samueljr

Members-

Posts

340 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by samueljr

-

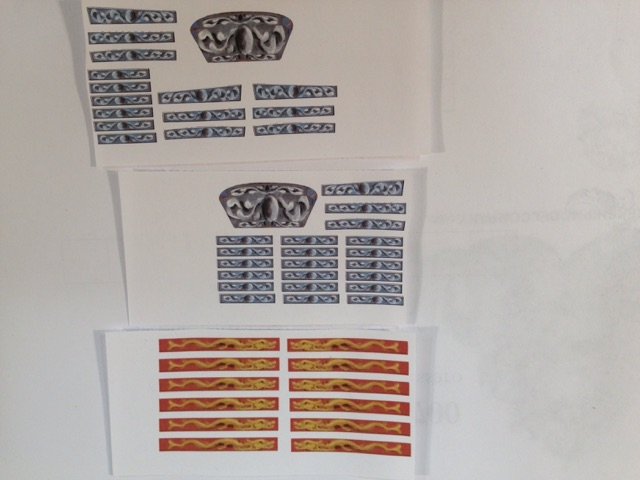

OK so I skipped a few steps here but this is where I'm at. It's been pretty by the book (kinda') As I stated initially I wanted a deeper color scheme so I've opted for a first coat of 50-50 thinner and minwax golden oak stain and then a full strength (lightly applied) of golden oak. I then hit everything with a wipe on poly. The paint is a windsor newton galleria black (the usual 97 (LOL) thin coats). I have ordered cherry sheets to make the lower molding out of cherry to match the finish. The top moldings are ripped from scrap from the kit. The bow is painted full black as I saw some images of barges with a full field of color. I thought the paint between moldings looked a little "race stripey" for my tastes. The carvings (or in my case all castings) will be a gilded gold with a dull finish. BTW I have purchased the resin castings from Syren and they are beautifully done. For those of you who are wondering why the keel is doubled the kit as designed CAN NOT withstand a fall from a table top to a concrete floor. After several attempts I was left with the option of re-enforcing the keel or starting over. I am thinking if continuing the frieze pattern onto the bench arms. I've attached a mock-up of it - opinions????? Also I have accepted Chuck's "challenge" and will be doing some additional carvings/details to the bow.............. to be continued Sam ARMS WITH INSERT030518.pdf

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well I've decided on a finish. As I've stated I'm looking at a more "older look" (without weathering etc.) something along the lines that the Russian builders accomplish. Something with some depth of color. I tried about ten different types of finishes from tung oil (various number of coats) to sepia washes, wipe on poly etc. The tung oil left it to "orangey" with the cherry wood. So I had to get something to take that edge off. I've decided upon a 50/50 coat of MiniWax Golden Oak brushed on and allowed to dry naturaly. I'll buff it out in 24 hours to take up any surface oil. It may darken or natuarlly patine on it's own and that would be fine. Thank's to Ben and Chris for their input Sam

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Ben That's actually what I'm using. The small surfaces combined with the tight grain make it tough to get it to bite in sometimes. Have you started working with any finishes yet? Using scrap from the sheets I've laid down a first coat of 50/50 (mineral spirit/tung oil) with a second coat of tung on top. It' will have to dry over night. Not excited about it so far. Reminds me of wood work/trim you find in houses. No depth. Once dry I'm going to try a wash of burnt sienna and a wash of yellow ochre to see if I can get a deeper patina. I've looked into bithumen(sp?) but not certain if that would be the way to go. If I don't like any of those I may take a look at some of the tinted Danish Oils. Also when I find the finish I want when do I apply it? I know the directions finish progressively, but if it's a two or three step process how to keep it consistent through the build? Sam

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks good Ben What glue are you using? Sam

