Trond

Members-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trond

-

The bell is in place. Whentthrough what size and how many deadeys I needed, more than I had. The bough a supplement package to the original kit with fittings, canons +++, but that was missing a lot and not very up to scale. So need to buy all blocks (boght some earlier) and other supplemtns for rigging. Also startet with the figure. So this is take 1 and I'll see how many tries before I get it right. 1st time carving.

-

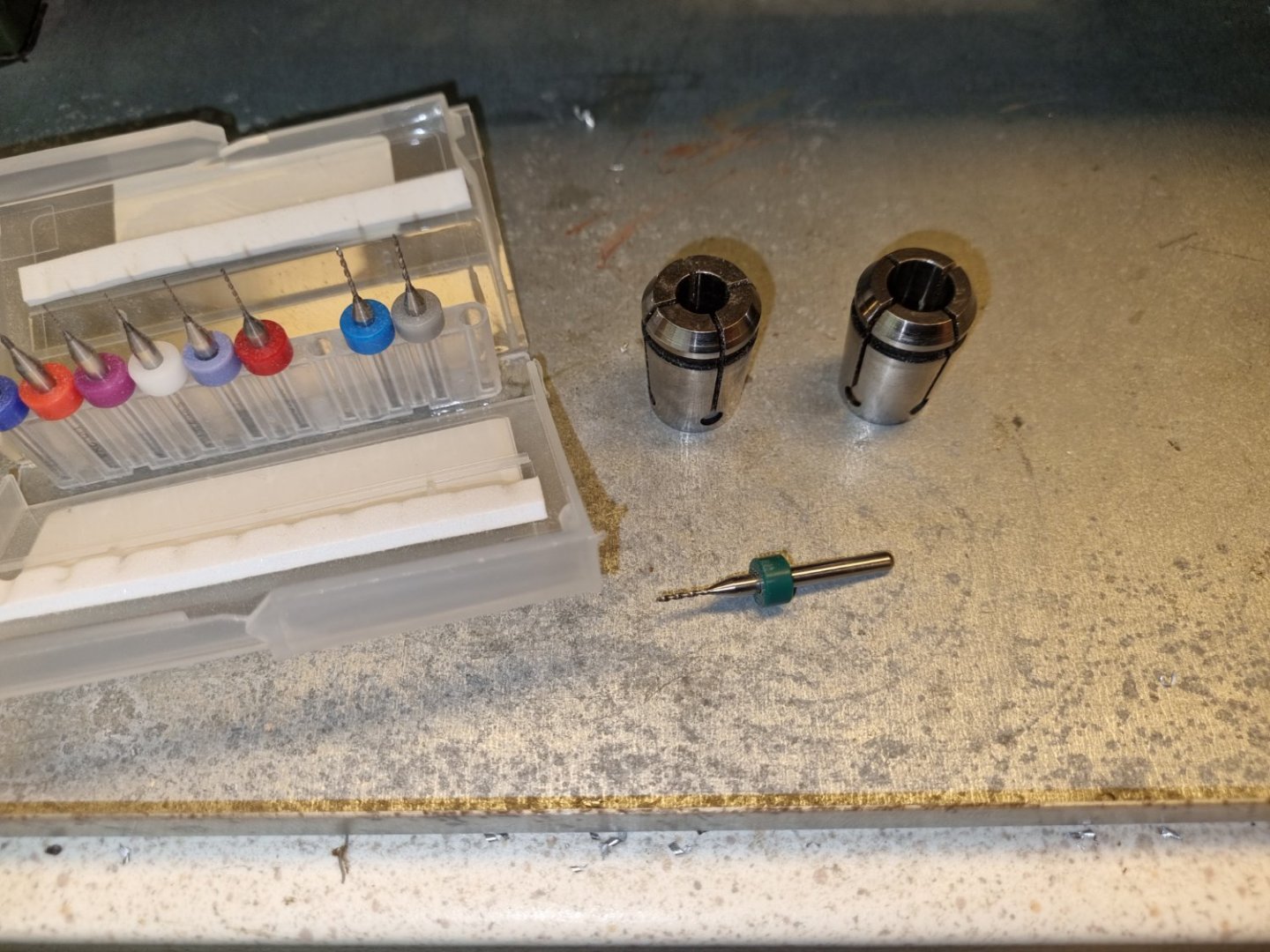

I screwed up with my order and bought something that I really didn't need. Thank to you Lyle I did another going through my thought and what I had and what I needed. I got stop my order right before it left the shop. Know I'm going through what I really need. So, I have a lath with a mill. What I didn't know or though about was by getting a set of collets other than Proxxon, since what they have are to big. By that I mean my very small drills 0.1-1.0mm which have a base stem of 3mm, which is to small for what Proxxon supplies or what I have. I also saw that it is possible to get a gear tooth chuck (10mm) with adapter that I can fit into my mill. So I've asked for price and delivery of small collets and a gear chuck. It saves me a lot of money and is more accurate than what I've used so far.

-

Nice work LyleK1. In the Armed transport Bount book there is detailed rigging and the figure is descibed as a women in riding clothes. I'm following the book as good as I can, but must admit I'm not sure how accuret the book is since from my understanding there is not to much detail from the real ship building.

