Srenner

Members-

Posts

220 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Srenner

-

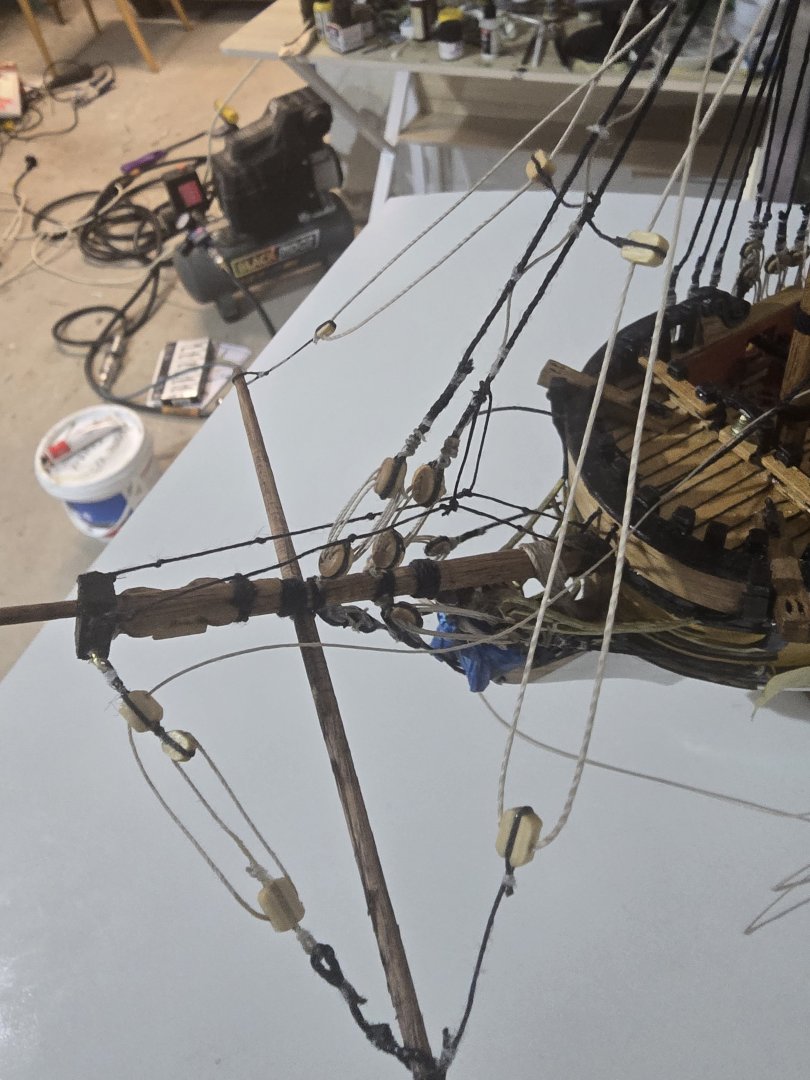

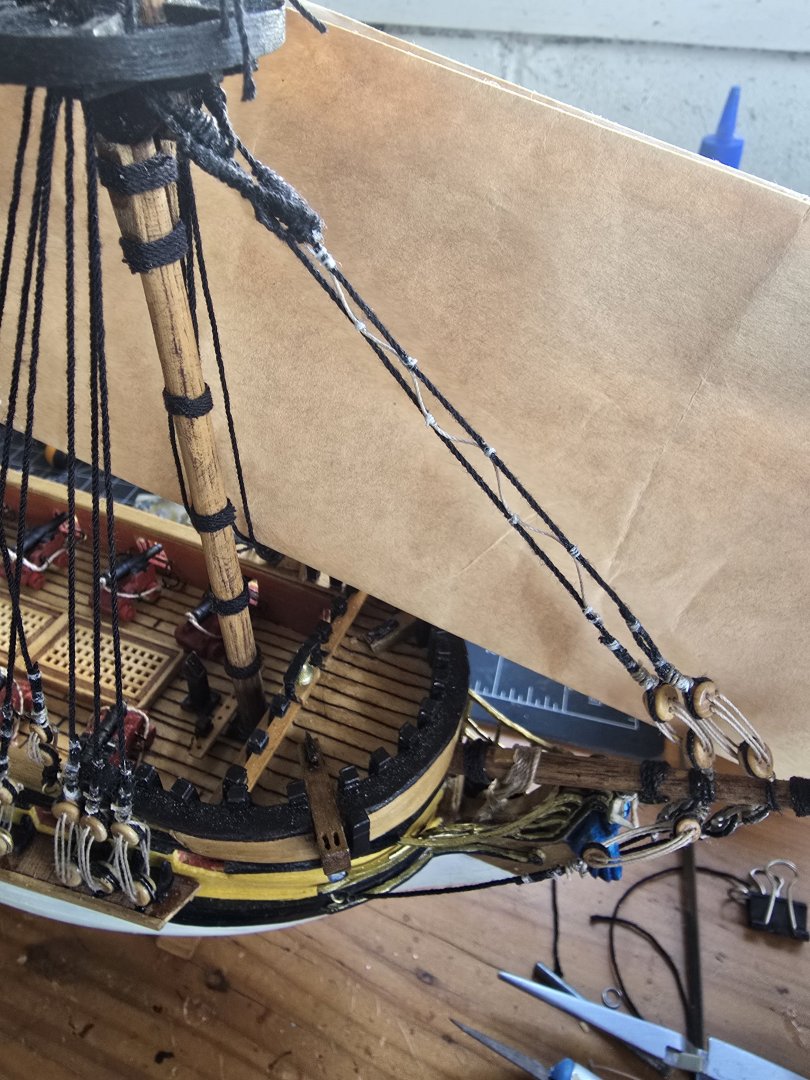

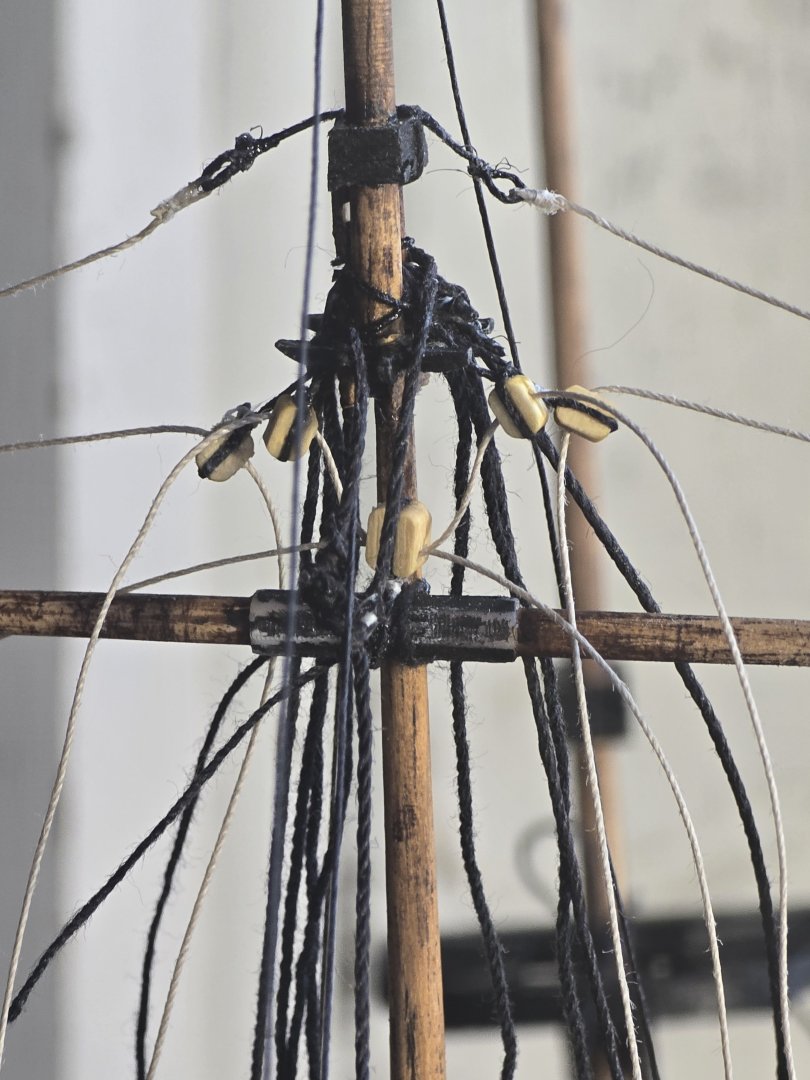

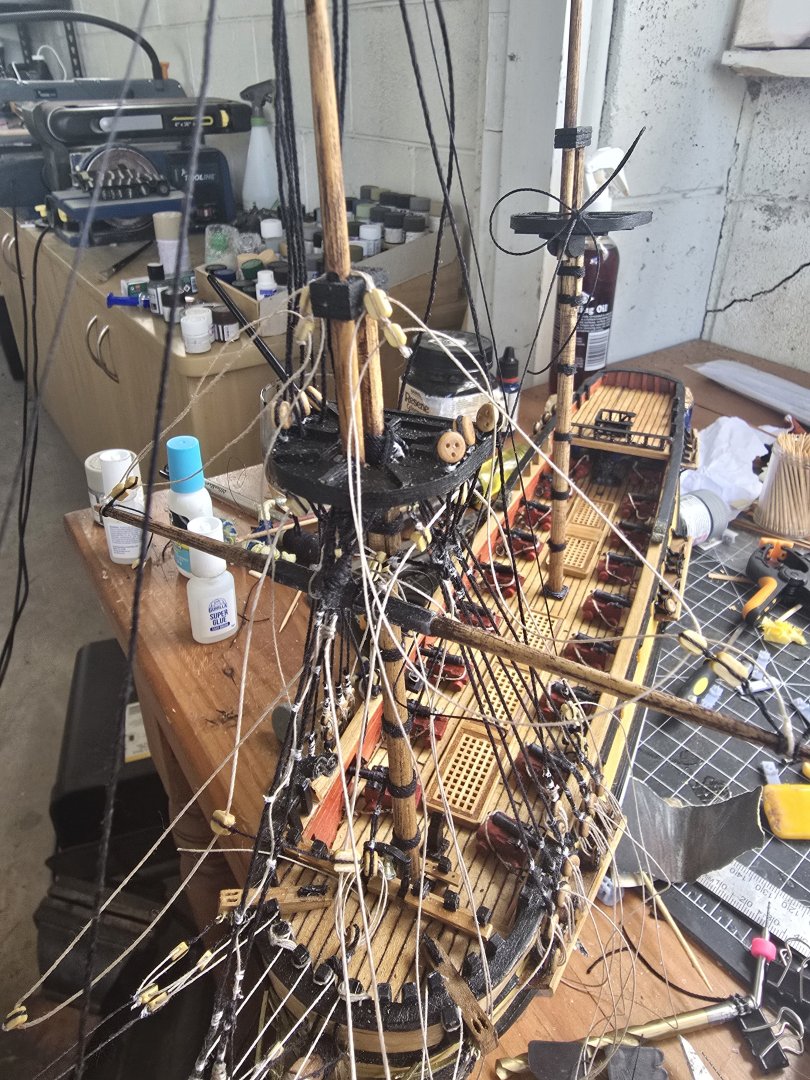

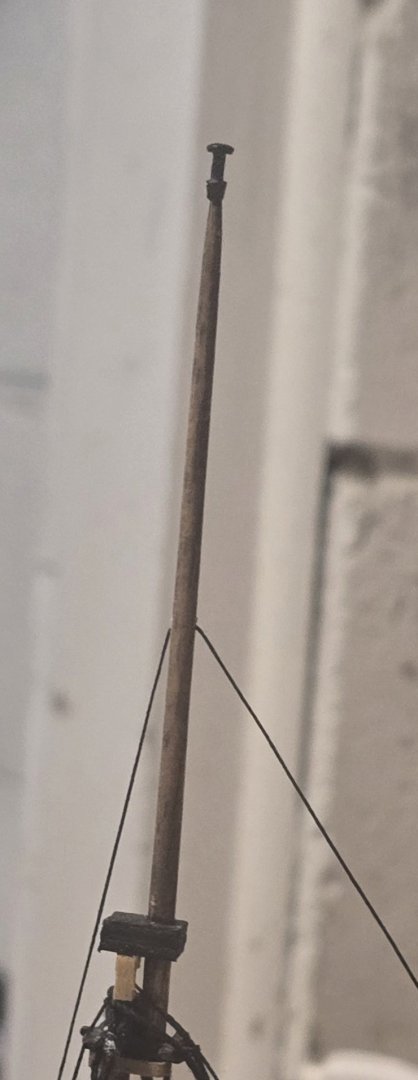

I hve rigged up the fore topsail tie and the fore topsail lift. Its getting lot of rope up there and a bit messt but i have all the inportant ropes in there. Cant imagine doing a sailing rig on 1/100 scale boat... too many ropes. I scaled the heaxagonal section and 3d printed that and stuck it on. Im going to put the final set of lifts on the top gallant after i have completed the topsail shrouds. Im hitting the wall a bit knowing that i have to repeat all of this again with the main and mizzen mast. It looks good but wow what alot of work to do it!!