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

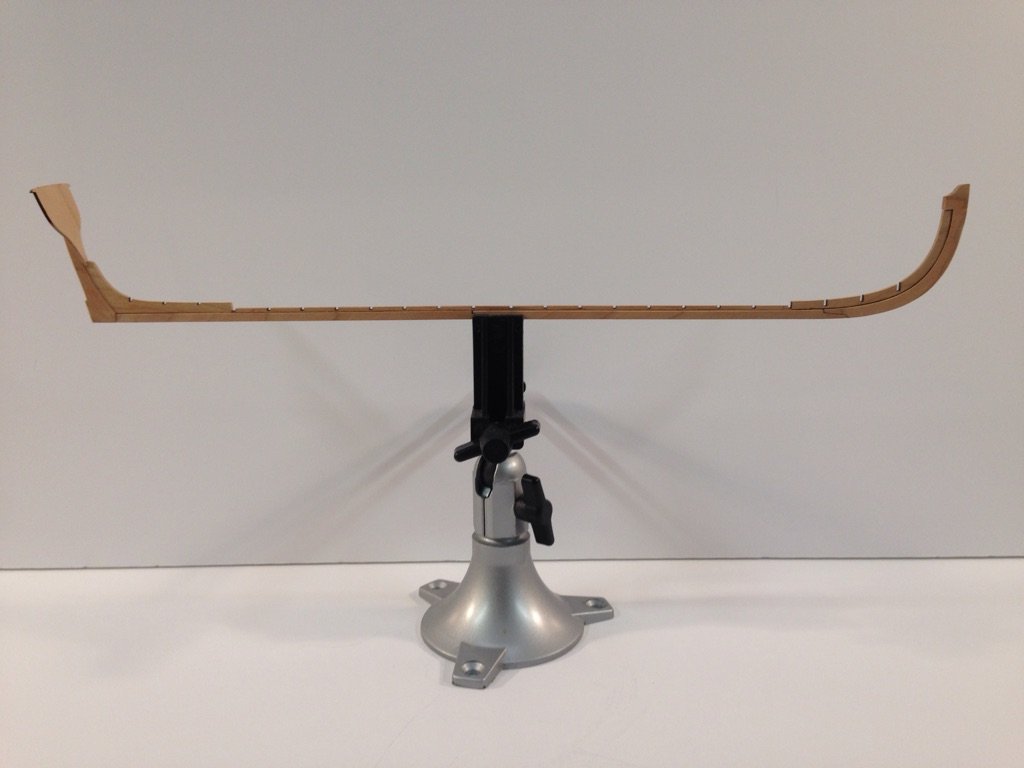

Chuck The jig does make it easier for squareness, alignment and setting a solid base for planking. But like any "tool" care must be taken to use it correctly and not to allow it's contribution(s) to lead to careless building habits. Chuck has designed and engineered a wonderful system for the builder to produce a plank on frame model but in no way is this reduced to a "slot A tab B" build. Care and patience as always should be taken to maximize the kit's attributes. Sam

