Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

213 -

Joined

-

Last visited

Reputation Activity

-

-

FreekS reacted to Remcohe in Hr. Ms. O 19 1938 by Piet - FINISHED - scale 1:50 - submarine of the Royal Navy Netherlands in service 1939 - 1945

FreekS reacted to Remcohe in Hr. Ms. O 19 1938 by Piet - FINISHED - scale 1:50 - submarine of the Royal Navy Netherlands in service 1939 - 1945

You are welcome Piet. I'm glad I could be of some help to realize your dream, and it was fun too chasing old drawings.

Remco

-

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hello all,

Hull is closed! Last planks have been shaped and mounted and after a night drying I used the band sander to shape the planks fit with the bow and stern pieces. Lots of sanding comes next - probably first with a little electric sander then with regular sandpaper.

Glass"fabric" has been ordered with low viscosity epoxy resin to seal the outside with a protective layer. Will need to read up on how this is done !

After that comes the point when the hull needs to be sawed in two for attaching the bayonet. brrrr.

Regards. Freek

-

FreekS reacted to Piet in Hr. Ms. O 19 1938 by Piet - FINISHED - scale 1:50 - submarine of the Royal Navy Netherlands in service 1939 - 1945

FreekS reacted to Piet in Hr. Ms. O 19 1938 by Piet - FINISHED - scale 1:50 - submarine of the Royal Navy Netherlands in service 1939 - 1945

Thanks to all who came and visited my dockyard and your "like" votes.

Today we reached a milestone of sorts. The anchor is finished and the cowling is cemented on and primed. I also painted the inside of the anchor "house" dark grey.

It was getting late and to let the primer cure, and it was close to quitting time anyhow, 1700 hours. So I went inside and had a well deserved brew. I showed the anchor to the Admiral and she wants one on a necklace - - - hmmmm - - - not No, she really likes it and that's a good sign

In trying to fit the anchor into it's little house I had to remove some more wood from the inside and in the process rubbed some of the paint off the hull. No matter how careful I was, well - - - stuff happens. This is no problem at all, it's just the paint and that area will be painted green anyhow. I finally got the anchor to slide in effortlessly, like it knew it knew it belonged there. That made me a happy camper.

Can't wait to paint that little sucker flat black - - - tomorrow and stow it out of the way..

NOTE, The blank pic locations cannot be reinstalled because somehow I must have forgotten to [ut them into my photo file. I do have them in my Word doc but they cannot be transferred to this post. Edited 05/ to/2014.

Now I'm close to painting the green on the topside, whoopee - - -

The completed anchor, unprimed and painted. Well, okay, it has a little battle damage looks like

The completed anchor, unprimed and painted., from another angle.

file:///Users/PeterV/Desktop/Picture%20clipping.pictClipping

Here we see the anchor stowed in its little "house." There is just enough room for it and it's deployment.

I have cemented the anchor cowling on and applied some epoxy putty to the front for hydrodynamic flow. It's not metal but if yuns don't tell I won't either Looks okay from ten thousand feet we used to say in the airplane business

I couldn't resist letting anchor, now primed, hanging down from it's cable. Ah yes, an unorthodox way but so what

Cheers,

-

FreekS got a reaction from yvesvidal in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from yvesvidal in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hello all,

Hull is closed! Last planks have been shaped and mounted and after a night drying I used the band sander to shape the planks fit with the bow and stern pieces. Lots of sanding comes next - probably first with a little electric sander then with regular sandpaper.

Glass"fabric" has been ordered with low viscosity epoxy resin to seal the outside with a protective layer. Will need to read up on how this is done !

After that comes the point when the hull needs to be sawed in two for attaching the bayonet. brrrr.

Regards. Freek

-

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hello all,

Hull is closed! Last planks have been shaped and mounted and after a night drying I used the band sander to shape the planks fit with the bow and stern pieces. Lots of sanding comes next - probably first with a little electric sander then with regular sandpaper.

