Srenner

Members-

Posts

220 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Srenner

-

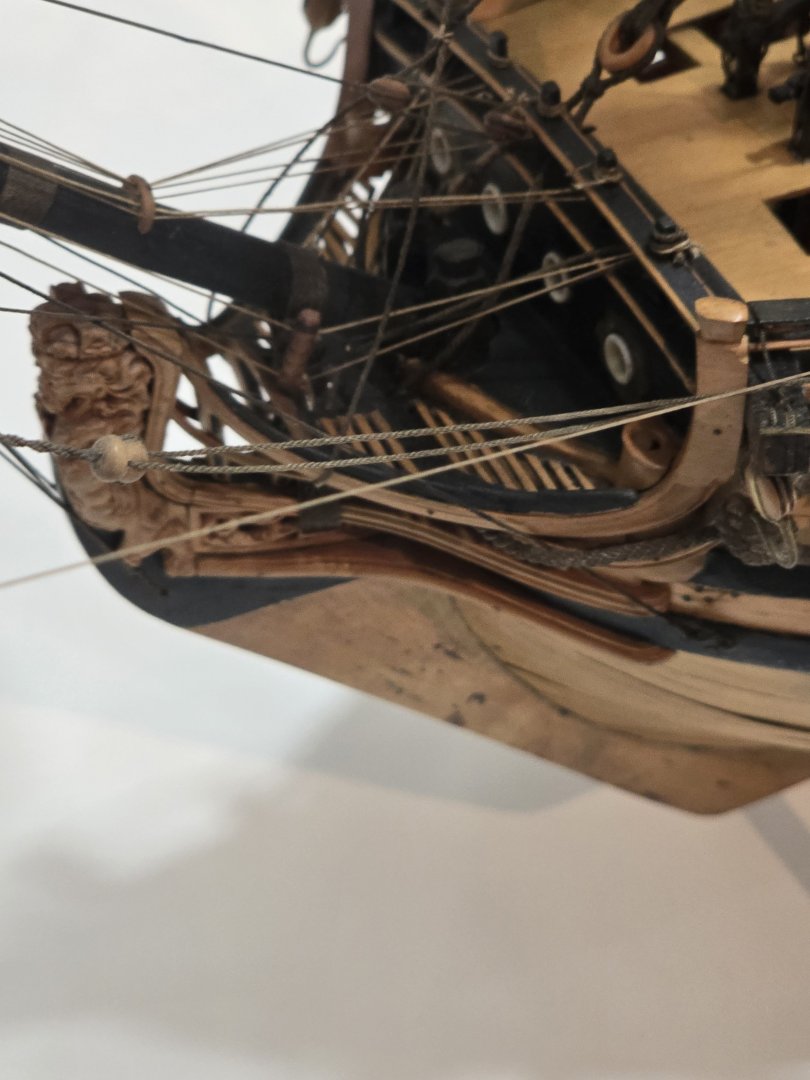

After hours and hours of mucking around in blender in a 3d curve environment, I'm alot happier with the head rails etc under the bowspit. They are copied quite closely to sister ship hms blandford. And very different from the original kit rails. Look it isn't perfect but to wrangle the curves in blender and print them out was cool and given me so much learning for bigger models in the future. I am pretty confident this will be the blueprint for this area in future. And I can scupt some nice decoration nexr time to fit in there. And Mrs greyhound has something to stand on and hopefully not fall off into the water!

-

I've finished the 3d printed rails so it was time to paint the good print of Mrs greyhound... a little apprehensive as painting figures is not my fortay and it's bloody small but the vallejo game colour kit seems to give the skirt some good highlights... and for a 4k printer the level of detail is good. So for a figurine you have never seen before posed by merehuman and printed on a anycubic 4k here she is....

-

Ship Ribbing with CAD?

Srenner replied to Sanjith_D's topic in CAD and 3D Modelling/Drafting Plans with Software

Throwing my two cents in here... to allow for the inevitable accuracy issues when lofting from 2d to 3d, laser burn and xy inaccuracy with the plotting table dont you add extra onto the bulkheads to allow sanding down to a smooth hull as per normal fairing during construction? The question is how much more which is pretty much trial and error until you happy with the results? Perhaps 1mm extra all round the "true" surface? Agree a simple design like a dory in bigger scales will allow for more inaccuracy in first attempts and be more forgiving. -

After seeing the bow of such vessels as HMS Victory I didn't like the 3d printed one I had on Greyhound so I pulled it off. Also to do the gammoning rope around the bowspit. Anyway I'm going to have another go at 3d printing some decorative rails that meet up better with the figure head. Rather than guess about the complicated curves in this area I tried to mock up with some wire the run of the rails, take some photos and then use a nurbs curve in blender to create a print file. Plus, minus the rails will go along roughly with these lines. But of course will print them and if I don't like them then print them again.

