-

Posts

400 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kgstakes

-

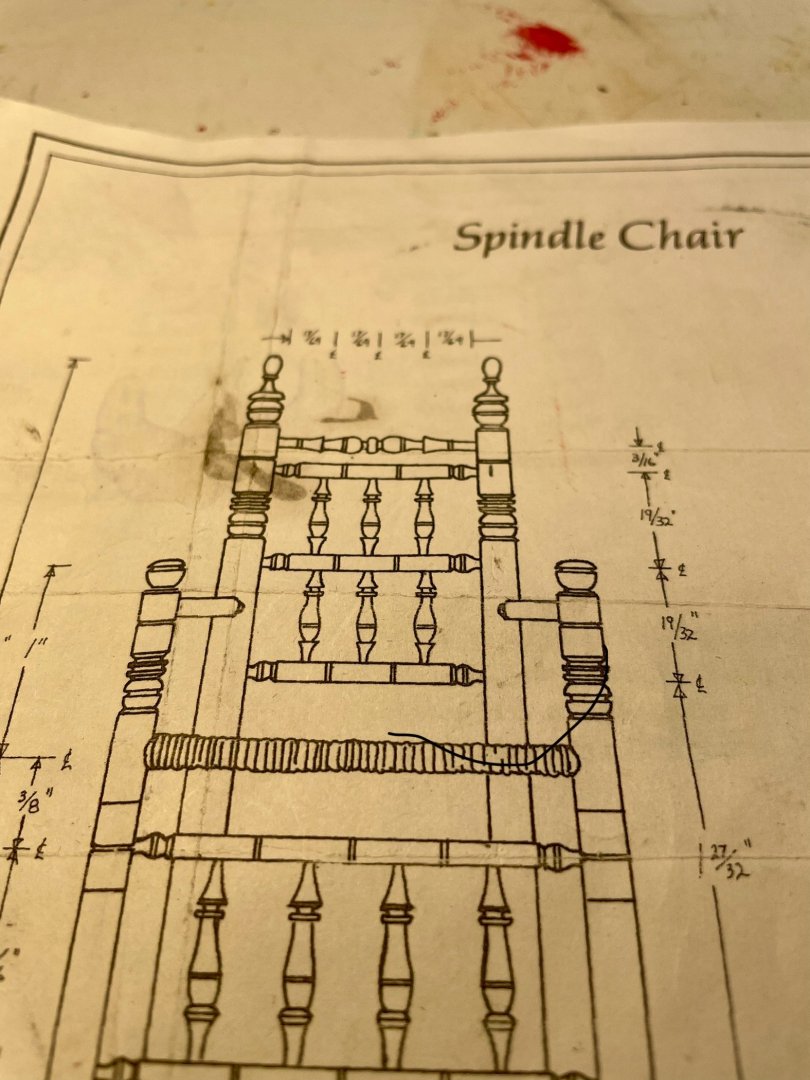

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

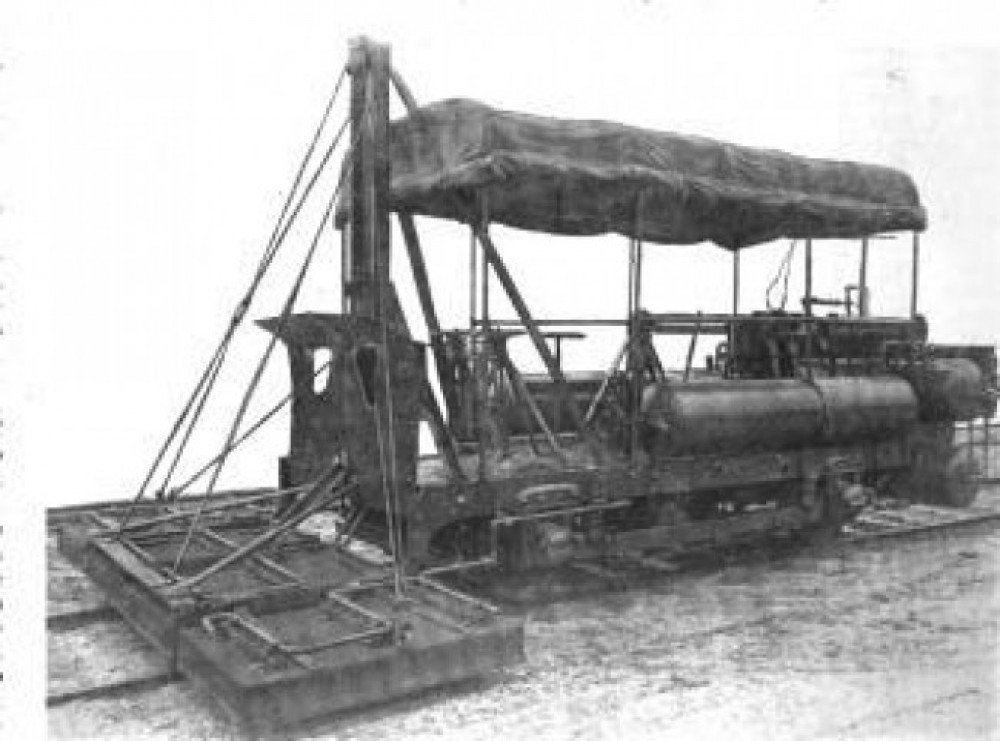

very true years ago with steam locomotives and early settlements the landscape was totally different than it is today. i lived in Colorado for many years and places in the mountains that are treed now were bare mountains back in the days of steam and mining. i was just showing ideas and i forgot about the photos you were trying to create in miniature. you do nice work and look forward to the progress.

-

Just some ideas for ground cover. Most is woodland scenics some trees are scenic express and the pine trees are made by me and the big tree behind the building is made from a sagebrush branch and then ground foam for foliage. Don't forget to add some branches or sticks as dead fall trees or dead standing trees. Makes the scene more believable.

-

ground up leaves and small sticks make great looking scenery. Ground foam (woodland scenics) and Scenic Express both have lots of scenery material to choose from. You can make your own trees or you can also buy them. I usually do a mix of scratch built trees and store bought trees. Your scenery looks great!! Keep up the good work, can't wait to see more.