Glass"fabric" has been ordered with low viscosity epoxy resin to seal the outside with a protective layer. Will need to read up on how this is done !

After that comes the point when the hull needs to be sawed in two for attaching the bayonet. brrrr.

Regards. Freek

-

FreekS got a reaction from SailorGreg in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from SailorGreg in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hello all,

Hull is closed! Last planks have been shaped and mounted and after a night drying I used the band sander to shape the planks fit with the bow and stern pieces. Lots of sanding comes next - probably first with a little electric sander then with regular sandpaper.

Glass"fabric" has been ordered with low viscosity epoxy resin to seal the outside with a protective layer. Will need to read up on how this is done !

After that comes the point when the hull needs to be sawed in two for attaching the bayonet. brrrr.

Regards. Freek

-

FreekS got a reaction from mtaylor in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from mtaylor in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hello all,

Hull is closed! Last planks have been shaped and mounted and after a night drying I used the band sander to shape the planks fit with the bow and stern pieces. Lots of sanding comes next - probably first with a little electric sander then with regular sandpaper.

Glass"fabric" has been ordered with low viscosity epoxy resin to seal the outside with a protective layer. Will need to read up on how this is done !

After that comes the point when the hull needs to be sawed in two for attaching the bayonet. brrrr.

Regards. Freek

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Planking is about 75% done, now I have to think about closing the gap and how to fix the last planks in place without using the small "vices" (klemmetjes).

Also in front of the boat the small plane I used to shape the planks and the Bajonet closure which just arrived from Norbert bruggen. Norbert is a legendary model sub builder in Germany and sells all sort of usefull parts.

However still lots of planking and sanding to be done!

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Ian,

The hull will be 68 cm long, and 11 cm in diameter. The original boat was only 20 meters long, and the model is 1:32.

At 125 tons displacement, the original was small, and the model will weight approximately 4 kg and have a dive tank, most likely a plastic bag, of about 500 ml

inside the model I will need to fit

- a motor with speed controller

- batteries and receiver

- pump for the dive tank (bag) with its controller

- two servo motors with pushrods controlling the planes and rudder

- quite a lot of lead to give stability and make up to 4 kg.

The boat will be very full!

Here's another picture of the original

Freek

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Thanks for the kind comments on my rubber motor Torpedo's!

Back to planking the hull.

I'm shaping each plank with a mini plane, but progress is slow. I learnt I need to ensure the plank is fully pre-bent before mounting on the hull. Six planks done and I think I have the hang of it now - though at cost of removing one after it had too much tension in bow section.

Certainly gives me a lot of respect from those of you creating much more complex hull shapes!

Freek

-

FreekS got a reaction from PacificCrossRoads in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from PacificCrossRoads in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