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

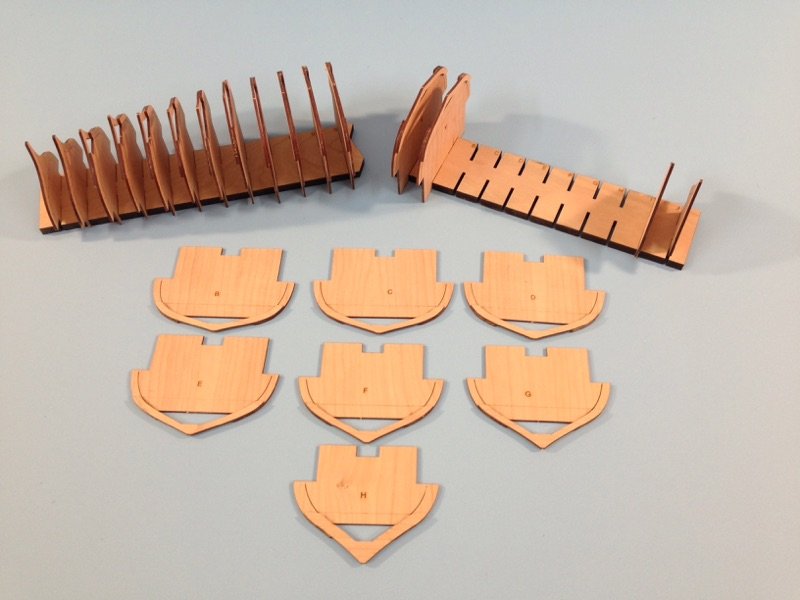

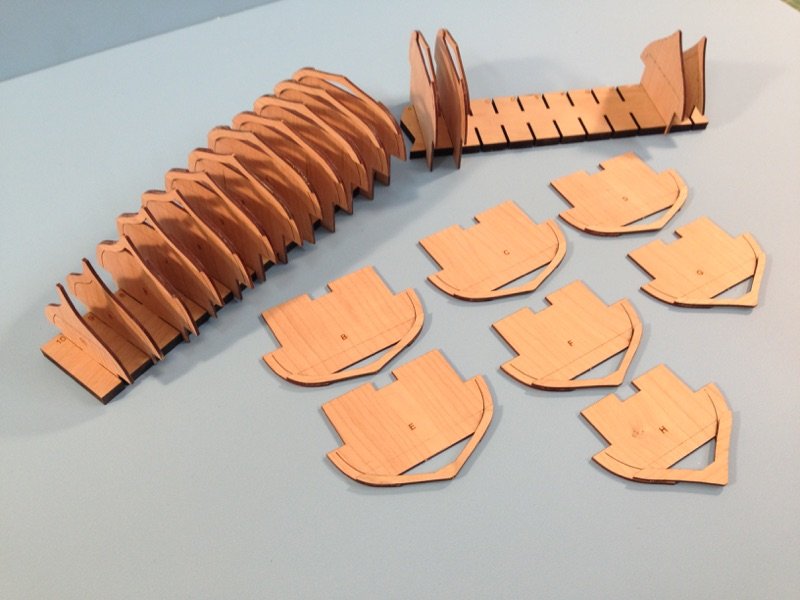

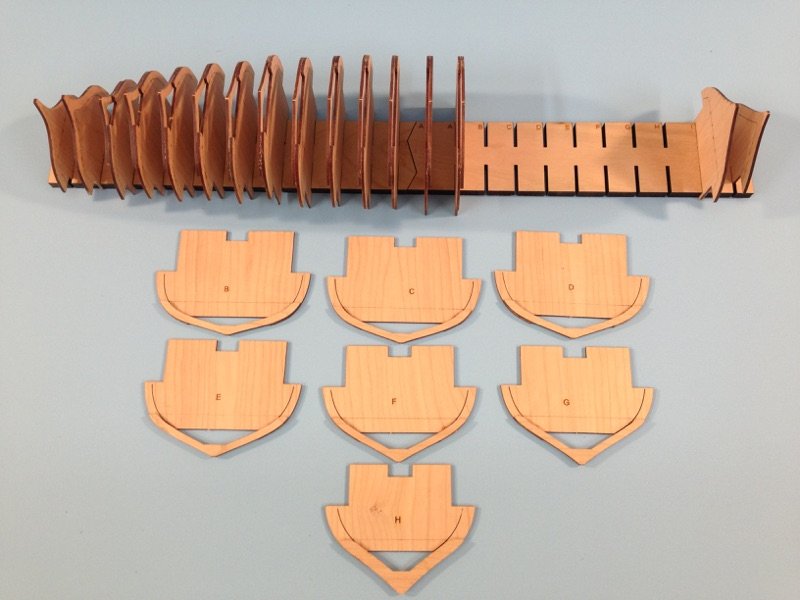

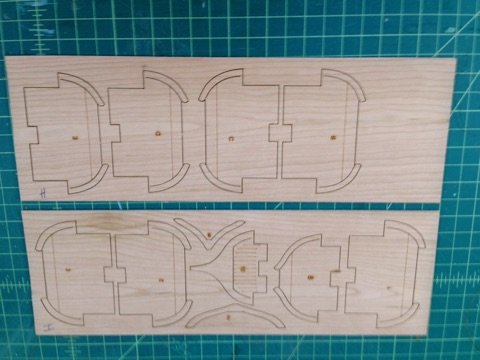

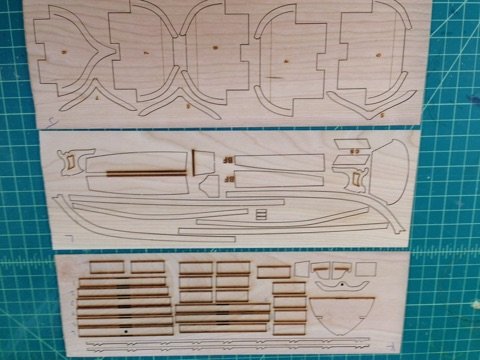

I returned to the QA BARGE this weekend and was able to get all the frames assembled. Just a few observations; The directions are specific in stating that each frame set should be separated and installed individually and then assembled. This should be followed as it is easy to mix up the parts as there is in some cases only a slight difference in shape and mixing them up is easily possible. Once all the frames were assembled I attempted to fit them into their respective slots on the boards. Once again as per the directions there was some mild sanding required to get the tabs inserted under a gentle press fit and not pressured in. Although not pictured I have dry fit the keel on the assembly. As with the bulkheads some of the slots on the keel were tight on the frames. I took a scrap piece of the cherry and used it as a test fit throughout. With a sanding stick I gently touched up the bottom of the bulkheads where needed. That's it for construction this weekend. I will spend the rest of my "BARGE" time testing finishes on the scrap wood. I am leaning towards a tung oil finish (maybe with some type of sepia wash) or a satin poly wipe on. Those results (and hopefully the assembled keel/bulkheads) here next weekend. Sam

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ben I'm leaning towards the tung oil also. I'd like something a little "warmer" if that makes any sense in the finish. I haven't run any tests yet though. I've even given some thought to the process the "Russian Builders" use with bithuman (sp) but that may be too aggressive. Sam

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Forgot to ask; What sealer are you using?

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ben How was the fit with the slots? Press fit as in directions or minor touch-up as per directions? Looking great Sam

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck What about a serious study of either the Stern or Bow. Larger scale (1/4"?) highly detailed. Always liked the illustrations in ZuMonfeld's book. I don't mean something like the VICTORY Bow section model not that far back. At the Bow not past the Catheads at the Stern not past the galleries. ??????

-

ok just thinking outloud..........

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ben Looks good. What are your thoughts on pre-scoring the bulkheads manually to facilitate an easier release later. Any pics of your sealed keel assembly? If yes what did you use? Sam