-

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

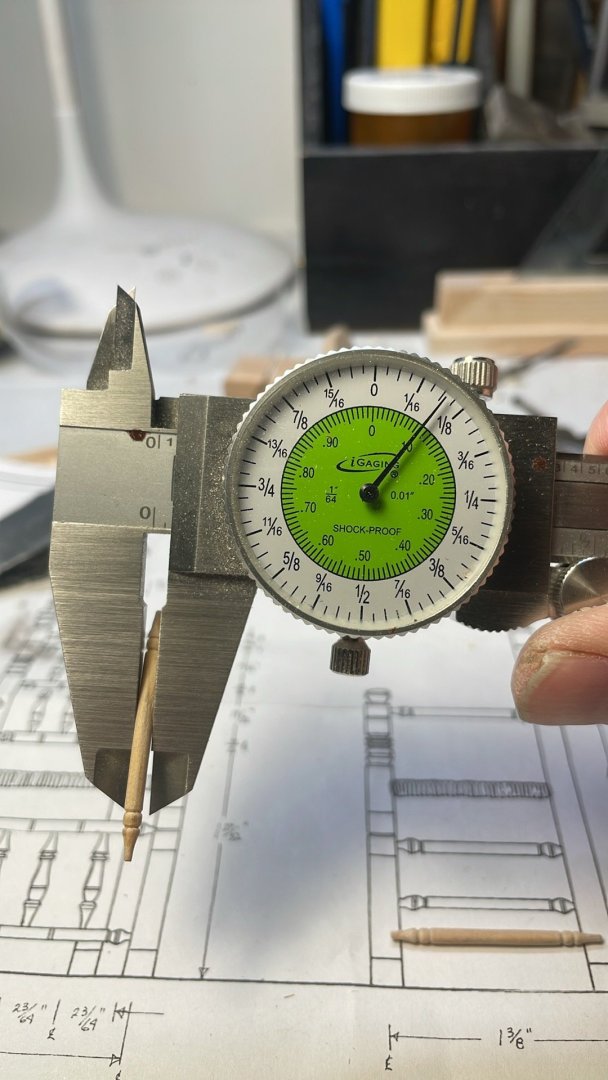

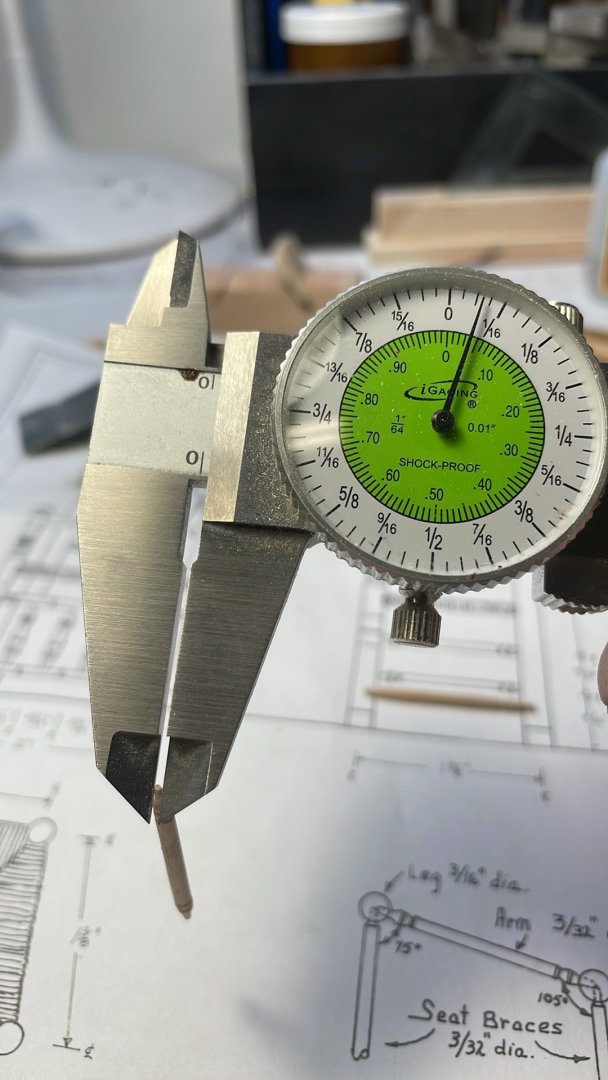

Few more pieces done have just a few more and then glue up, put a finish on it and then start on seat cushion. -