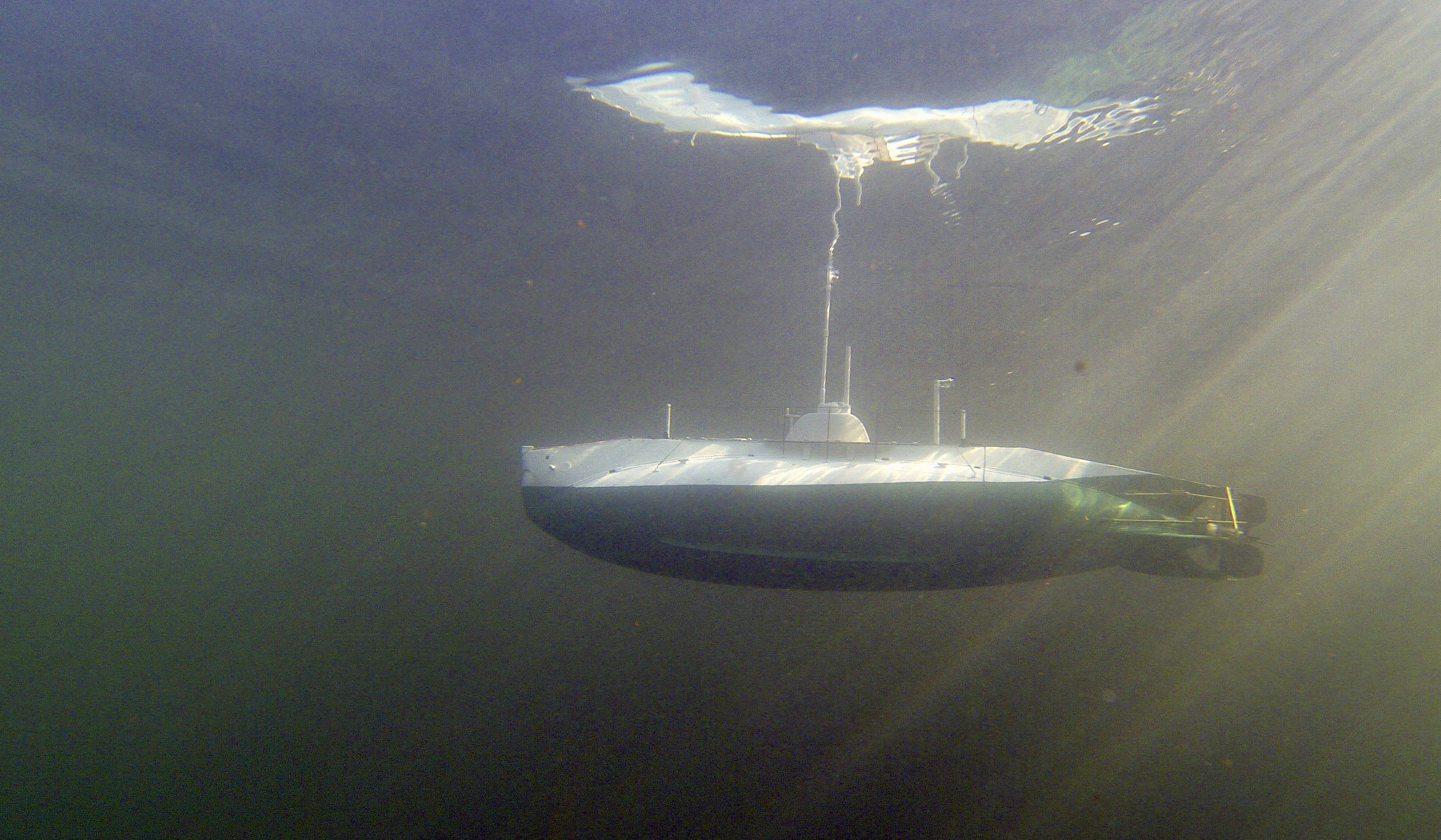

INTERMEZZO

I still owe Piet a video of the K-XVIII shooting a torpedo from the deck tubes.

Here's a mini video build log of the work I did to make the torpedoes operational - using rubber motors as the propulsion method.

Hope you will enjoy the 5 minute film - the sub shot is right at the end

Freek

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hello all,

This is my first build log on the forum, and my third ship overall. The first was a Dutch Navy contemporary frigate Zr Ms de Zeven Provincien, and the second a world war 2 submarine, Hr Ms K-XVIII. Both are radio controlled and both hulls were made with the bread and butter method. That worked out very well for these larger vessels but now I intend to build a much smaller sub and will need to be much more economical with space.

So this will be my first hull built out of wood with planks on ribs.

Hr Ms O-1 was a Holland-class submarine built as a private venture by Wilton Feijenoord and sold to the Dutch Navy when it has passed some trials set as condition for her purchase. In subsequent exercises she proved very capable to defeat the then surface ships of the Dutch Navy. She patrolled the North Sea during WW1 (but thankfully the Netherlands remained neutral throughout that conflict).