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

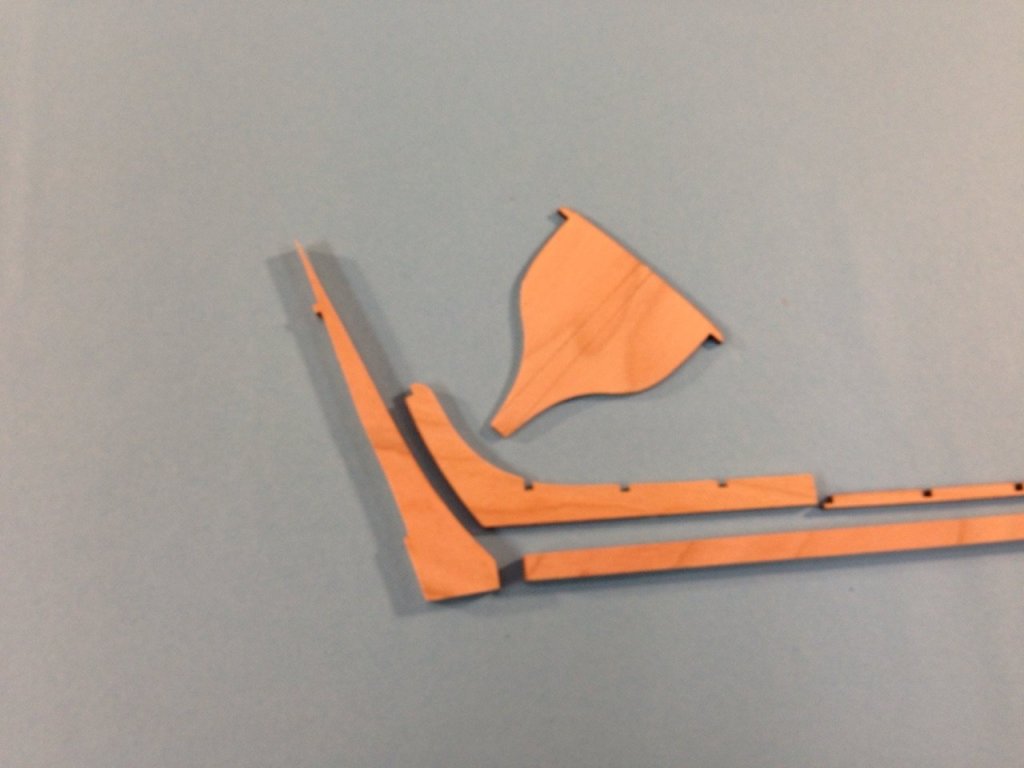

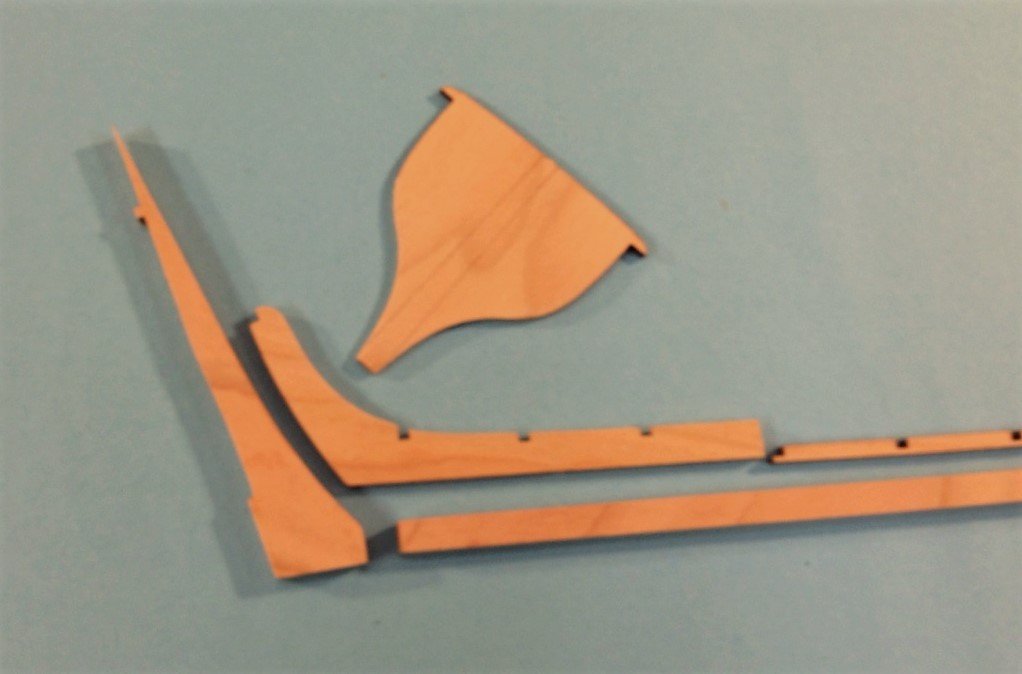

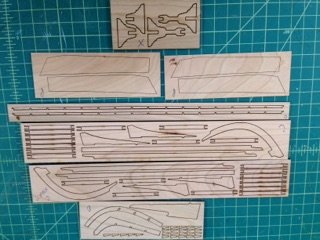

Well the clamps are off and the work on the BARGE is done until next weekend. I have another personal build I want to spend some time on and a kit design project just getting underway. Keep an eye on MSW for news on that coming soon........... I taped together a couple of pieces of thin cardboard to make a small firm envelope to store the flags, inset and sweeps' artwork and the chip board laser cut piece. I'll leave them safely in the bottom of the box until they are needed. Sam