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

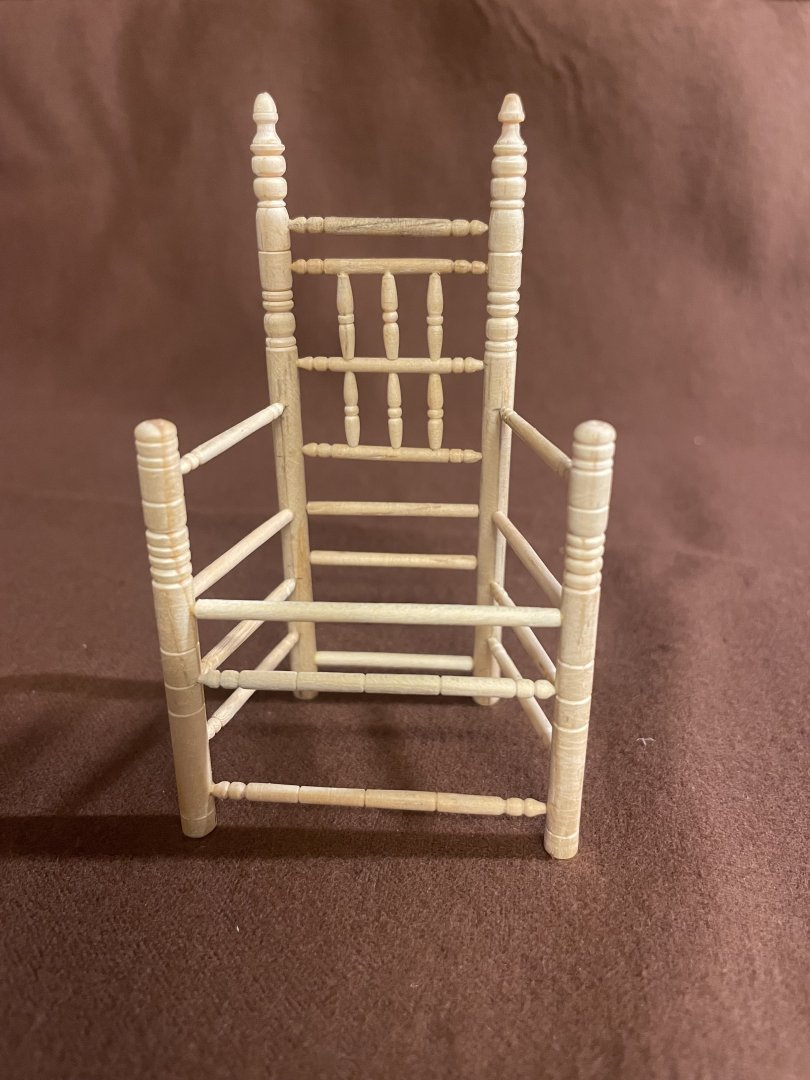

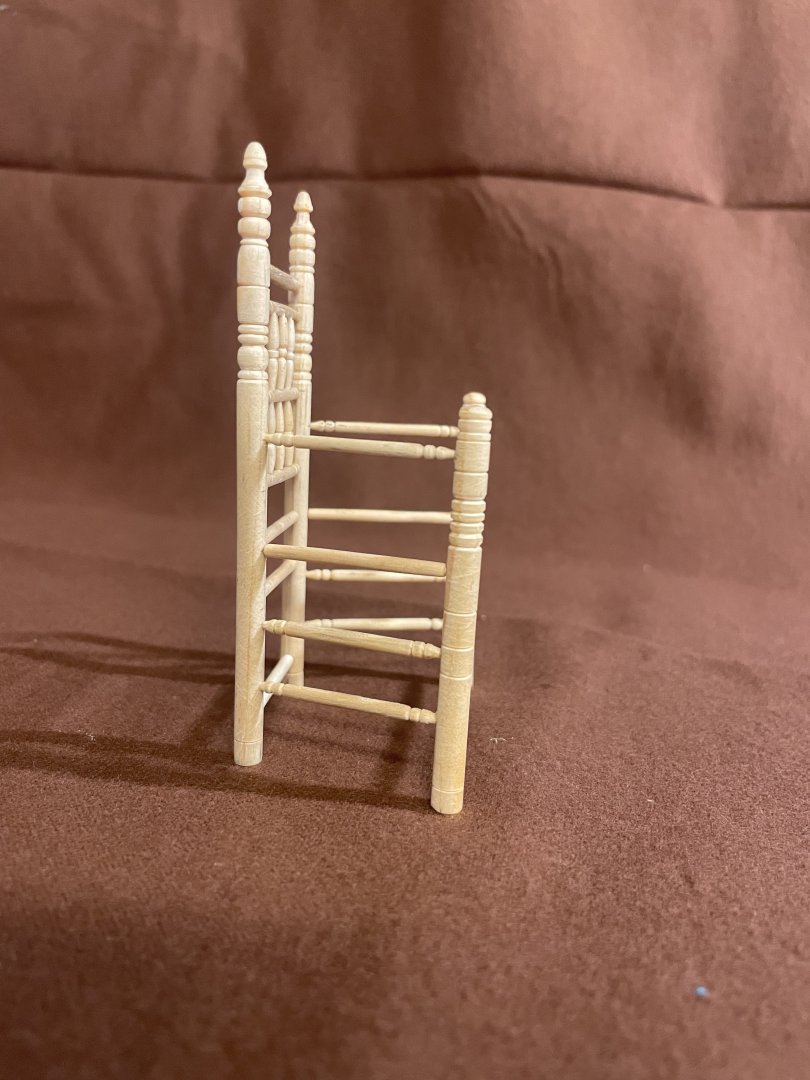

