guraus

Members-

Posts

361 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by guraus

-

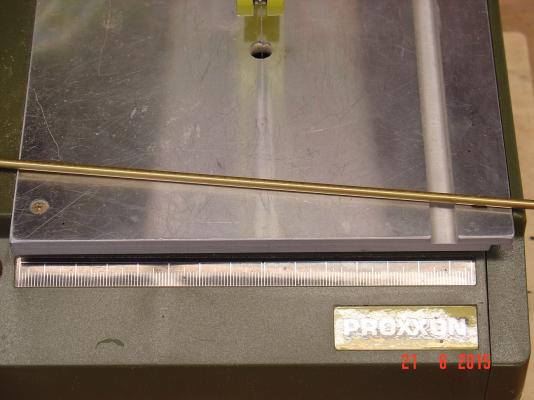

Proxxon Micro MBS 240/E Band Saw Review

guraus replied to Blue Ensign's topic in Modeling tools and Workshop Equipment

I have this same saw for several years now and I was very happy with it, but recently no more. Last month alone it broke 5 blades with very light use - and they are 23$ each. I don't know what is wrong with it but I don't think the issue are the blades. Here is what happens: after installing a fresh new blade and a little usage I start hearing a repetitive noise like the blade is hitting something at each turn and shortly after the blade breaks ALWAYS at the welding point. When the toc-toc-toc noise starts the blade will break even if it turns empty without cutting anything. I always buy the same Proxxon blades from Amazon and I don't think the problem are the blades. I think that in time the saw parts got worn by extensive usage and miss aligned. I am not an expert by any measure but what I can see is that the plastic on the two wheels is worn and I am guessing the blade does not sit true on them and get a bit twisted which makes it hit the guides and after a while it breaks. The upper guide is three bearings and the blade touches their exterior rounded part but the lower one is just a notch in a piece of steel. My money are on the lower one. I just got a new batch of 4 blades and I will try one without the lower guide - see what's happening. If someone has more experience with these tools and can share some light on what could be the cause of this problem, I would greatly appreciate. Regards, Alexandru -