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

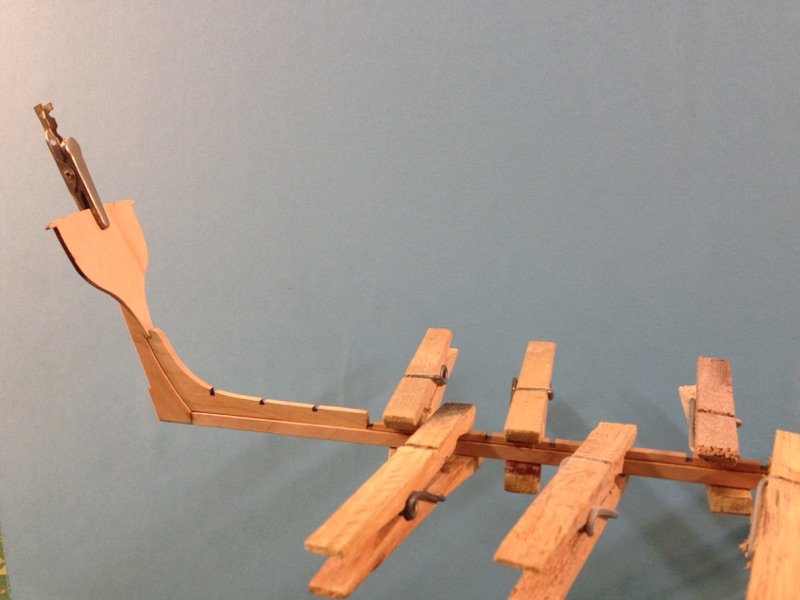

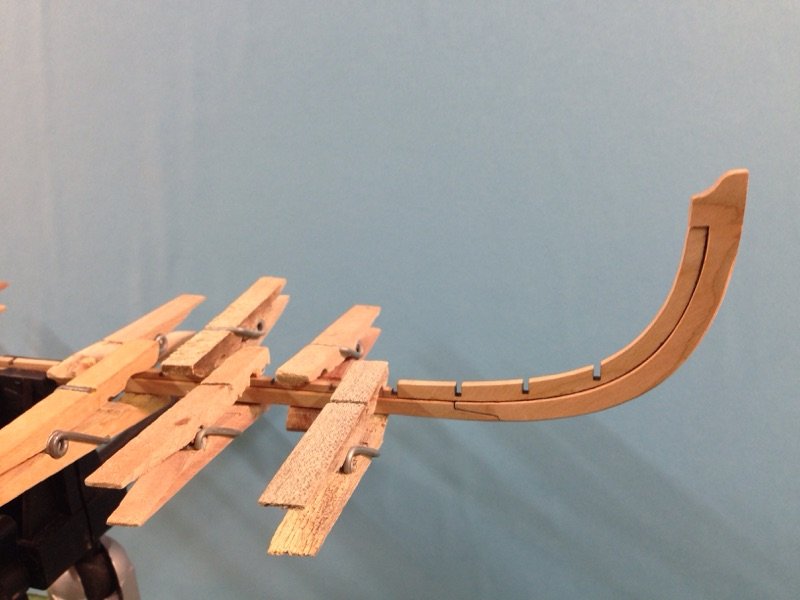

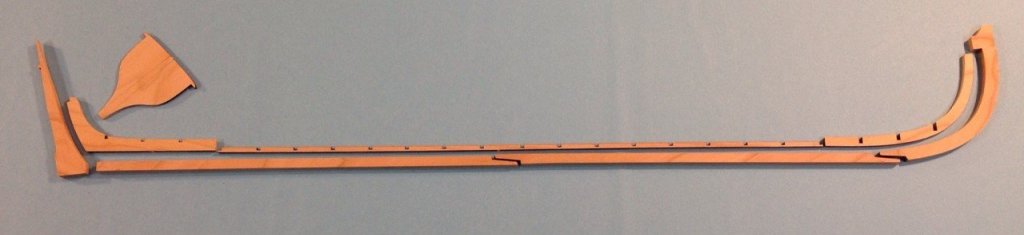

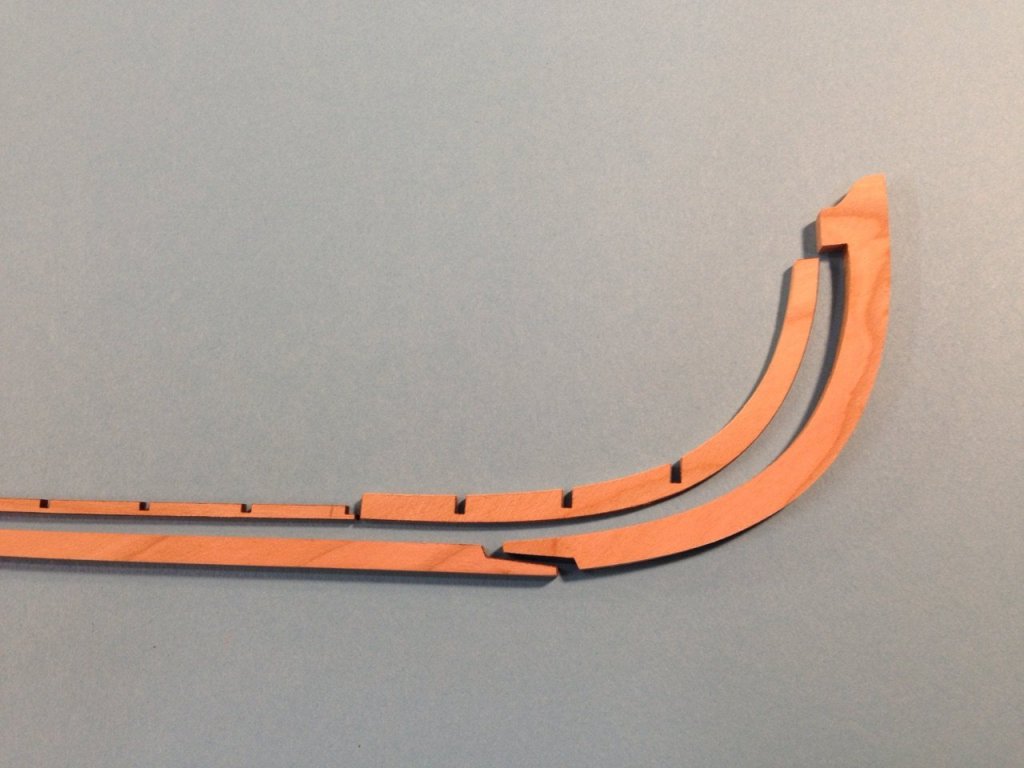

Progress?............. One of the things to take note of with this kit is glueing parts. Obviously the goal is to have a pristine surface ready for finish. Glue on the raw wood will affect the sealer, oil or whatever is to be used. With the small surface areas that contact in these first few steps it is imperative that enough glue is used to bond but not so much to squeeze out and cause finish issues down the road. It is almost necessary to let the first (almost transparent) coat of glue to seal the char providing suitable surface(s) to bind. The second coat is just as thin. Tooth pics were used as spreaders and good old fashioned clothespins were the right depth and more importantly the best tension/pressure to act as clamps. I have been using Titebond (yellow) as my primary glue with just dots of a medium CA to hold pieces in place until the yellow sets up.