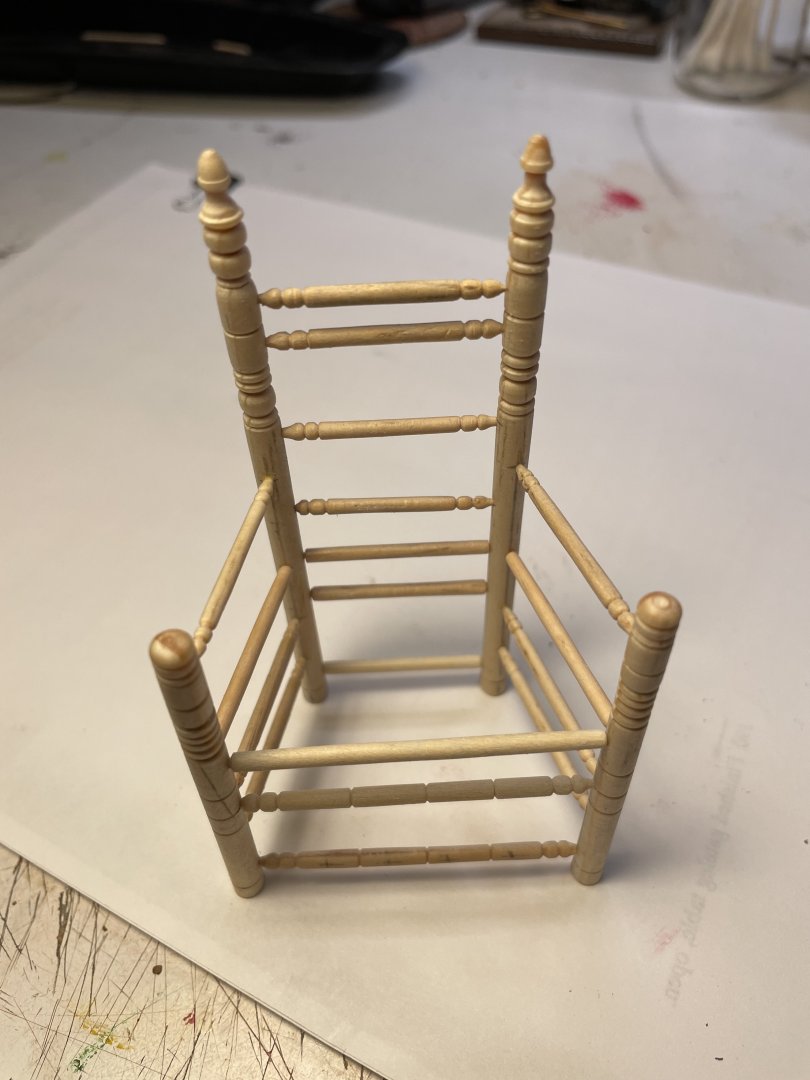

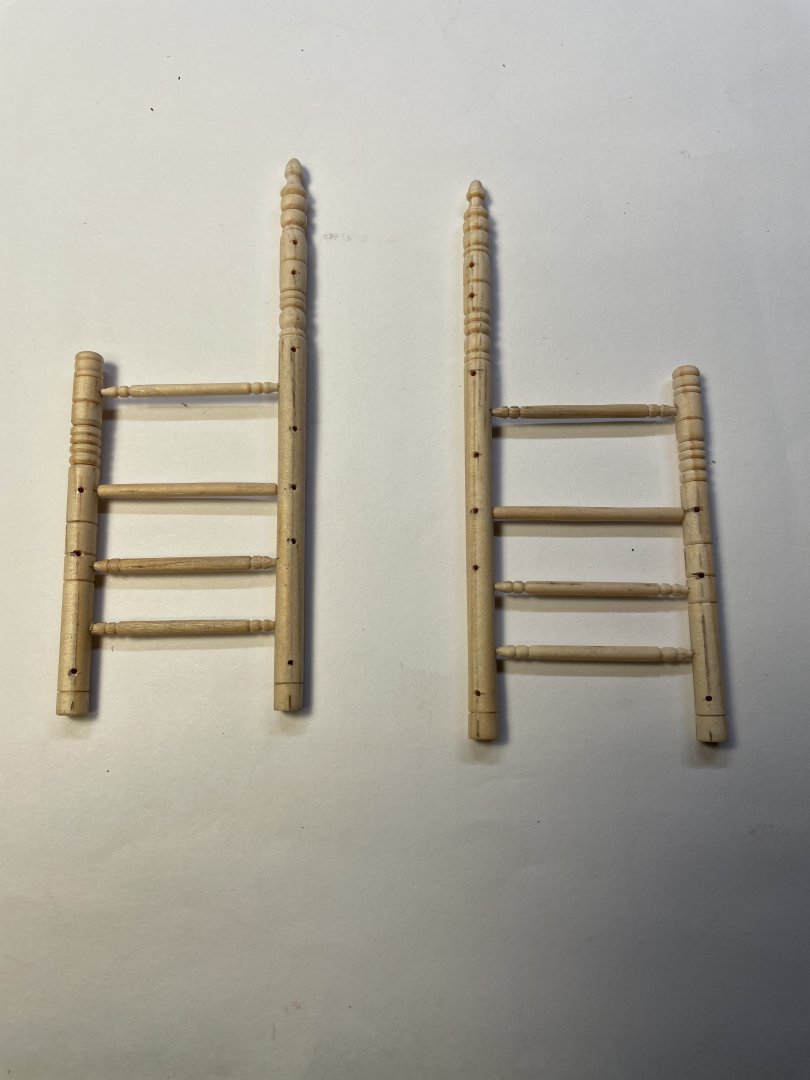

Test fit most of the pieces still have the small backrest pieces to turn. It’s coming out great, at least I think so for basically my first big ok small turning project. -