-

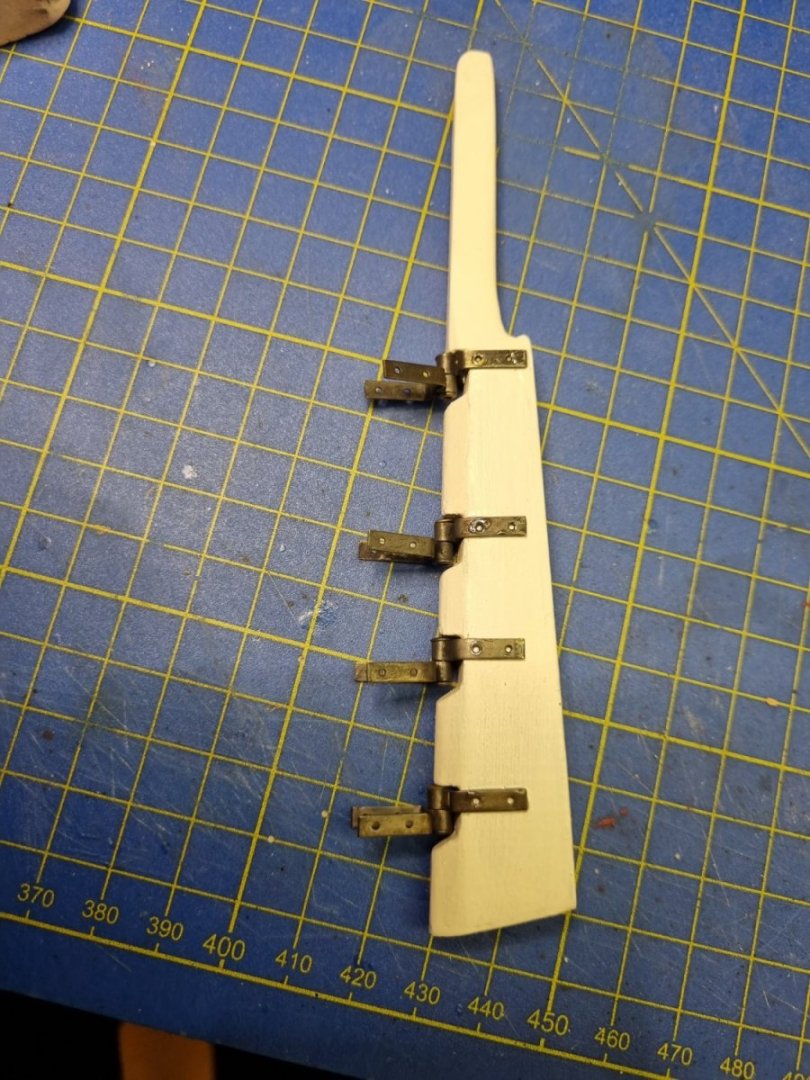

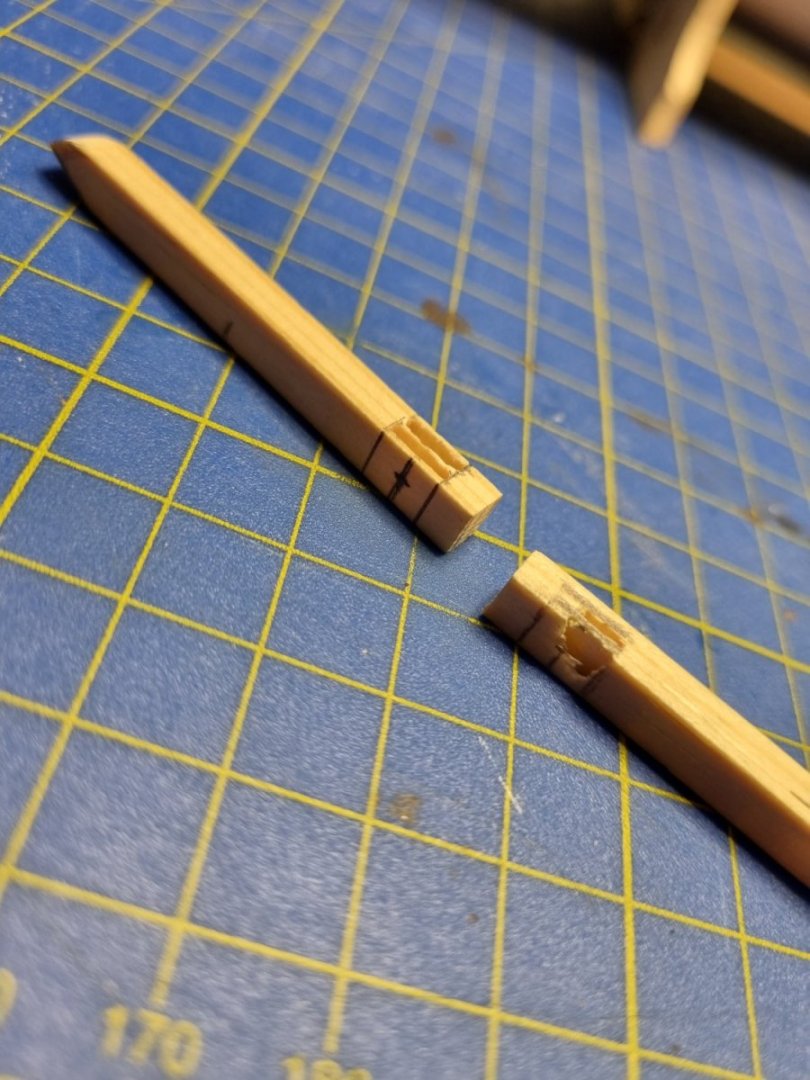

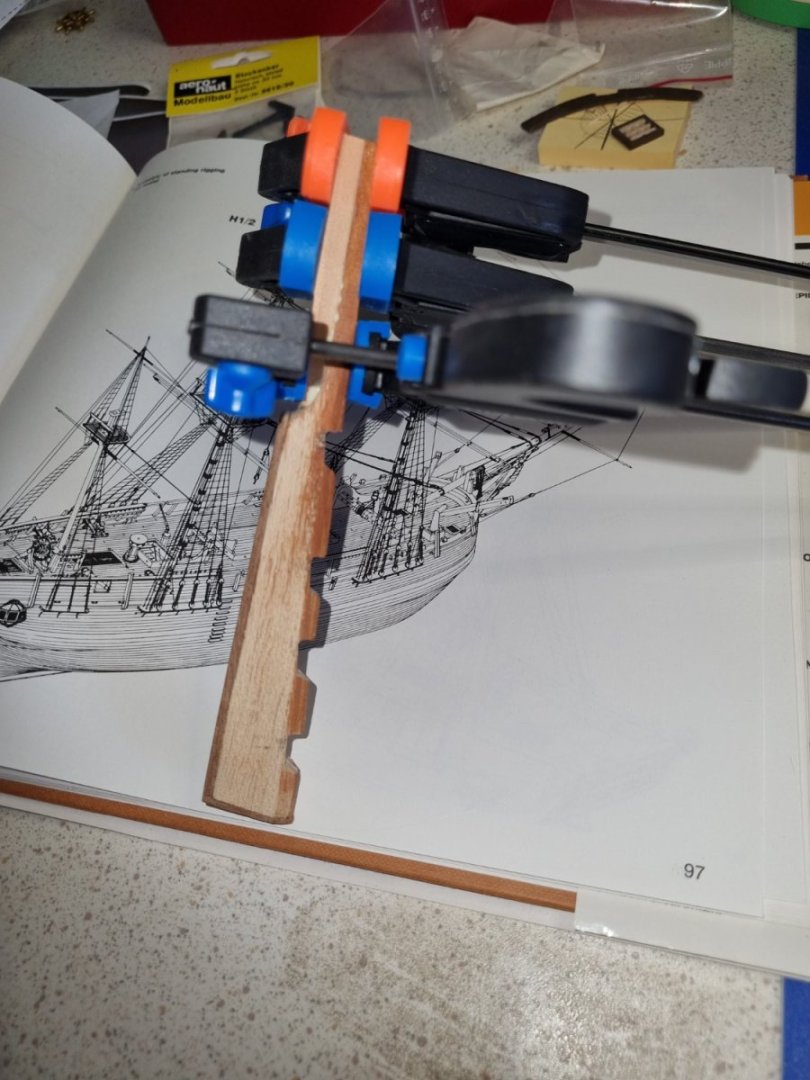

Next is the rudder. I accually could use the on in the kit with some modifications. Added on some wood and made som notches for the hinges. I cheated and bought the hinges. Had to paint it several times to get an ok finish. At the same time I'm working on the Timberhead. The challange has been making the hole at the tip. My drill jig is not stable enough. The with of the holes are 1.2mm. So