The Holland boats have beautiful lines, and I was hooked when I saw a working model of an Austrian Holland class at a meeting in Lichtenstein some years back.

Please feel free to comment and advise as I have some experience, but little in this kind of hull building especially.

Groeten, Freek

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Thanks all for your kind words!

Yesterday I managed to stiffen the pressure hull by inserting wooden blocks in-between the frames. This will help the planking of the hull - without taking away from the room inside the boat. The boat seems straight and next step is for me to verify the accuracy of the frames with a plank, and to start drawing the complex bow and stern pieces - which will be the end-points for the planking.

Also late last night we performed the age old ceremony of fixing an old coin in the keel. We selected a 1 Dutch cent coin (no longer in use since the euro) from my birth-year and with the image of Queen Juliana on it. This tradition hopefully assures 'een behouden vaart' - safe travels over the high sees.

-

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from GrandpaPhil in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Thanks Anja!

On my birthday I made the bow and stern from wood left over from my frigate project. Using a band sander I got the pieces nicely in shape and even prepared the muzzle of the single 18 inch torpedo tube that the O-1 had. More time went into checking the frames and correcting small deviations. I started making the planks, from 3 x 8 x 600 mm wood. These were narrowed at both ends and after a few hrs soaking were clamped in place to bend them into the required shape.

I made about 5 of 30 planks so have to do a few more!

Note how small O-1 is vs K-XVIII !

Freek

-

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Planking is about 75% done, now I have to think about closing the gap and how to fix the last planks in place without using the small "vices" (klemmetjes).

Also in front of the boat the small plane I used to shape the planks and the Bajonet closure which just arrived from Norbert bruggen. Norbert is a legendary model sub builder in Germany and sells all sort of usefull parts.

However still lots of planking and sanding to be done!

-

FreekS got a reaction from Elia in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elia in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Planking is about 75% done, now I have to think about closing the gap and how to fix the last planks in place without using the small "vices" (klemmetjes).

Also in front of the boat the small plane I used to shape the planks and the Bajonet closure which just arrived from Norbert bruggen. Norbert is a legendary model sub builder in Germany and sells all sort of usefull parts.

However still lots of planking and sanding to be done!

-

FreekS got a reaction from mtaylor in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from mtaylor in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Planking is about 75% done, now I have to think about closing the gap and how to fix the last planks in place without using the small "vices" (klemmetjes).

Also in front of the boat the small plane I used to shape the planks and the Bajonet closure which just arrived from Norbert bruggen. Norbert is a legendary model sub builder in Germany and sells all sort of usefull parts.

However still lots of planking and sanding to be done!

-

FreekS got a reaction from Elia in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elia in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

INTERMEZZO

I still owe Piet a video of the K-XVIII shooting a torpedo from the deck tubes.

Here's a mini video build log of the work I did to make the torpedoes operational - using rubber motors as the propulsion method.

Hope you will enjoy the 5 minute film - the sub shot is right at the end

Freek

-

FreekS got a reaction from michael20 in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from michael20 in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Planking is about 75% done, now I have to think about closing the gap and how to fix the last planks in place without using the small "vices" (klemmetjes).

Also in front of the boat the small plane I used to shape the planks and the Bajonet closure which just arrived from Norbert bruggen. Norbert is a legendary model sub builder in Germany and sells all sort of usefull parts.

However still lots of planking and sanding to be done!

-

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Ian,

The hull will be 68 cm long, and 11 cm in diameter. The original boat was only 20 meters long, and the model is 1:32.

At 125 tons displacement, the original was small, and the model will weight approximately 4 kg and have a dive tank, most likely a plastic bag, of about 500 ml

inside the model I will need to fit

- a motor with speed controller

- batteries and receiver

- pump for the dive tank (bag) with its controller

- two servo motors with pushrods controlling the planes and rudder

- quite a lot of lead to give stability and make up to 4 kg.

The boat will be very full!

