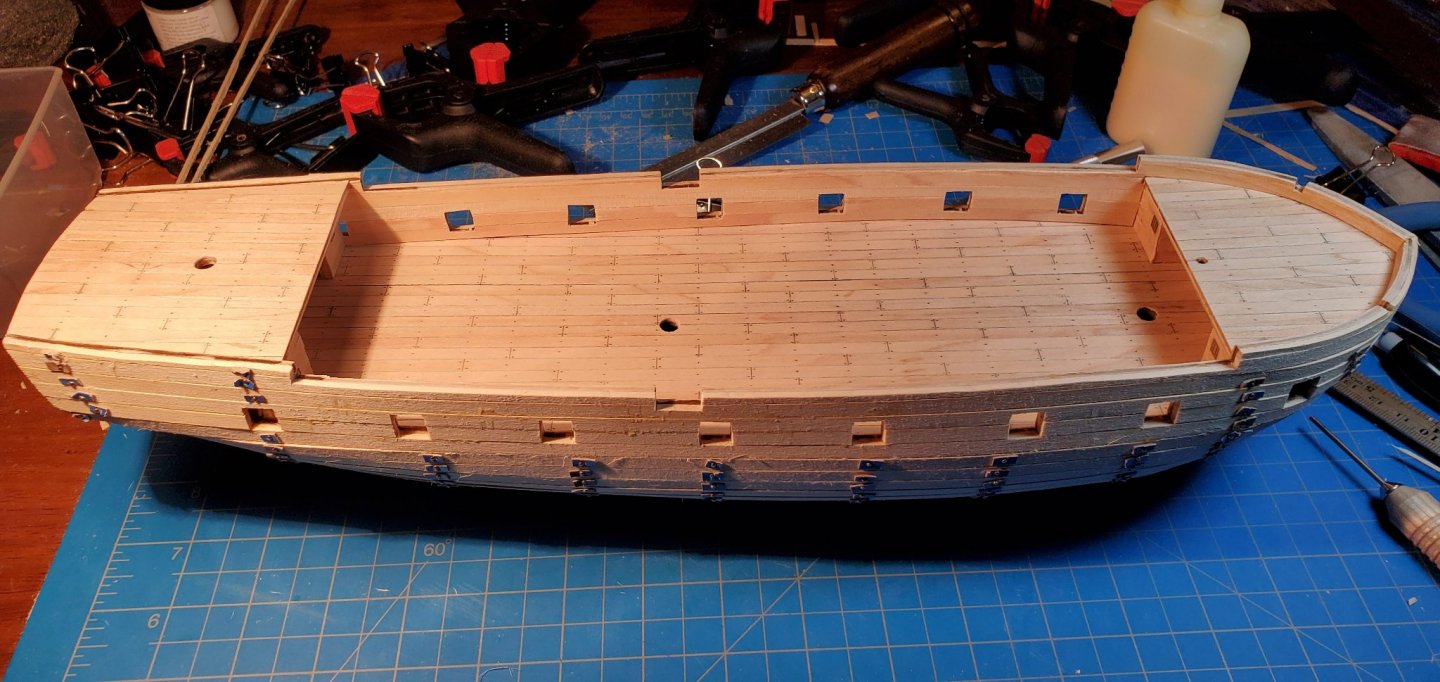

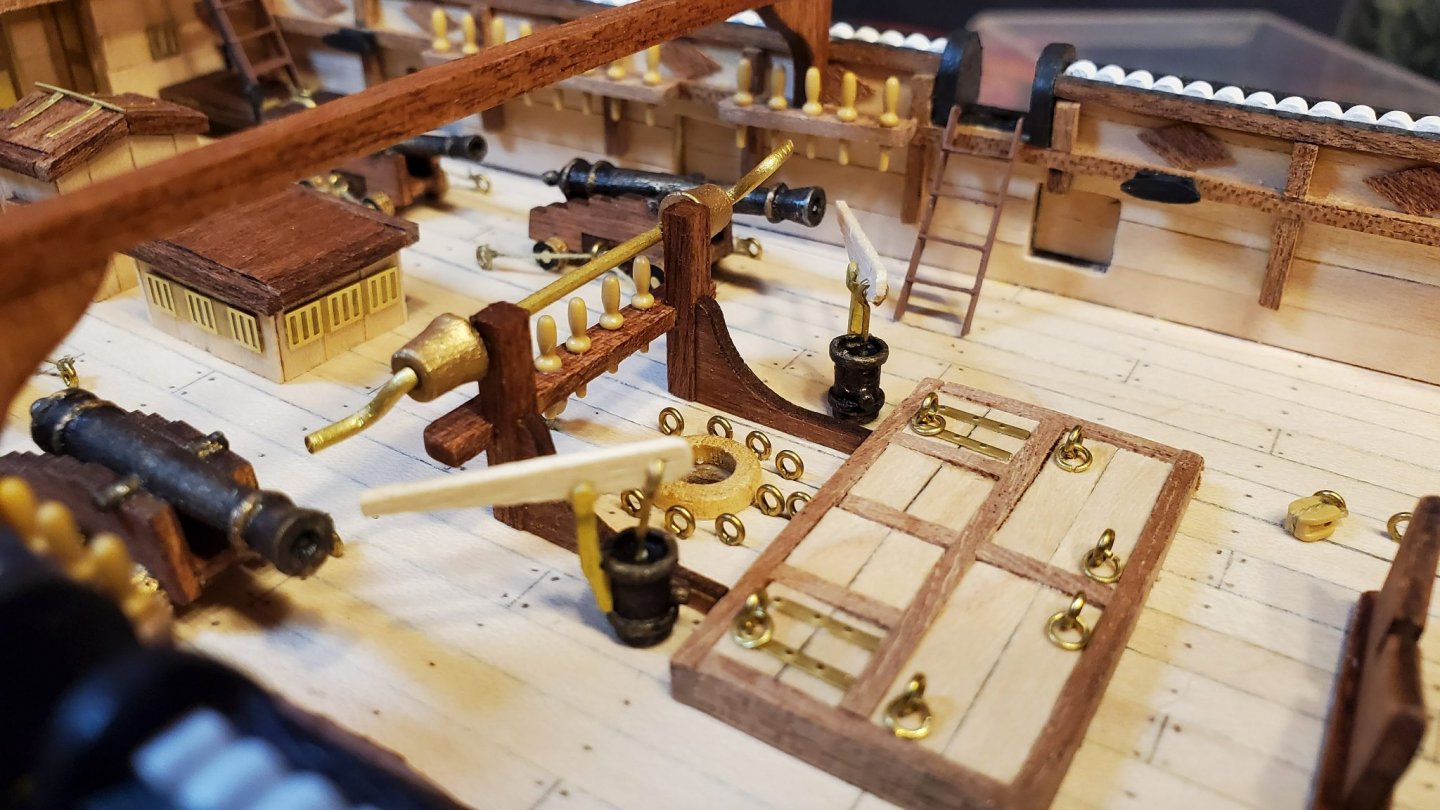

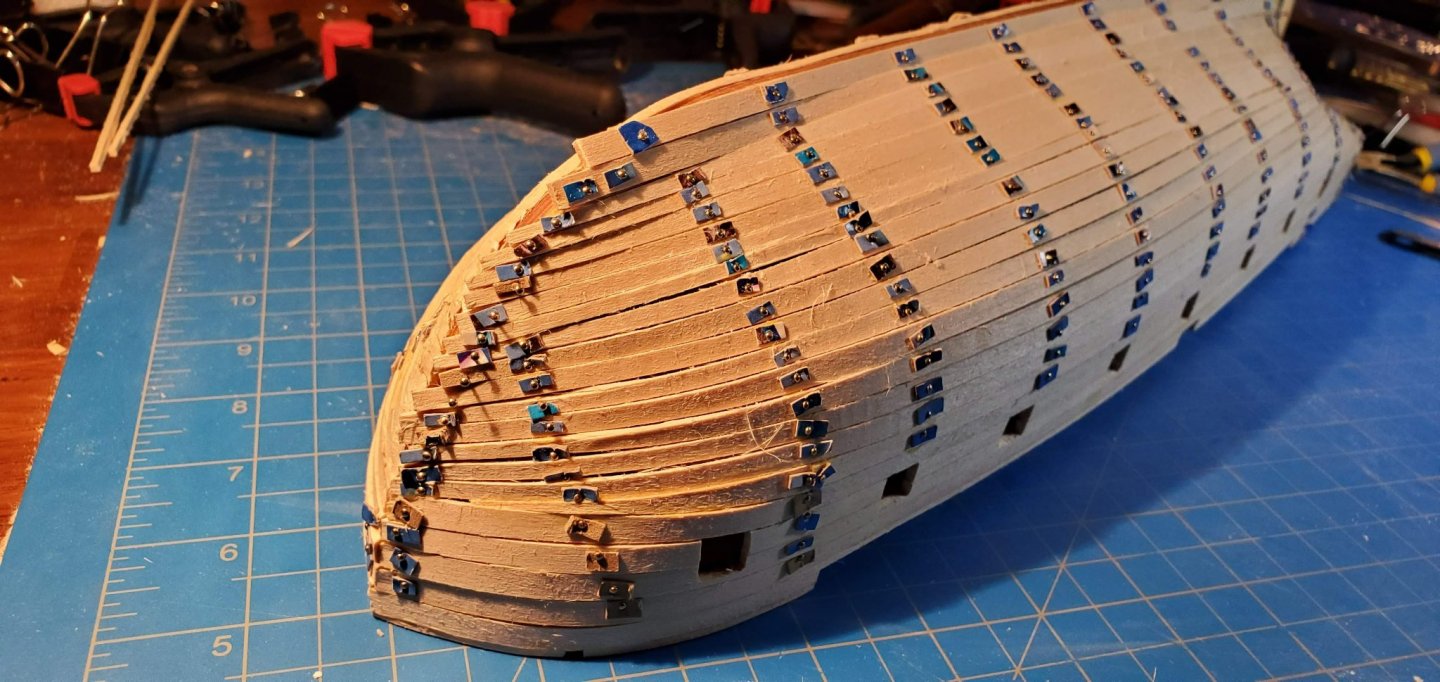

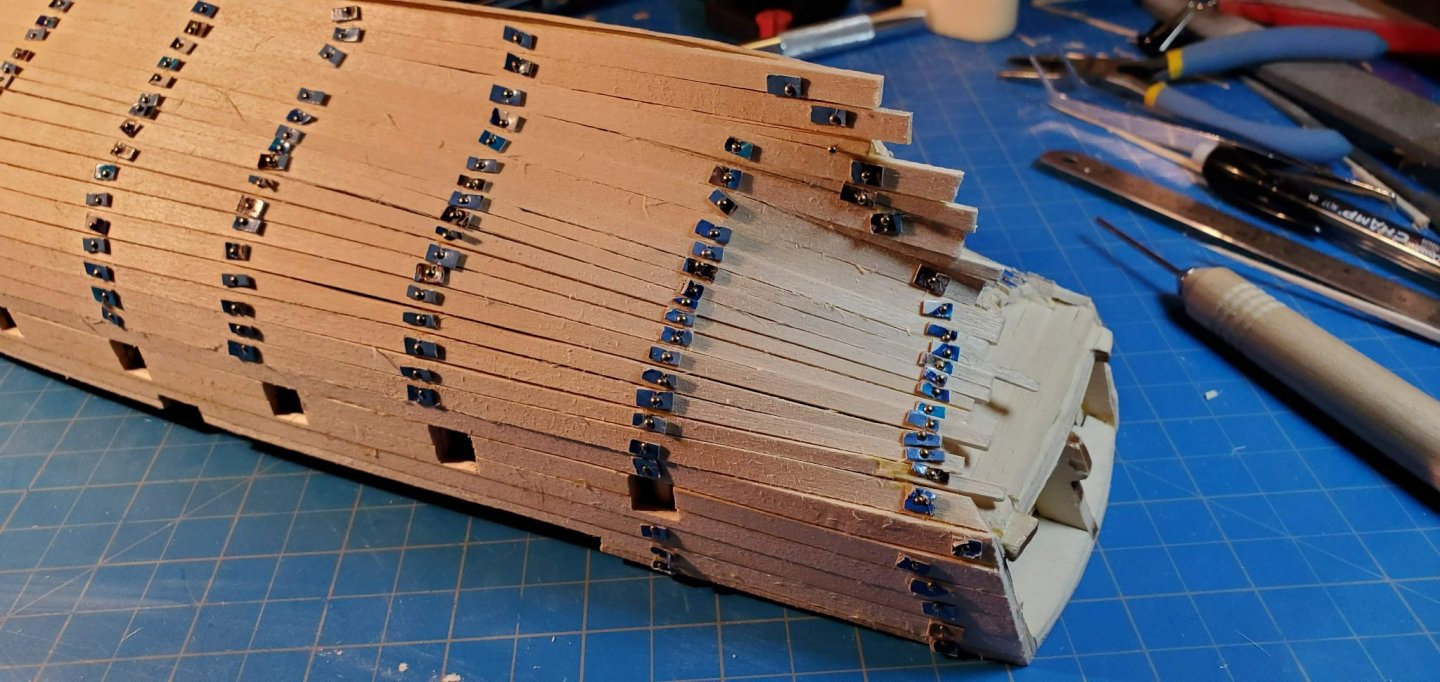

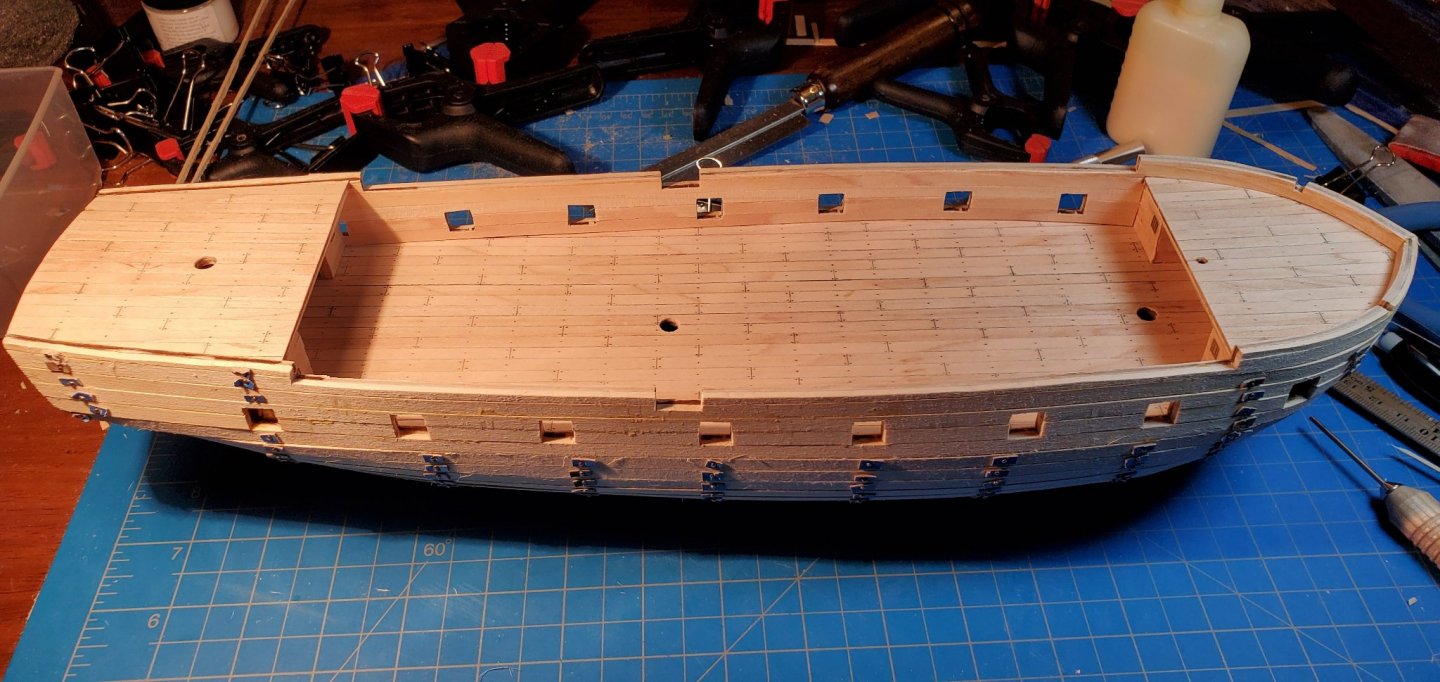

Thought I'd throw my hat in to the growing number of logs for this ship - I guess the more the merrier! I'm a little late to start a log - I started building in late February doing 2-3hrs work most days. I would guess I've put in the best part of 100hrs so far. This is my very first wood model ship. I've done a lot of Metal Earth type models over the past year or so, including a few ships such as PieceCool's very decorative Wind Breaker and Black Pearl This has given me a lot of experience at working at a small scale so I hoped this skill-set would help with building a wooden ship. So decided to opt for an ambitious first build of the Beagle. The scientific significance of ship was also very appealing to me. This choice was also heavily swayed by the availability of OcCre's YouTube step by step build videos. And these have indeed turned out to be an invaluable resource. Here's another excellent online resource I found for visualizing the ship: https://www.cloudtour.tv/beagle/. There are some differences in the OcCre ship compared to the virtual model in the details - but the general layout out of both versions are very similar. I only have a few pics from early in the build, just after the first