-

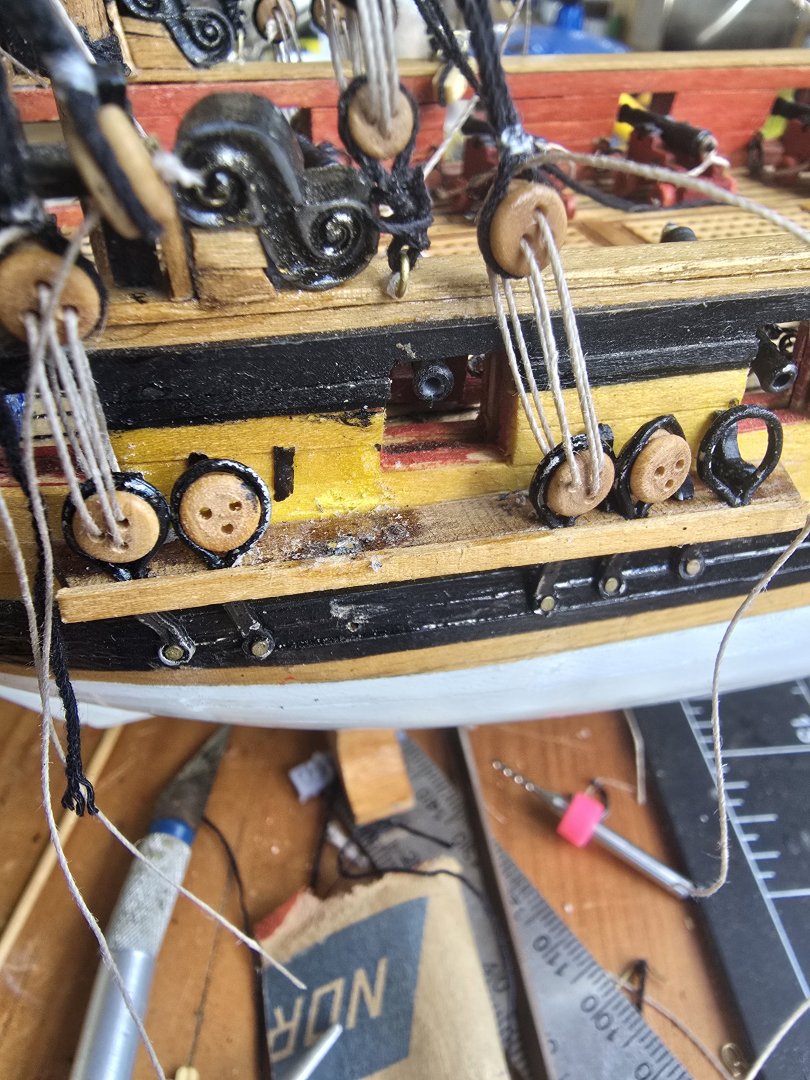

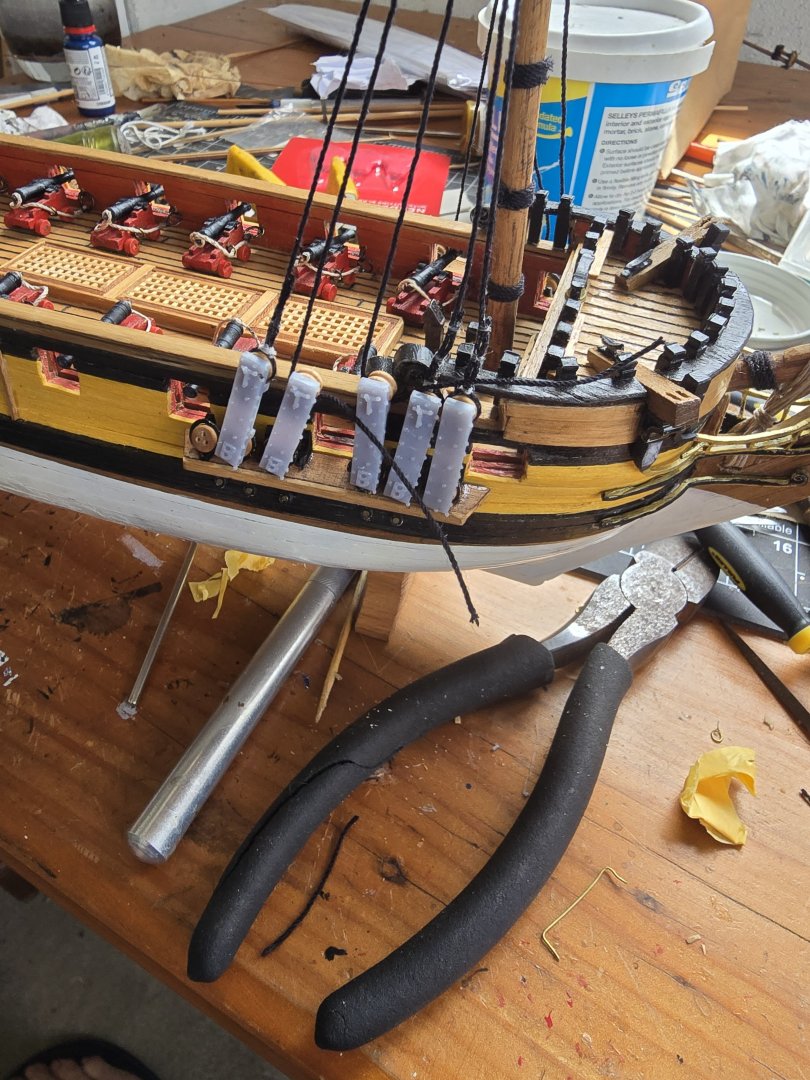

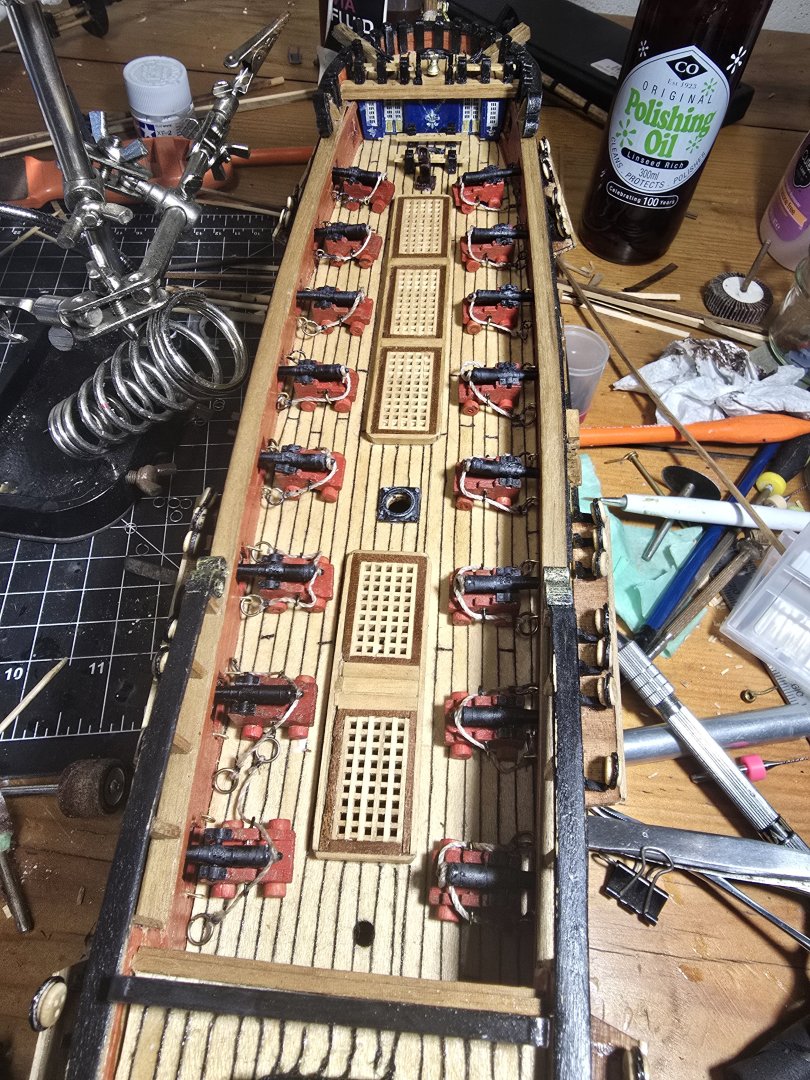

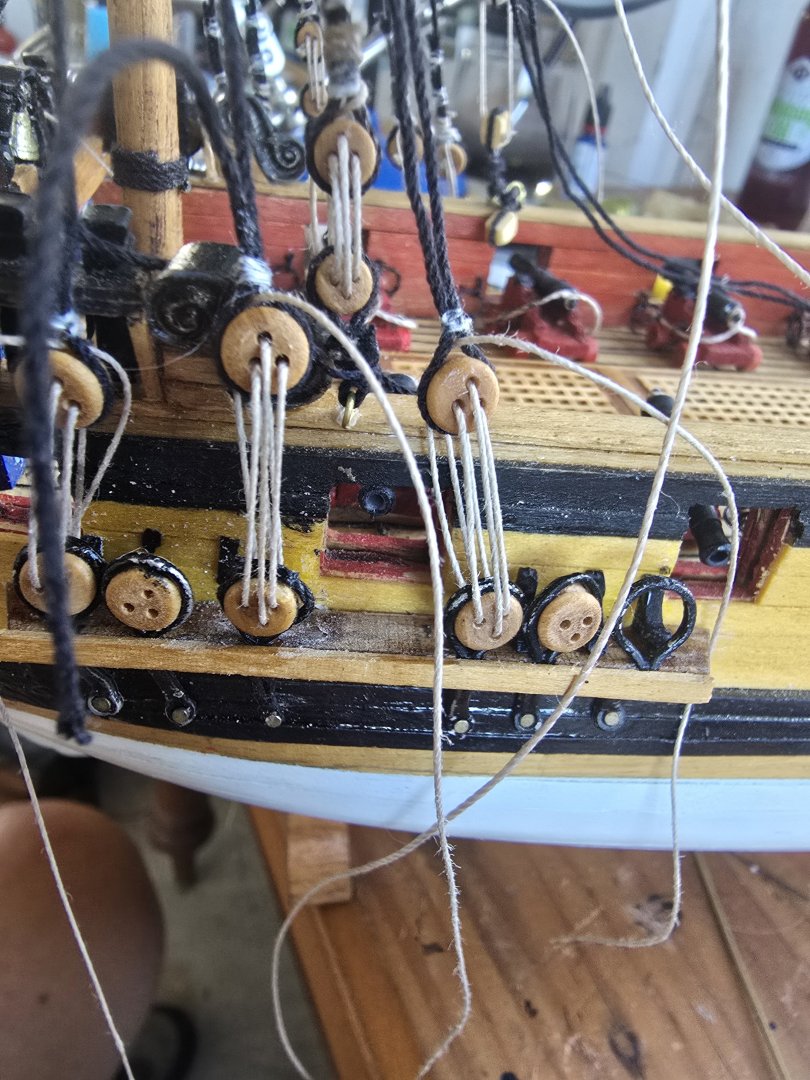

I might be doing this all wrong but ive tidied up alot of the line down at the fore bitts.. my belaying plan is not following any sort of accuracy, im playing with what the kit gave me in terms of instructions. The only thing i am doing is rigging the fore lift near to the edge of the ship on long blocks as per lees book but in the paterrson book it goes to a block on the fore channel. Once again if i had more space i could do that. I put the block on the rail instead. I will be putting coils of rope over each belaying pin so probably wont