samueljr

Members-

Posts

340 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by samueljr

-

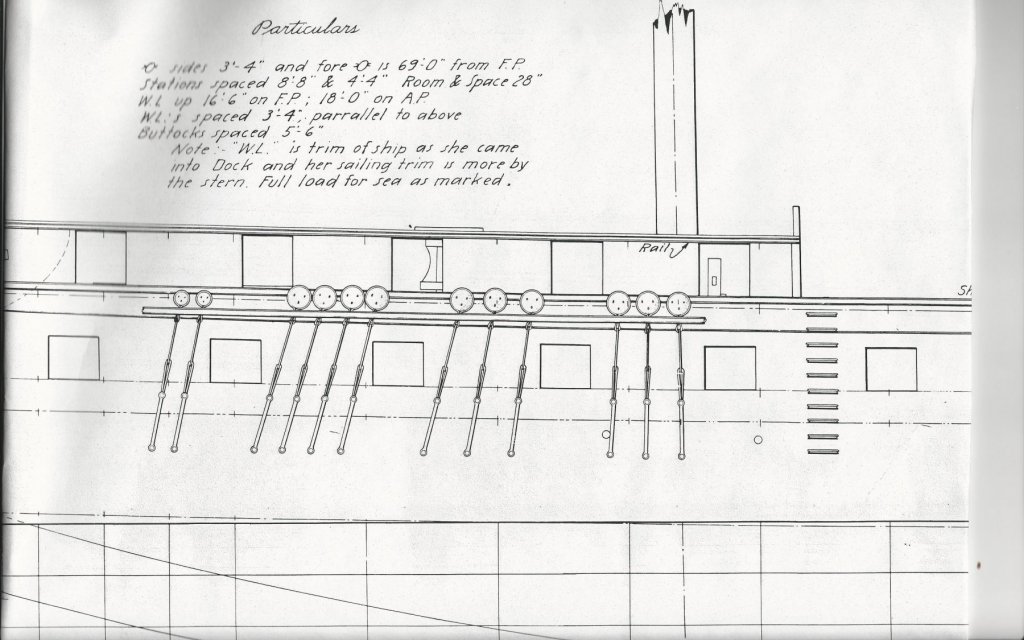

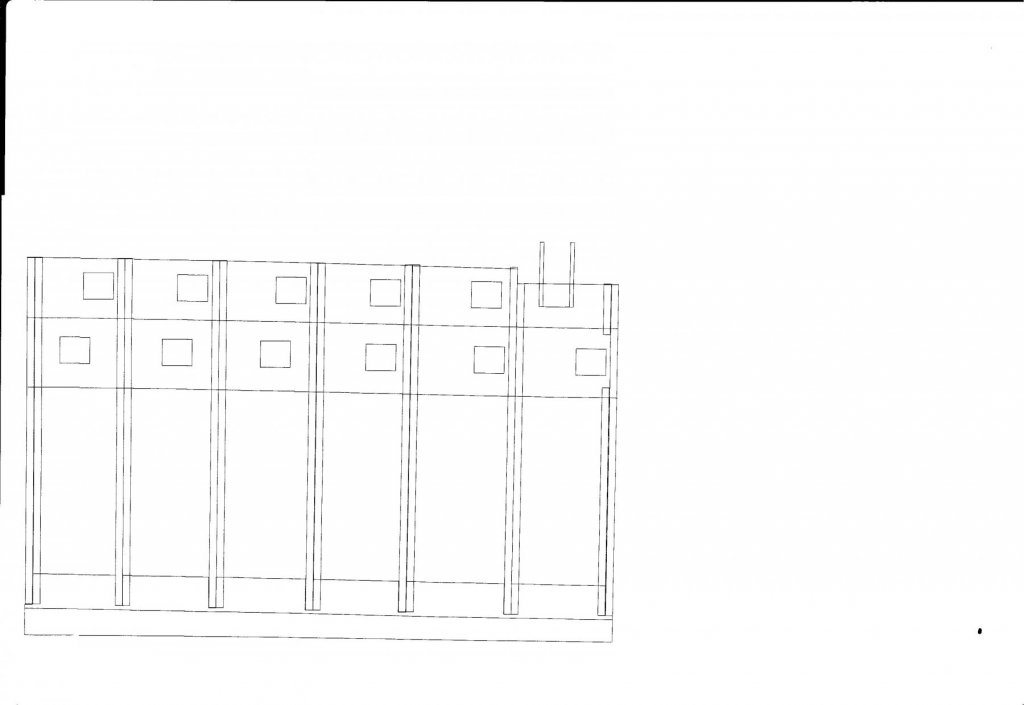

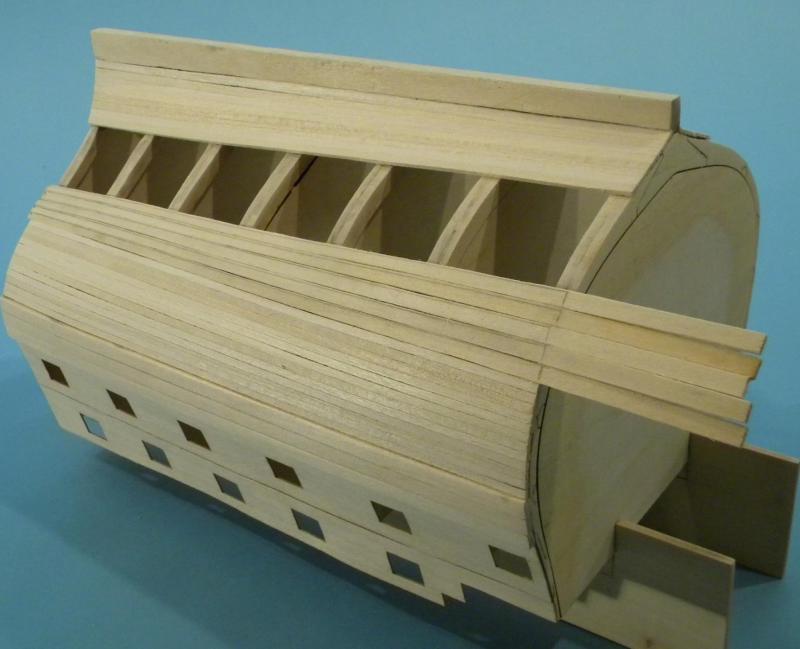

My thanks again to everyone for their interest and likes. The journey has just begun. There has on several occassions been coment on the gun port alignment. It could be the angle of the photographs (for that I apologize) but the ports are not in line. Although they are not in the usual staggard sequence from deck to deck which most of us are used to, they are correct as per the source material (the drawings of the PRESIDENT after capture as per the Admiralty) I've attached an image of the drawings used for the build here and will later this evening upload an image of the PRESIDENT's port alignment. Thanks - Sam

