MajorChaos

NRG Member-

Posts

301 -

Joined

-

Last visited

About MajorChaos

- Birthday March 21

Profile Information

-

Gender

Male

-

Location

Southern Middle Tennessee

Recent Profile Visitors

-

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

-

robert952 reacted to a post in a topic:

Muscongus Bay Lobster Smack by SiriusVoyager - FINISHED - Model Shipways - 1:24

robert952 reacted to a post in a topic:

Muscongus Bay Lobster Smack by SiriusVoyager - FINISHED - Model Shipways - 1:24

-

MajorChaos reacted to a post in a topic:

Muscongus Bay Lobster Smack by Venti - Model Shipways - 1:24

MajorChaos reacted to a post in a topic:

Muscongus Bay Lobster Smack by Venti - Model Shipways - 1:24

-

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

-

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

-

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

-

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

MajorChaos reacted to a post in a topic:

Norwegian sailing pram by Kenchington– FINISHED – Model Shipways – 1:12

-

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by J Snyder - FINISHED - Model Shipways - 1/12 - My First Model

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by J Snyder - FINISHED - Model Shipways - 1/12 - My First Model

-

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by J Snyder - FINISHED - Model Shipways - 1/12 - My First Model

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by J Snyder - FINISHED - Model Shipways - 1/12 - My First Model

-

MajorChaos reacted to a post in a topic:

Muscongus Bay Lobster Smack by palmerit - FINISHED - Model Shipways - 1:24

MajorChaos reacted to a post in a topic:

Muscongus Bay Lobster Smack by palmerit - FINISHED - Model Shipways - 1:24

-

aaronc reacted to a post in a topic:

Bluenose by MajorChaos - Model Shipways Kit No. MS2130 - 1/64 scale - Canadian Fishing Schooner

aaronc reacted to a post in a topic:

Bluenose by MajorChaos - Model Shipways Kit No. MS2130 - 1/64 scale - Canadian Fishing Schooner

-

aaronc reacted to a post in a topic:

Bluenose by MajorChaos - Model Shipways Kit No. MS2130 - 1/64 scale - Canadian Fishing Schooner

aaronc reacted to a post in a topic:

Bluenose by MajorChaos - Model Shipways Kit No. MS2130 - 1/64 scale - Canadian Fishing Schooner

-

Knocklouder reacted to a post in a topic:

Muscongus Bay Lobster Smack by MajorChaos - FINISHED - Model Shipways - 1:24

Knocklouder reacted to a post in a topic:

Muscongus Bay Lobster Smack by MajorChaos - FINISHED - Model Shipways - 1:24

-

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

MajorChaos reacted to a post in a topic:

Norwegian Sailing Pram by CommodoreErie - Model Shipways - 1:12

-

robert952 reacted to a post in a topic:

Lowell Grand Banks Dory by MBerg - FINISHED - Model Shipways - 1:24 - First Build

robert952 reacted to a post in a topic:

Lowell Grand Banks Dory by MBerg - FINISHED - Model Shipways - 1:24 - First Build

-

MBerg reacted to a post in a topic:

Lowell Grand Banks Dory by MBerg - FINISHED - Model Shipways - 1:24 - First Build

MBerg reacted to a post in a topic:

Lowell Grand Banks Dory by MBerg - FINISHED - Model Shipways - 1:24 - First Build

-

It looks great! Great job!

- 69 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

aaronc reacted to a post in a topic:

Lowell Grand Banks Dory by MajorChaos - FINISHED - Model Shipways - 1:24

aaronc reacted to a post in a topic:

Lowell Grand Banks Dory by MajorChaos - FINISHED - Model Shipways - 1:24

-

kuya reacted to a post in a topic:

Benjamin W Latham by MajorChaos - Model Shipways Kit No. MS2109 - 1/48 scale - The American Fishing Schooner

kuya reacted to a post in a topic:

Benjamin W Latham by MajorChaos - Model Shipways Kit No. MS2109 - 1/48 scale - The American Fishing Schooner

-

Diver reacted to a post in a topic:

Medway Longboat 1742 by MajorChaos - 1:24 scale

Diver reacted to a post in a topic:

Medway Longboat 1742 by MajorChaos - 1:24 scale

-

woodartist reacted to a post in a topic:

Medway Longboat 1742 by MajorChaos - 1:24 scale

woodartist reacted to a post in a topic:

Medway Longboat 1742 by MajorChaos - 1:24 scale

-

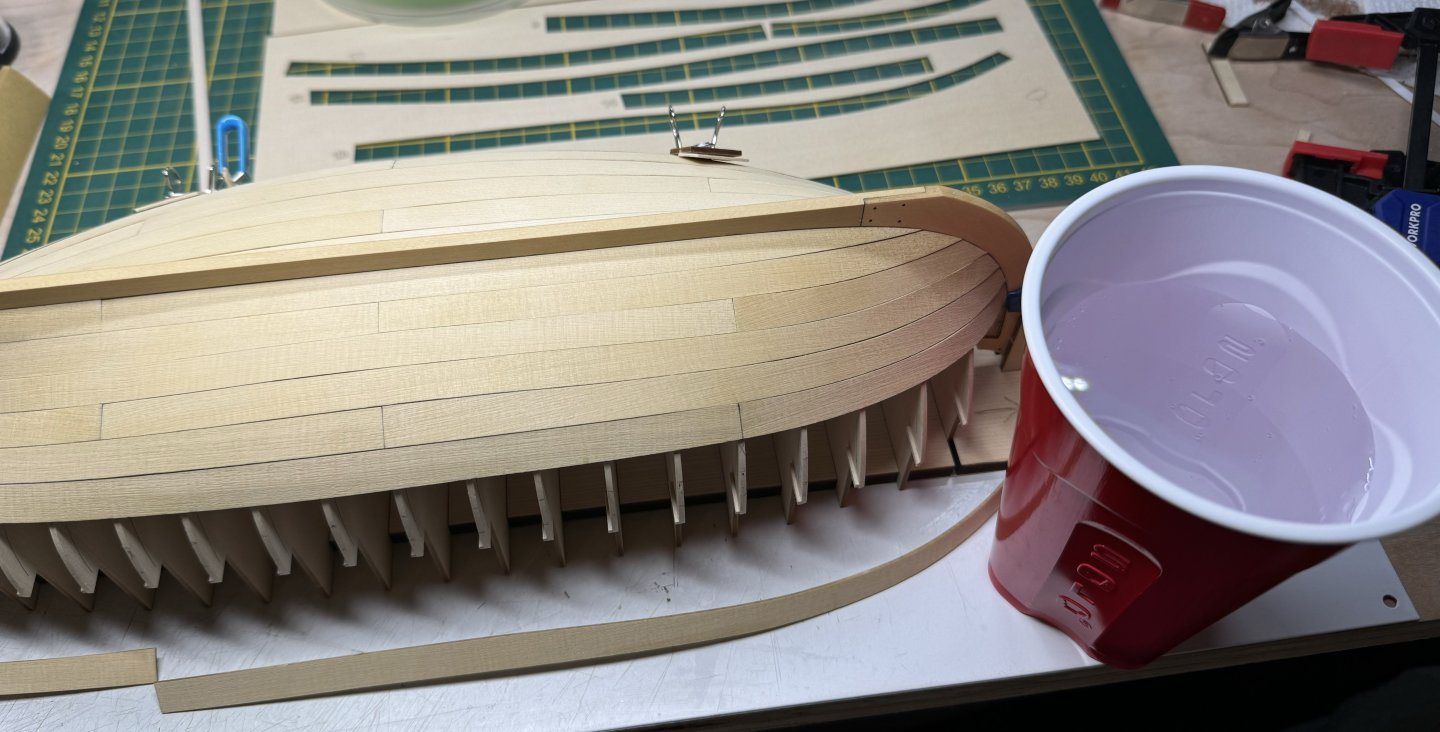

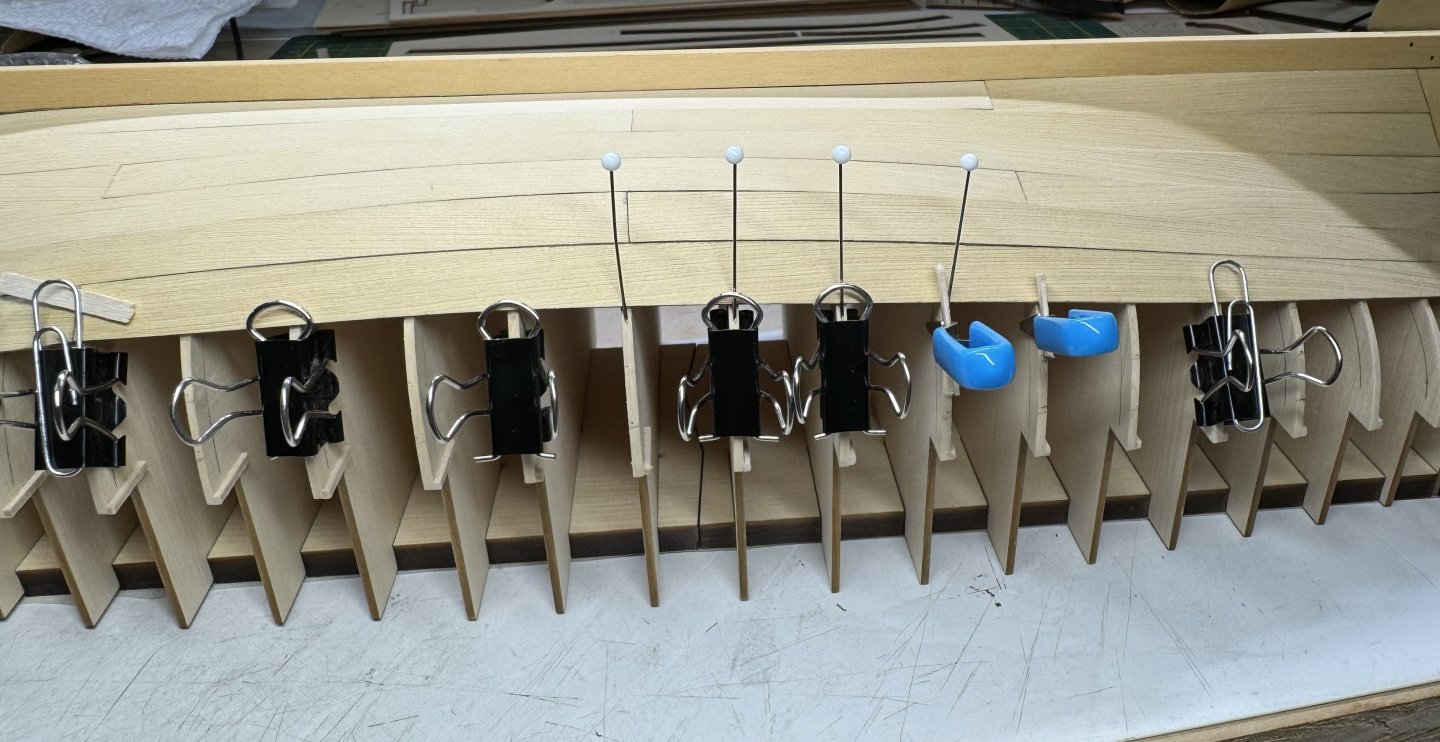

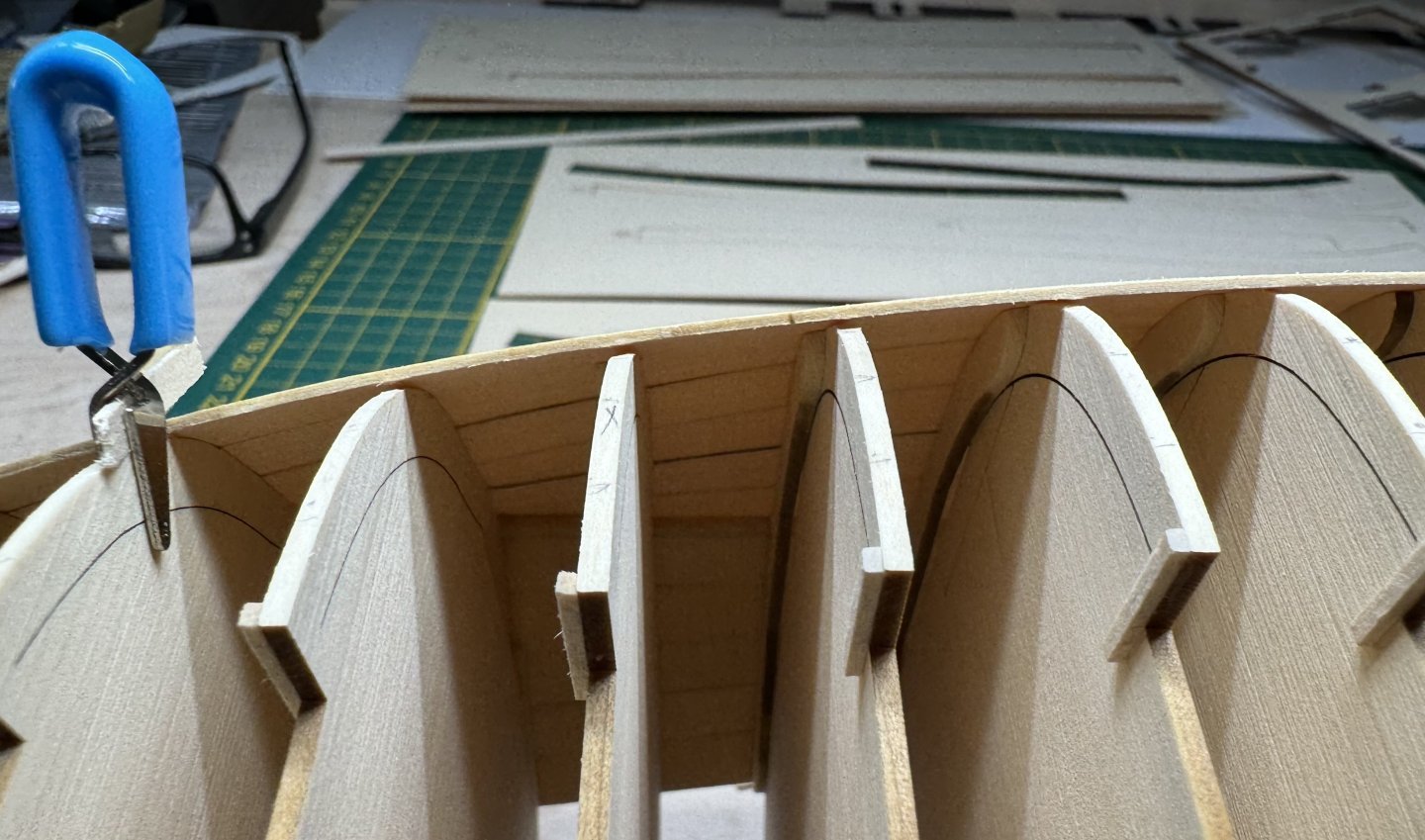

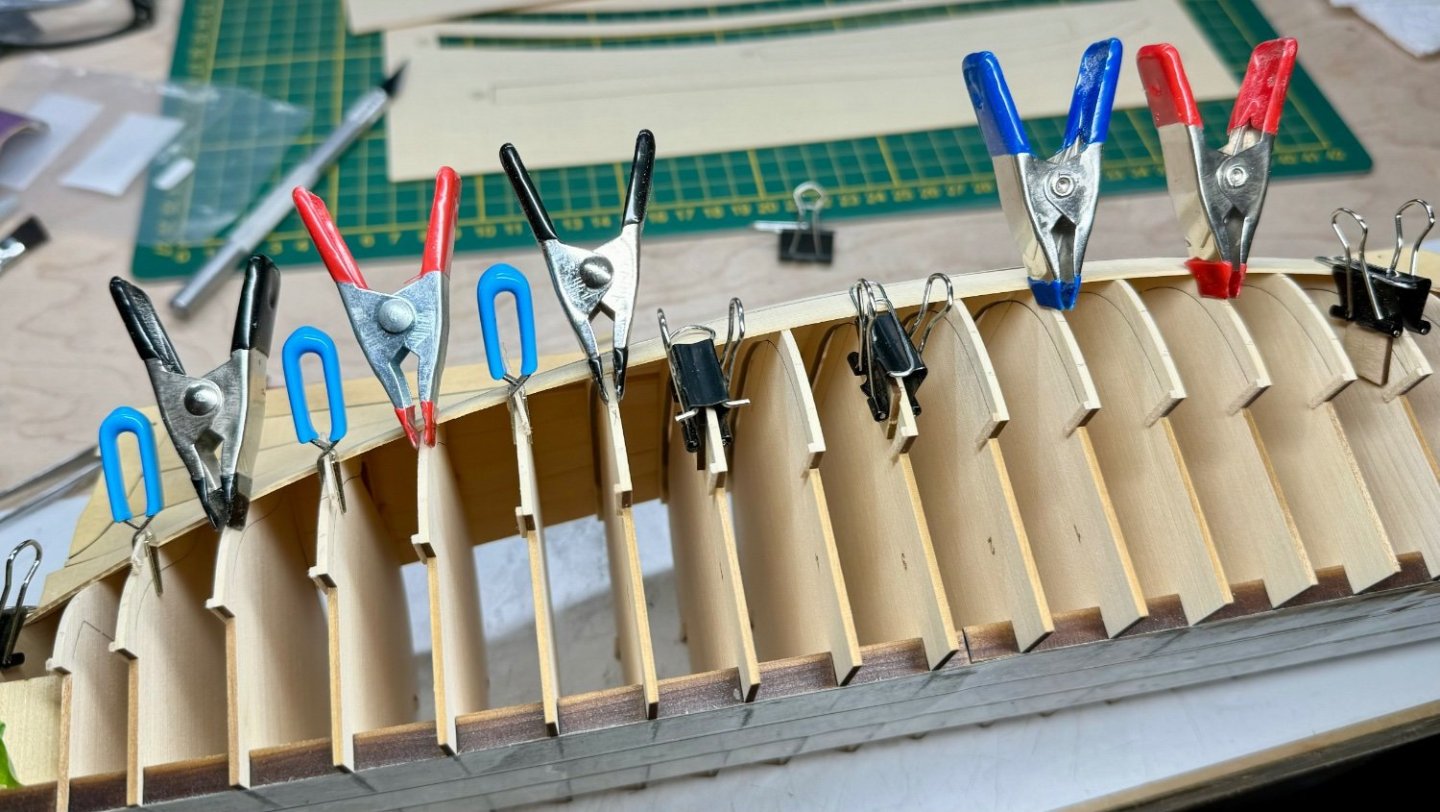

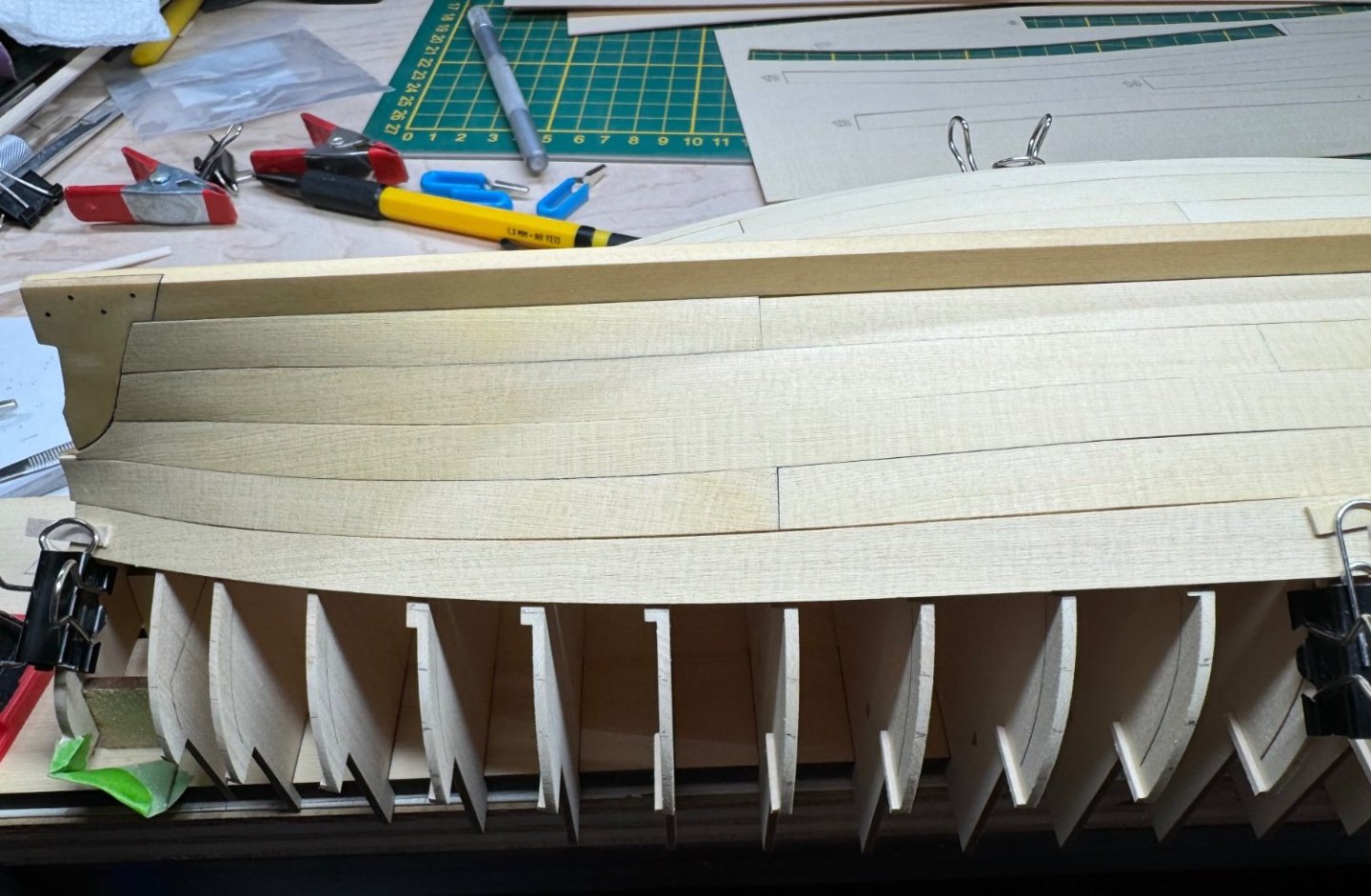

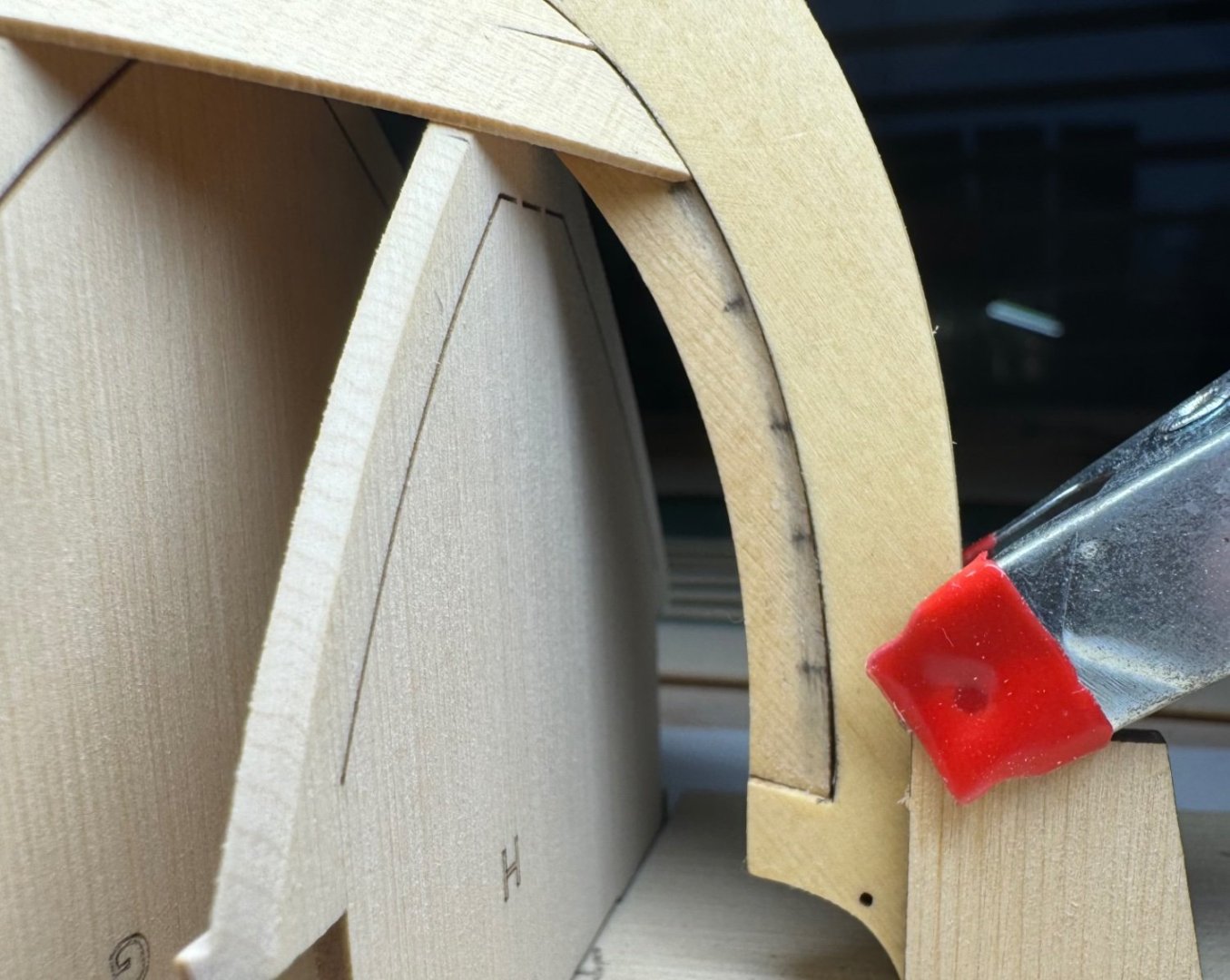

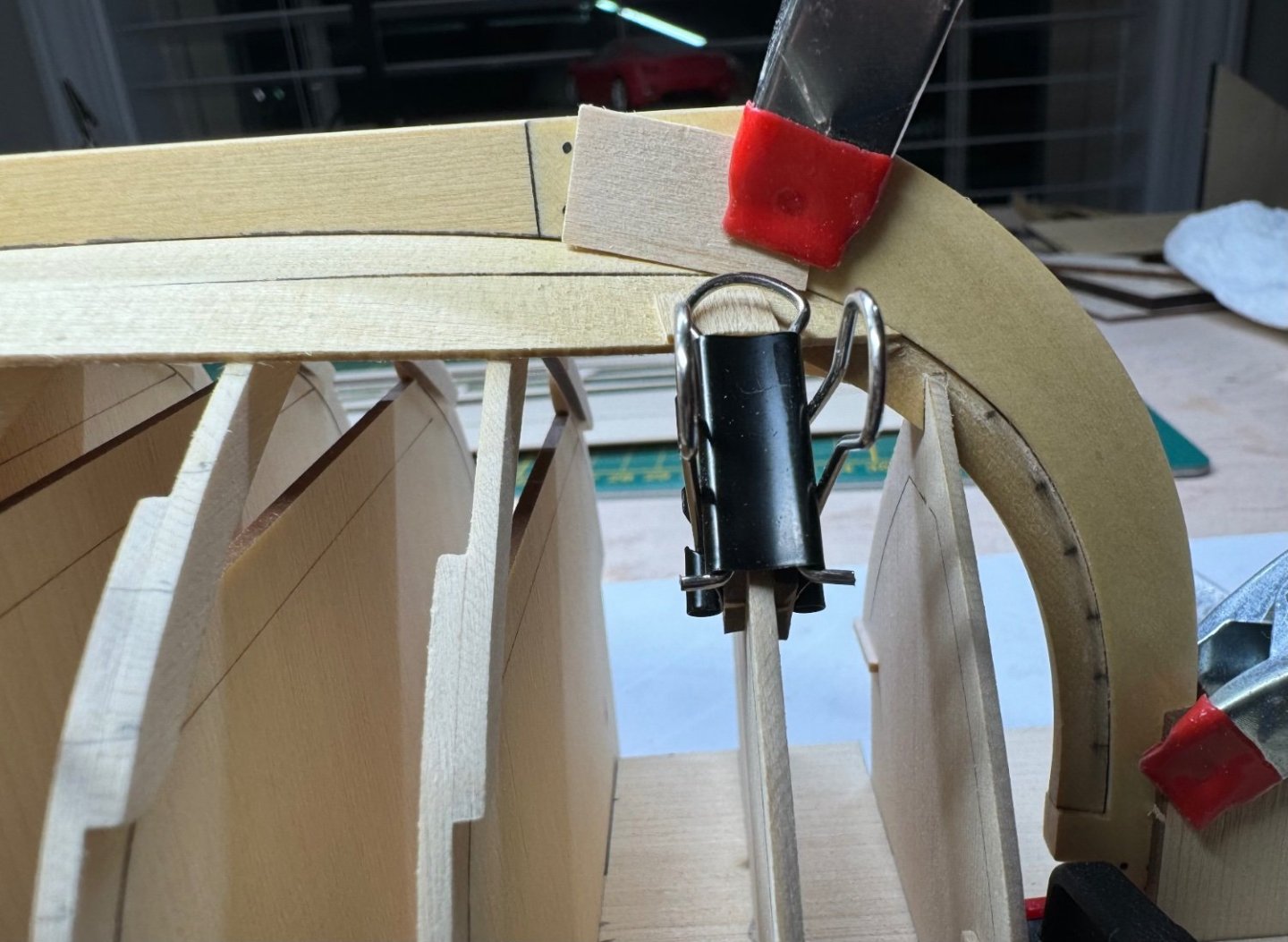

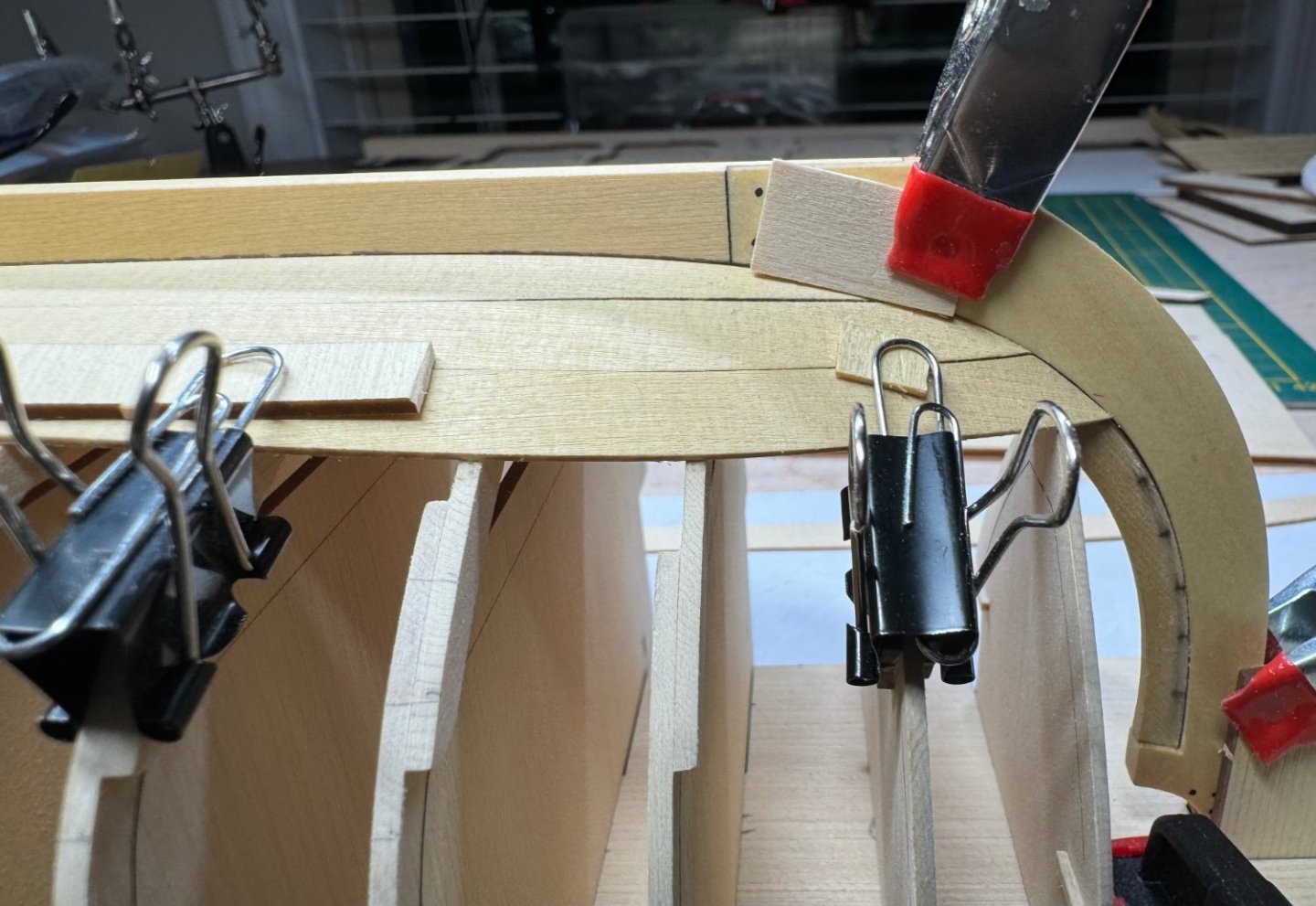

I'm seeing the dents. I’m getting most of them out. I’m able to bend the planks well with water. They hold there shape well, it’s the curve of the frame I’m struggling with. 13-1 it’s laying down nice so far. I’ve tried the heat, I can’t get the plank to stay bent/shaped. I’m struggling with the pieces staying springy. I can get some areas great and others spring up. I’m getting better with each plank. Maybe I’m not getting the plank hot enough. With the water I can break the structure of the wood and can feel it go limp. Kinda like a wet noodle. It becomes very ply able. Then I use heat to set the curve. I’m not able to reproduce your results with heat only, my lack of skill for sure.