see them I didnt tie the truss pendent correctly but just glued the lines on approximately and also rigged the nave line and belayed it on the fore bitt.

-

I managed to rig up the jeer blocks okay... very fiddly but hey this is rigging. They a little lopsided but im not going tk change it... its close enough for me today. Now i have the fore yard no i am going to start belay pinning down at the base of the mast... again quite a lot of tricky stuff to wind around the belaying pins down there.. might have to cheat and just spot glue it and then put a coil of rope over the rope.

-

3D printing material question

Srenner replied to CPDDET's topic in CAD and 3D Modelling/Drafting Plans with Software

I have found the phrozen 8k resin to be the highest detail and pretty strong due to the number of "nano particles" in it. But it is brittle and dont think it would like machining post print. -

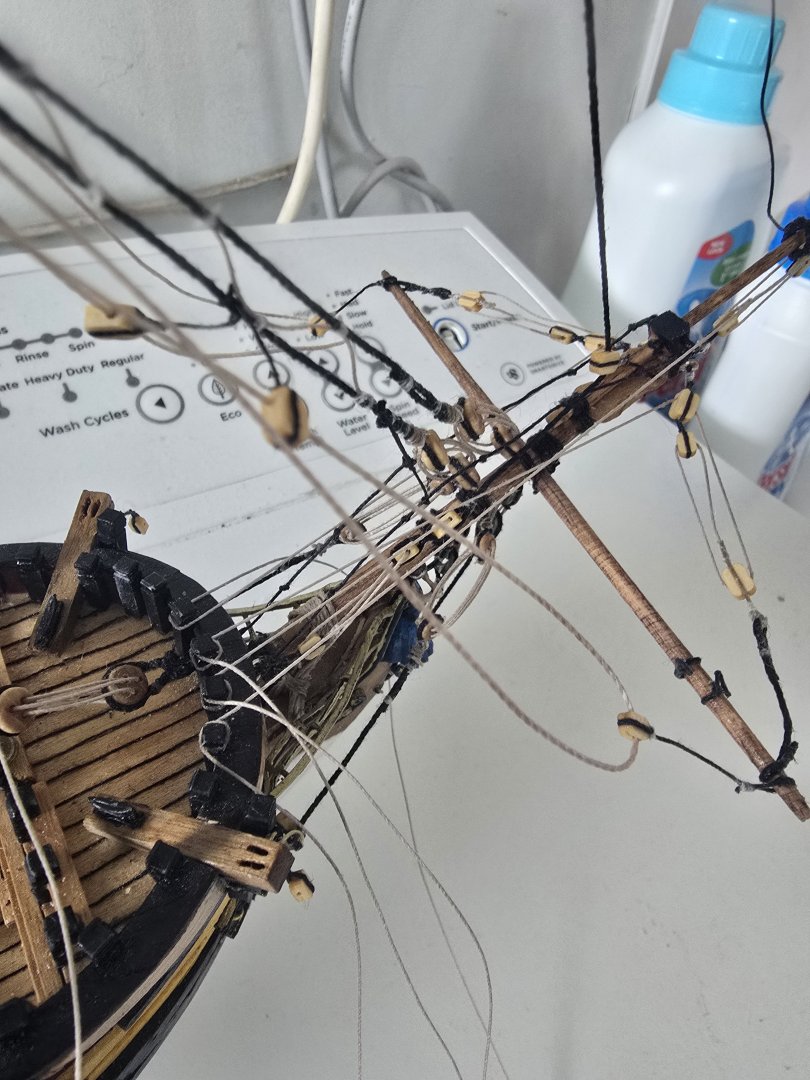

I may be doing this all wrong but its getting pretty congested around the fore top area so i rigged the jeer blocks onto the spar before i rigged it up and then poked the stirrups up under the for stay and then im going to stap them to the mast afterwards. The parrel is so small and delicate i basically just stuck it on for the look. It isnt going any job with holding up the spar. And i had a bit of a mistake with the lift blocks but i have followed the 1719 pattern according to lees book