I need to figure how to make them even and parallel. I definitely should by my self a good columnar drill. Need to look around. Anybody have any referance on good ones?

-

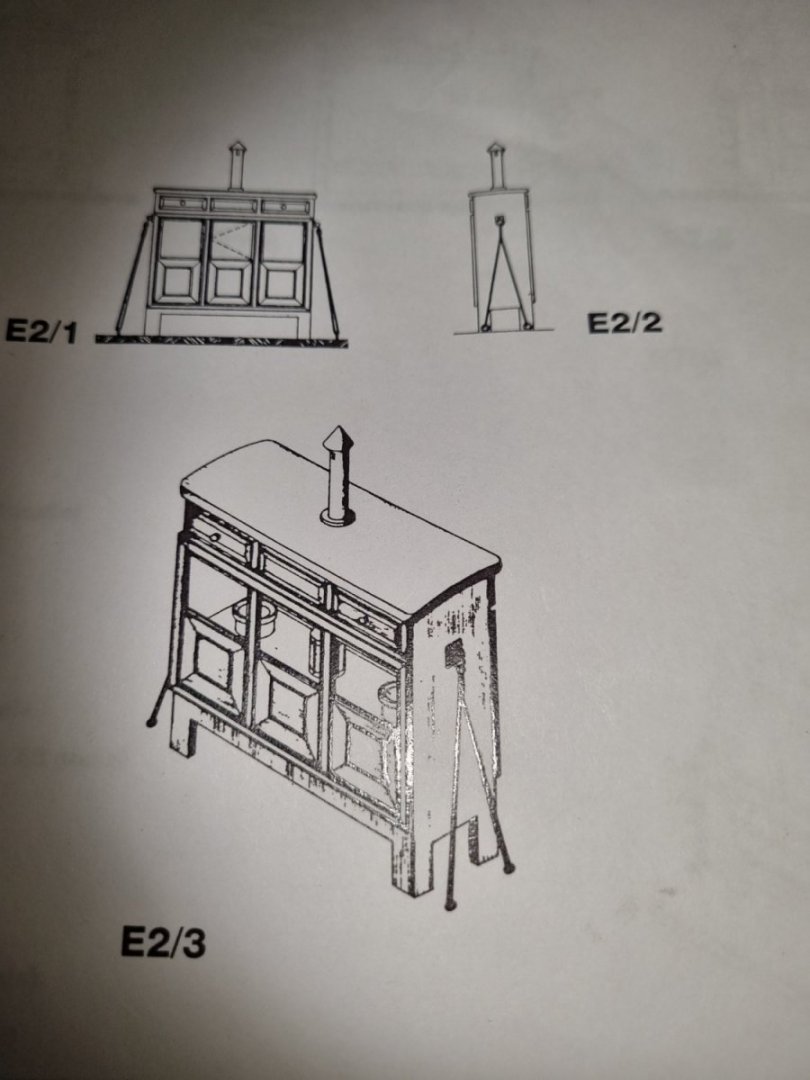

All the top fitting is scratch build and will be. The only thing I can use from the kit now on is 3 types of rope and maybe the mast and spare. So It is sometime frustrating, but at the same time satisfying. I learn alot and it's fun to see the ship beeing built kind out by my self, using HMS Bounty book.