-

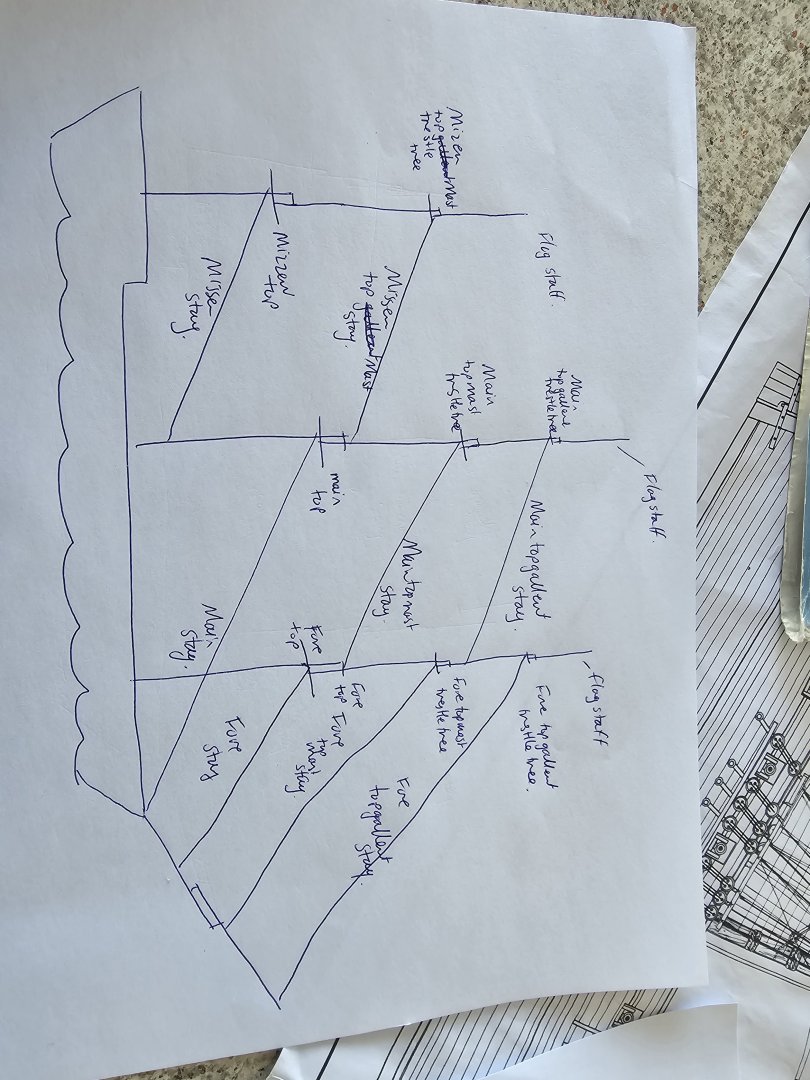

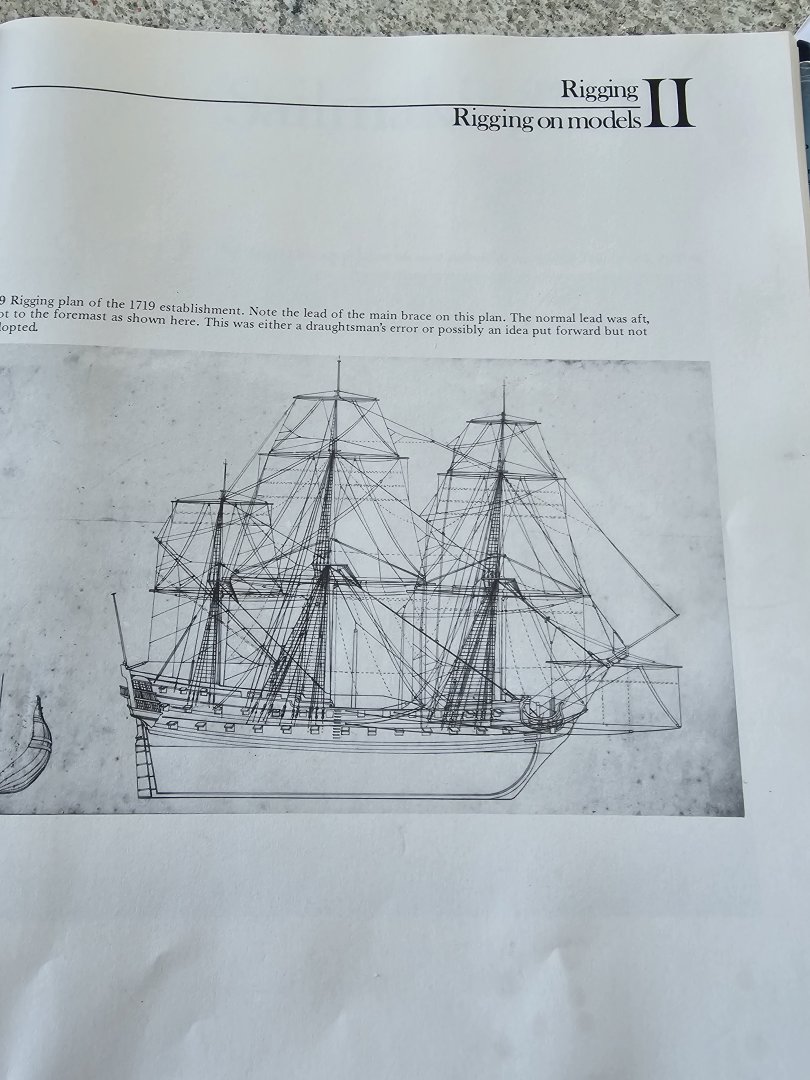

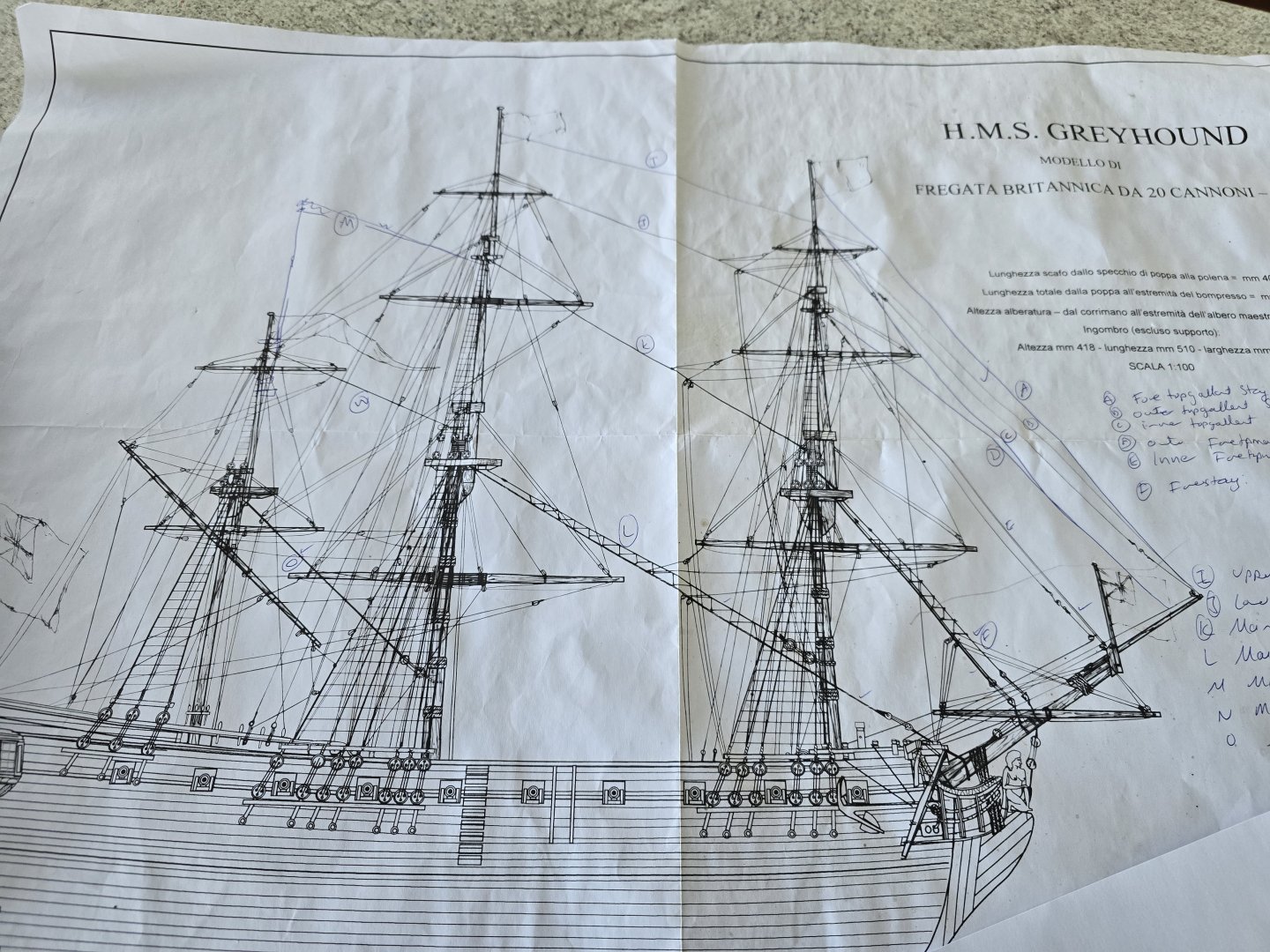

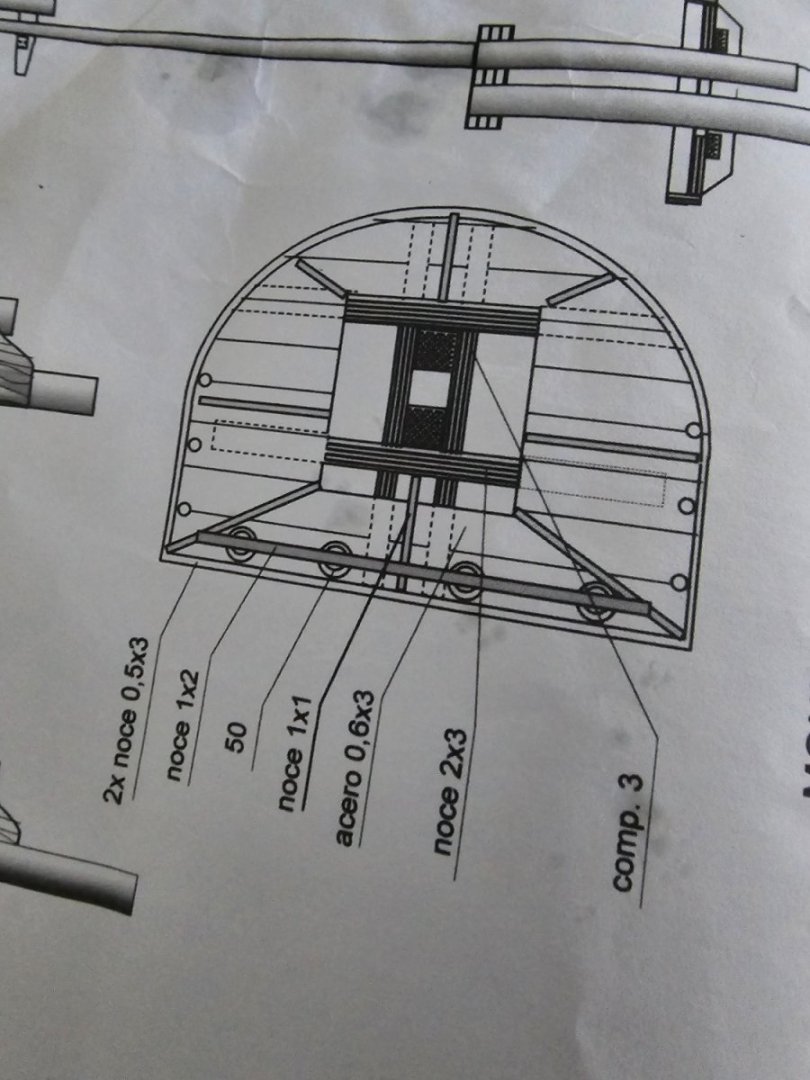

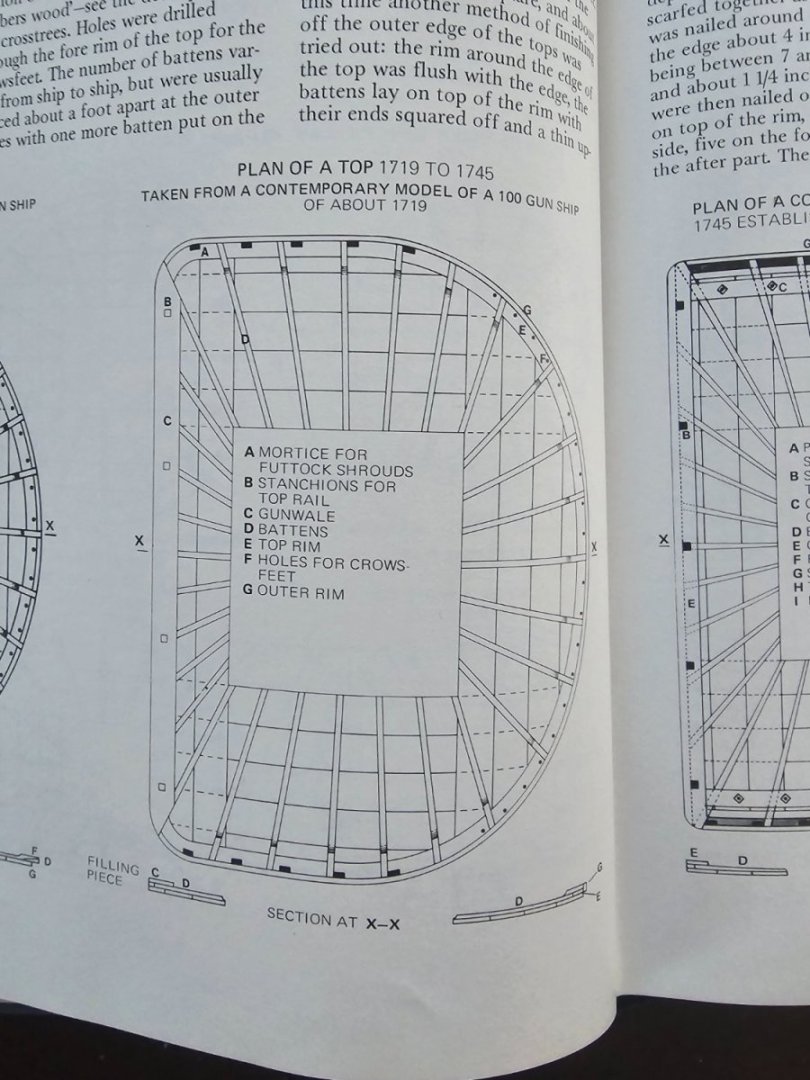

Can people help me to understand the rigging plan for a 1719 establishment? I think I have it right now but if you can check my simplified diagram and the names. The plans that come with the ship are completely wrong and I want to start my ship of sail modelling career out correctly so that I can copy it for new builds later. Essentially I will be going off the lees book but help from here on the website and not the plans in the kit The annoying thing is I will have to scratch build some trestle trees for the flag staff at top of each mast and guessing the height of each mast is probably wrong in kit. But not too worried as long as I get the stays correct on this first build