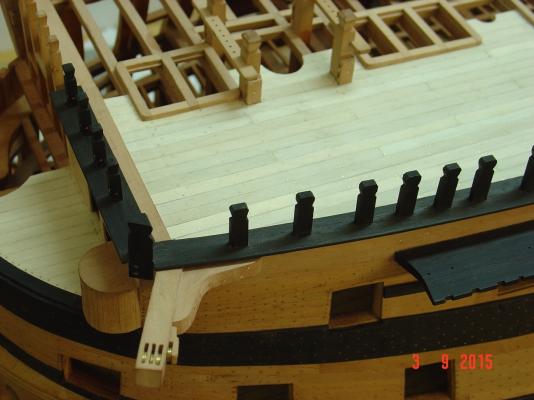

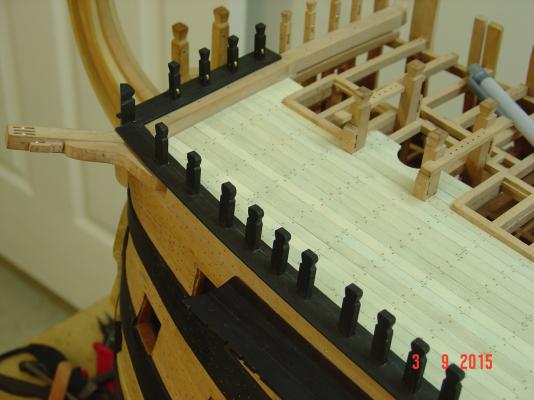

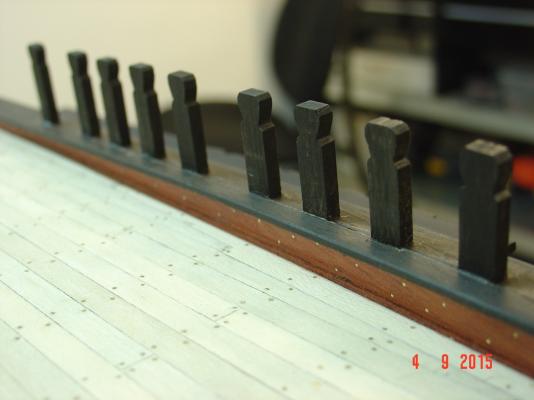

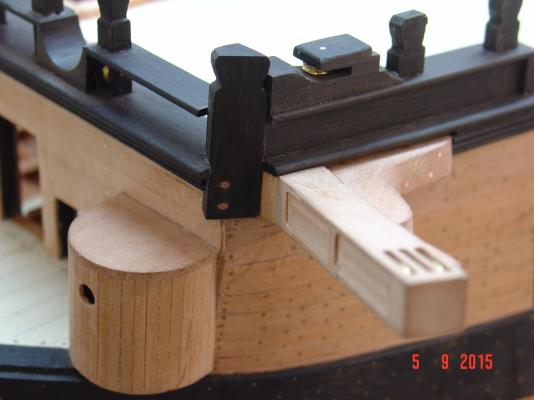

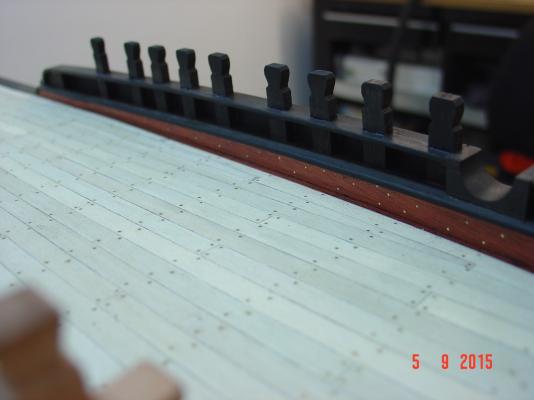

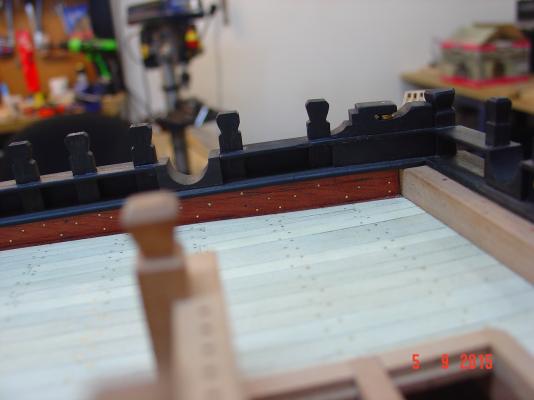

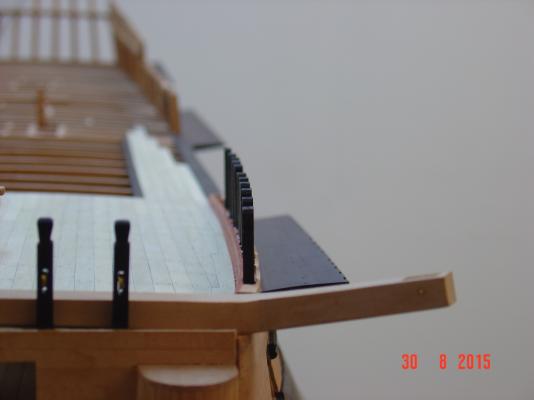

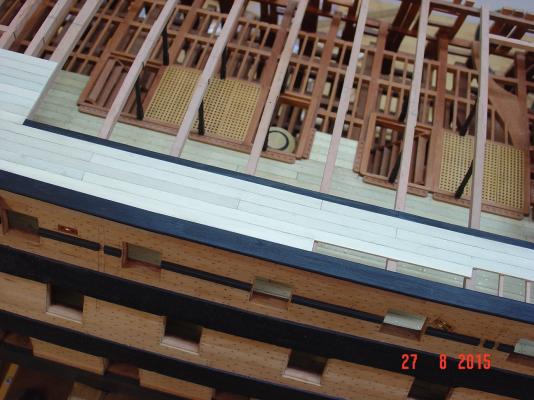

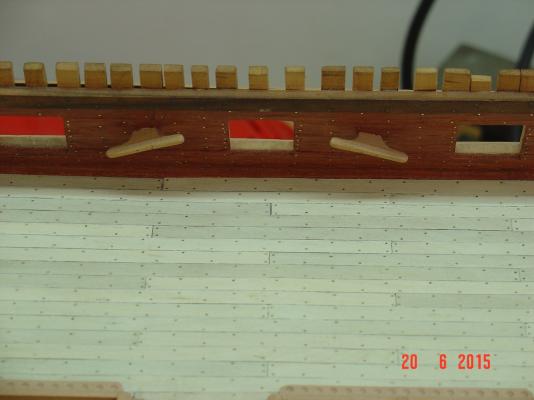

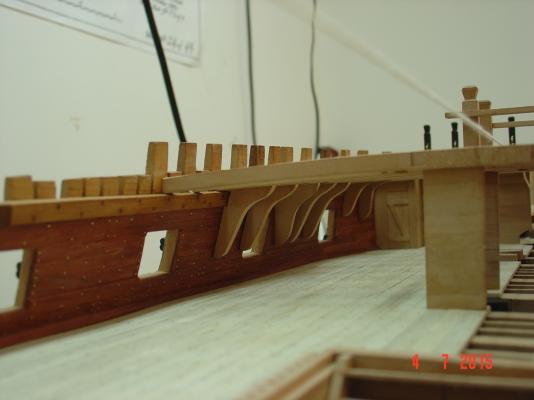

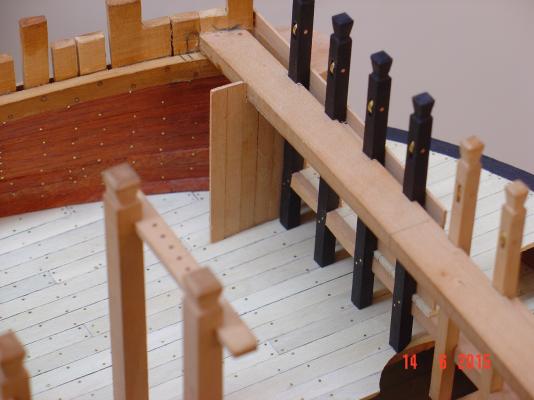

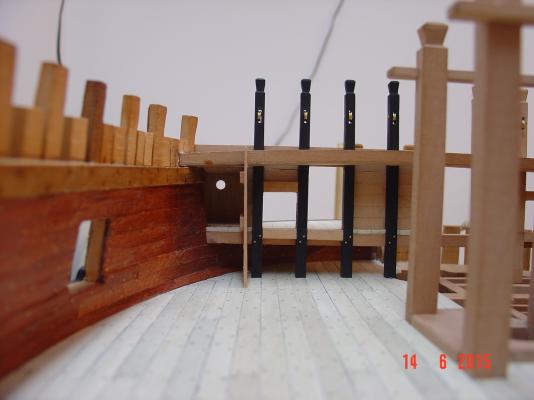

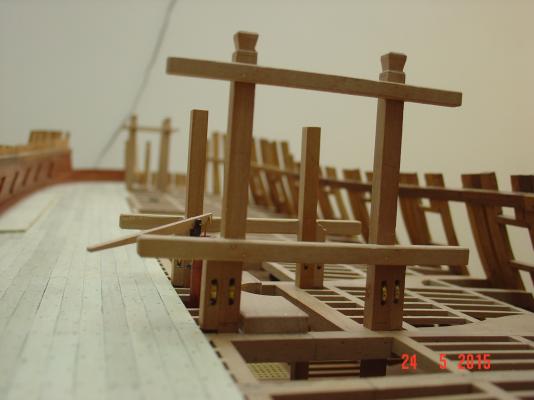

Hello Hobbie, I visited Victory several years ago and I had less than a day as we left from London in the morning by train and we returned in the evening. I can give you two advices a bit contradictory for your visit: do a lot of detailed pictures - you will be glad later. Be prepared for them: I emptied two sets of batteries doing that as I had to use a lot the flash for the interior. take the time to "take in" the ship. I regret now as I didn't have much time to do that and I've seen the ship basically through my camera lens. With that said I wish you a great visit. Here are some more progress pictures on my model Still working on the forecastle, but closing in fast. Regards Alexandru