-

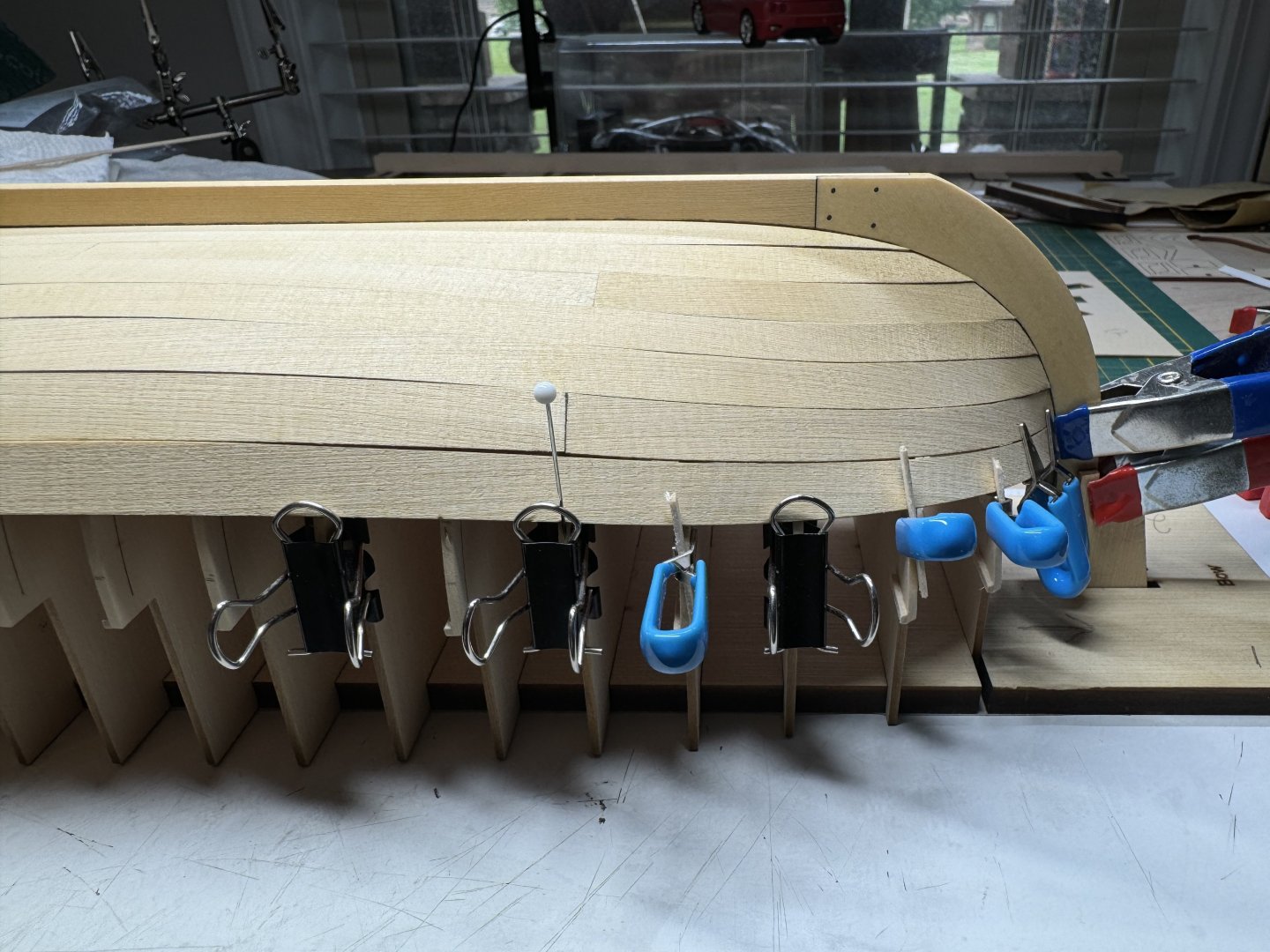

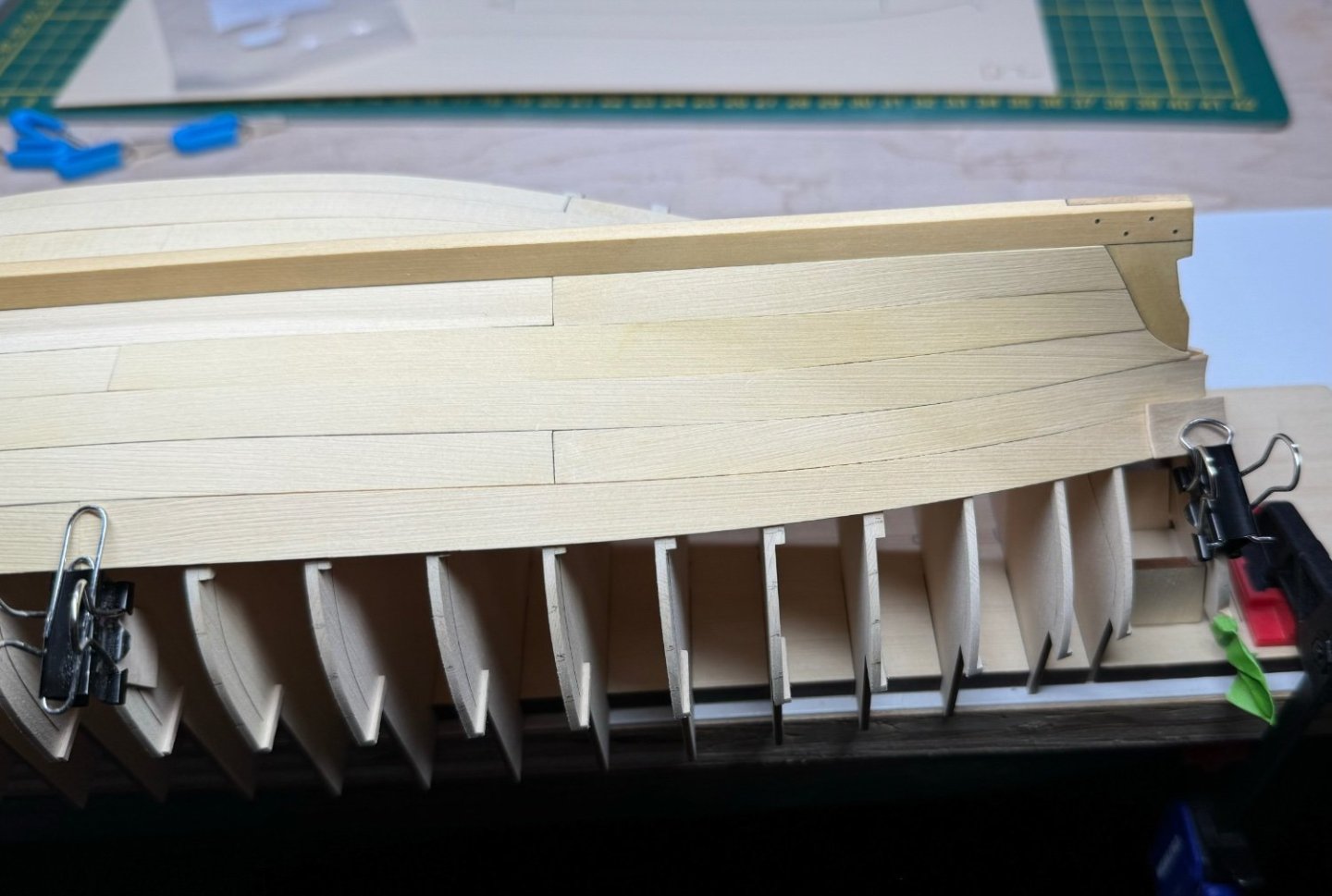

Well, 12-2 took just a bit longer than I planned. Because of all the curves and bends for this one, I glued the bottom side and left the top run loose. Glued on both ends. I’ll pull it down on the top to shape it. I’ve tried water and heat, I just can’t make this one stay formed. I tried to use super glue and I clearly don’t have the technique down for that. The Titebond works good the way I work, it gives me just a bit longer work time and holds quick when not loaded. Sometimes life just doesn’t cooperate. I have learned if I don’t want to do something I shouldn’t force myself. Parts of this wonderful kit looks nice with my work and other parts look like I should take a belt sander to the whole thing. I’m learning and having fun. Let’s see if I can string a few days together with work on the Medway. Thank you for the likes and the follows in this project.

-

I’m still here. I’m getting back to fixing plank 12-1. After being away from it and looking it over, I’m making a mess of it. Slowing getting the edges back down, I had to clean the up some, just short of taking the plank off. I’ve got a plan after I get it off the board to secure some stuff better. Life and work has been kickin my butt.

-

Its looking great! I did the same thing with the extra cut, I made patches to fill it in. I wonder how many OcCre boats are built with this mistake. It was very easy to miss.