-

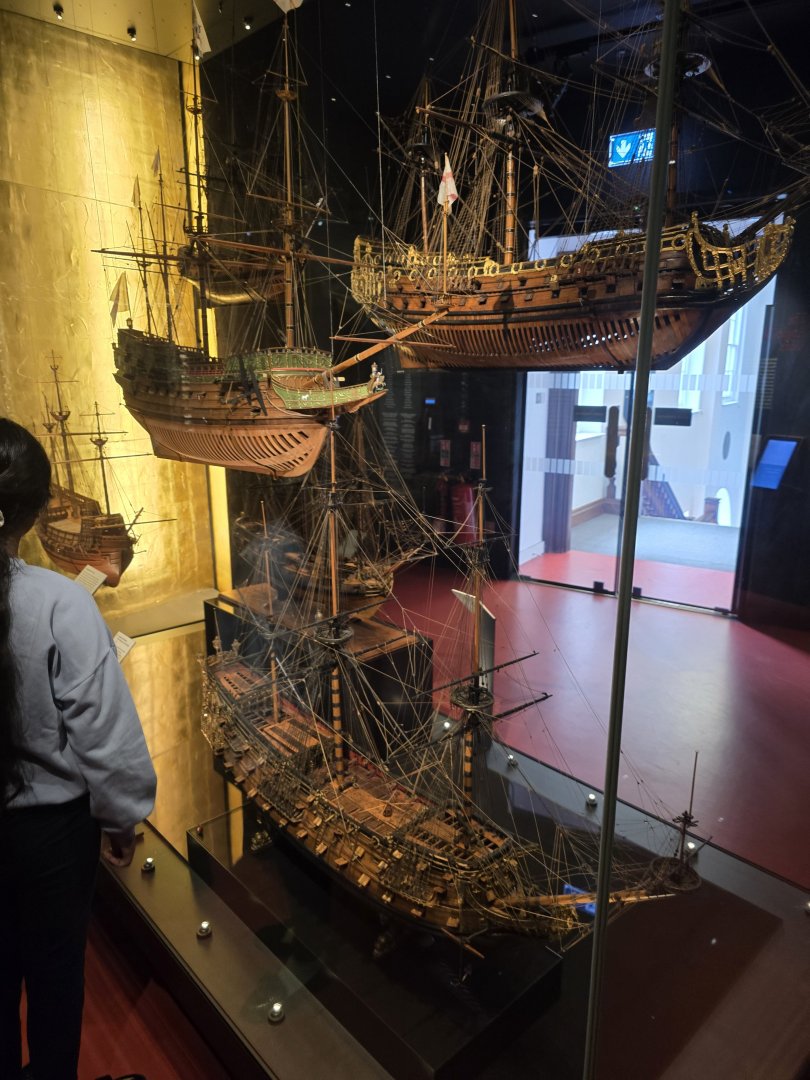

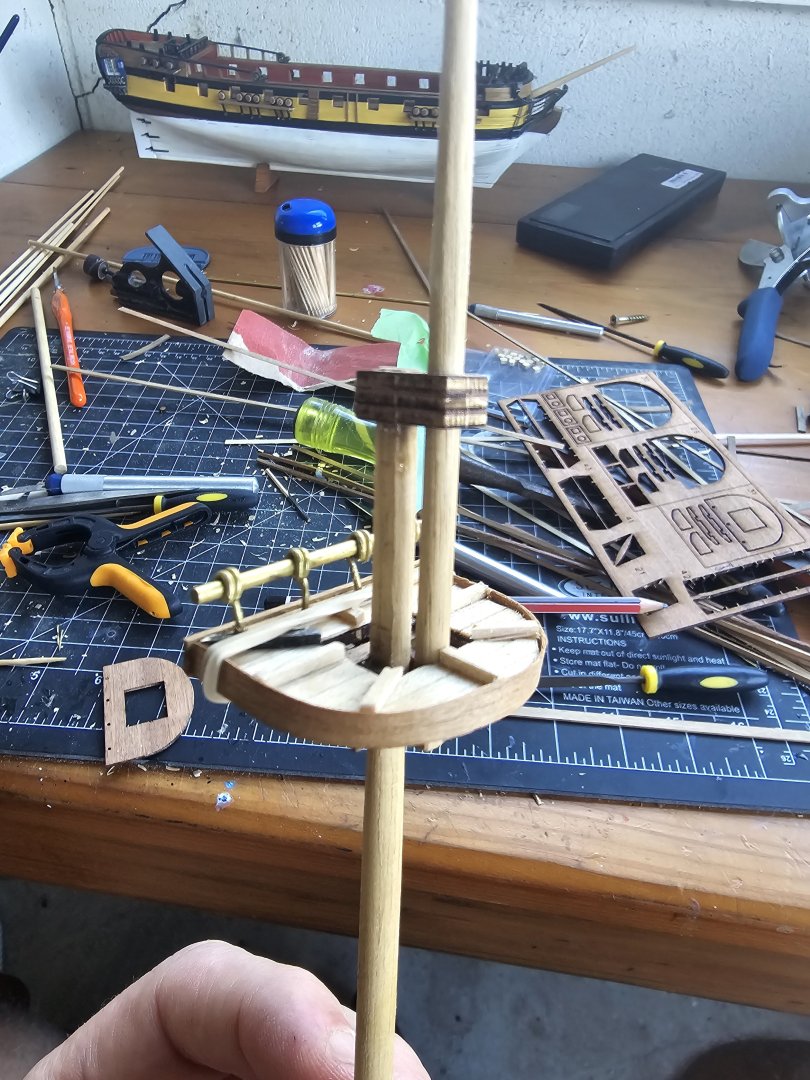

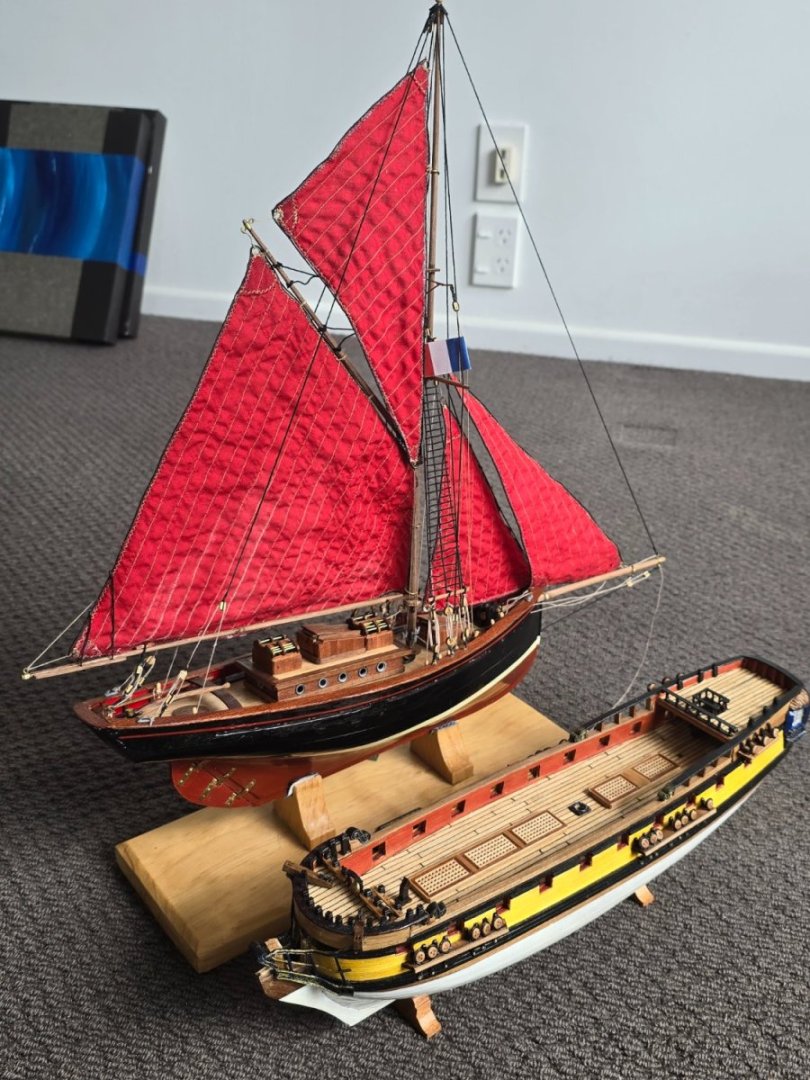

After being back from Europe for 4 weeks, I am starting to get back into the model ship building. I have been working on the mast sections and starting to near completion. The way I did the mast tapers was through squaring the dowel at the taper end then using a drill and a file to round it off and decrease the taper down from that to the base. No one is going to get the vernier out to see if the taper is correct as the amount of ropes etc make looking at the mast detail difficult. After seeing so many other model ships in Greenwich and else where I am going to remodel some parts of the ship to make them simpler. Ships are not made to have lots of fine detail. HMS Victory was very utilitarian on the inside and outside. And finally a pack of Vallejo game colour paints arrived after being out of stock for six months. Going to get down to painting up the figure head and clarifying the bow area of HMS Greyhound