planking. As you can see in these pics I was concerned about being able to remove the pins after the glue had dried. So I made myself a whole bunch of small rectangular washers from cereal box cardboard. These worked really well - you could push the pins in all the way with a pin-pusher so it holds the wood down securely. Then when dry, the pins could be easily removed by sliding a flush cutter under the cardboard washer and pulling out. You'll also see in these pics I opted to go for the more traditional way of tapering the planks along the whole length rather than the way OcCre suggest of using full width planks then inserting triangular sections to fill the gaps. I'm not sure there is any advantage to my way over OcCre's way other than it may have given me more useful experience for future builds. For bending the planks I used one of these: https://www.agesofsail.com/ecommerce/amati-form-a-strip-am7381.html. In my research I've seen many people say not to use these - but I found them really useful and made bending the planks easy and quick. The only thing is you can't use them if the inside of the bend is going to end up visible as you end up with a bunch of indentations on the inside. For the deck planking and second hull planking I highly recommend the way they do it in the OcCre videos using contact cement. I was a bit nervous about using that method as I was afraid that as soon as I attached the plank it would adhere and would not be moveable to adjust and close gaps. But this is not the case - it does not adhere properly until you apply firm pressure, so it is easy to adjust just right, then when a section is complete just apply firm pressure with a rounded wooden object and everything will stick firmly. I used DAP Weldwood Contact Cement which worked great for this application. I did manage to put quite a major slice in my thumb with an Xacto knife due to a plank splitting when I was trimming the top edge flush with the deck - certainly learned my lesson to be more careful when making cuts like that. Fortunately didn't cut through any tendons so it's all good now other than a numb section due to cutting through a nerve. So skip forward a month and I'm now just before building the dinghies and long boats. I'm very pleased with how it has progressed. There were a few mistakes along the way which required some effort to rectify - but that's how you learn right? I did have an issue with my set in that it is short probably two lengths of the 1mm brass wire. I had to start substituting the 0.5mm and 1.5mm wire for some things, and some 1mm steel wire I had laying around for some parts that get painted. Talking of paint - I used Historic Ships brand Black and White paint for the hull. This gives a semi gloss finish which looks really nice. It does take about 3 or 4 coats to get a consistent finish, but it