-

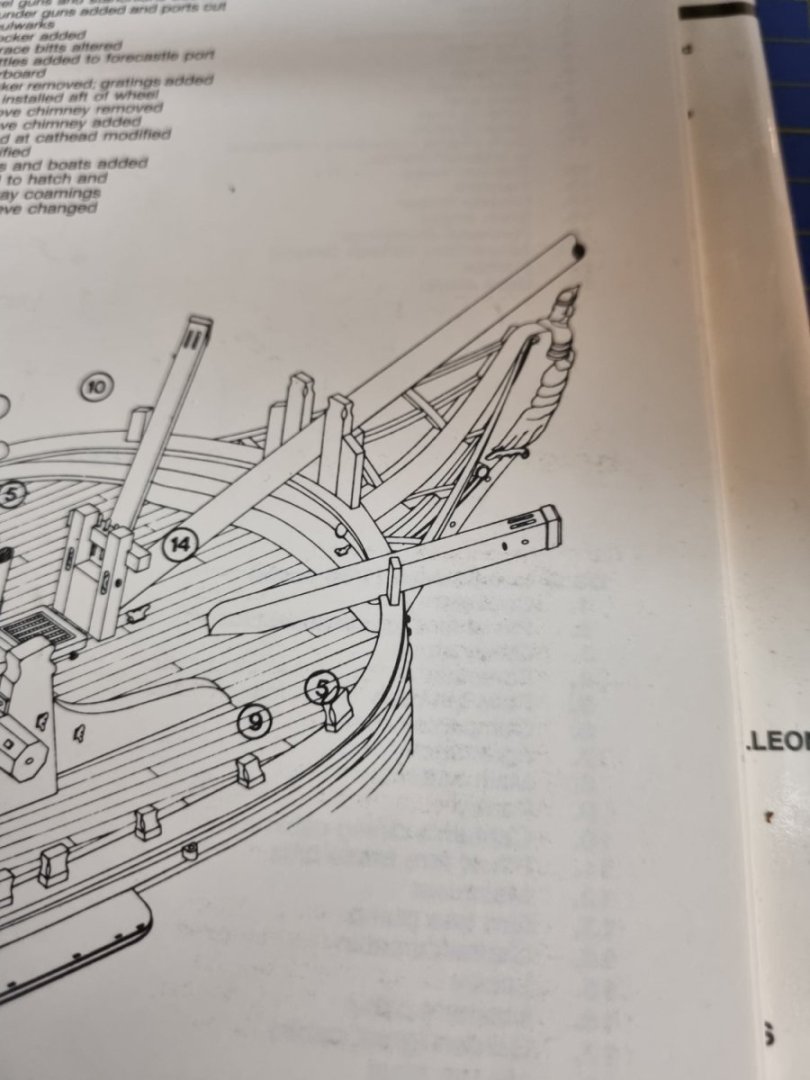

I is showed on several drawing in the The Armed TRansport Bount by John McKay. I see he is an architectural draughtsman and he has several referances. I must admit I'm not deep into the sourcees on ship, yet ( but may come over time) So I trust this guy. My kit is far off the real Bount, so I guess by following John McKyay as far as possible would be good. Can't follow everything since my kit Bounty is not in correct scale.

