Olaf

-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Olaf

-

-

-

On 6/20/2022 at 11:29 PM, RGL said:

Too big for me! I have a LOT of reference material for her so let me know if you need anything. Trumpeter won’t build Japanese warships but obviously their subsidiaries will. It’s a bit like spitfire kits, people will always buy one. There is some amazing stuff coming up in 1/200 but damn it’s going to take up a lot of space.

Hi RGL. I found your old post. Do you still have any parts for 1/200 Yamato? Worth to ask even after so long time 🙂.

-

Hi everyone. Is anyone on this forum from Canada?I want to buy photo etched set from Canada. Seller from Canada Amazon not posting to Europe 😭. Or maybe someone can recommend forum in Canada so I can get any help there please?

-

On 6/8/2024 at 5:51 PM, wefalck said:

There is no 'scale' for rivets, only size. So the question is how big on the prototype would these rivets be?

Second question: what type of rivet? There are many ways in which rivetting and forming their heads can be performed: half round, countersunk (barely visible on a model), half countersunk, flush (which then would be invisible on the model), hollow rivets, etc.

So a picture of the prototype you want to achieve would be needed to give you informed advice.

I would, however, suspect that rivets in 1/200 scale on AA gun mounts would be rather small, with heads of a diameter somewhere around 20 mm max. This means, that in at a 1/200 scale we are talking of diameters of less than 0.1 mm. Assuming that we are talking of half-round heads, the only practical way would be tiny (really tiny) blobs of paint or white glue. It would be a challenge to achieve consistent sizes. In summary, I think I wouldn't bother.

The tool you showed, although I don't know it, seems to be the kind used by aircraft modellers to indicate flush rivets by slightly marking the surface. This is not what you (presumably) need and the resulting marks would be grossly overscale anyway.

Thank you for your advice and informations. It was very useful lesson for me 🙂. You are right. This rivets can be almost invisible in this scale.

-

-

Hi guys. What kind of magnifiers are you using? I don’t know which one to choose?

- Keith Black and Canute

-

2

2

-

On 5/13/2024 at 10:18 PM, Nirvana said:

Olaf, thanks for the videos, I would recommend everyone to use the technique from the last video. I have been doing somwthing similar. But this is the way to go.

Thank you @Nirvana that I could help a little :). This is just beginning of my way to modeling and now I am collecting all parts and informations for my project including 3D printing extra parts. Just need search for someone else who is very good in 3D reisen printing. All parts and tools will cost me trple more than model 😅.

-

4 hours ago, paul ron said:

Found it.

- thibaultron, paul ron, cotrecerf and 2 others

-

5

5

-

Hi everyone. I am looking on YouTube Chanel where modeler was showing how to clean airbrush without stripping off airbrush on parts. He is from USA. I had this link but lost it! Can anyone can help me out with this please?

-

-

Hi guys. I found on AliExpress PE paravanes for 1/200. Somebody bought from AliExpress any products and was happy about this side? I know that comes from China but this kit looks fine. Or maybe I am wrong?

https://www.aliexpress.com/item/1005002376800441.html?gatewayAdapt=glo2kor

-

On 10/28/2016 at 1:09 AM, RGL said:

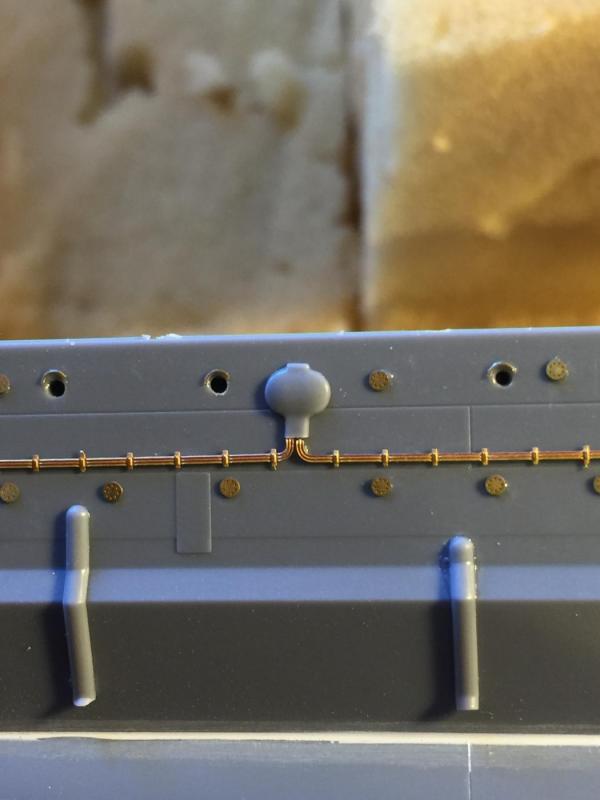

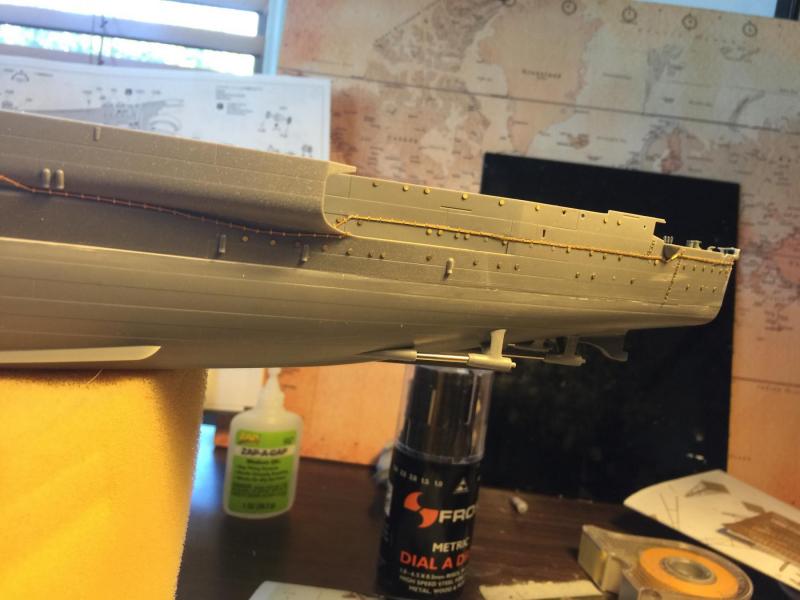

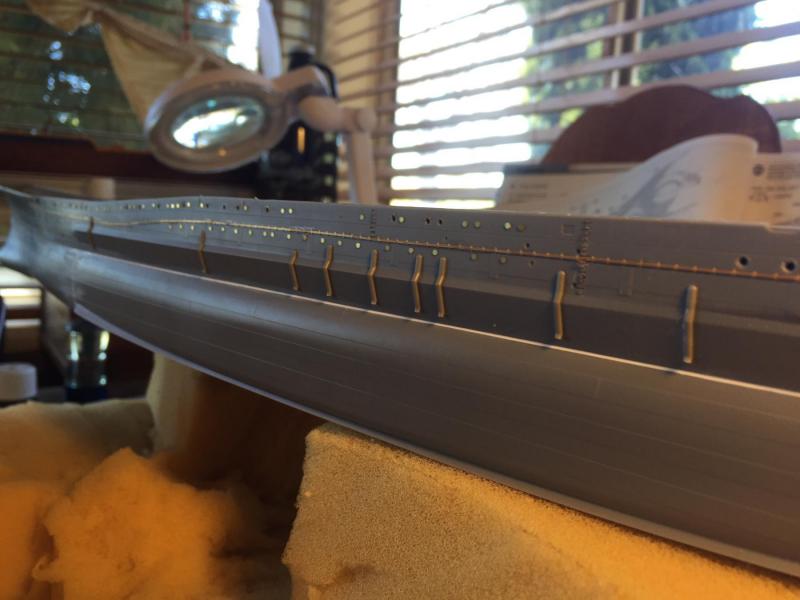

Moving along with the hull, I have placed the degausing cables. You are given two options, one closed and one open. I used the open one as it looks better and I suspect Tamiya got the idea from the photos of the wreck

but I suspect the keyboard warriors are correct when they say the covers have rusted off. Still, looks nice.

but I suspect the keyboard warriors are correct when they say the covers have rusted off. Still, looks nice. .

.

So all up there is about a metre of it, which at 1/350 is a lot.

Hi Greg. Can you tell me what is diameter of this cables please? I would like to make for 1/200 scale. Pontos 1/200 doesn’t have for this cables . I would like to sand of molded one and put replacement.