dries pretty fast. I also used Historic Ships Clear Satin varnish for everything that needs varnishing. This dries fast and is very quick to clean off brushes with water. For stain I used Minwax Dark Walnut and Red Mahogony, and more recently got some Red Chestnut which I prefer and used for later parts of the build (e.g. the deck house roofs). In hindsight I wish I had treated all the interior sapelli wood with the Red Chestnut as that would have given a nicer contrast. For all the black fittings I used matte acrylic paint, firstly because it only needs one coat to get a good finish, and second my understanding is that on small objects gloss does not look very realistic. For the cannons and figurehead I used a mix of matte black acrylic and Liquid Leaf Classic Gold. I actually mixed the paints together in various proportions to get the desired patina rather than using the black then gold method shown in OcCre's video. Then I used a very small amount of the semi gloss black dry brushed on top to get relief around the nooks. In the next pic you can see I had to substitute 1.5mm instead of 1mm brass wire for the axle on the central pin rail due to there not being enough 1mm in the set. Looks OK though I think. In the next pic you can see an issue with the foremast belaying pins. I spaced each set of three pins exactly as shown in the scale drawings in the instructions. But this makes them too close and each set of three pins will not insert all the way due to interference. I almost remade the whole piece but in the end just decided to put up with it. If you are building this ship I would suggest spacing these pins out slightly more than shown on the drawings. There a small gap between the keel and the hull that can be seen in the next pic. I should have spent more time test fitting and shaping the keel here. I was happy with how the wire bending went for the transom decorations, I think my Metal Earth experience helped here as you have to do a lot of careful forming and shaping of metal sheets. You can see here I did not sand down the internal support blocks at the stern on the starboard side enough. It wasn't clear in the instructions that they basically need to be sanded down to the width of the keel at the very back. Here you can see another mistake I made. The anchor wale on the port side shown here is correct. But compare it to the first pic, you'll see on the starboard side I accidently made it slope the other way, towards the back as you go down. It's one of those errors that no one viewing the model would ever spot as you never see both at the same time - but I know it's there, grrr! Another mistake I used the wrong thickness of wire for some of the wires that make up the bow (this is not why I am short on the 1mm wire though). Well that's it for now. I'll post further updates as progress is made.