-

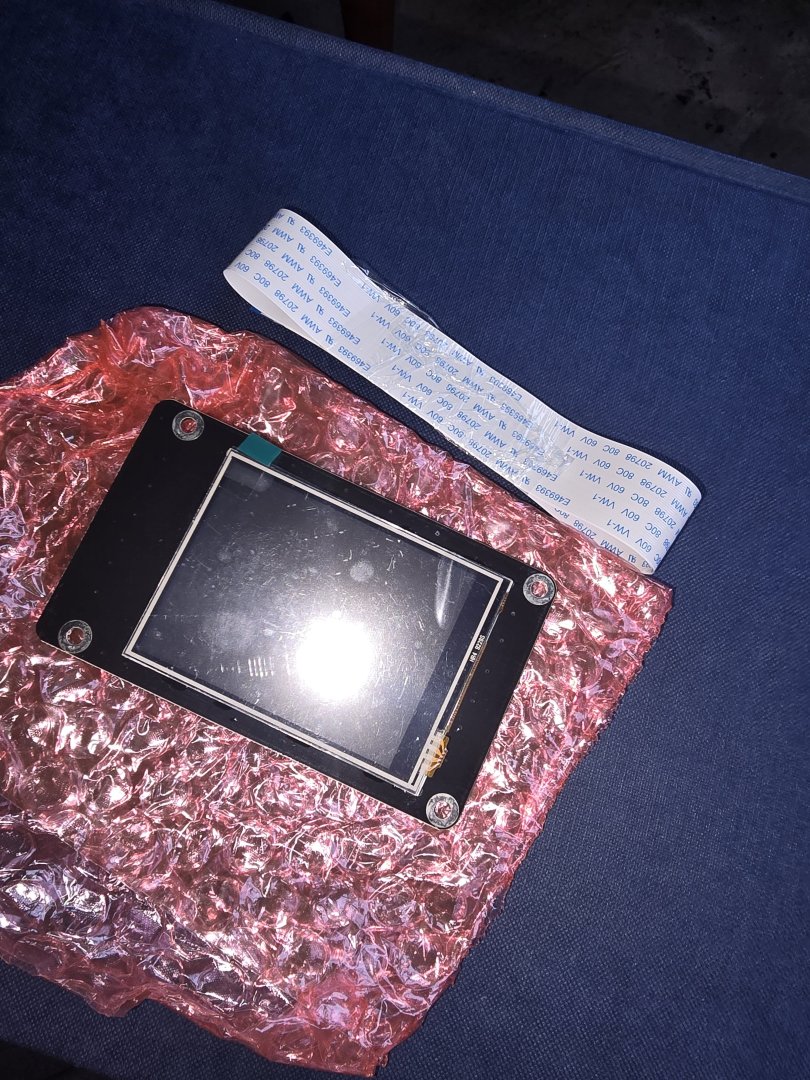

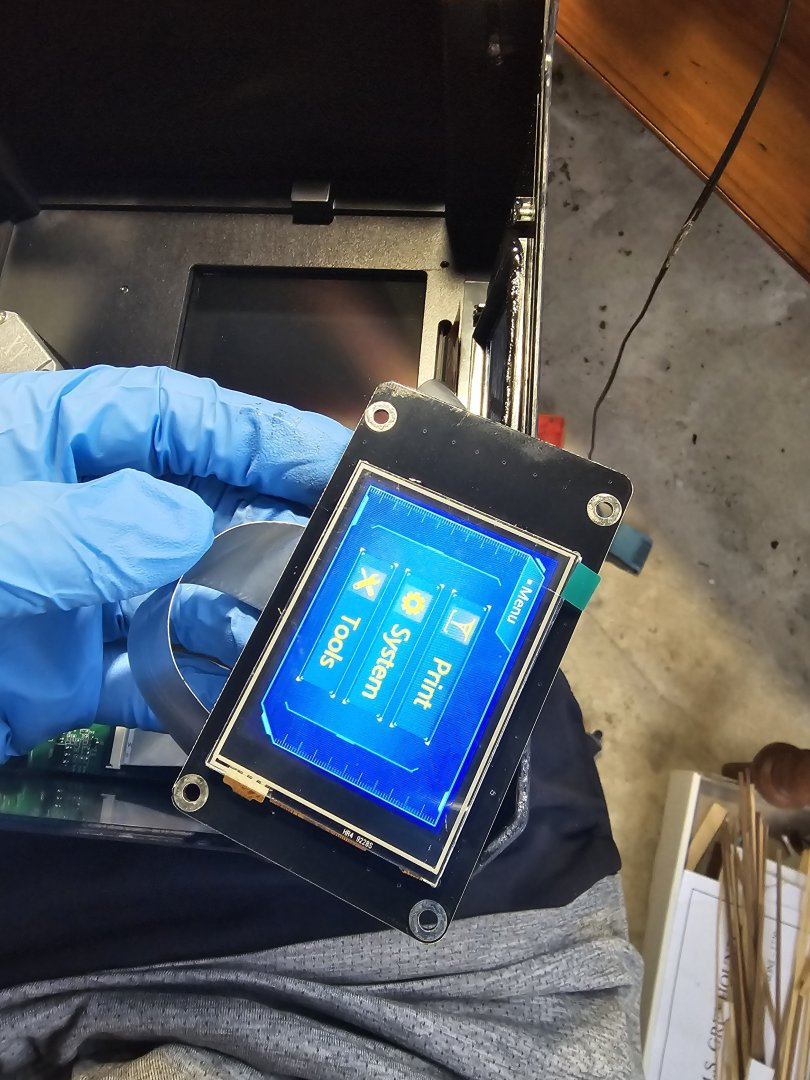

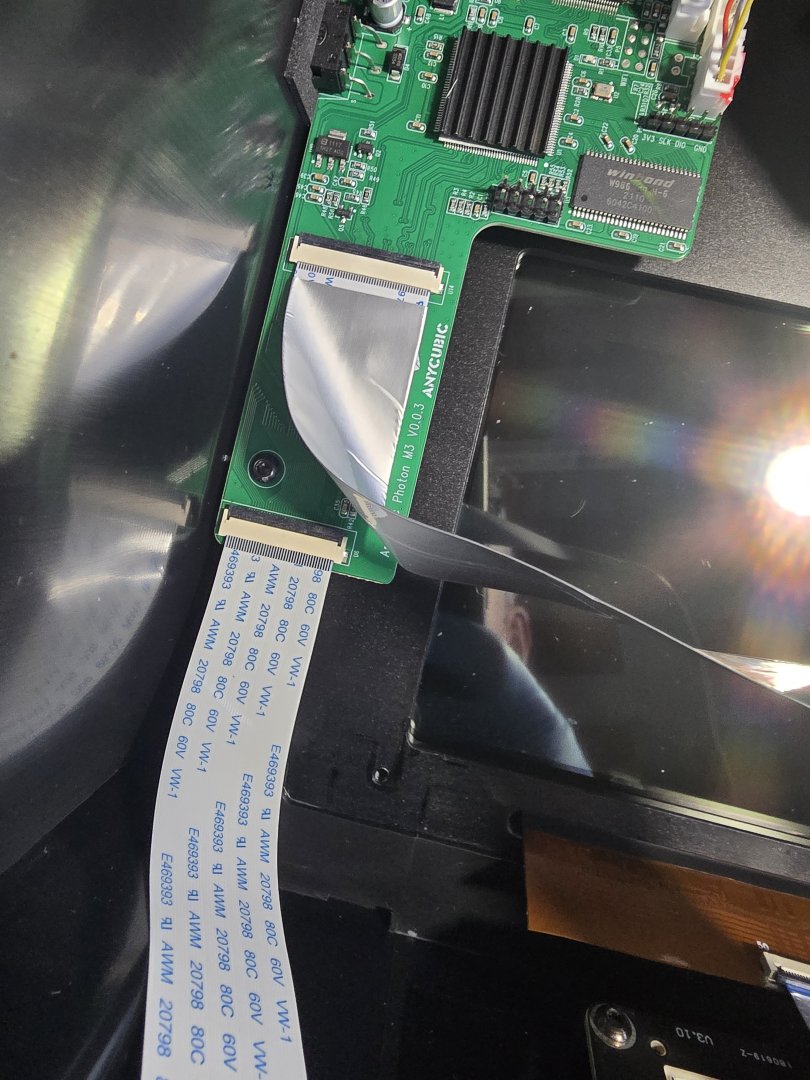

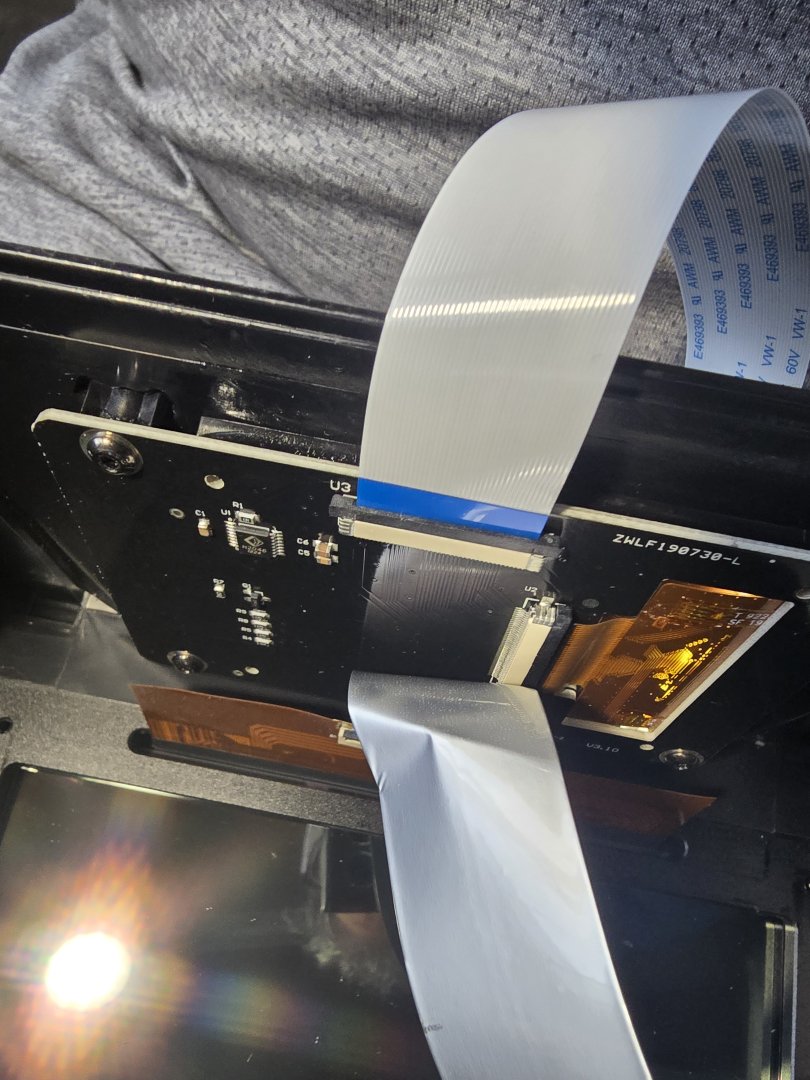

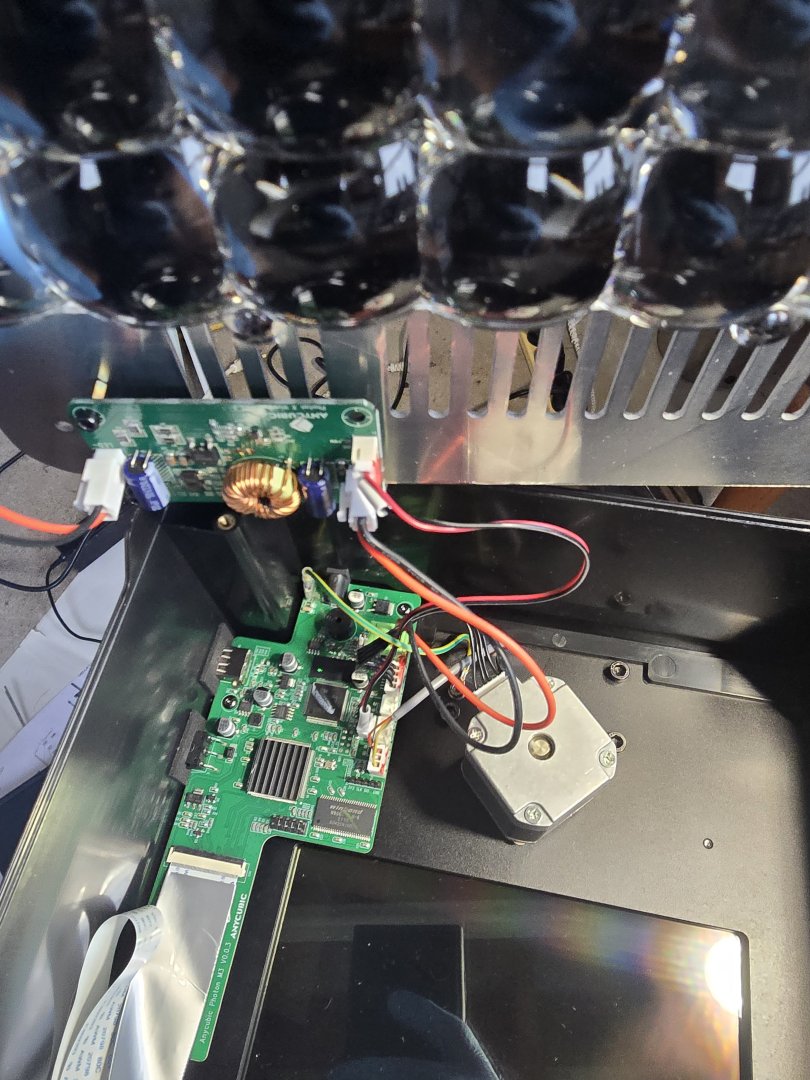

I have a anycubic photon m3 and the touch screen control panel cracked meaning it was really hard to use. So after googling around the process of changing spare parts didn't seem that hard, so I jumped in and tried to find a 2.8 inch touch screen replacement. Anycubic were out of stock so needed to find after market solution. I can recommend that chitu systems who write chitubox have spares for printers and I ordered the 2.8 inch screen and 7 days later it arrived from China. No instructions but tonnes of videos on the web to sort of follow. So the process to fix the