-

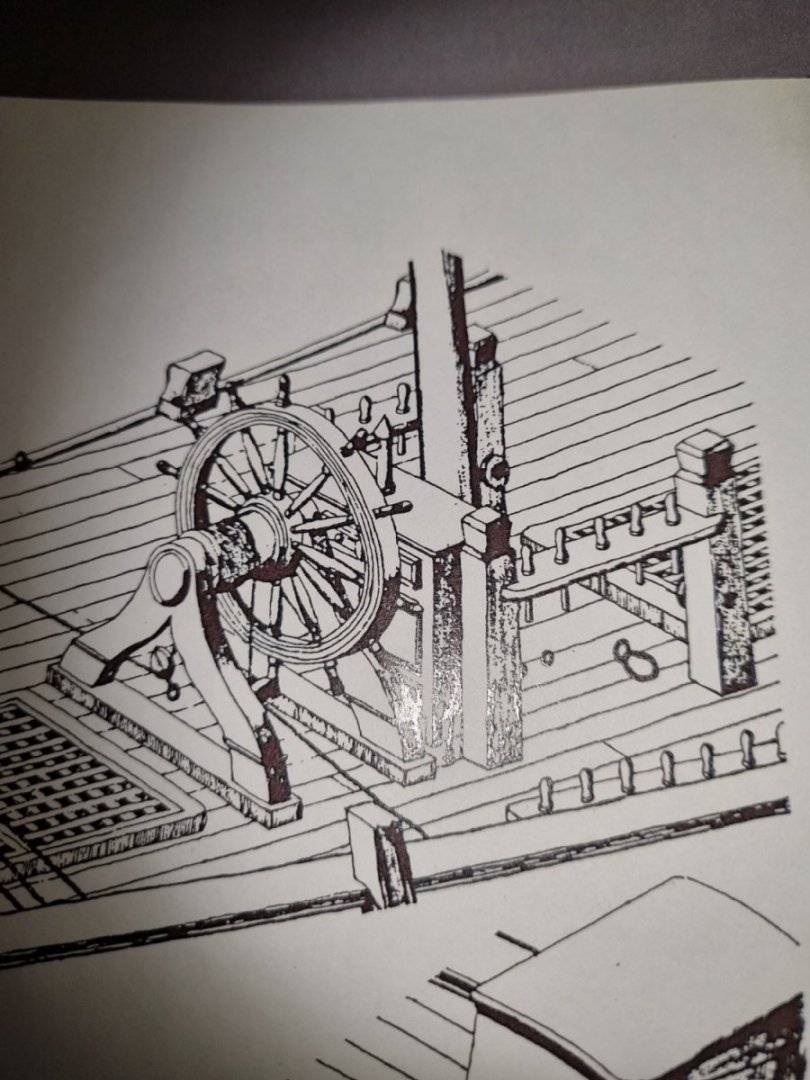

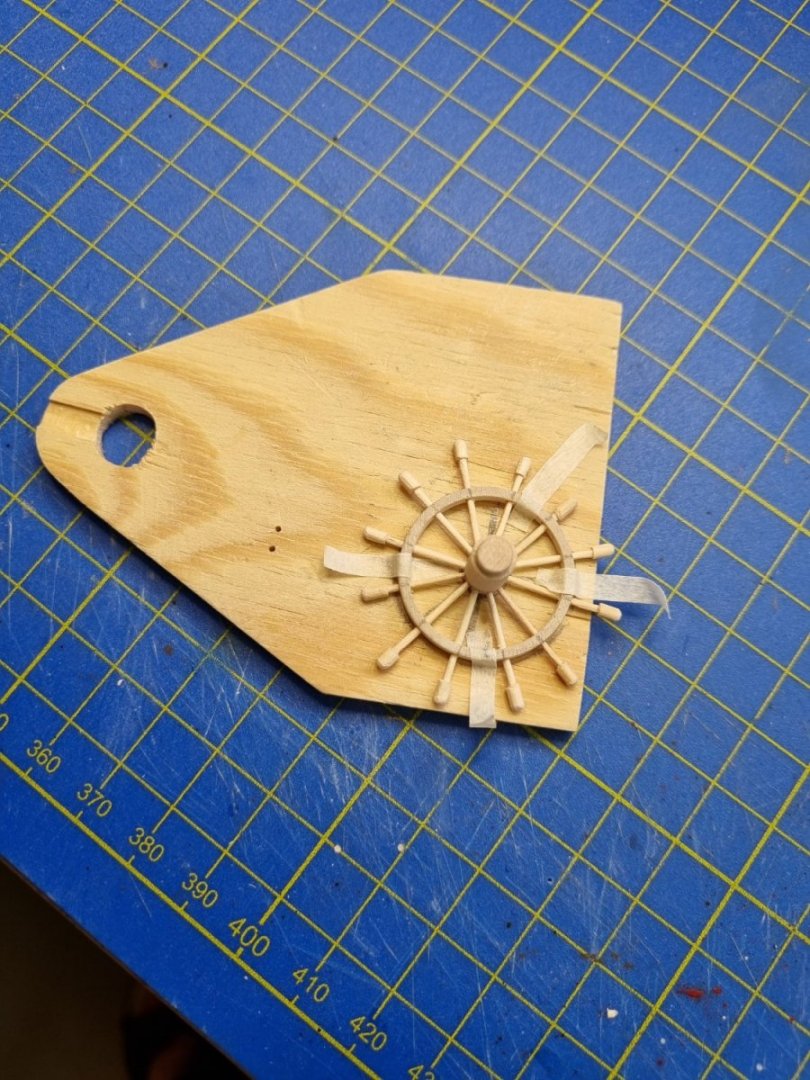

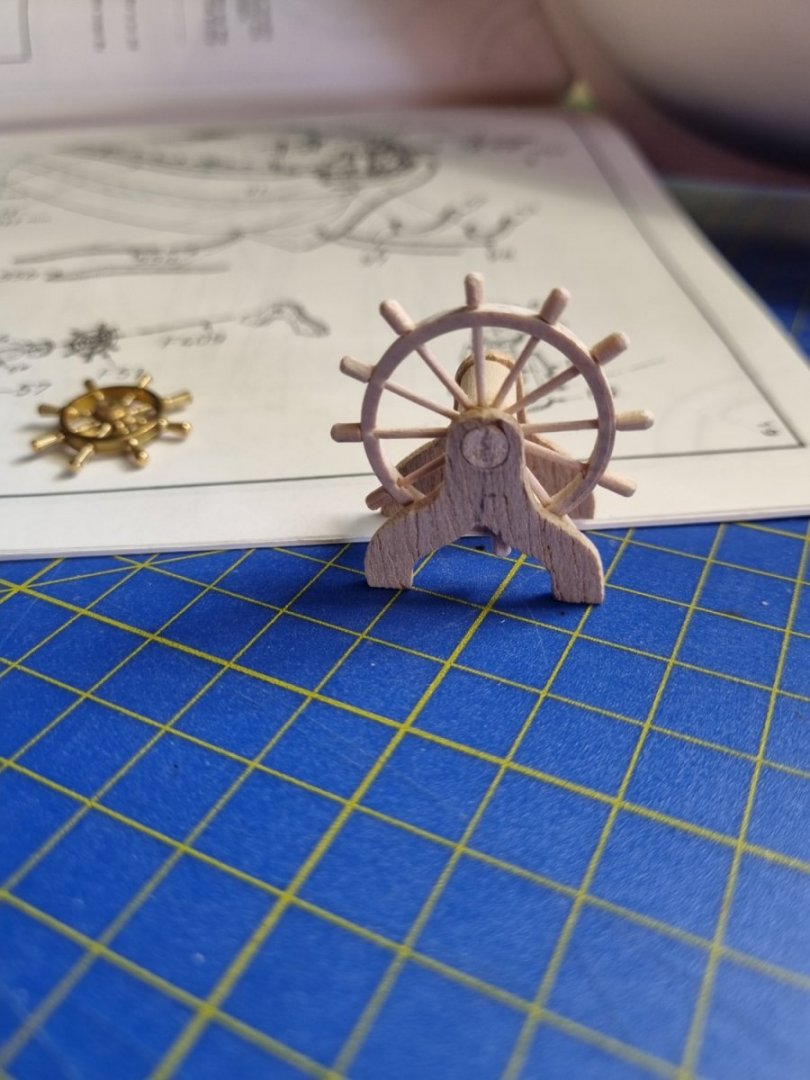

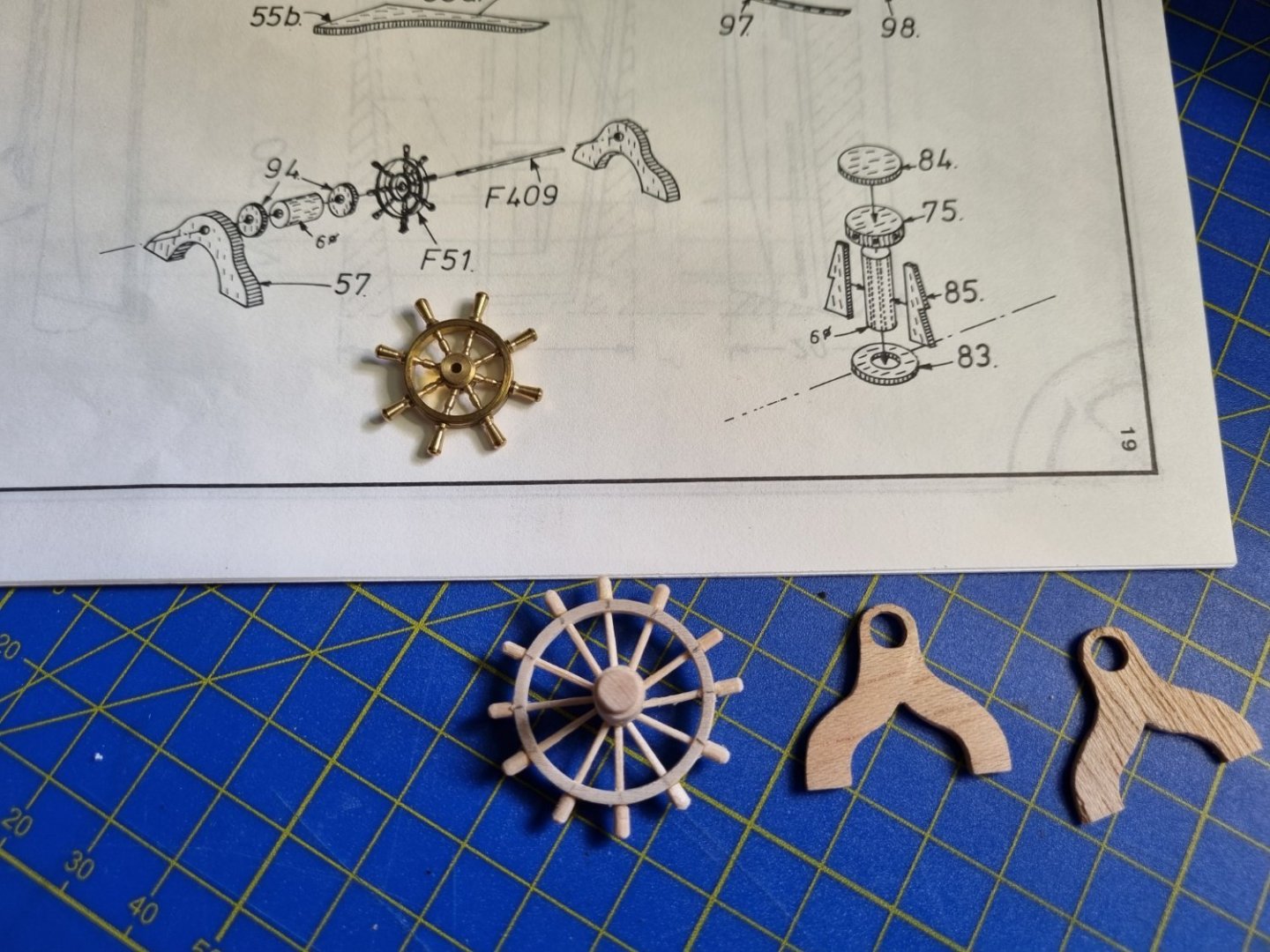

Here is a try-out on placing out steering wheel, shelf and rope securing station (don't know what is called, need to look it up). I do have a challange and that is securing the shelf before placeing the rope securing station , in accordence to book. Does anybody know anything about the securing rope? The only "rope" i have is a whit "rope" that following the kit or black sewing machine thread. I need to get myself a rope machine.