-

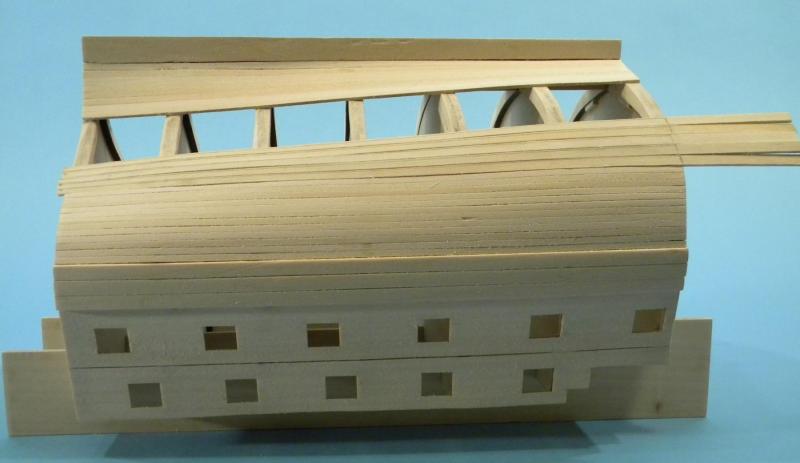

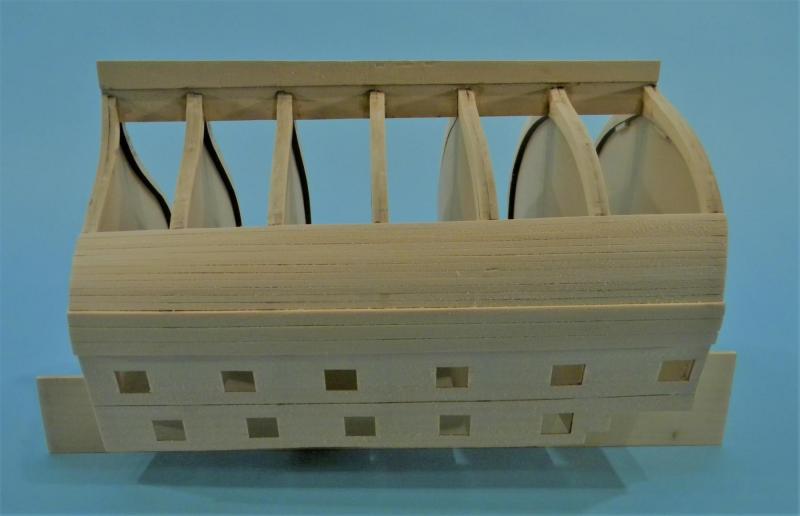

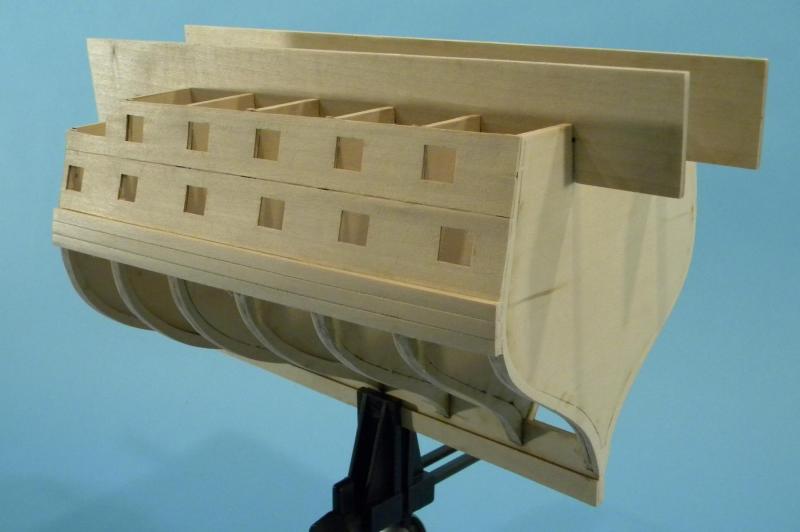

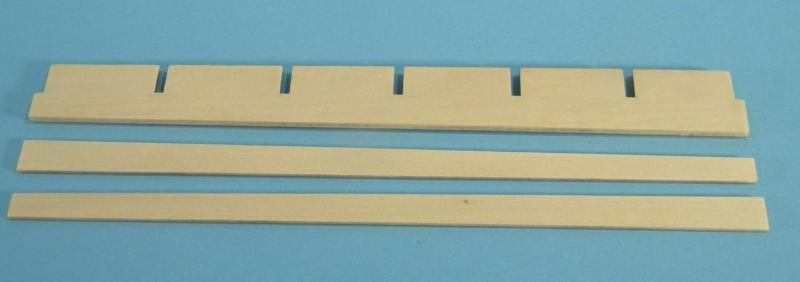

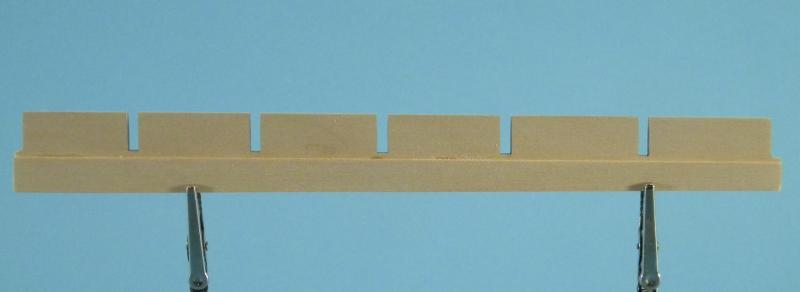

As stated in a previous post the gun port stripes consist of 4 - 1/8" x 1/16" strips glued together off of the hull, progressively sanded and painted with several thin coats and then with a coat of wipe - on poly. They were cut to length (the reveal is on 1/32" on each side) the edges were painted white and then they were glued into place. The first and last piece(s) were left just a bit long and then sanded back into the hull. Next Up - Planking the rest of the side

-

The next area moving upward are the gun port stripes. To get a crisp paint finish a number of steps will be/were performed off the hull and prior to installation. The area(s) around the gun ports and their inner edges were painted. Additionally 4 - 1/8" x 1/16" strips were painted white, while 1 - 3/16" x 1/16" strip was painted black. All surfaces were sanded progressivley. The strips and hull area were given several thin (water consistancy) coats of paint with a very light sanding between coats (600 grit) and wiped down. After the final coat of paint a finish of wipe - on poly was applied. The colors used are Artist Acrylics, Titanium White for the stripe and instead of a deep or stark black (such as Mars Black) Paynes Gray was used. It is a duller black, almost sooty in apearence. The white strips will be glued together off of the hull and then cut to length to fit between the gunports. The black strip will cap the installation. This will create a sharp definition between the black and white surfaces. Next up: installation of the strips