-

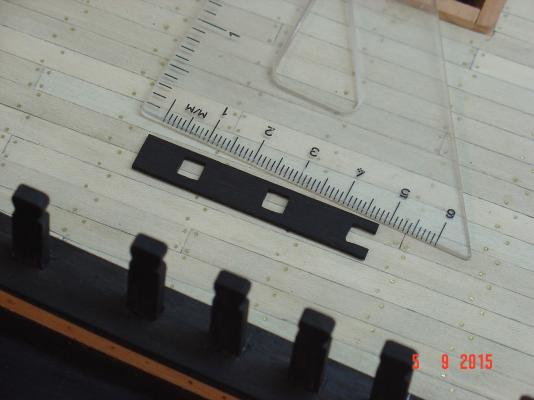

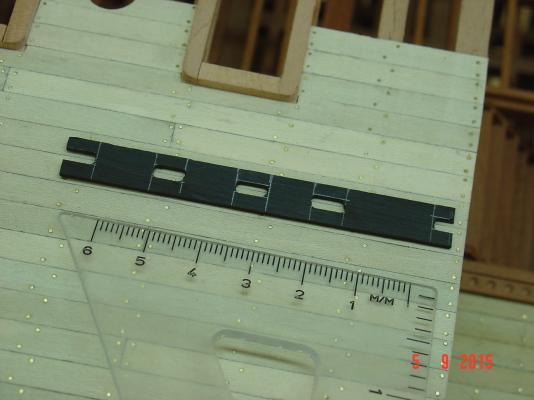

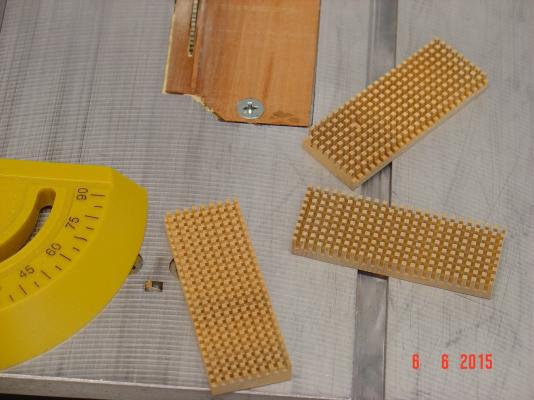

I don't think the ebony is difficult to work with. Except for the black dust it makes (my power tools are always connected to the shopvac when I work with) I kind of like working with. Once you understand you can't really bend it and stop trying to do that, it works fine. Cuts well, file or sand very well, very nice to turn or to mill. It is forgiving some times as say you did a small hole through it in the wrong place - you just put a drop of white glue in it and file/sand the top a bit: the black dust will fill the hole and it becomes quasi invisible black on black. Is ideal for making moldings. As is quite expensive - especially the real African deep black ebony - I have a special scrap box only for it in which I keep every small piece I cut off for potential future reuse. At the wood store I bought a while ago pen turning blanks and what they call "cut-offs" sold by weight form their scrap box. I am well stocked for a while. Hope this helps, Alexandru