-

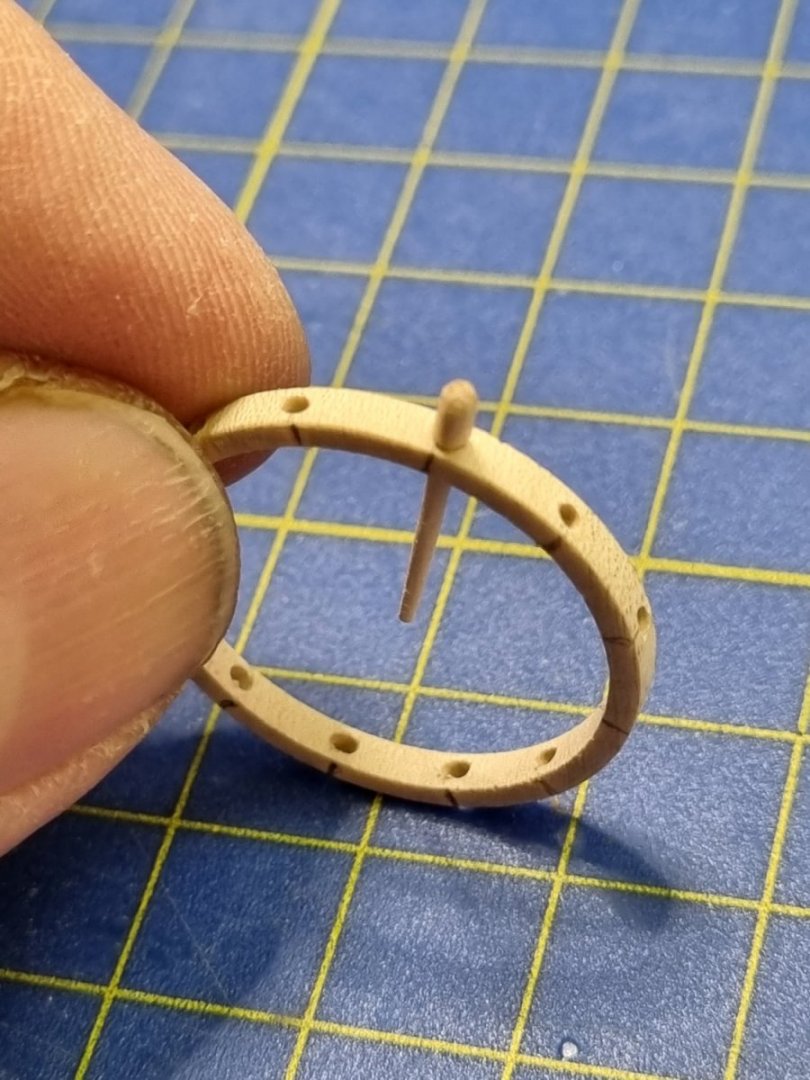

I'm useing Armed Transport Bounty as referanse since the kit drawing is very bad. In the book the drawings show 12 spokes. It was a very challenging job, but satisfied when I completed it. Sometime I feel I'm doing more scratch building than kit building and I couldn't have done it without the book.