-

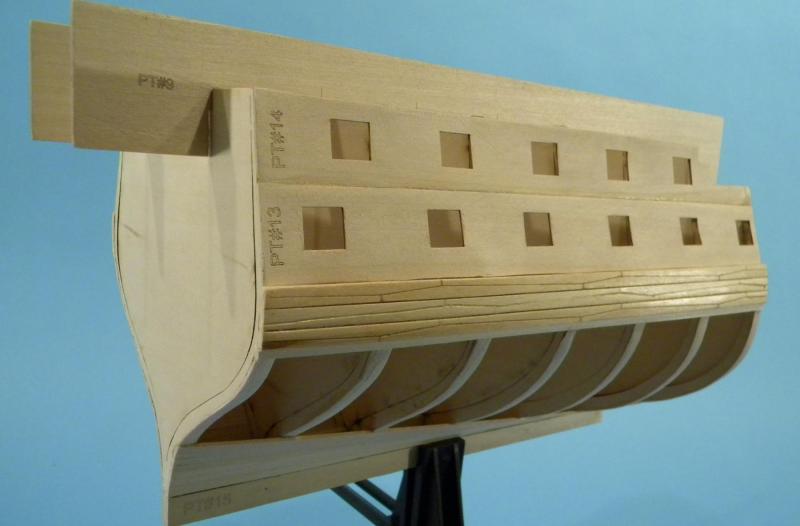

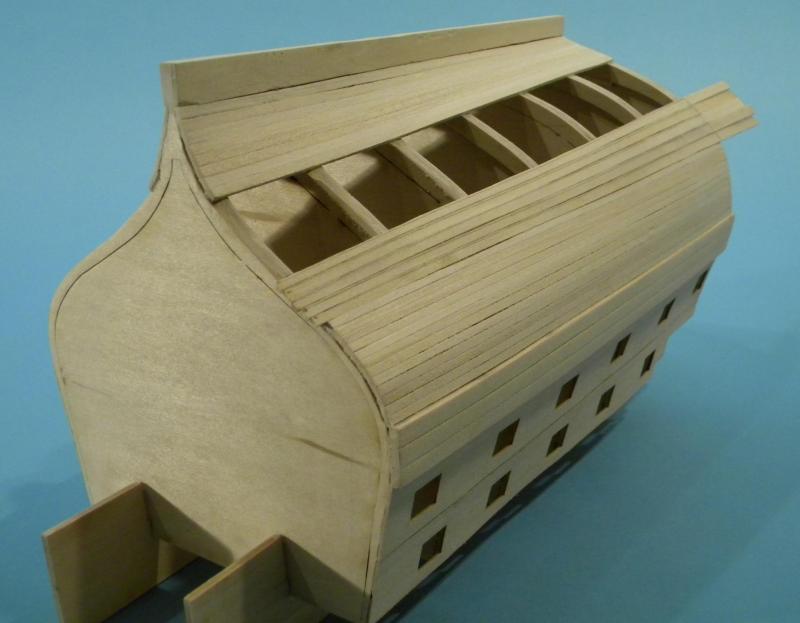

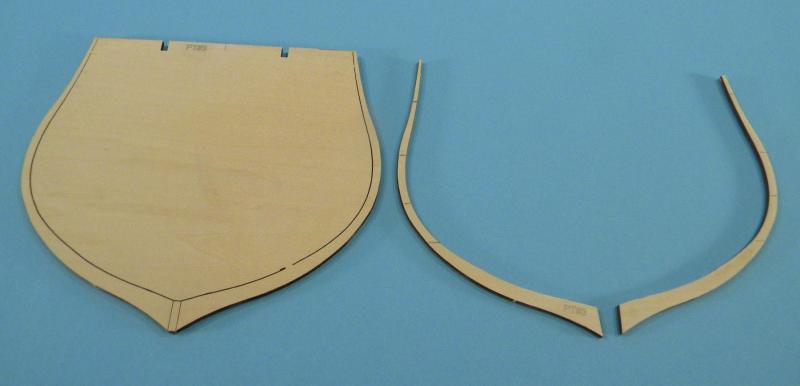

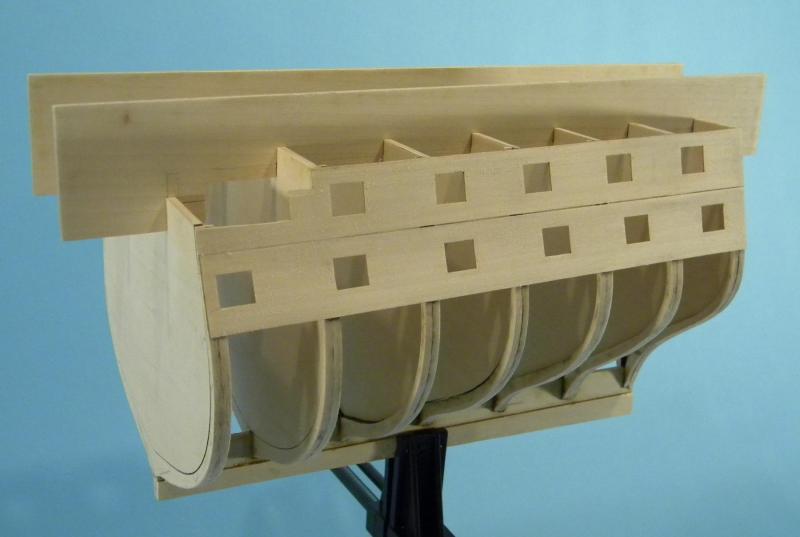

For those of you who have asked my apologies for not responding sooner, the source material for the build are the plans of the PRESIDENT after capture and the deck drawings of the UNITED STATES. There will be some additional sources as the build progresses all on the recommendation of acknowledged experts on the subject. A cradle was created for the hull out of plywood. Felt was glued onto the surfaces to offer a soft resting place and hold the hull firm. Above the wales I placed 3 - 3/16" strakes. All 1/16" thick. They arrive just short of the gun port openings (apprx. 1/32") creating the sill reveal. Once the inner tongues are removed the gunports will be fully framed internally. As all with the lower planking theses strakes were pre-sanded.