-

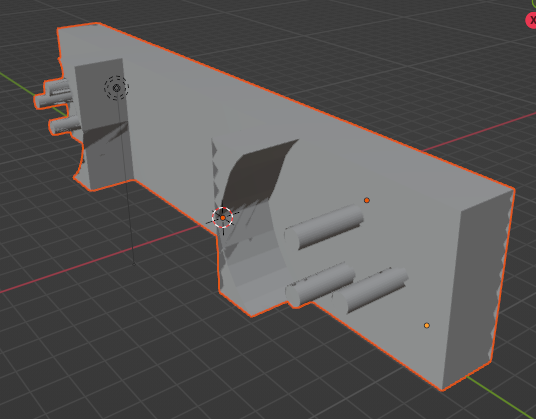

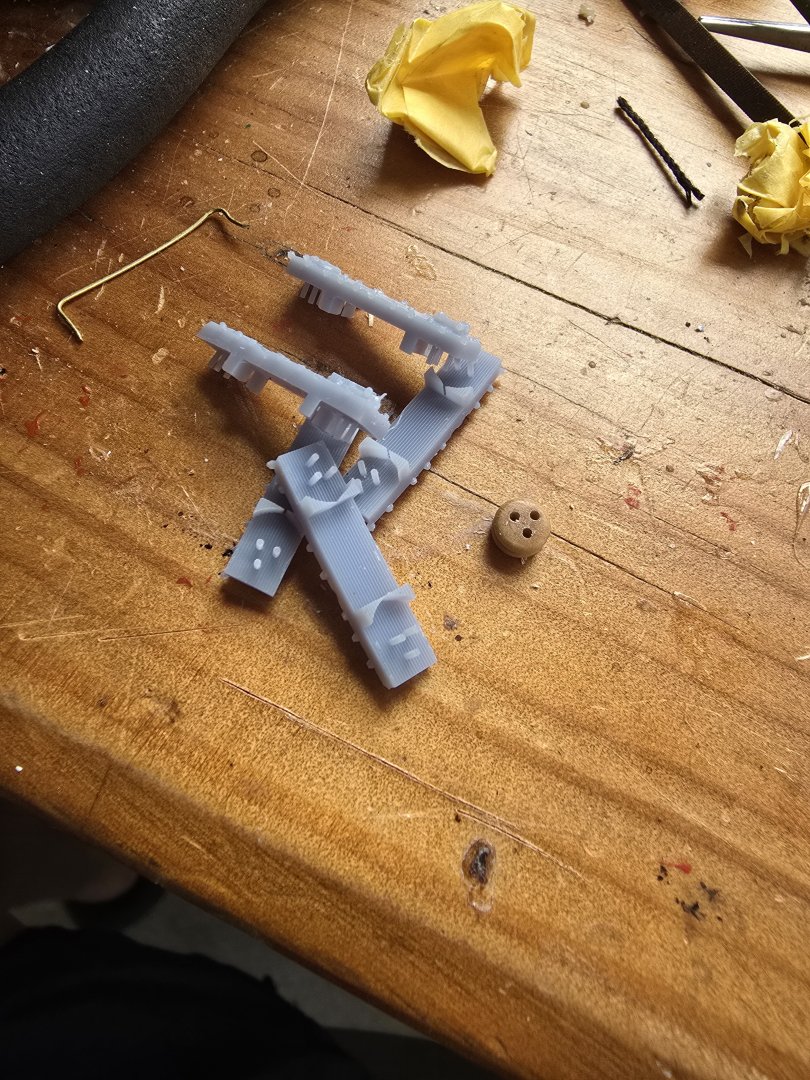

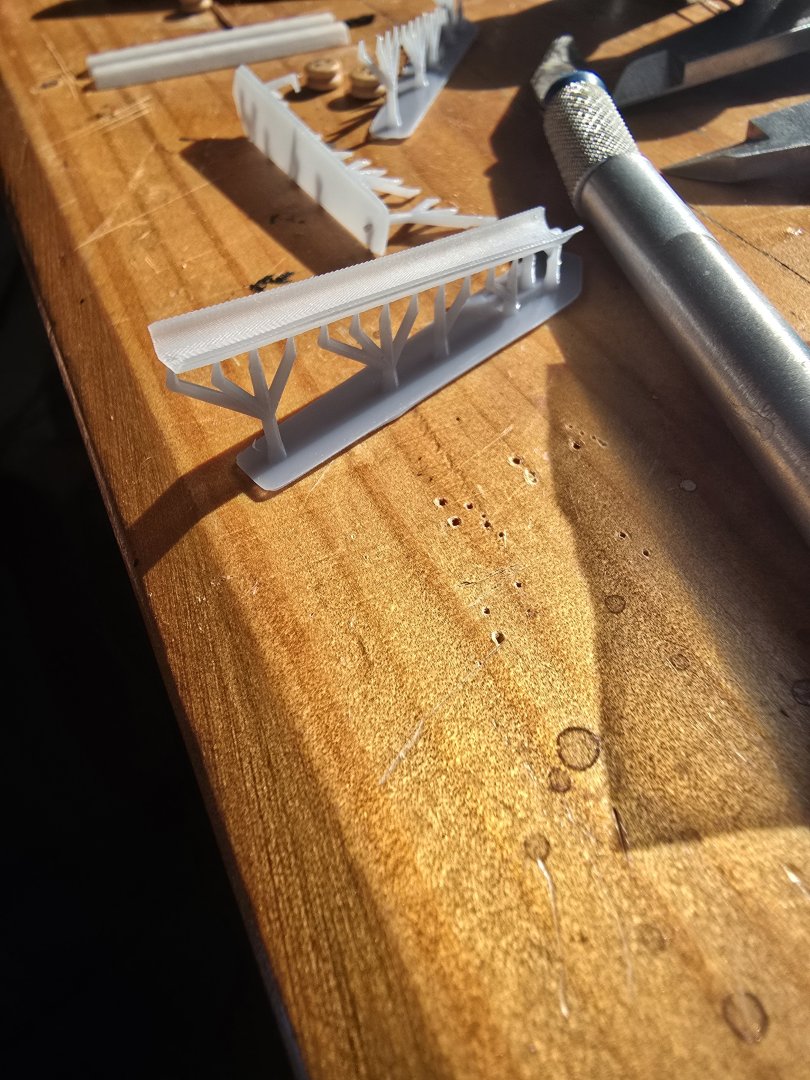

Working at 1/100 scale there was no way i was going to make realistic parrals for 1720 rigging with wood so i once again turned to the 3d printer. Ive gone it.. they very delicate to take the supports out of and i broke 5 just to make one so print off heaps of clones. But i have realised it doesnt end in a parral, the trucks dont have a end parral! So back to the printer again. I must say i love that it takes about 10 minutes per print these days with the rapid resin. 1720 it was indeterminate if the yards were left on place or lowered so thats why the parrals are needed.