screen is as follows, the photos document the steps as well: 1. Take off the bottom plate screws and remove the bottom plate. 2. Undo the electrical cables to give better access 3. Take off the plastic guard to stop cables crossing into the lcd and laser area of the printer. 4. Take off the control panel card 5. Undo the cables by flicking the little black bars on the connectors upwards. 6. Plug in the new screen and make sure the screen going in the right way up. There are no marks indicating the top on the Chinese card. 7. Re screw the screen into the printer. 8. Due to different plug in point on the replacement the original printer cable was slightly too short but chitu systems sent a spare cable in the box which was long enough. 9. Remove original cable and plug in new one. Push black retaining bars back down to lock in. 10. Replace cable guard and tuck all the cables down out of the LCD screen perimeter. 11. Test again all good before base plate placement. Plug in cables and screw down plate. I left the plastic screen protector on.. it works with it on and gives a little bit of protection from resin drips from the vat That's it.. all fixed

-

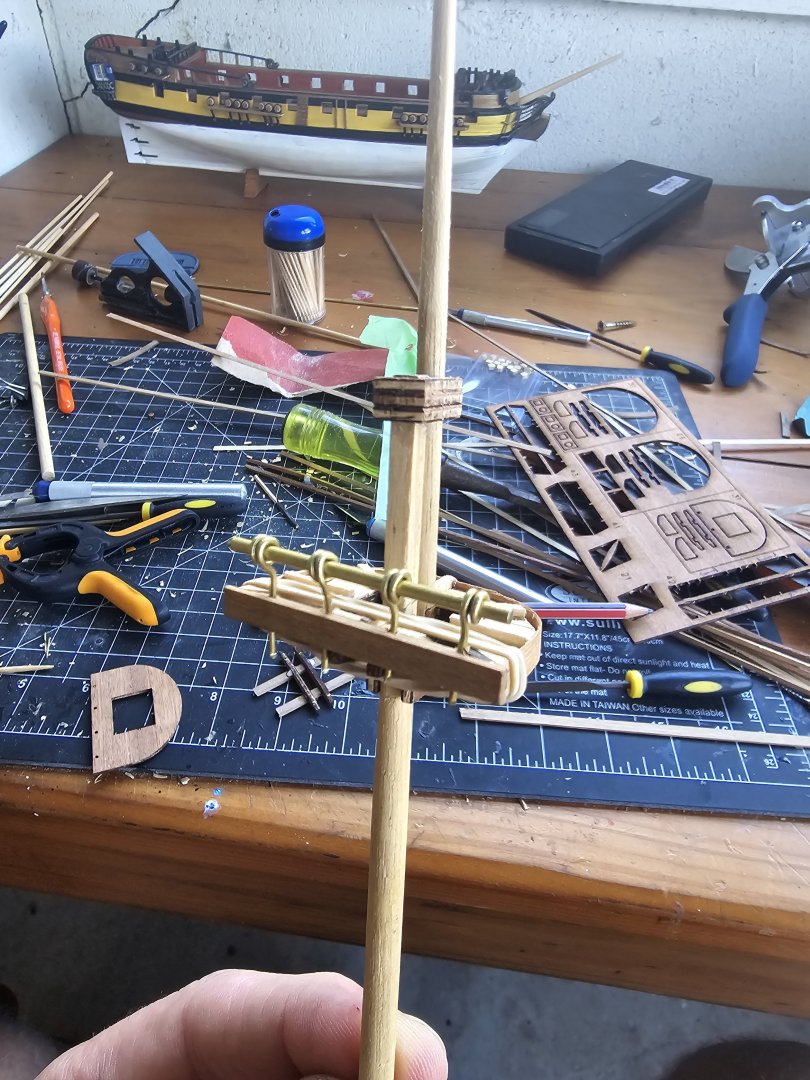

Working on the bowspit collars as per 1719 collar arrangement with the heart blocks on the bottom for the Bobstays amd the deadeyes for the fore preventer stay and the forestay. Tried my first gammoning and ok with the result.. at 1/100 scale hard to get a perfect knot but happy enough. Pretty much I'm ignoring the kit rigging plan and just using the lee's book.