-

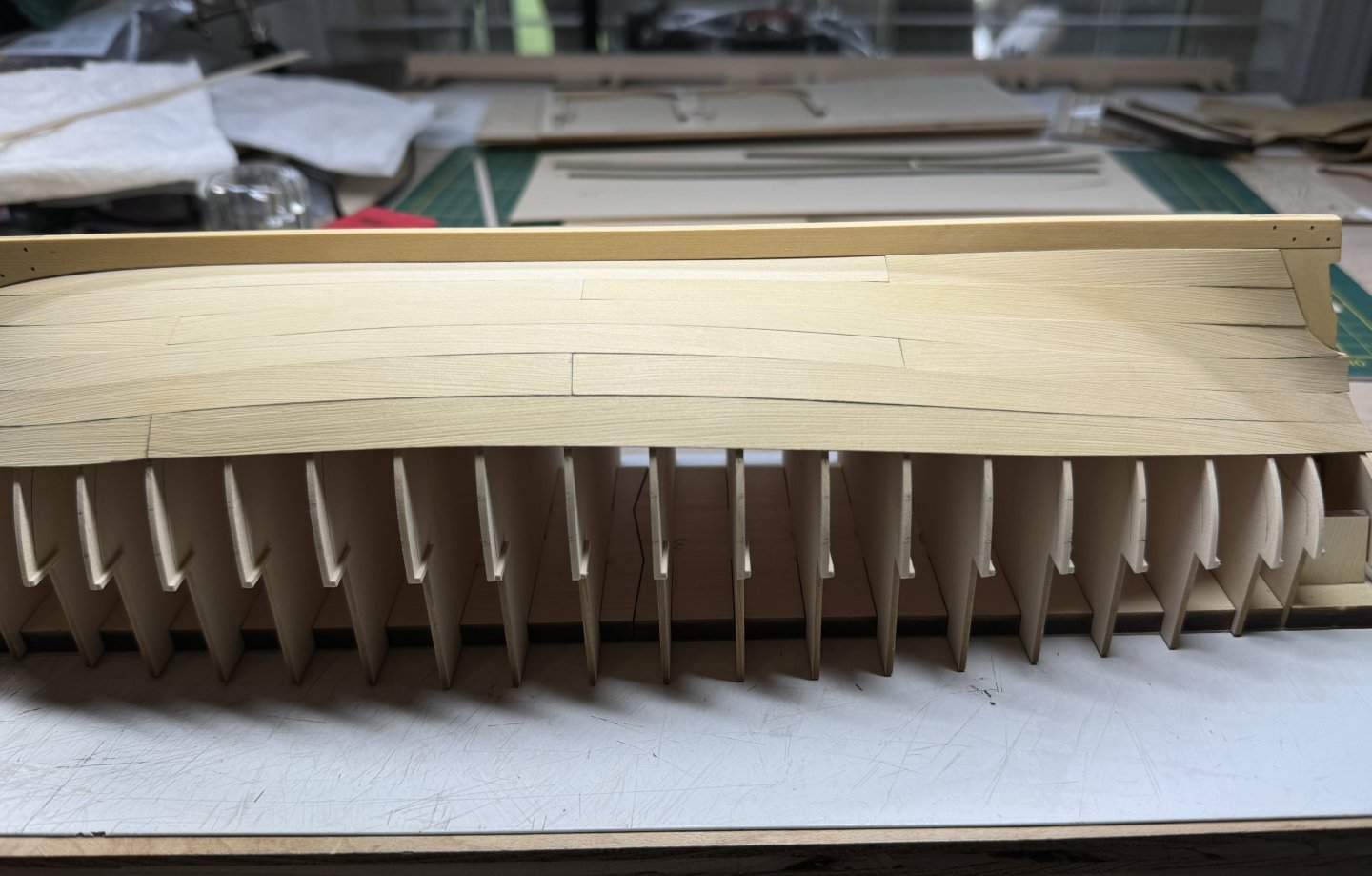

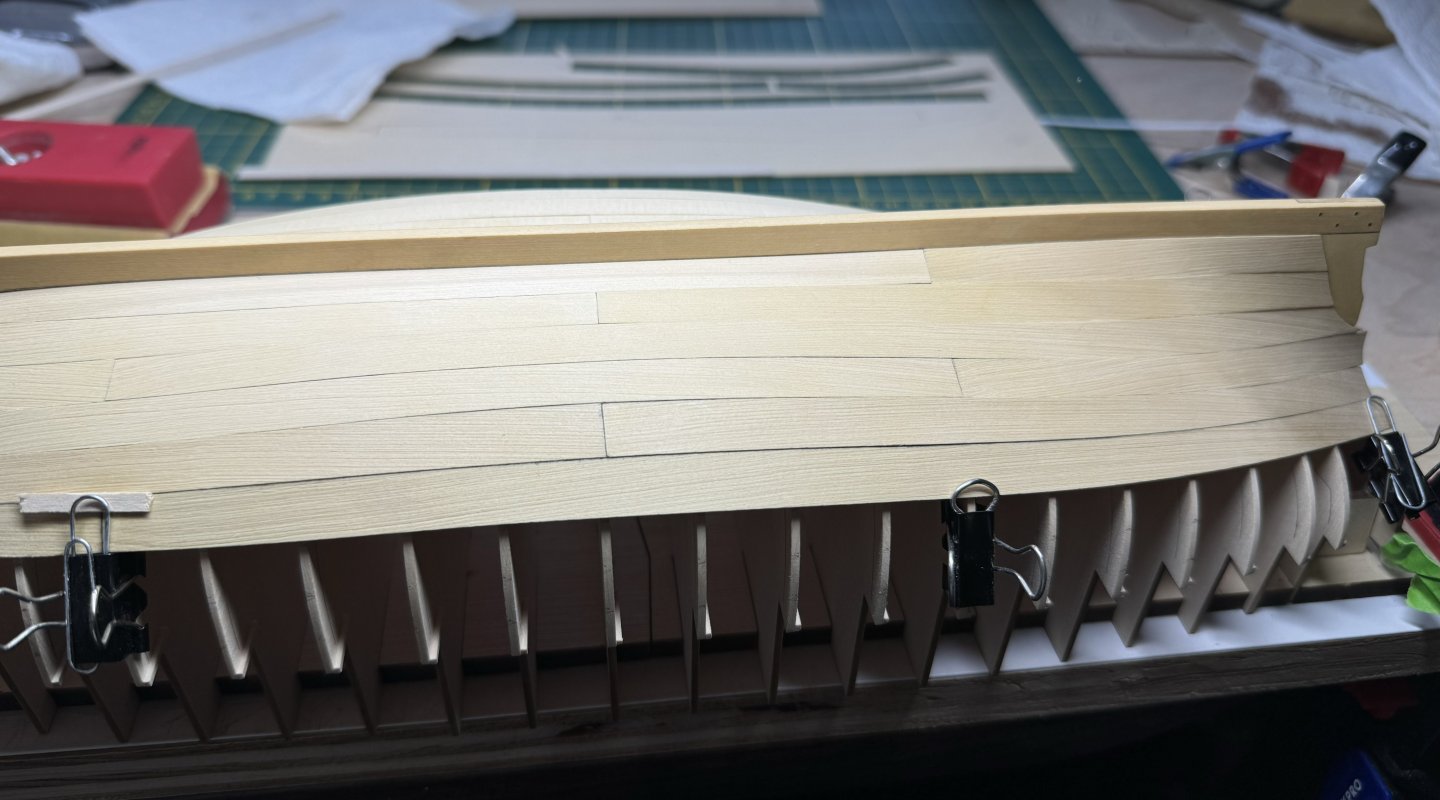

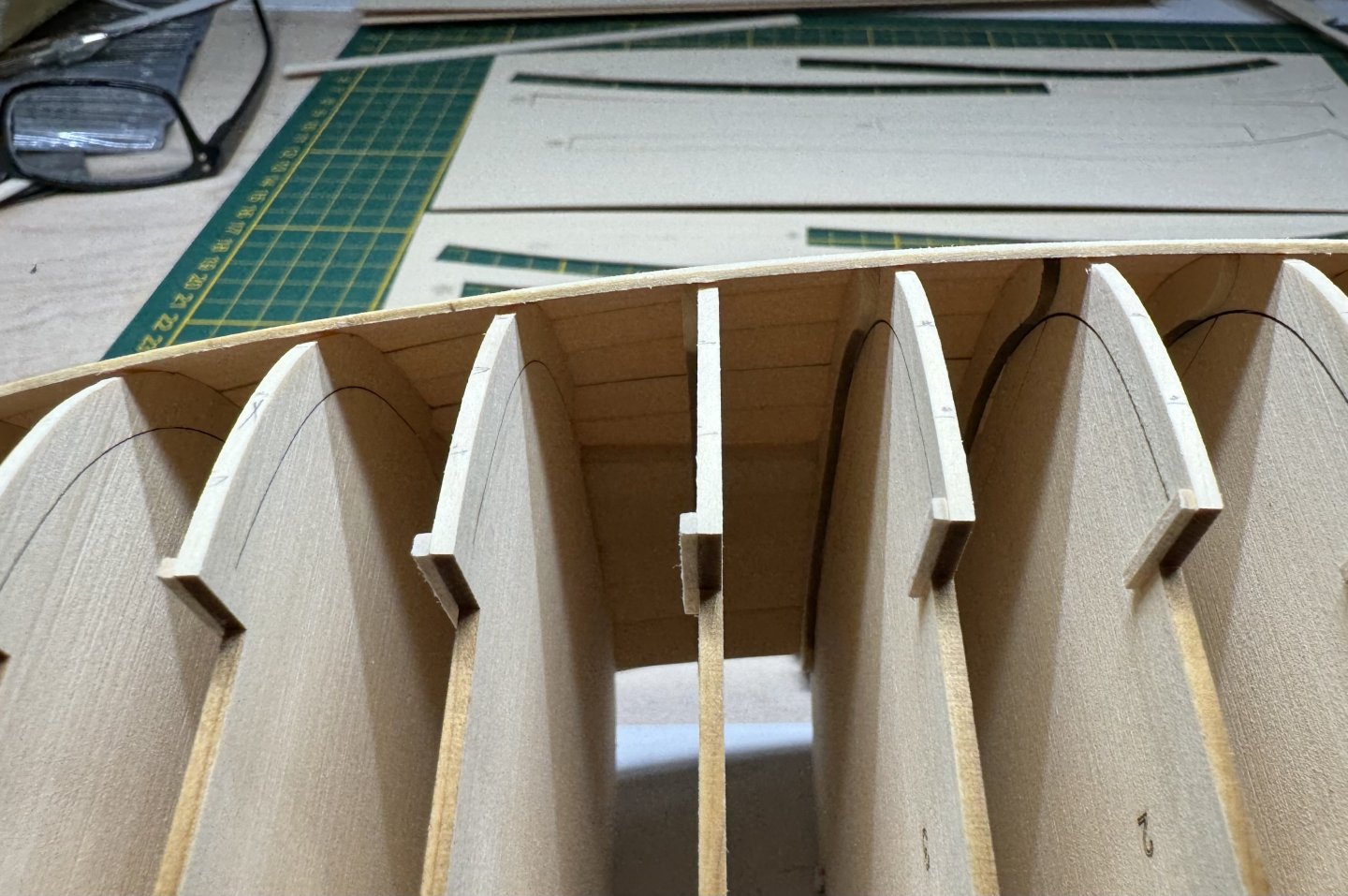

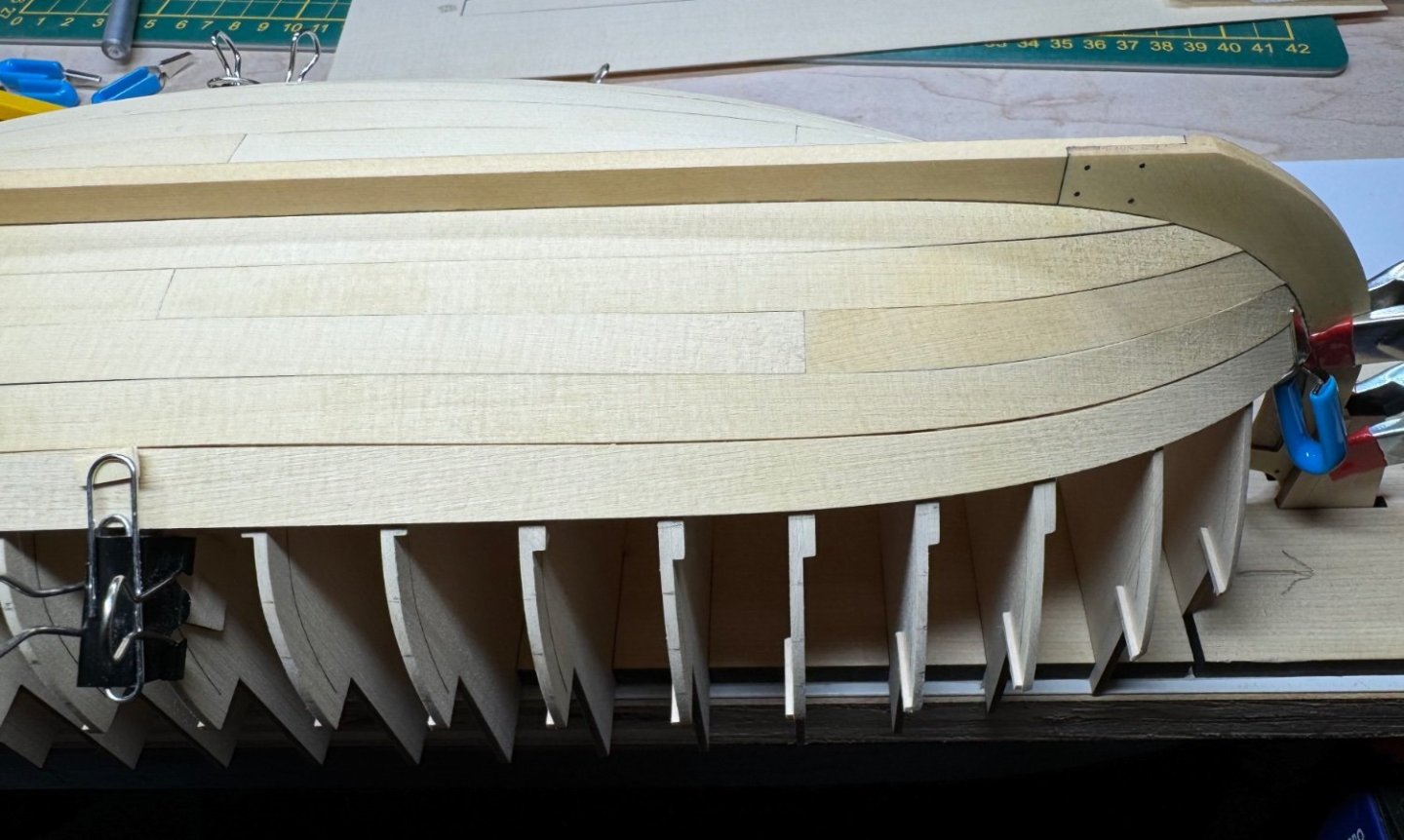

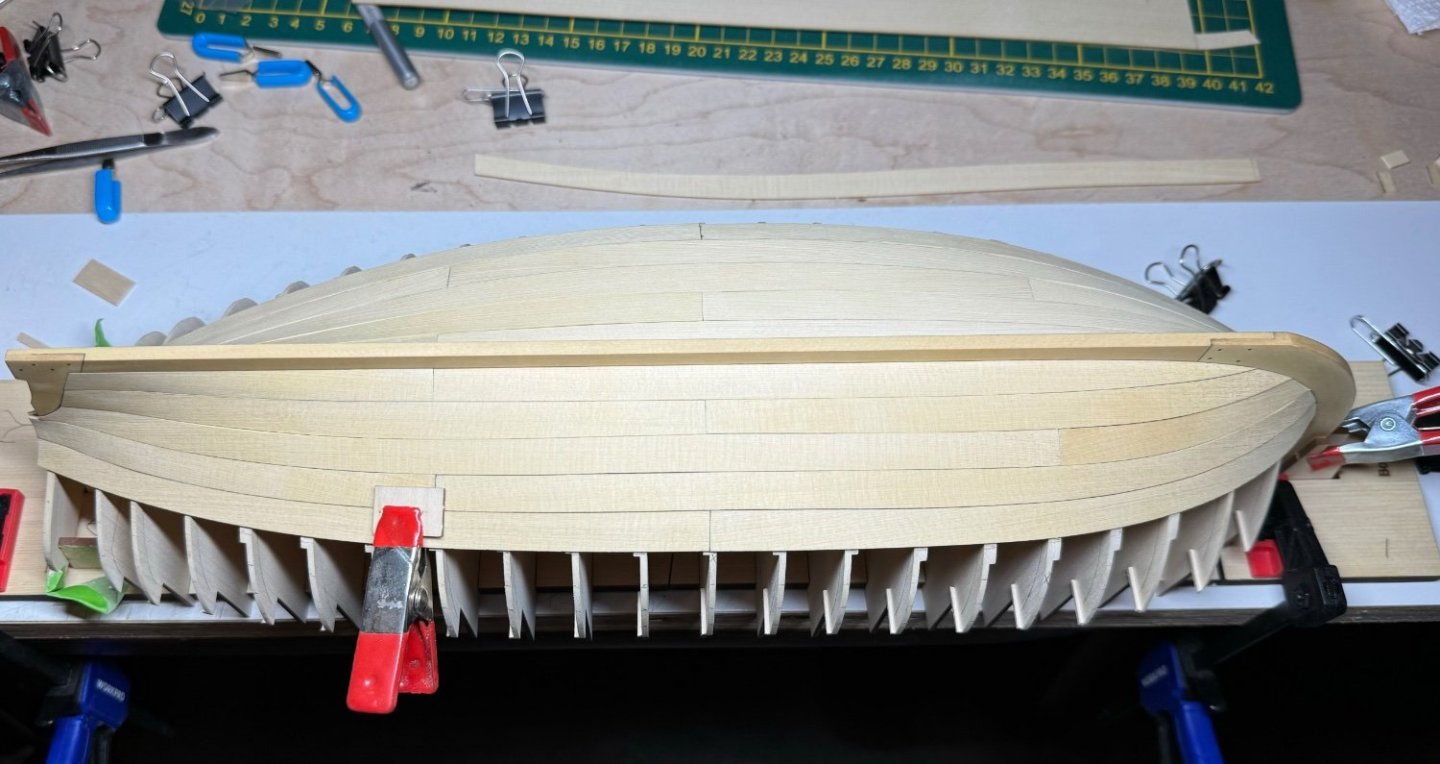

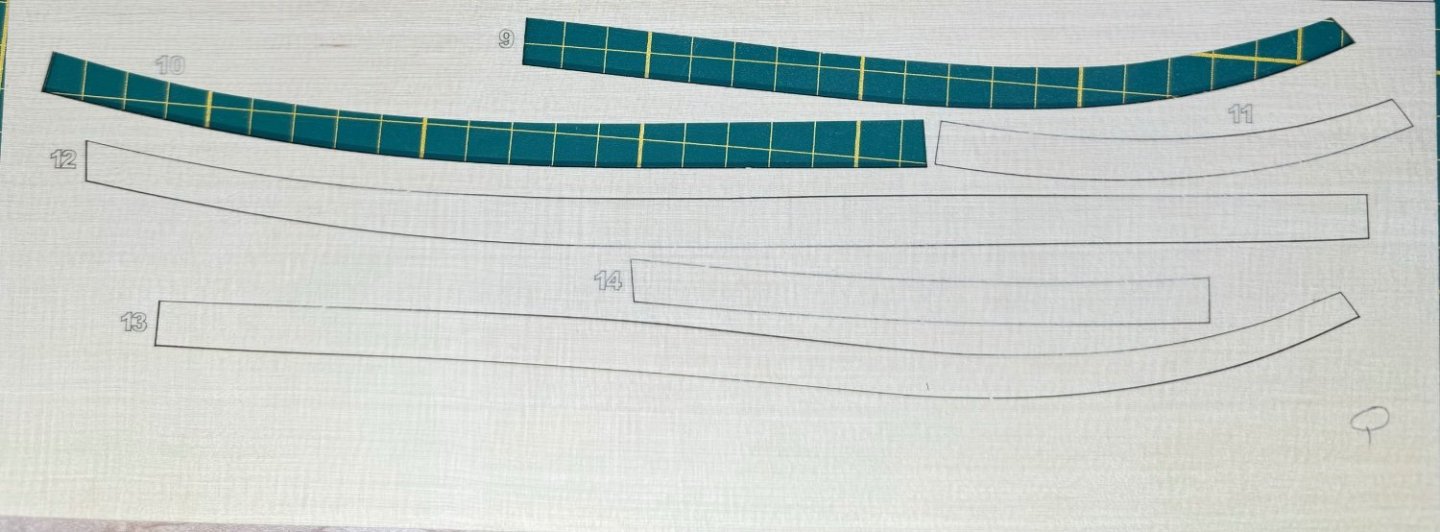

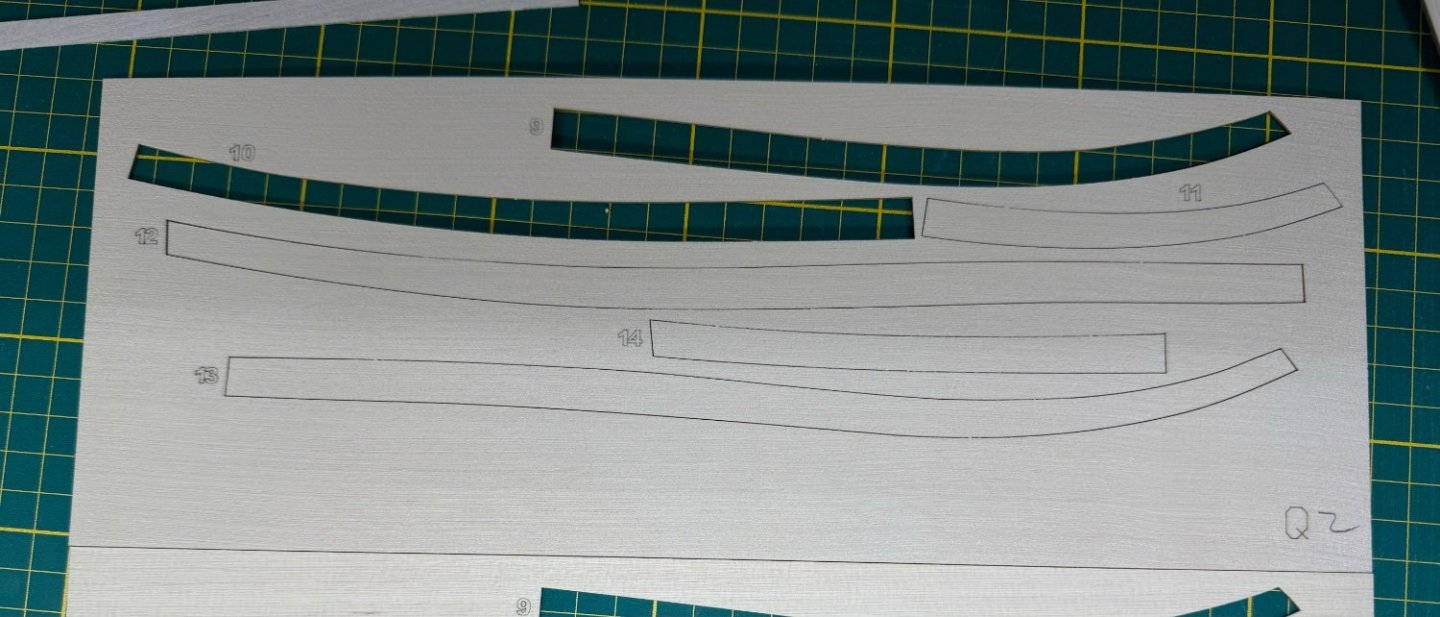