-

Hi Keith- im up to rigging the truss pendants... where is toni's tutorial found? On this website?

- 341 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

What i do love about model making with ships is that there is many ways of making something with different materials, different manufacturing techniques both additive and subtractive and there isnt a right answer. In making a yard i could have turned the wood and shave a hexagonal central region. I could have left it round. Ive experiemented with making two hexagonal parts on the 3d printer which sheath the 4mm dowel to create a hexagonal centre piece. The hard part of this is paint to colour match or maybe i paint it black.. if its black it tends to hide the detail so im trying for a wood match this time... if it looks dumb i will paint it black and white or grey dry brush to bring out the hex shape.

-

Did i tell you the white metal chain plates that come with the kit are rubbish? If i had my time again which i wont i would either 3d print them from strong plastic or make my own with rope as it 1719 and iron wasnt used for chain plates yet. I broken my second one rigging up the foremast. My fix for this as i nailed the chain plates down, is to bend some 1mm brass wire around the deadeye and then super glue it onto the broken stump of the plate and wind black fishing fly fishing silk around the base with more super glue. Dont use the kit ones unless your very careful!!

-

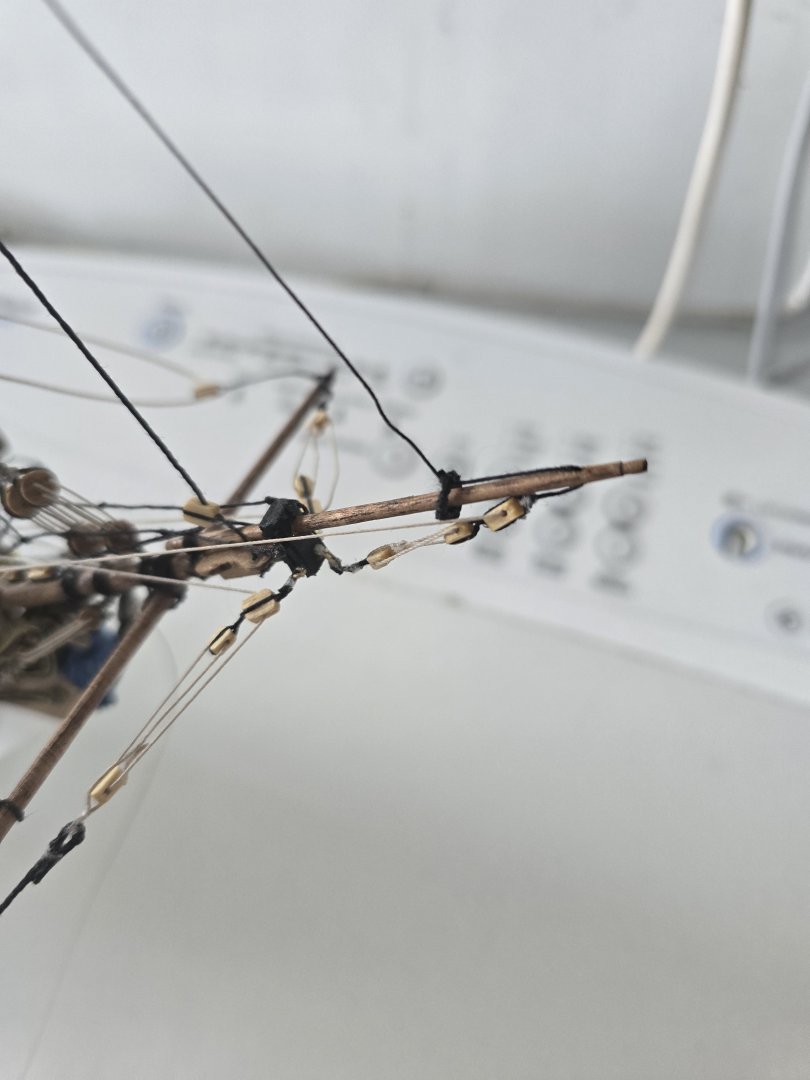

I love rigging ships! But it is fiddly work. Been working on the spirit sail yard area and taking direction from lee's book for 1720 following as much as i can. Decision point coming up.. unclear if grethound had a outer topmast preventer stay and if that had a block and tackle the same as the inner stay after passing the bees. Quite proud of the horses.

-

Its been an epic couple of sessions on the rigging and im loving it but the arms get tired holding them up and trying to get very fine motor skills out of them. Fore stay and preventer stay has gone in and i did try and worm and snake them... first effort but im reasonably happy with the result. Its a bit of a worry as it was tricky and a lot of work had gone into the stays anyway. I know there should be hearts instead of deadeyes on the fore stays but the kit came with bugger all hearts so deadeyes it is.