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

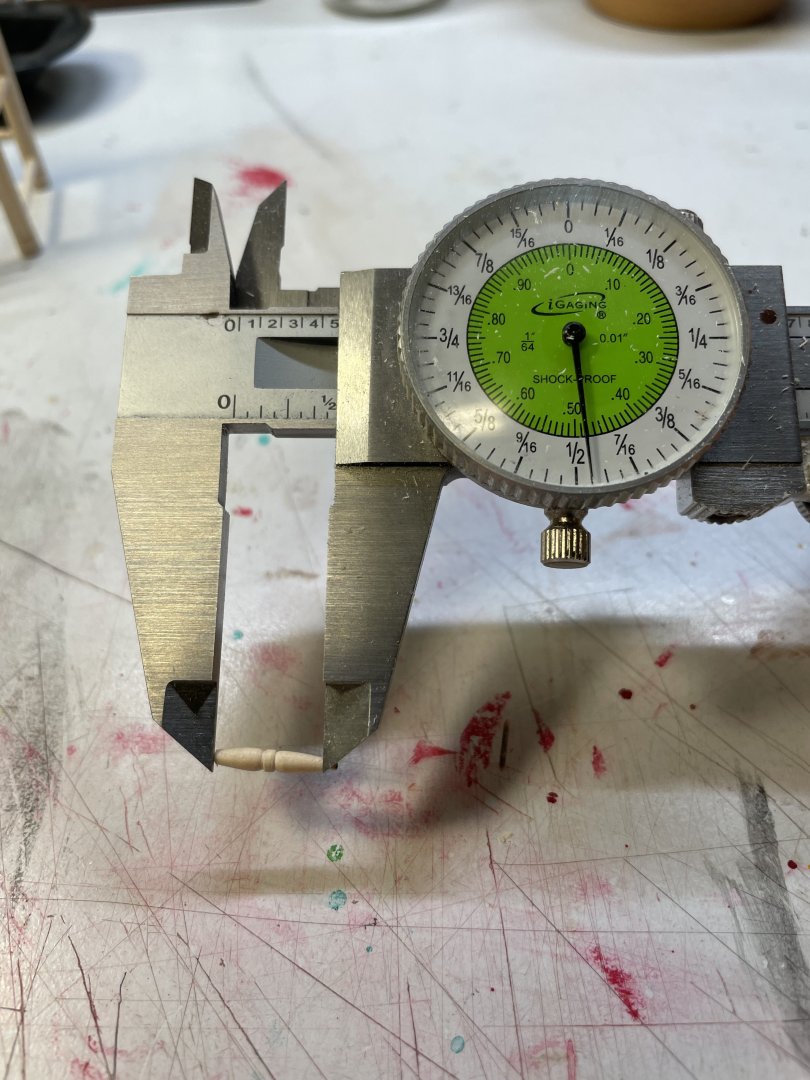

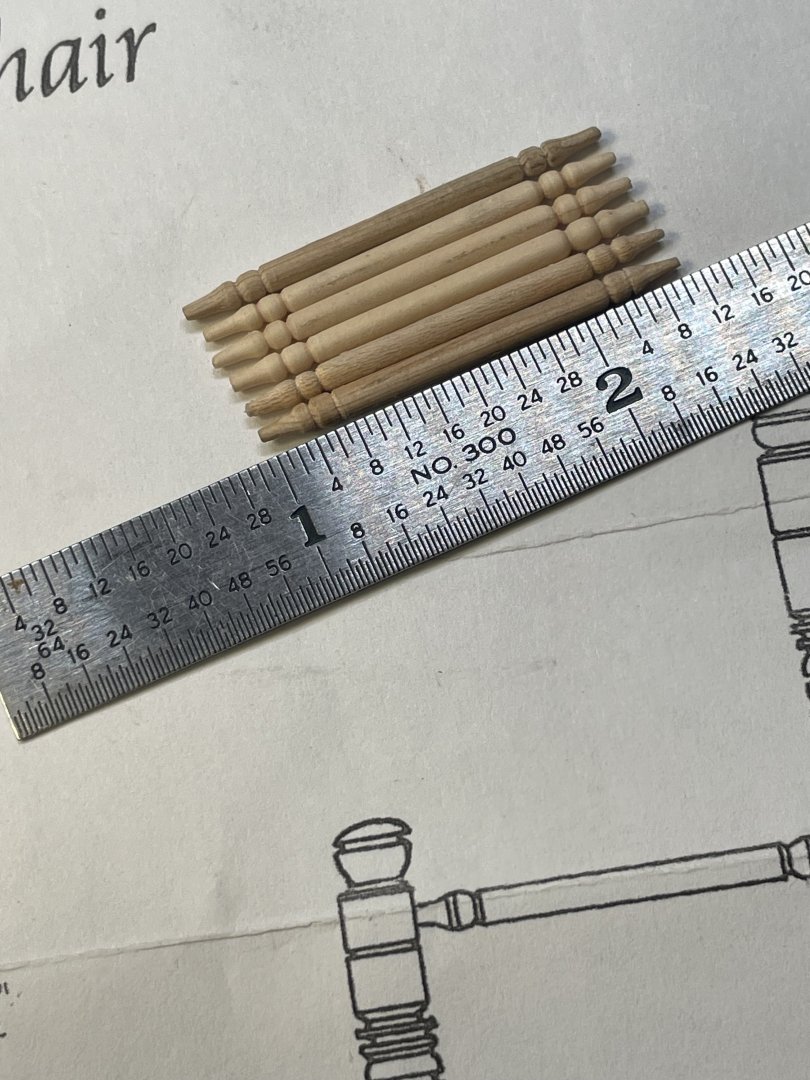

Doing some more turning. Been learning more about this little lathe. What possible to turn (wood wise) and not possible to turn. Most important thing I’ve learned is constant pressure on tool post and very very light cuts. Seems for every two I get right, I’ve trashed 4-5 pieces. Here is a picture of what I’ve got done so far. Have 4 more spindles to turn and they are the smallest ones. Then figure out where all the holes go for the tenons on the spindles. And not mess any up🤪🤪. -

Paul Ron, When I was building my first scale horse drawn vehicle I thought how in the heck am I going to get a thin pinstripe. I tried the drafting pen and it worked !! Been using that trick ever since. Give it a try, it takes some practice (on scrap painted surface) but once you get the technique down, it looks a lot better than trying to use decals, or try masking for a stripe. Let me know how it works for you.

-

I used just regular old craft paint for striping. So if I messed up. It was easy to remove without any damage to the base color. After thinning the paint (in a spare jar) I would dip the pen in the jar to load it then wipe the outside of it on a cloth (careful not to press too hard or you might unload the pen) and then do your striping. Using a straight edge you have to have it off the part you want to strip or you run the risk of the paint running under your straight edge. The trim on the coach help me with this but you could easily glue small blocks on just enough to raise it and it will help a lot. free hand I’m not that steady anymore so some free hand stuff is a bit shaky