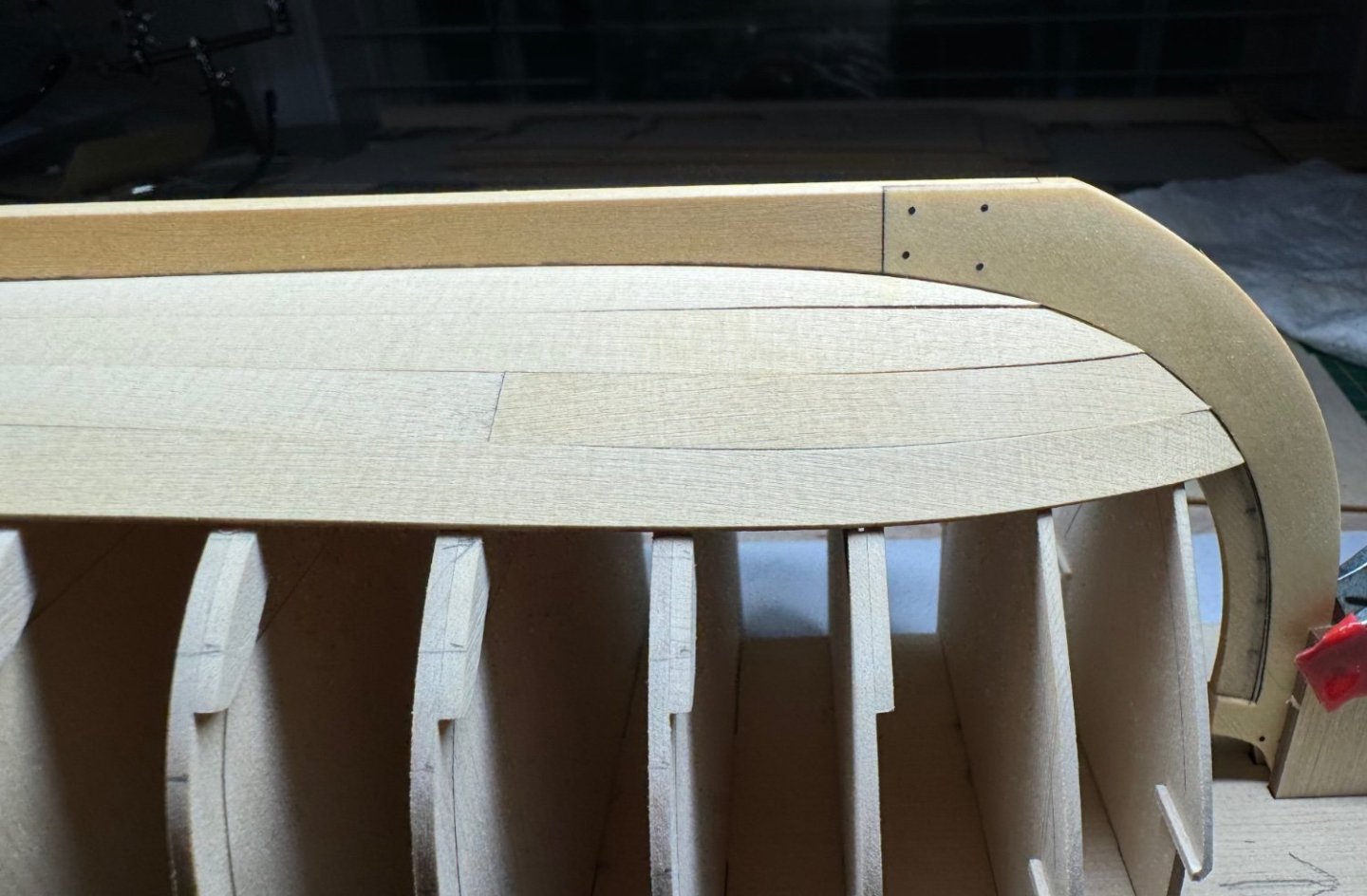

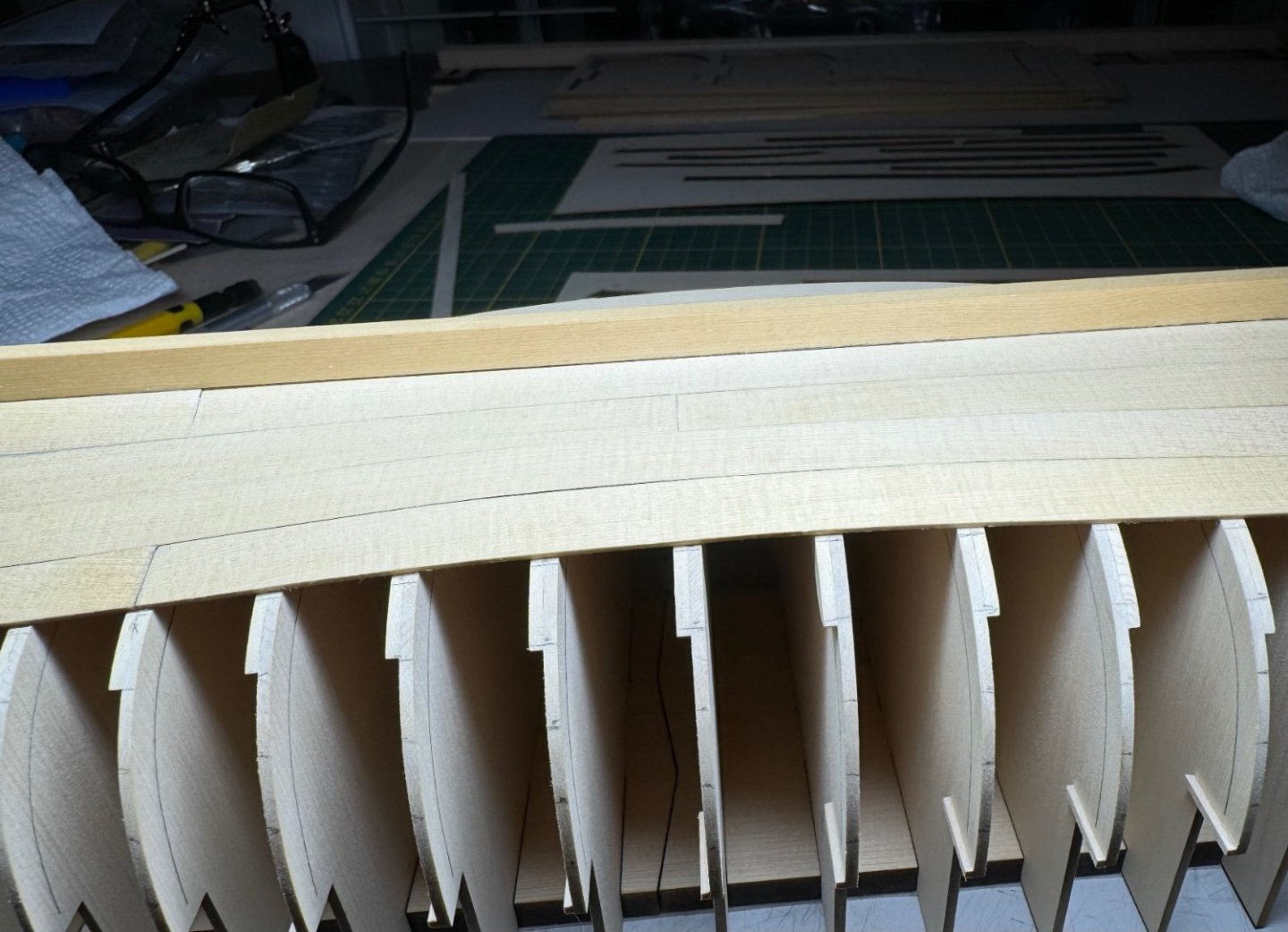

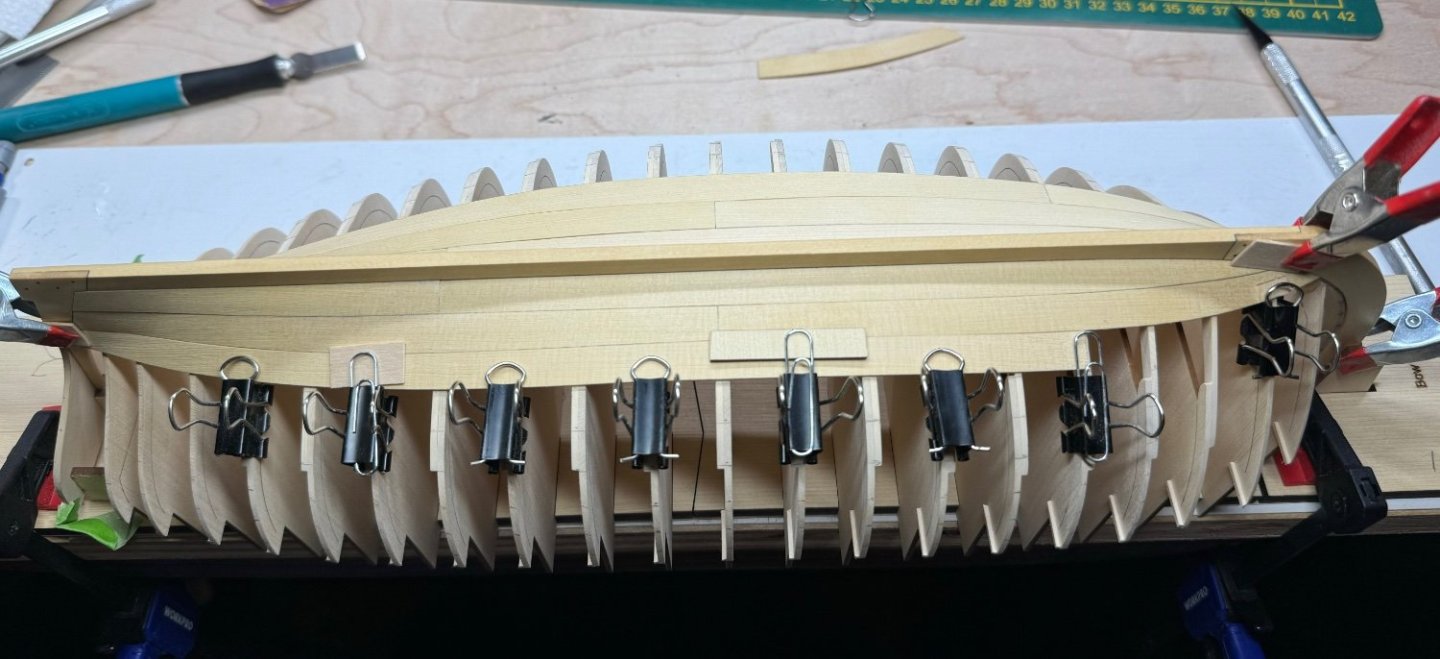

Anyone that has built this boat won’t see anything new, if you have not and are looking thru this log, the sheets are lettered and strakes numbered. The last picture here. Q and Q2 are the same sheets. 9 and 10 are placed. They fit close without any trimming/fitting/sanding. Which I thought was working out nicely. After a bit of fitting they look good glued in place. When I flip this over I’ll post what it looks like inside untouched after the frames are cut free. I’m getting quicker placing the strakes, maybe not to long.