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

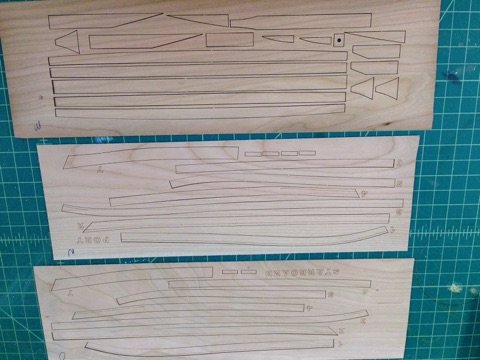

Good morning all Thanks to everyone so far who has checked and wished well so far. Bob - nice job on HALIFAX Thanks to Nils, Jason, Dan, Mike, Steve Grant - I'll PM you on my other project Anyway, the build is underway. The thing that is to be stressed continuously with this build/kit is patience. Care must be taken i handling the pieces and the builder should always read the directions thoroughly before proceeding. Unlike a lot of kits this is definitely a "manual" build. In that I mean the builder has to read the manual. Just a cursory read is not sufficient. The plans are supplemental to the manual. Chuck has provided a very clear process that will produce a beautiful build. I've released the first series of parts and removed the char as directed. The keel assembly needs to be beveled and then I can put it together. That will be later this weekend.