-

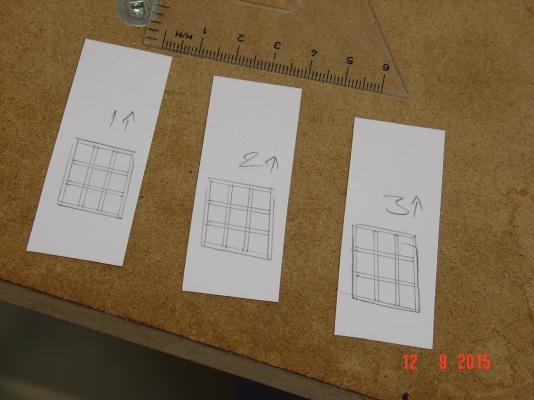

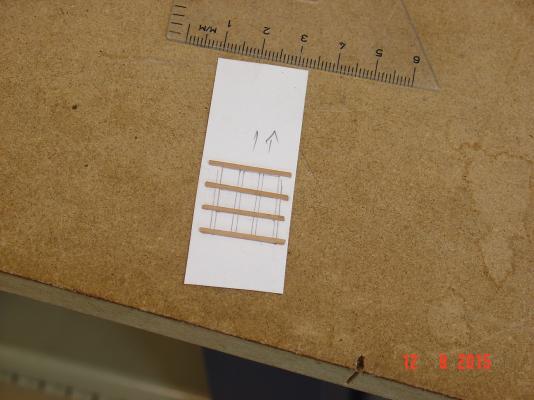

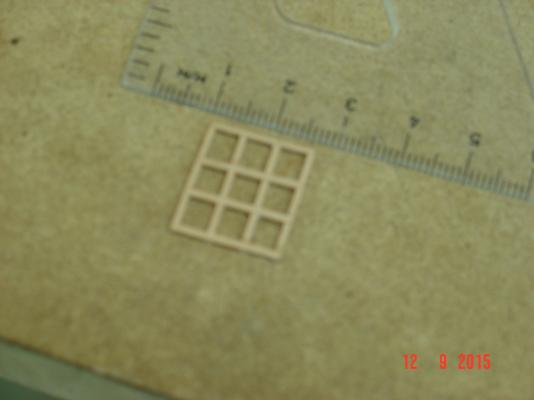

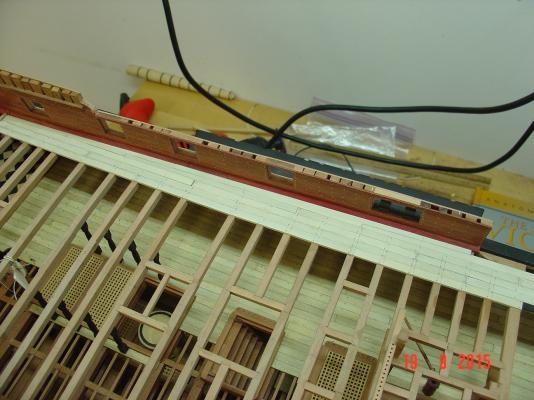

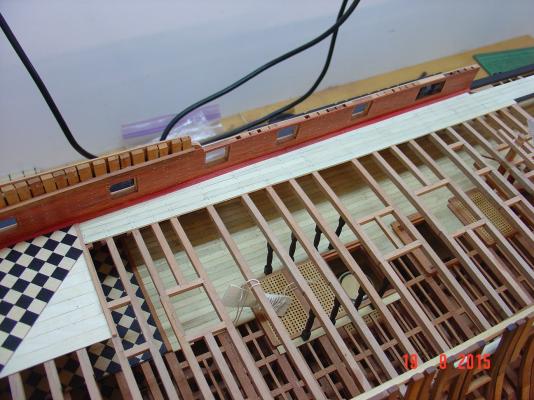

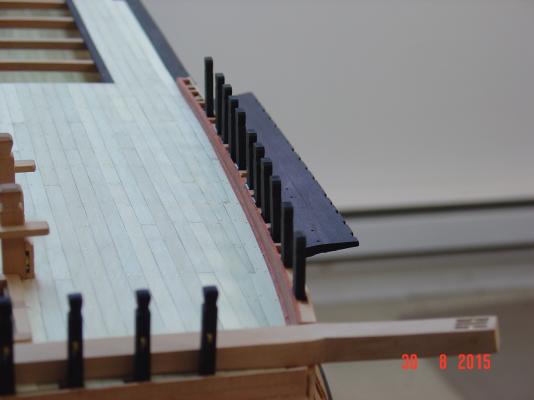

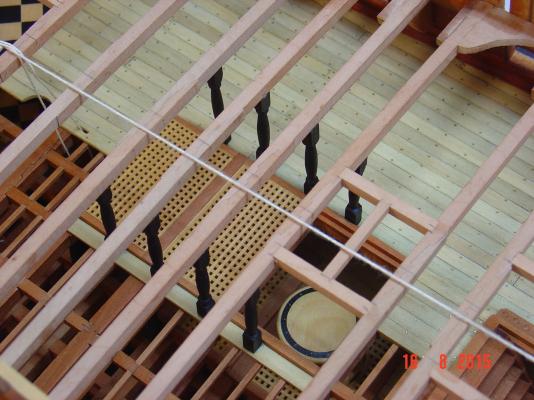

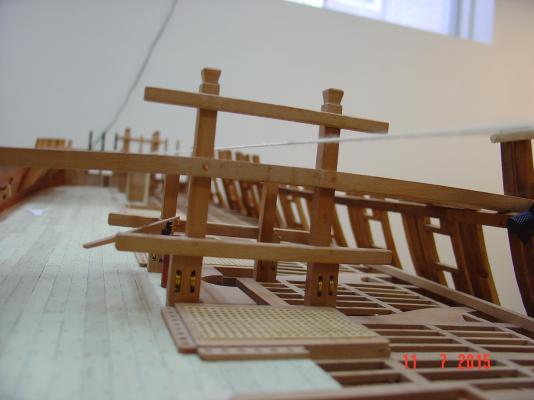

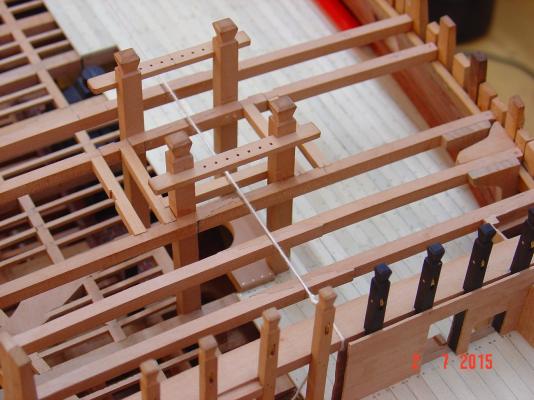

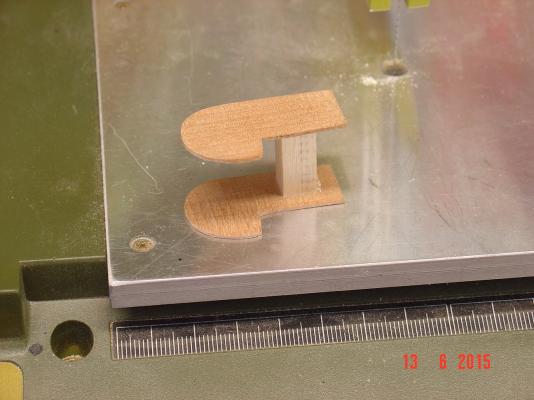

Hello all, Quarter deck almost complete - missing last two beams - somehow I counted them wrong. I still have to add several hanging knee and lodging knees too. Before someone asks, in the before last picture the space for the companionway between the first (lower) two beams is shifted toward left as in the plans. The upper deck below was oiled as there will be nothing else that needs to be glued to it. Regards, Alexandru

-

Mark, Thank you for contributing to the beakhead deck debate. Your input is appreciated. Unfortunately for my model is now to late to change anything - it will have a raised platform as there is one in the Victory in Portsmouth. Was that there from the beginning or not I don't know. I personally find it suspect to loose all that space (between the two decks) on such a crowded ship. Greg Thank you for appreciation of my work. Alexandru

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.