-

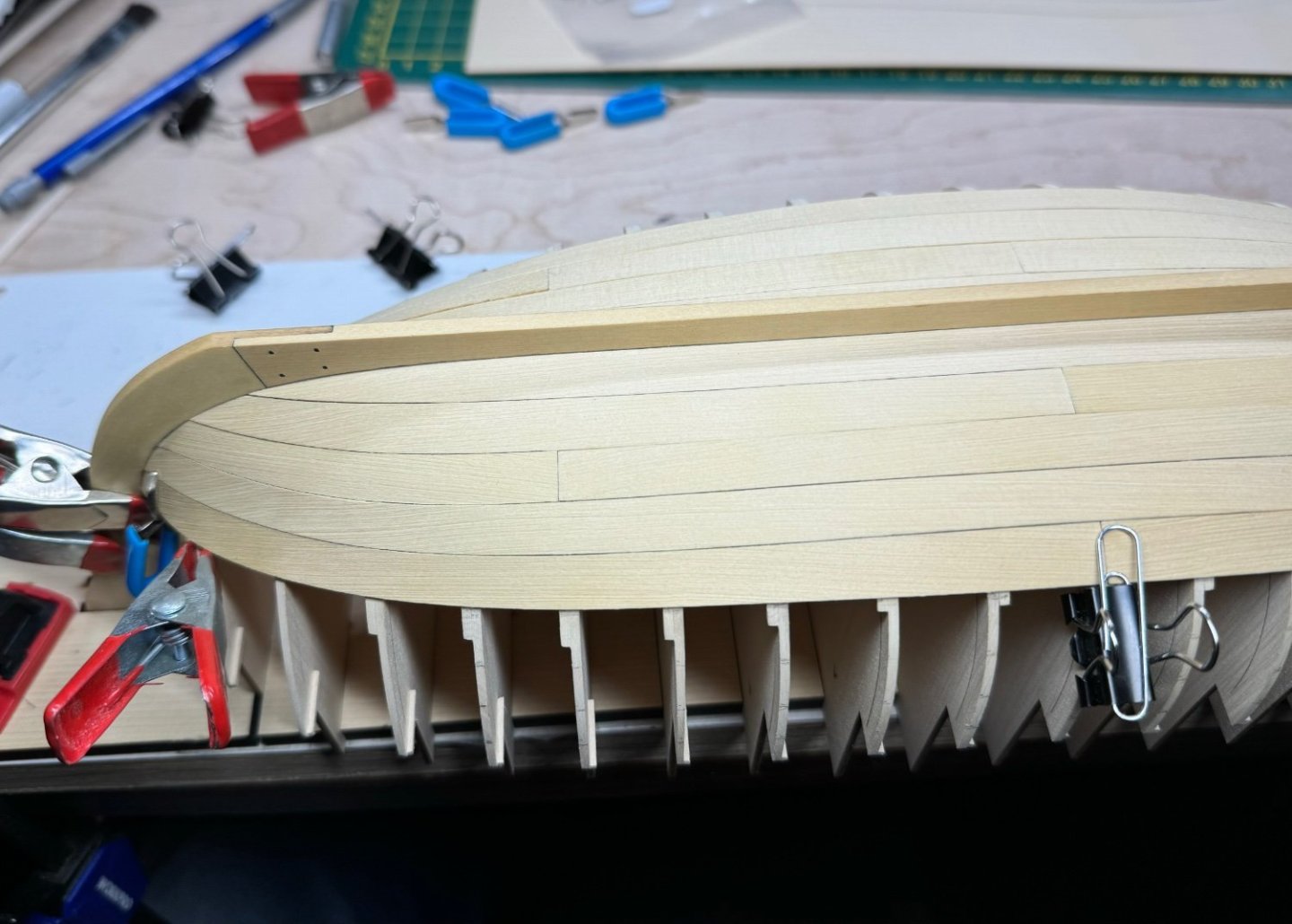

7-2 and 8-2 glued in placed. Changed to sheets to Q2 and Q. 9-2 placed. 10-2 hanging out wondering when it might get glued, it’s waiting until it might hold that curve good. I guess everyone hopes the inside looks ok when it’s gets flipped. The 9-10 strake is less than 1mm away from the tick marks, at least on the 2 side.

-

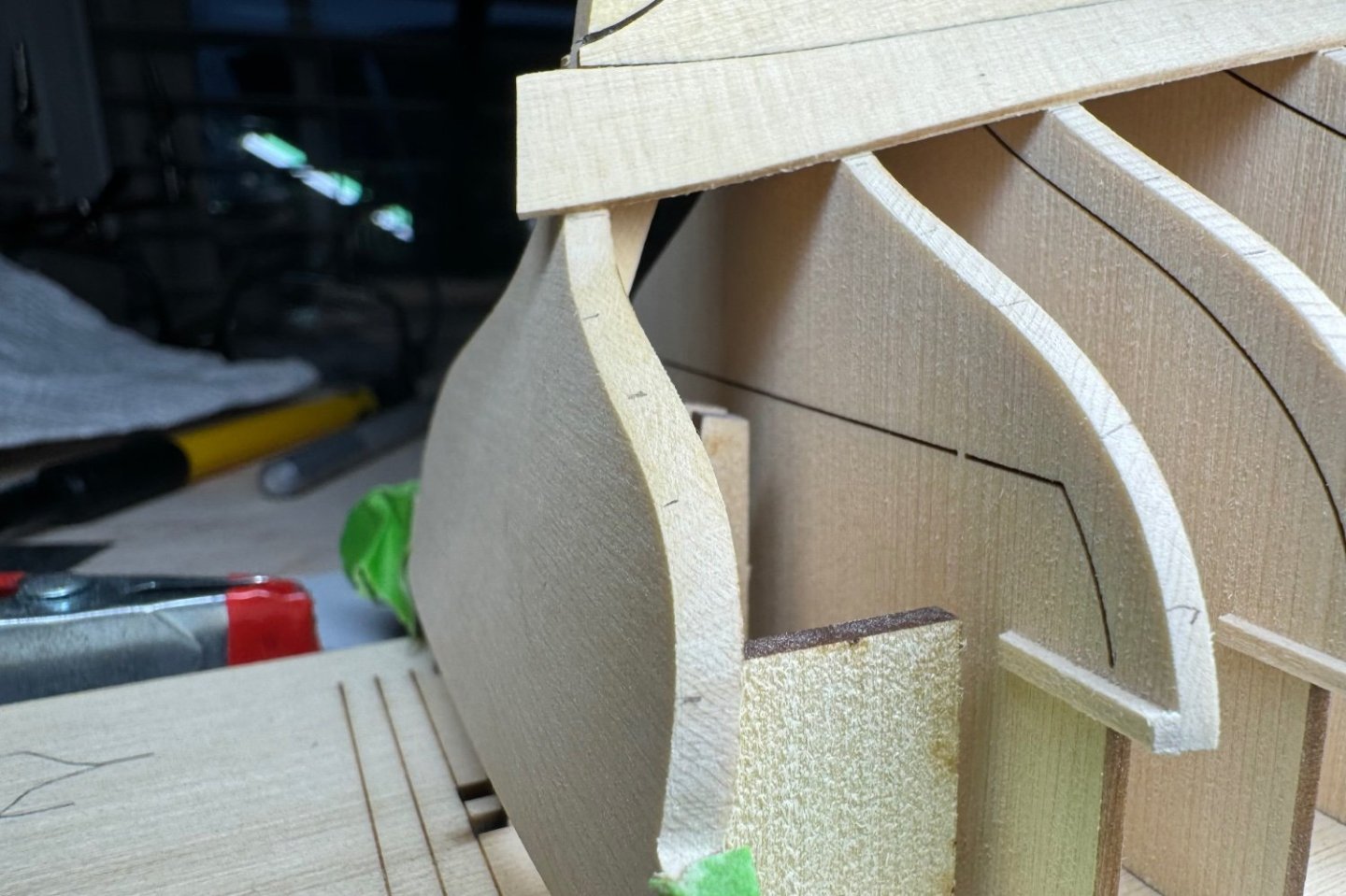

Thank you for the likes and the follows. Hope everyone enjoys the visit. Thank you for stopping in. I don’t like wordy build logs so I made my own lol. Focus. Planks 7-1 and 8-1 went well. I did not use much for clamps, I tried to glue part of 7-1 and then the other section later. I worked to get it laid down without spring up on its own. It went in very well and held the frame curve nicely. I was able to bend a spot with just heat and it held, that was neat. And I burned my fingers, or at least got them hot lol, it takes commitment to hold it, can’t use clamps or tools because it will mar the wood. Good news a drop of water makes it look brand new again if dinged. The cedar responds to water very well. But does smell like wet dog fur when damp haha. I can see some spots I need to pull down when I get it flipped over. I should make notes but it wont be hard to find them. Some spots are springy, not much but some. I see the keel spot I need to wedge back into the rabbit. I can’t get to it well with the frames in place, it will have to wait, but it will clean up. The tick marks front (bow) and back (stern) are working out well. The tick marks in the middle are getting slightly wider, but not bad, it is consistent. We won’t tell anyone if we don’t make the sheer line correctly, will we…. I figure the marks in the middle are marked wrong by me or I’m sucking the middle line of the boat in slowly plank by plank. It’s not growing, it’s just short. As long as the sides match what can I do. EDIT, the tick marks are the transfers, the lines are below the 1/64 tape line. I marked it below so when I placed the planks the lines could still be seen. I did not extend the small tick marks once marked, so I knew what they were. The older solid lines under the planks are the glue line, don't go below. I'm used to marking on the planks to line up stuff. As it will be WOP finished I'm avoiding marking on the inside or outside face of the plank, I'm flying blind from my normal planking method but its going ok. So far the keel planks have kept me on track. 4 floating ends on the next planks might trip me up but its not enough to matter sliding a plank fore and aft in placement. 8-1 is laid up tight against the transom with no gap. Last I looked. Happy about that. The build board had a small twist in it when I got done with planks 5 and 6 on both sides. I’ve held it down with clamps on both ends so I can push against it and it not go flying around on the table. When I pulled it up to flip it for 8-2 and 7-2 planks it was flat again. As I come up the sides the twist will lock and or not flex anymore. Hopefully it’s not a banana when I’m done lol. Highly recommended to hold the build board down flat. I’d like to not people and keep doing the boat but my business doesn’t run well without me. I might be done with planking by April, slow and steady. About 1.5 hours per plank. I figure I’m out 35-38 hours in right now. That’s around $5291 in labor cost for my business. I’ll be gone for a week this month so I might not make it unless I get a good day or 2 on the weekend.

-

OUTSTANDING! It looks wonderful.

- 88 replies

-

- Muscongus Bay Lobster Smack

- Finished

-

(and 1 more)

Tagged with:

-

Thank you for the words of encouragement and the likes and follows. I always see something I could do better, after the glue sets. Plank 6 side 1 didn’t curve at the bow. It’s flat against the bow rabbit. On a normal mortal boat I could fill it with some filler. I wish it was a little bit better in places. Some places look great. I’ve been very careful with the hull. So far I’ve hammered on the keel with the sanding block, the clamps, finger nails, sanding files and my pencils. None of it on purpose. WOP seems darn durable. I know. Clamps.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.