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ben, I'll be following you - literally ........... Sam

- 74 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

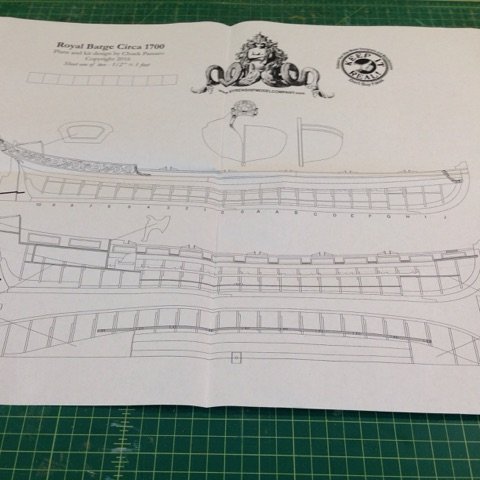

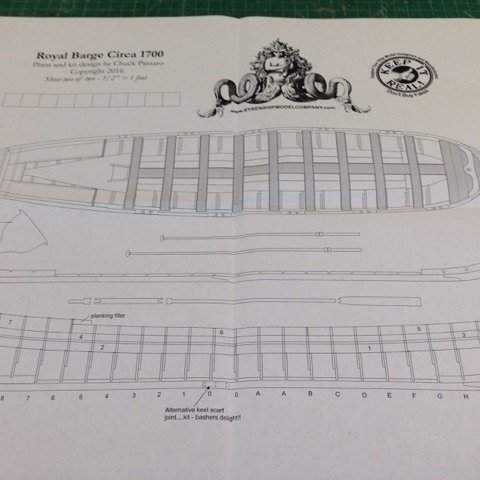

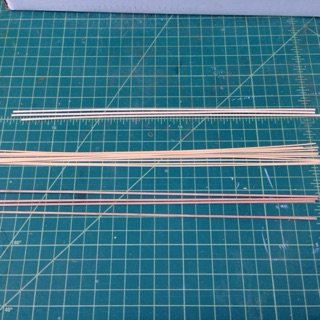

I've only submitted a couple of logs on MSW and they've been more progress than build logs in that It has been pics of where I'm at and not necessarily how I got there. I'm going to try to make this a little more comprehensive so here goes.......... The BARGE arrived to my house in Western New York from Syren's offices in New Jersey in about 4 days. Cant beat that. The box was much smaller than I anticipated only being about 15"x4"x6". I opened it to find everything neatly and securely placed and and well packaged. Included are two plan sheets 18"x24" at a scale of 1:1. The manual is a 3 part PDF download from Syren's website that I had printed out and spiral bound at Office Max. I opted to print it in B&W, after binding it was $12.99. The same production in color would have run close to $60 so B&W it is. The parts are all extremely well cut and appear to be very easy to release. What is surprising is the delicate feel of the parts. A lot of the sheets are only 1/32" so patience and care must be shown in handling. One thing that caught my eye was how pretty the cherry wood is even unfinished. The color is consistent and the grain is very attractive. With a finish coat or oil on it it should be beautiful. The flags provided are sharp and detailed as are the inlays for the BARGE and the markings for the oars. The details of the 7 castings included are crisp and need virtually no remedial work prior to finish. As far as unboxings go this was pretty uneventful. The quality of all included are what has come to be expected from Syren Ship Model Company - perfect.

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You guys heard it - PARTY AT CHUCK'S!

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Kurt Making a pot of coffee - may not sleep tonight............... Sam

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

So excited I forgot to attach the picture..............

- 47 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.