-

Posts

1,935 -

Joined

-

Last visited

About Trussben

Profile Information

-

Gender

Male

-

Location

OKI, NC

Recent Profile Visitors

-

Trumper07 reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trumper07 reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Ryland Craze reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

Ryland Craze reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

rcweir reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

rcweir reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

gjdale reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

gjdale reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

Trussben reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50-gun ship

-

davyboy reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

davyboy reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

davyboy reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

davyboy reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

JpR62 reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

JpR62 reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

JpR62 reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

JpR62 reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Ronald-V reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Ronald-V reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Ryland Craze reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Ryland Craze reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

Trussben reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

Trussben reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by westwood - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

Trussben reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

Trussben reacted to a post in a topic:

HMS Portland 1770 by Trussben - Portland Scale Ship Co. - 1:48 - 50 gun 4th rate

-

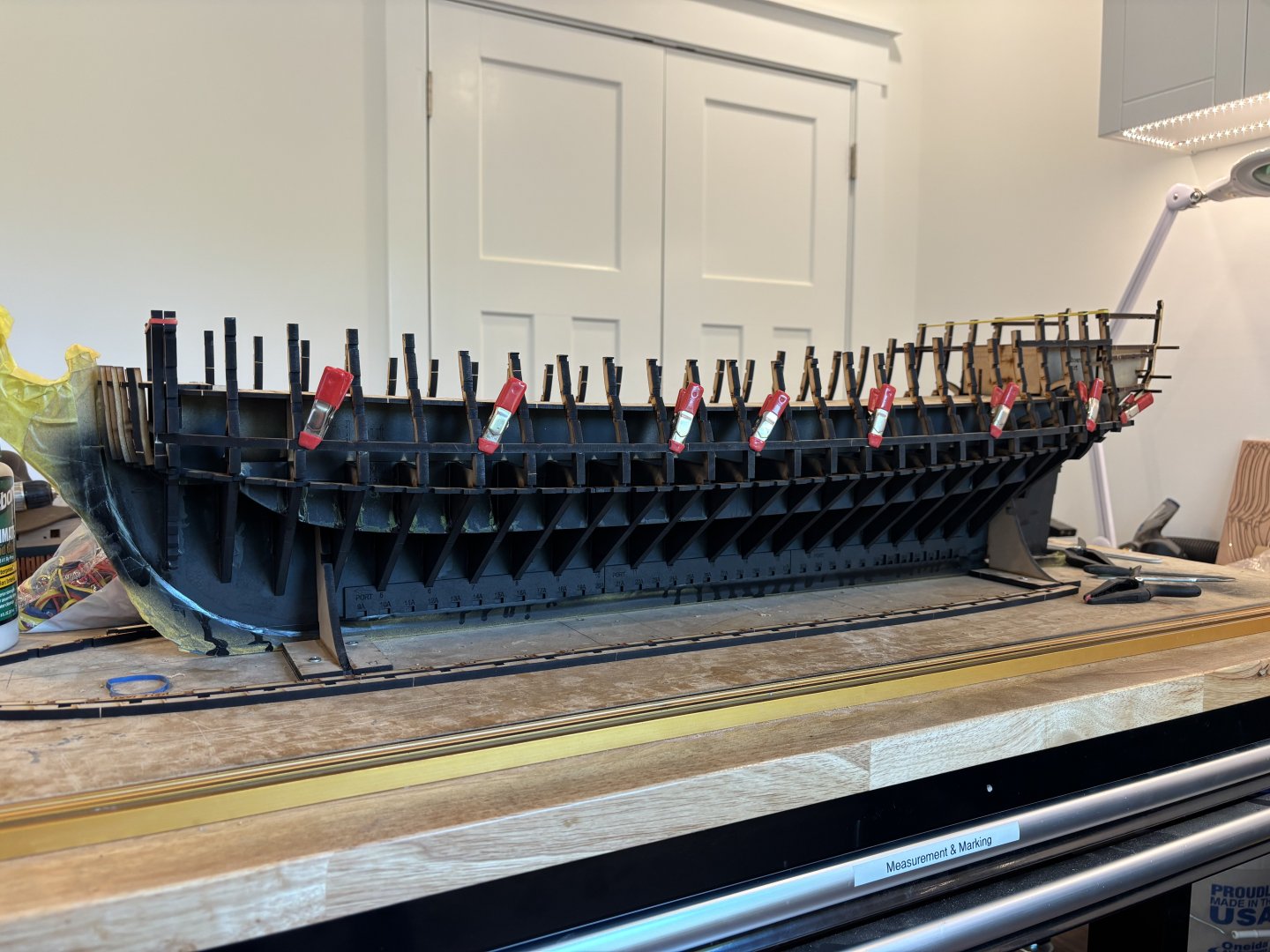

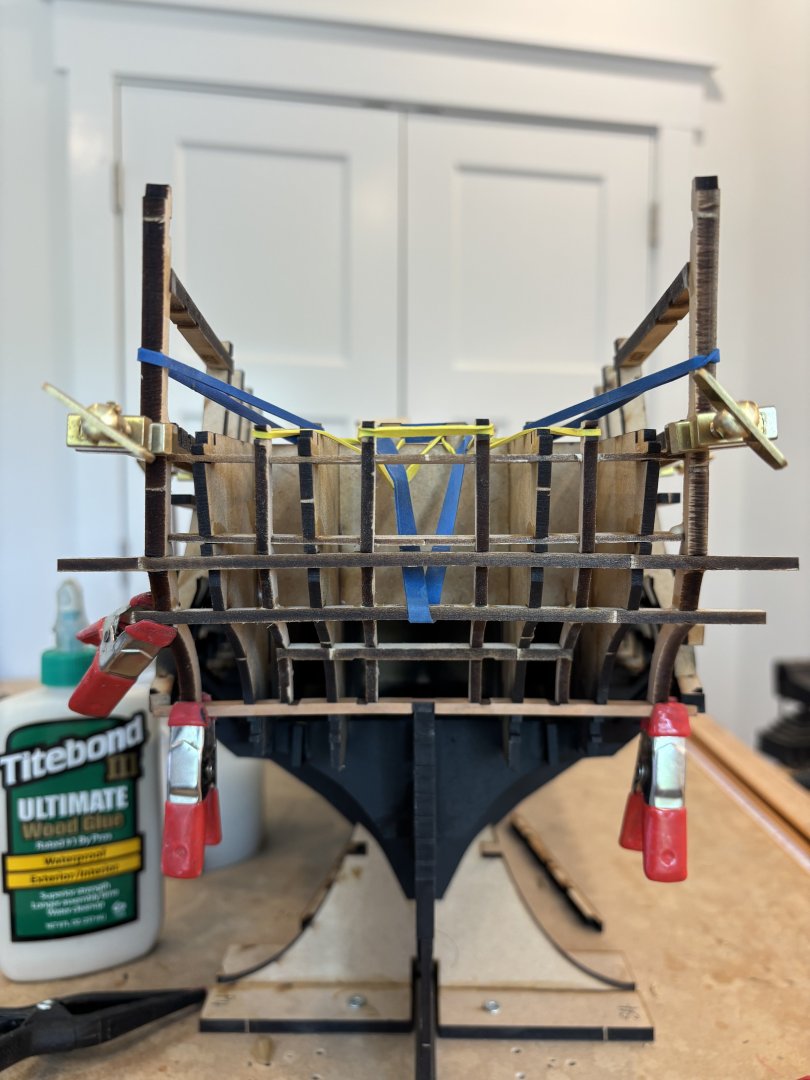

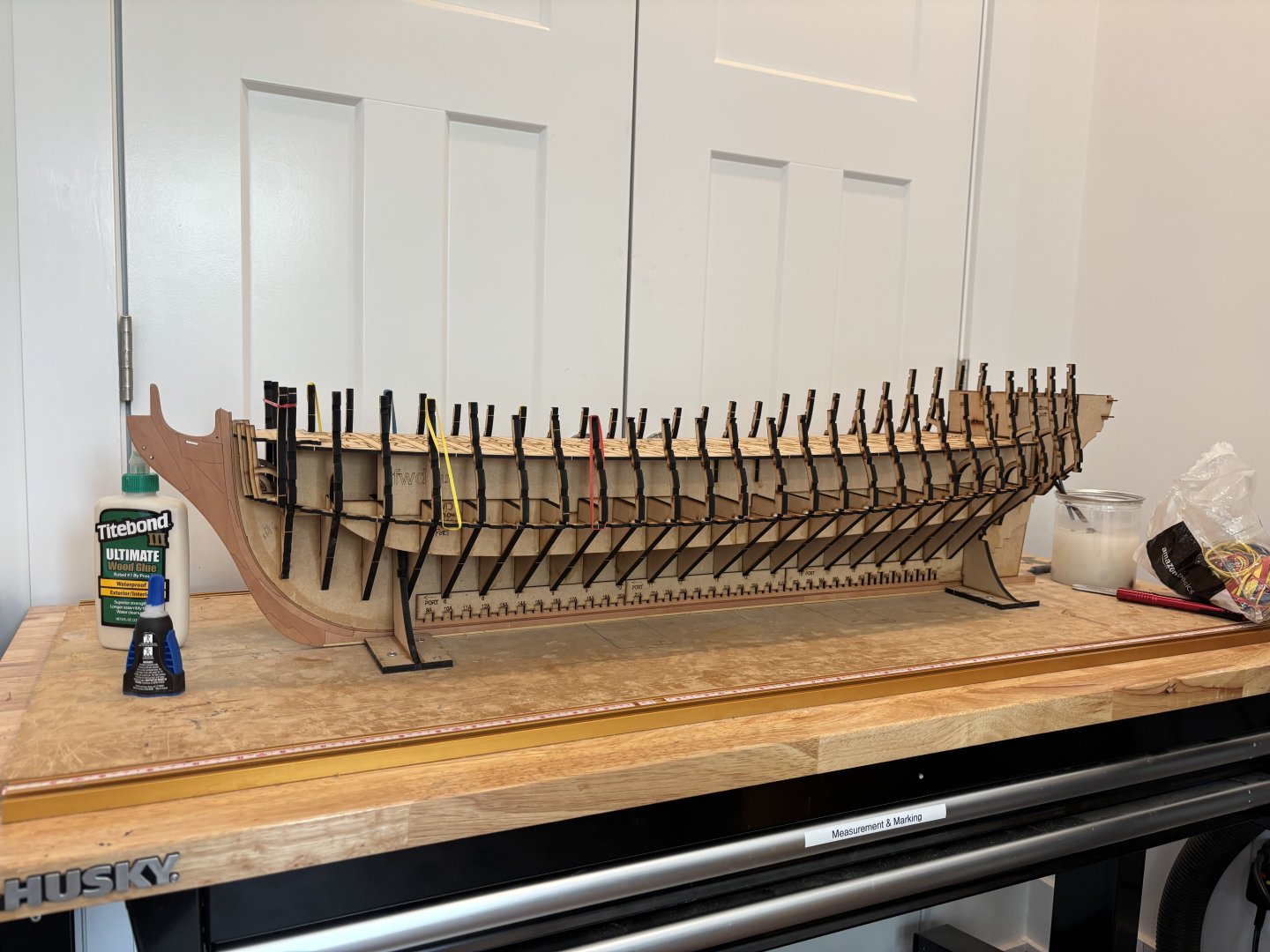

The beginning of the stern framing starts with the “wing” transom, this part has etched and cut into it the positions for the counter Timbers and the aft gunports. I carefully removed the laser char and then using heat I bent it into shape so that it clicked into the jig slots correctly. It only gets glued to the central former at the moment - NOT to the jig pieces!