-

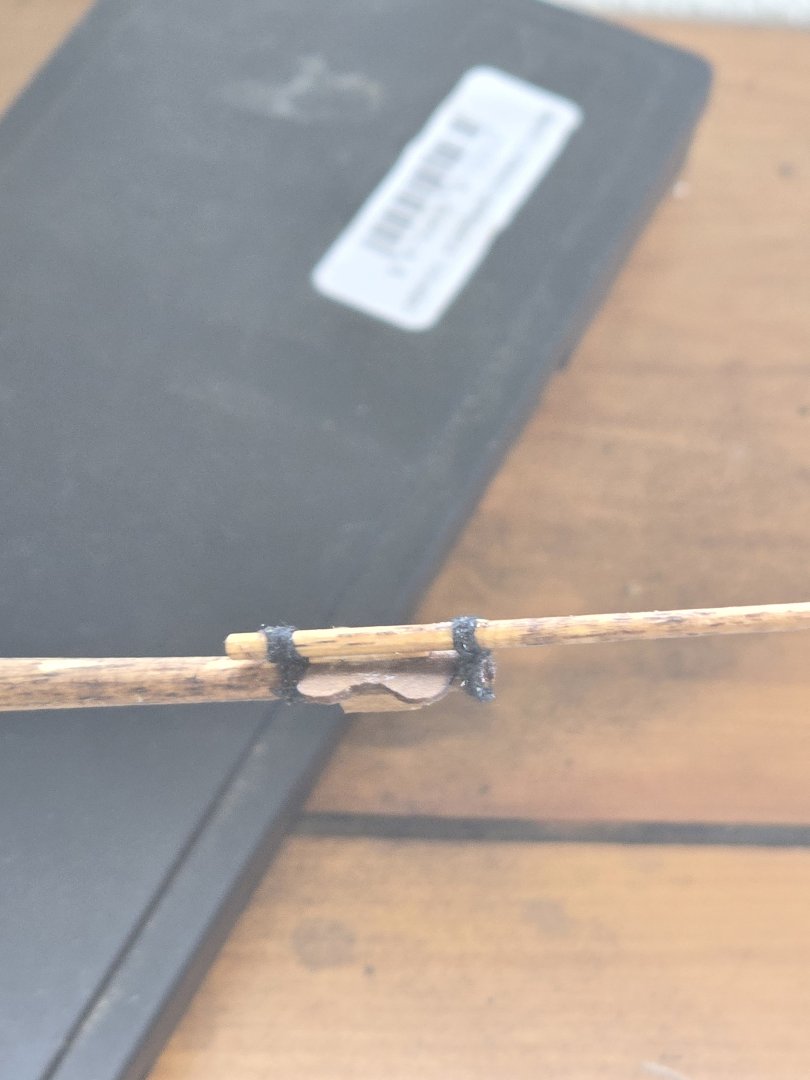

Starting to make progress on the main and the fore mast. The woodlings have gone on thr fore cast and made the main top. Have put bees on the bowspit and figure of eight lashings on the jib boom. No spirit top on this model. Next is the woodlings for the bowspit and start the heart blocks for the shrouds.

-

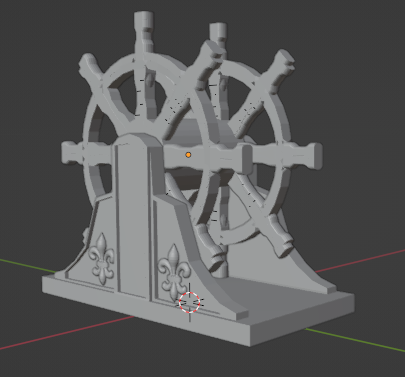

I've completed the fore mast, just have to taper last section. The kit supplied parts take a bit of alteration so that the mast is straight. Have to make the hole in the fore top slightly longer on a bow to stern axis to get the two pieces of dowel straight. I wanted a aged look to the mast so I used a dark timber stain to bring out the dowel grain. Then light sand. Then used linseed oil to dark the light wood colour. I'm going to gloss them up with a coat of shellac at the end. Picture of the completed wheel , 3d printed and painted

-

Hi... the rail width is 5mm in figure 9 so the timbers below that need to be less. I think either way is okay... I personally bought extra walnut 1mm x3mm so that it was 3 layers of 1mm equal to 3mm with 1mm overhang at the rail each side to allow the rail edges to be chamfered.

-

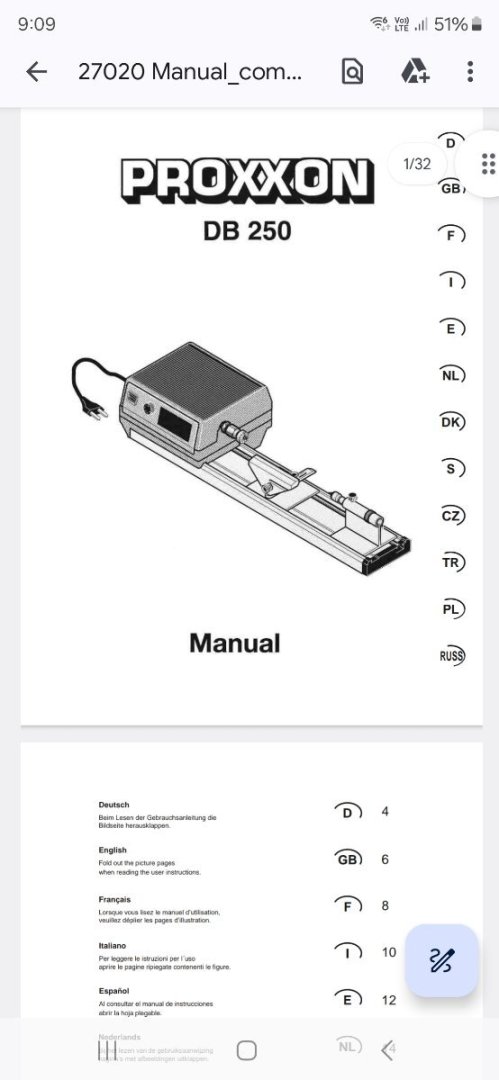

Proxxon mini lathe verdict

Srenner replied to Srenner's topic in Modeling tools and Workshop Equipment

I looked at this Chinese options @Gregory but the centre to centre distance since there is no pass through is around 200mm. The green machine is 300mm. The mast on the billings drakkon boat was 450mm or so from memory tapered. Some spars I would image on 1/48 scale would be wider than 200mm on older ships. My concern is you spend $495 dollars and get a machine for a certain job but can then possibly step up to a Chinese lathe/milling machine in the 800 range. A milling machine would be great for the hexagonal sections of the masts or the square sections as they go through the mast cap. But can achieve that with a file and sandpaper as well. Machine choices hard... -

Proxxon mini lathe verdict

Srenner replied to Srenner's topic in Modeling tools and Workshop Equipment

Can you by a add on tool holder and screw thread feed for this lathe? -

I see some people using the proxxon mini lathe and it comes with collets upto 10mm and quite long centre to centre measurement. What's the verdict on that machine? Price is good too for nz dollars. Really just want to make a good taper on my mast and spar sections as the old drill and sandpaper method is a bit hit and miss. Yes it's approximately right but want that added machined quality to it and keep the mast sections straight centre to centre. But it's going to be a hand piece taper and again not a autofeeding or angle feed on this model. Maybe the result won't be that flash.

-

You need to study that cut away section diagram on the plans and think from the outside in to work out what will look good with the rails on the outside, the planking wood and then coming back to the 1mm strip. Once you decide that then follow the suggestion from the deck shape for the runs of those timbers and if need be shim out the bulkheads to get a nice run. I don't think you should cut the deck in back to your bulkheads. Better to build them out. The bh are plywood so can be cut off or sanded back from the inside if required. I covered mine completely so can't see them edge on. But same thing with deck.. I didn't want to see that plywood vaneer edge on the outside hull so the basswood planks covered it. That's why I recessed that rail in.

-

I was going with the top rail width. If the rail is 5mm then the hull needs to be around 3-3.5mm width finished if you want a overhang on the rail of say 1mm each side. So that's 3 thicknesses of 1mm strip to make up the hull to the rail. FYI the timber provided is not 1 mm thick exactly it's about 1.3mm measured using a vernier scale. I think mine came out close to 4mm thick giving a rail overhang of 0.5mm each side

-

Hi... I don't think there is enough decking to do the lower deck... although i wasn't that careful and didn't try and minimize the cut off ends... adding up all the small left over cuts might be enough for the lower deck. Can't you just buy 0.7mm basswood strips from a supplier anyway if you wanted more?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.