-

HMS Beagle by Krupi - OcCre - 1:60

Techtonic replied to Krupi's topic in - Kit build logs for subjects built from 1801 - 1850

Looks like we're both at exactly the same stage - I just put the ribbons on my Beagle too. I did remember to put the strips on the front (there are actually 4 on each side). They have a slight slope to them which I did - but it was only after everything dried I realized that I sloped them forward on one side and backwards on the other - so annoying! It's one of of those things that nobody looking at it would spot - but I know it's there, and that really frustrates my OCD! -

HMS Beagle by Krupi - OcCre - 1:60

Techtonic replied to Krupi's topic in - Kit build logs for subjects built from 1801 - 1850

Since I mentioned the cardboard washers in this thread I thought I'd post a few pics now the the first planking is done to show the method. With the washers in place it is easy to remove the pins using shear cutters. Still needs trimming, sanding and filling but I'm pretty pleased with the result for my first ship. For the first couple of planks below the bulwark I used the method in the instructions of using whole planks then filling the gaps. But then I decided to try the usual method of just tapering the planks for the remainder as I figured this would be better practice for future builds. -

HMS Beagle by Krupi - OcCre - 1:60

Techtonic replied to Krupi's topic in - Kit build logs for subjects built from 1801 - 1850

I started attaching the first gunwale with leaving the pins proud by 2mm, but the wood would ride up and separate from the join through the slack. So I decided to try the washer idea again. After some more experimentation I've found that cereal box cardboard works really well. It's dead easy and quick to cut into small ~ 3mm x 5mm rectangles and is perfect for the job. I found using the washers with the unfinished side of the cardboard down works better as it helps stop the cardboard sliding around as I'm applying pressure with the pin pusher. With the washers it allows the pin heads to actually clamp down and hold the joint correctly. Then the pins are also really easy to remove by inserting flush cutters under the cardboard and leveraging upwards. -

HMS Beagle by Krupi - OcCre - 1:60

Techtonic replied to Krupi's topic in - Kit build logs for subjects built from 1801 - 1850

Yeah that's what I'm trying to achieve, but I'm using a pin pusher so you can't see how far in the pin has gone. I just experimented with using the deck plank as washers but unfortunately they split when driving the pin through them. I still like the idea, I just need to find some thin material that the pin head can't go through. I'm thinking of maybe cutting little squares out of something like a plastic milk container. Or I guess I can just push the pin in a small way with the pin pusher to get it started and then tap it in with a small hammer until the head is the right height. -

HMS Beagle by Krupi - OcCre - 1:60

Techtonic replied to Krupi's topic in - Kit build logs for subjects built from 1801 - 1850

I just started building the Beagle a few days ago so I'm following the builds here with great interest. One idea I had regarding the pins is to make a bunch of 5mm x 5mm wooden square washers by cutting up some spare deck planking strips. Then I can put each pin through a washer then into the hull. I can later grab the washer with needle nose pliers and pull the pin out. I suspect most of the washers will split and break off rather than pull the pin out - but then the pin head should be exposed enough to get under it with some shear cutters and pull the pin out that way. Well that's the plan anyway... We'll see how it goes!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.