-

Allen Thank you for your interest. The wale is actually not parallel to the gun ports. The angle of the photos (even straight on) is skewing the perspective a bit. Also, the scale of the build (1:76.8) is an OK size but a distance of say 2" is barely 1/32" so it changes are slight. The gun ports actually rise moving fore to aft about a 1/16" of an inch as well. The source material for the build is an acknowledged historical source(s) endorsement by a recognized and accredited organization. The build is 9"-3/4" long, 6" high (hull) and 5"-3/4" at beam (6"-3/4") at widest point. Height when masted will be approximately 34" with a main yard (w/stunsils) at 19". The keel in scale is only 12" deep from bottom of garboard strake. Much work to do............. Samuel

-

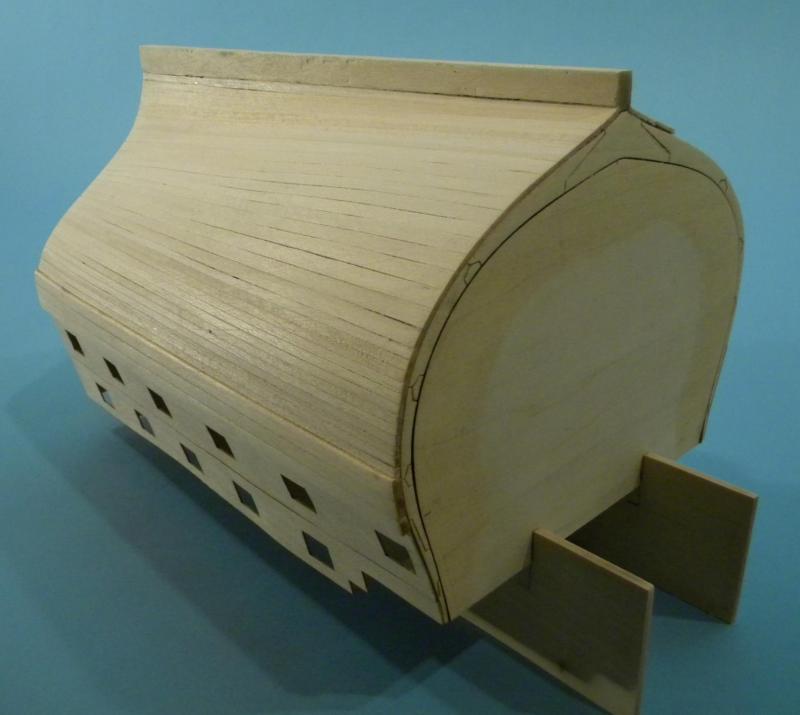

Starboard side. Wales are installed. They feature a laser etched/embellished anchor stock planking detail. This will be repeated on Port. The wales, (for photgraphic detail) have been given a coat of wipe-on poly to highlight the etch. When finished they will be painted black. There is one 3/16" strip installed below the wale. From that point down to planking band "C" the hull on Starboard will be left open for view of lower deck details. A thin veneer was added to each bulkhead/frame face between the wale and band "C" providing a cleaner surface for finish (either paint or stain) Next up: Above the wales

-

Port side middle band ("B") is comprised of 11 planks. The planks are 3/16" forward tapering to 1/8" aft. The first 5 are installed and the spacing/measurements are checked to assure the planks are running true. The remaining planks are tapered and installed with the 11th plank being un-tapered until it is installed to make any adjustments necessary for inconsistencies in taper of previous planks. The entire side below the Wale is sanded with a series of progressively finer grade of sandpapers (4-5 steps) from 80 to 600 grit. The entire hull is then wiped down with a tack cloth and blown with compressed air.

-

Chuck Maybe I missed sometime ago but when you're spinning the stock in the drill what's holding the drill and what's stabalizing the wild end of the stock? Sam

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Bob, Super as always. Love the way you handled incorprating the knees onto the deck. I actually flirted with the idea of a totally un-planked deck and then using a clear sheet of plastic/styrene to allow all deck componants to be placed as normal. The idea was dismissed but I think there's "something" there if the trend continues for open decks............... Any way great work as always. Any progress on the head rails? Let me know if you need something. Sam

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Stuntflyer Great tip and method! Nice work too......... Sam

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Bob, I'll PM you tonight to see what images/files you'll need Sam

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.