-

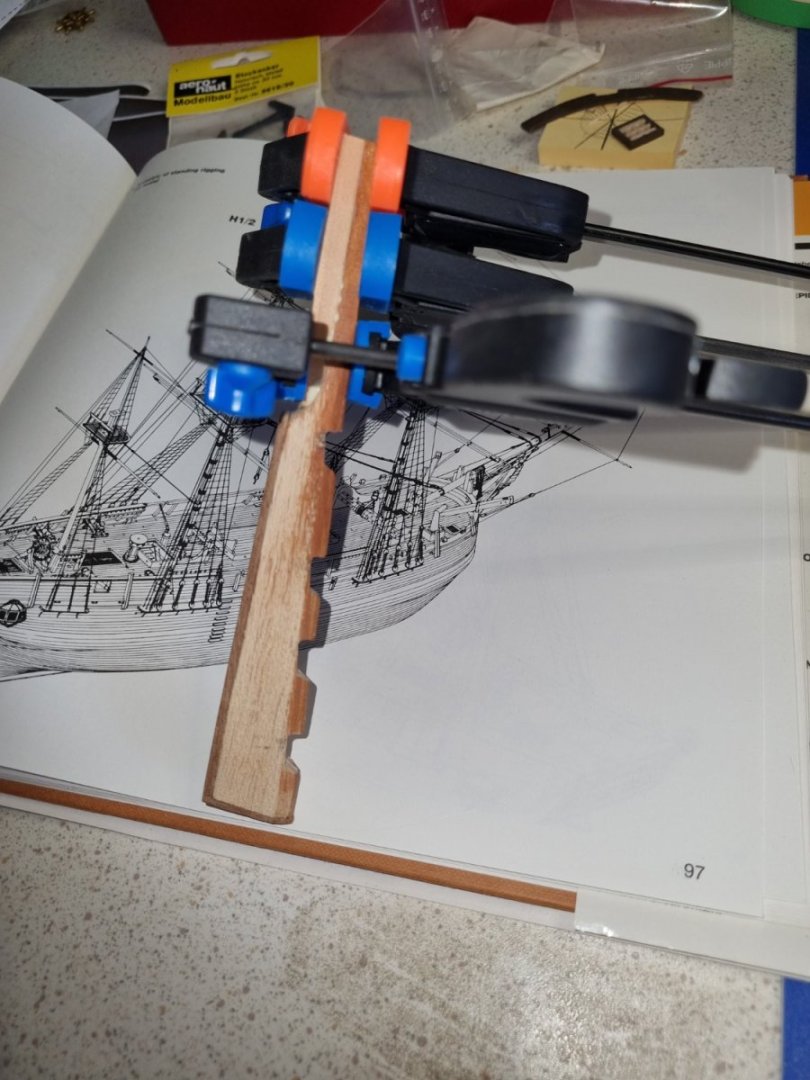

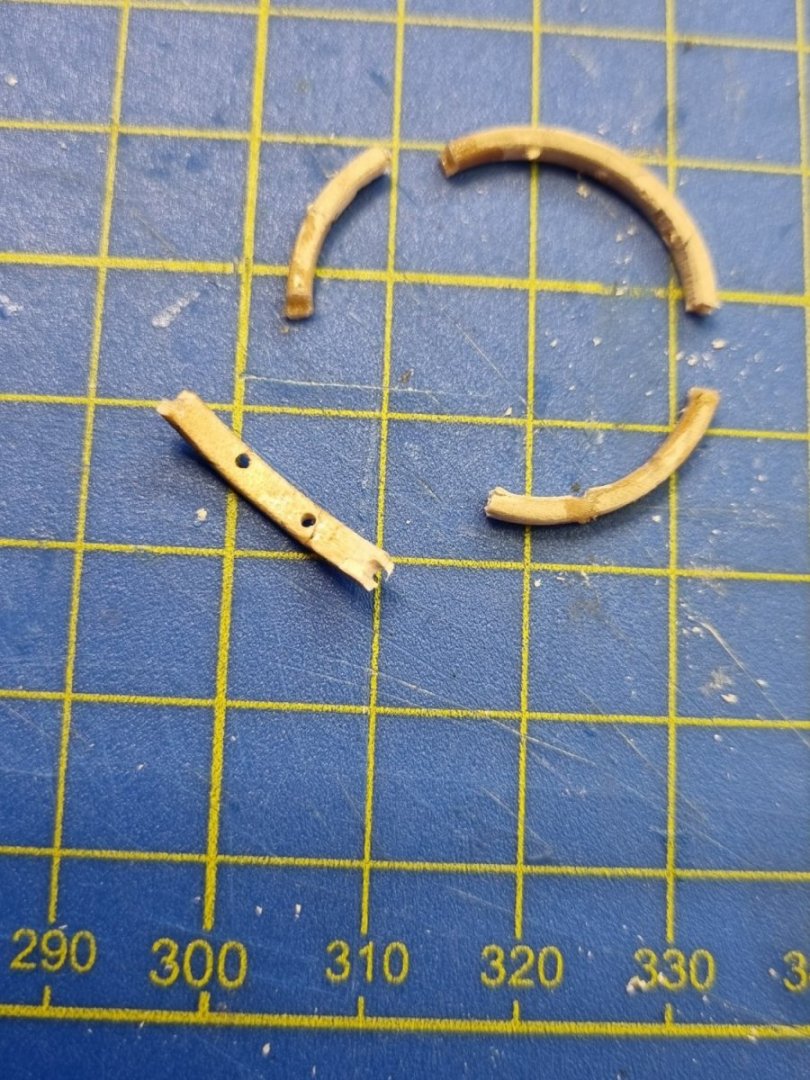

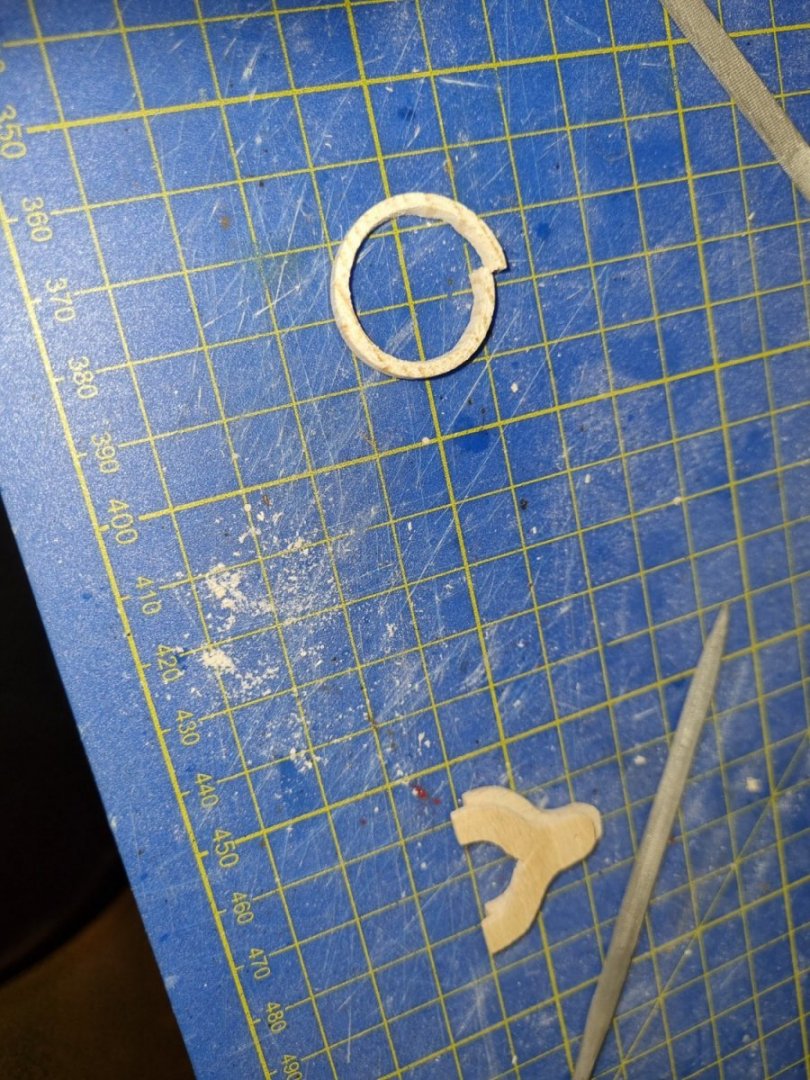

I had a lot of problems making the helm and had to get different woods, something that is hard. Did a lot of trial and error. A lot of frustration when almost everthing is ready then, the last part of making breaks all. Well, after may tries I got it right, and that makes all the failure forgettable. I used wooden toothpick as base for making the helm pins. Made a jig for installing the pins. Picture showing trying out the jiig and see if I drilled the holes correct, inner stem and outer ring, ok. So the final product before paint. And compare to the kit helm....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.