-

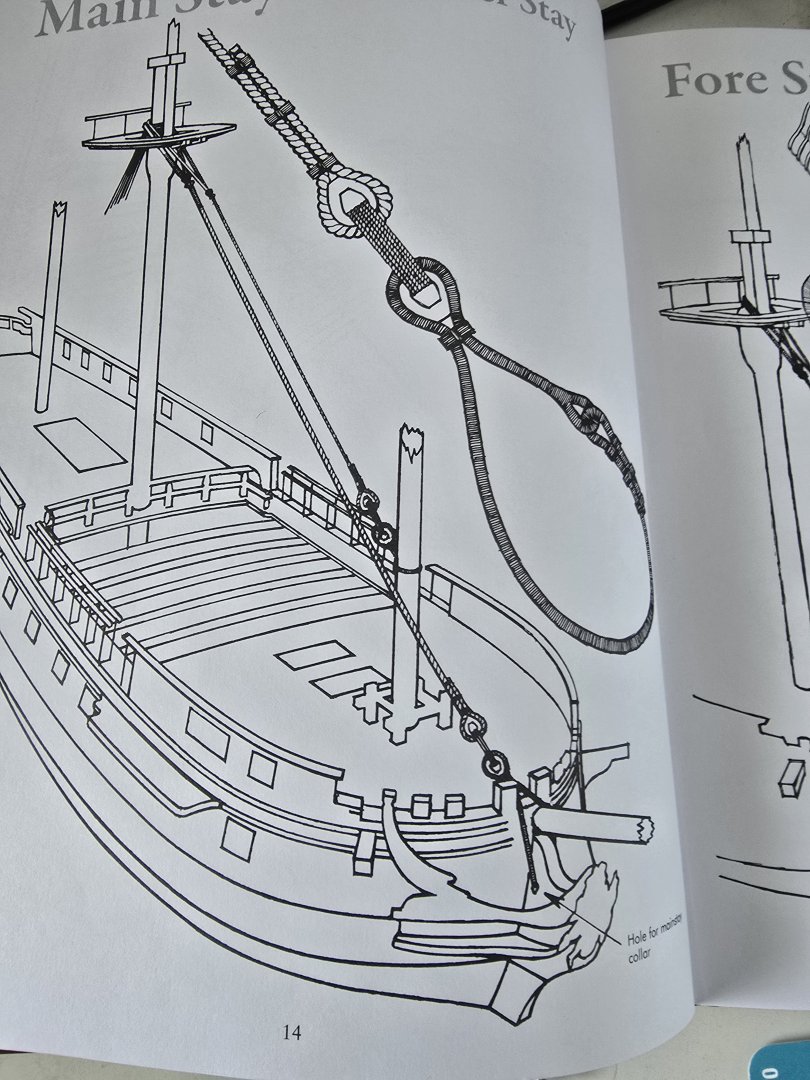

Starting to rig the foremast shrouds and decided to print some deadeye templates with the correct spacing to help. it only took 3 proto types but I think I am getting there. I have started on the starboard shrounds first, then go onto the fore stay and the main stay next. Question, which side should the main stay pass the foremast by convention? on this picture its the right hand side - is that correct?

-

Ratline thread recommendations 1/75 scale

Srenner replied to John AA's topic in Masting, rigging and sails

There is also fly tying threads 2/0 is roughly 0.12mm have to use the dernier to estimate the diameter and it comes in colour's and waxed options -

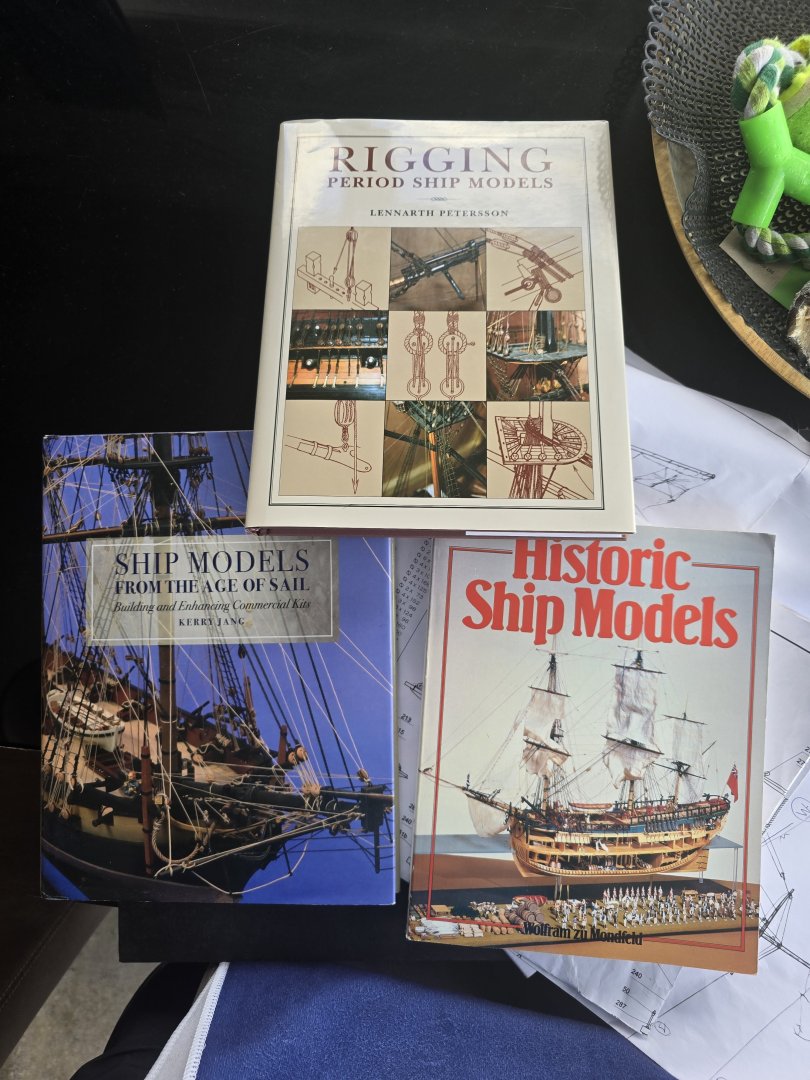

I bought some beginner books from Amazon about square rigging and ship modelling from the recommended list on this very site. So while they coming i did refer to the frank martini book ship modelling simplified and started to rig up the fore stays in pairs and taping them down first. But have also realized using the rigging for English boats book that this model does not have enough shroud deadeyes in the channels to be accurate. In the Lee's book it says seven deadeyes in the fore mast shrouds which makes sense being six plus one preventer shroud. So decision time do I rip the channels off and try and bodge a new channels or go with the kit? Also suspecting the kit provided blocks, deadeyes and rope all not to scale so makes it difficult to progress with more accuracy. I'm comfortable progressing knowing that the kit will be a good beginners guide and not get hung up on the technical accuracy. There are many skills still to gain so everything a learning.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.png.1ce1ae8d97779147fb6a981f862a5709.png)