-

On 10/20/2016 at 8:30 AM, RGL said:

There is a build I'mfollowing on another forum that's quite good as it points out the bits that the instructions don't tell you about and is nicely weathered. When I get an airbrush there is a wealth of info on it, I know how to but there is so much good stuff out there now on the internet that did not exist back in the day that it's a whole new world. I think the secret is to be subtle. I imagine the hull will be battered and dirty but the Japanese were and are so fastidious the areas that were accessible would be as clean as possible or their seniors would have flogged them.

I keep telling myself stop rushing.

Hi @RGL. Can you please give me a link for this forum ? I would like to get so many information as possible before I start my project. I can see there are more Pontos PE for 1/350 Yamato model than for 1/200 Yamato scale model. I would like also replace cables going along side the ship. It will be difficult.

-

21 minutes ago, myxyzptlyk2003 said:

I don't use them. My ship modeling area is only used for ship modeling. The counters have kitchen counter type coverings. In over 20 years they still are clean and without significant cuts.

Hi @myksyzptlyk2003. What kind of surface do you use for cutting of PE?

- thibaultron and mtaylor

-

2

2

-

Hi guys. I saw a few type of cutting mats. Which ones do you recommend?

-

Like above guys. Which color better for Yamato hull?

-

5 hours ago, GGibson said:

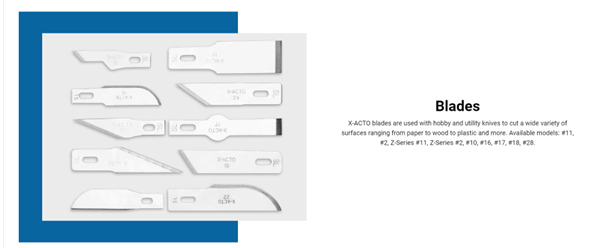

Hi GGibson.Can you give some examples of this blades and what knife I can use for this blades please? I just getting nystagmus on websites🙃

-

6 minutes ago, Roger Pellett said:

Since you have posted this under metalworking it would seem that you are considering metal. Metal, particularly brass can be an excellent choice for very small parts as grain is not a factor. A piece of hard brass wire should work.

Thanks for advice. I think it will be best choice.

- Roger Pellett, Canute and mtaylor

-

3

3

-

57 minutes ago, allanyed said:

What actual diameter do you need? One idea that comes to mind if I am picturing this correctly in my mind, you can run bamboo through a draw plate to the largest diameter you need for the mast then taper as needed with sandpaper. My preference is to start with bamboo skewers or chopsticks and split them to a workable size, then run them through the draw plate holes until I reach the diameter I need.

Allan

Thanks for replaying mate. I think I will try use first tooth picks. And use sandpaper make smaller diameter. Thanks for idea what can I use 😀. Will have fun with it.

-

Need suggestions how to make small masts for Yamato lifeboats. I think to use 0,2 wires to do this. What do you think guys? Anyone can give me some advice and tips please?

-

-

Hi guys. I am looking where to buy aftermarket two rudders for Yamato. Maybe someone knows where to get it please? I try find in UK but can not find it.

-

3 hours ago, Jaager said:

I like the shape of the Fiskars Softgrip Ergonomic Detail Knife for hand feel.

A very common blade is the #11 shape. Getting a 100 pack of a high quality #11 blade, not the OEM version is my choice.

When researching this, I just discovered that XActo - which as not been my choice for blades - has a XZ series that has a zirconium nitride coating

Feedback suggests that the hard coating makes the tip prone to snapping off - especially with lateral force. If your cuts are straight line they might work.

An alternate direction is a double bevel 1/4" violin makers knife. #11 shape - just a bar of steel with no handle. Expensive but it is lifetime for one. There are maybe 6 widths.

With both disposable and permanent blades, very frequent shroping on leather charged with a green, red, or gold polishing compound crayon keeps a fine edge and reduces changes. I do not know if zirconium is harder than the compounds. It may require diamond.

Can I replace blades on this particular model @Jaager? Doesn’t say anything.

-

1/200 Trumpeter IJN YAMATO - issued by MRC/Gallery Models

in REVIEWS: Model kits

Posted · Edited by Olaf

The same me🙂. I am now in process of buying extra aftermarket parts and another staff for him. Still looking for Fujimi PE . And can’t find it anywhere 🥲.