Here's another picture of the original

Freek

-

FreekS reacted to Piet in Hr. Ms. O 19 1938 by Piet - FINISHED - scale 1:50 - submarine of the Royal Navy Netherlands in service 1939 - 1945

FreekS reacted to Piet in Hr. Ms. O 19 1938 by Piet - FINISHED - scale 1:50 - submarine of the Royal Navy Netherlands in service 1939 - 1945

Thanks again everyone for visiting and your "like" votes, it's much appreciated.

@ Popeye, yeah, only two small cuts and the last one didn't even bleed I's just a nuisance when I clean my hands with MEK. Yes, the details will make it look more authentic and then to think that I was not going overboard with detailing - - - hmmmmm - - - - must have had rocks in my head

This morning before lunch and helping the Admiral with making Thanksgiving dinner, I did spend some time in the COLD shipyard. Yes, it was cold at Palm Coast, Florida, down to 10 degrees C In any case I braved it and made two small net cutter pieces for the dive plane top guards. Instead of soldering them on I am trying CA glue and see how they hold up. I just need to be careful not to bump them too hard, I may cut myself - - - again

Then I thought to make a harpoon from the info I gave to texxn5 at the kit build section. For the result of my try go see John's build log.

Okay after fiddling with harpoons (and my father could have used one when they were cruising in the Indian Ocean in 1939. They caught a shark and used the boathook to drag the monster on deck) I finally quit procrastinating with cutting the hole in the bow side for the side anchor. After I removed the small piece of the side I was elated. It was not as bad as I had imagined. I also removed some of the side planking bulkheads to allow enough space to house the anchor It's now just a matter of desiding how big / small this anchor should be and by looking at the pic of the K XVI Kreek send me I can estimate it pretty well.

It's a lot simpler then I was thinking of and can make it happen so that I can stow the anchor on board and also let it go down. I'll also make the cowling above and in front of the opening as the pic of the O 20 shows, somewhere in my log.

This gives me now also more confidence in opening one of the mine tube locations and install a tube with a model of a mine. No, I wont make a mine loading trolley, too much like work

Now it's also a matter of getting some copper to make the anchor and the screws. I think I'll try a copper water pipe junction, can buy some at the local hardware store. After the anchor stowage place is done I'll paint the topside green, hopefully soon.

That means - - - the conning tower

Okay, here are the pics of this morning's work.

The final net cutters installed, I think - - - I hope.

This is the place where the side anchor will be housed. The opening is still in the rough, much more work is to be done before we can stow the anchor. It'll have to be opened up some more on the bottom and some wood removed from the frames inside to allow me to cement the back wall and sides in. Then the cowling on the outside, veneer or brass shim ??? Don't know yet, will experiment with both.

Cheers,

-

FreekS got a reaction from Elia in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elia in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Ian,

The hull will be 68 cm long, and 11 cm in diameter. The original boat was only 20 meters long, and the model is 1:32.

At 125 tons displacement, the original was small, and the model will weight approximately 4 kg and have a dive tank, most likely a plastic bag, of about 500 ml

inside the model I will need to fit

- a motor with speed controller

- batteries and receiver

- pump for the dive tank (bag) with its controller

- two servo motors with pushrods controlling the planes and rudder

- quite a lot of lead to give stability and make up to 4 kg.

The boat will be very full!

Here's another picture of the original

Freek

-

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

FreekS got a reaction from Elmer Cornish in HrMs O-1 by FreekS - FINISHED - 1:32 - RADIO - first Dutch submarine 1906-1920

Hallo all,

Thanks for the kind comments on my rubber motor Torpedo's!

Back to planking the hull.

I'm shaping each plank with a mini plane, but progress is slow. I learnt I need to ensure the plank is fully pre-bent before mounting on the hull. Six planks done and I think I have the hang of it now - though at cost of removing one after it had too much tension in bow section.

Certainly gives me a lot of respect from those of you creating much more complex hull shapes!

Freek