but I got it done. i tried Vallejo paints and for some reason I couldn’t get it to work. I would think any paint should work just get the consistence right. You want it to flow out smooth but not too thin to where when you start it blobs before you strip. Hope that makes since. Hope this helps answer some questions you all have. Paint pens that you can buy are a good choice to, I just have done it this way before so I knew what to expect.

-

I've used this on other models and it works great - if you get the paint thinned enough but not too much. I couldn't tell you exactly how much thinner to paint but look for the consistence of ink or just a bit thicker. Just trail and error. Here's a video and some pictures of my pinstriping. Video.mov

-

This is looking great!! I been thinking about doing one of these models but first have to finish up the one model I'm working on. How is the overall build ? Would it be a good model to build for a second ship build ? I built the Mississippi Riverboat by Occre and that was my first build.

- 25 replies

-

Spindle chair by kgstakes - FINISHED - 1/12th scale

kgstakes replied to kgstakes's topic in Non-ship/categorised builds

-

Gloster Meteor F8 by AJohnson - Airfix -1/48- PLASTIC

kgstakes replied to AJohnson's topic in Completed non-ship models

Question, what are the two upright pieces on the wing tips do? The details look great and the paint job is excellent. Great job!! -

Gloster Javelin FAW.9 by AJohnson - Airfix -1/48- PLASTIC

kgstakes replied to AJohnson's topic in Completed non-ship models

I like the paint work, looks great. And the "dirt" on the steps is a nice touch. Makes it look real. Great job!!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.