-

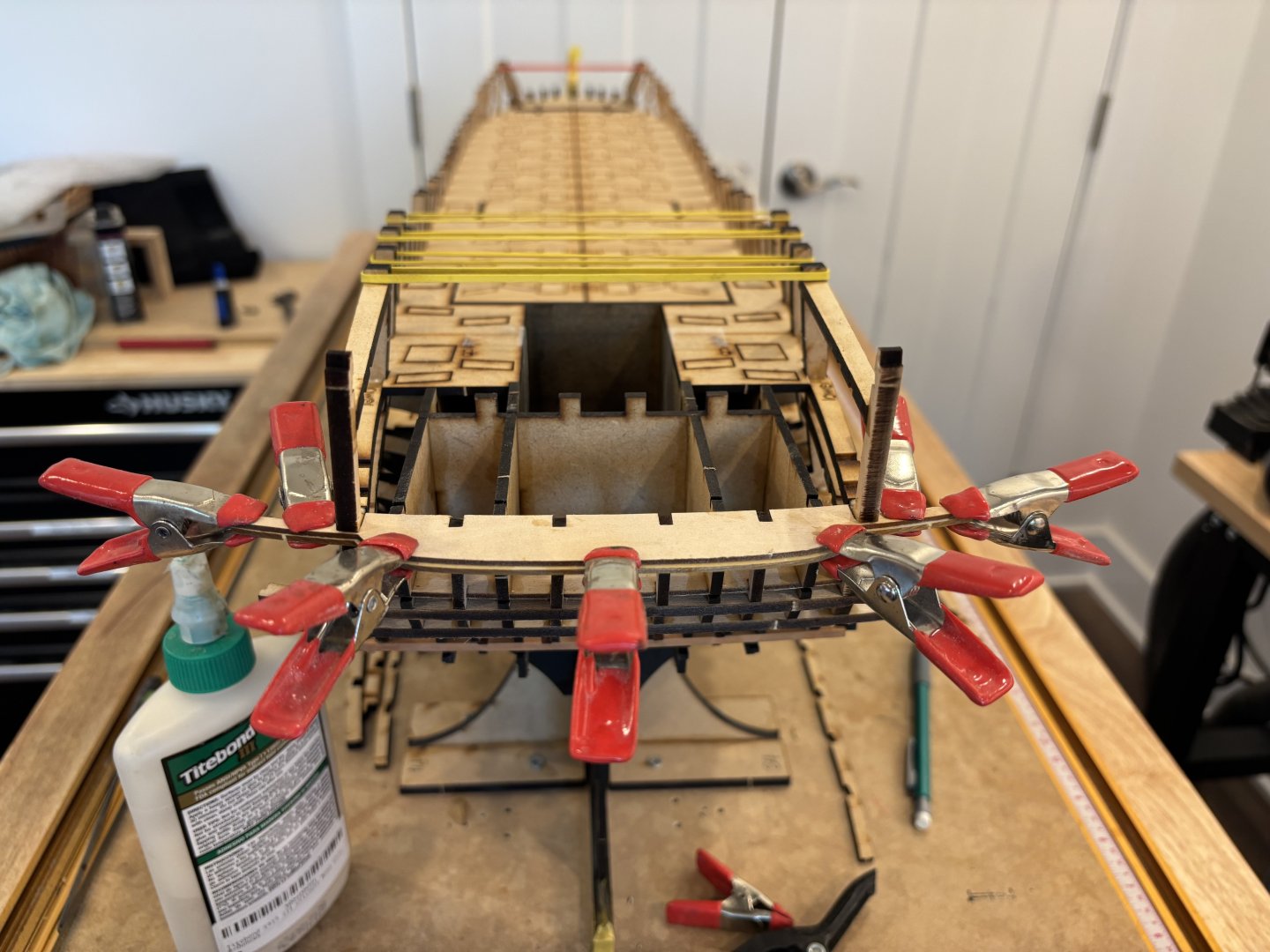

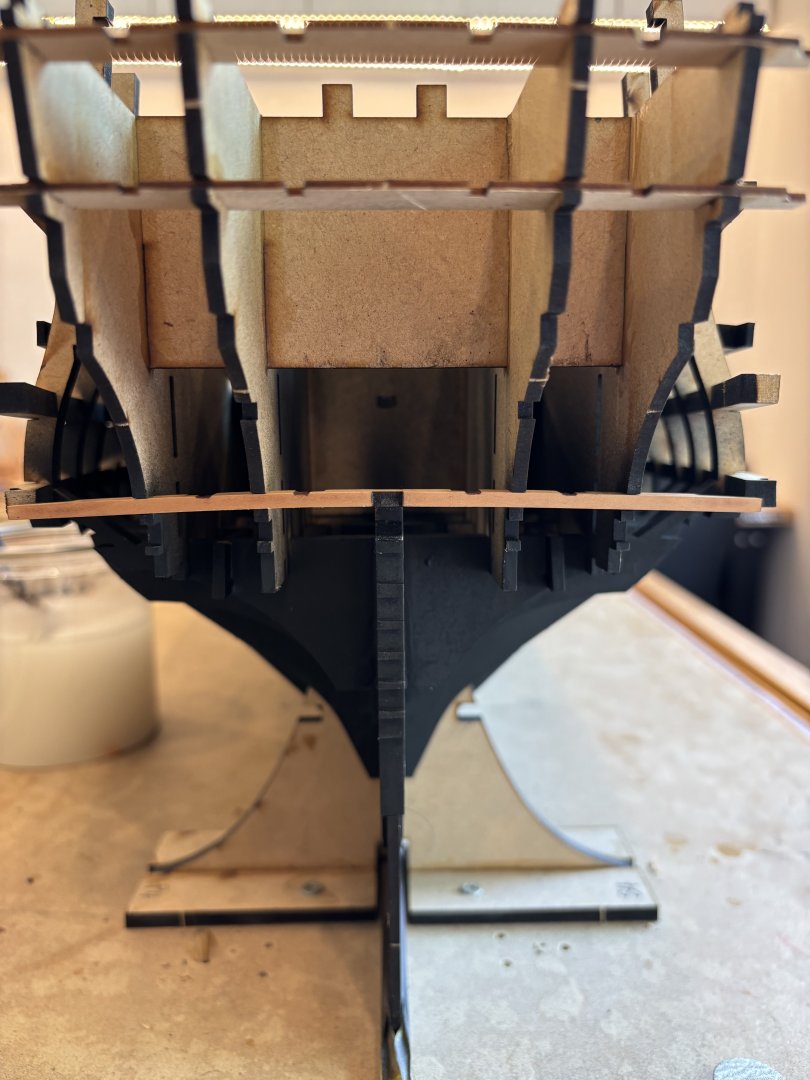

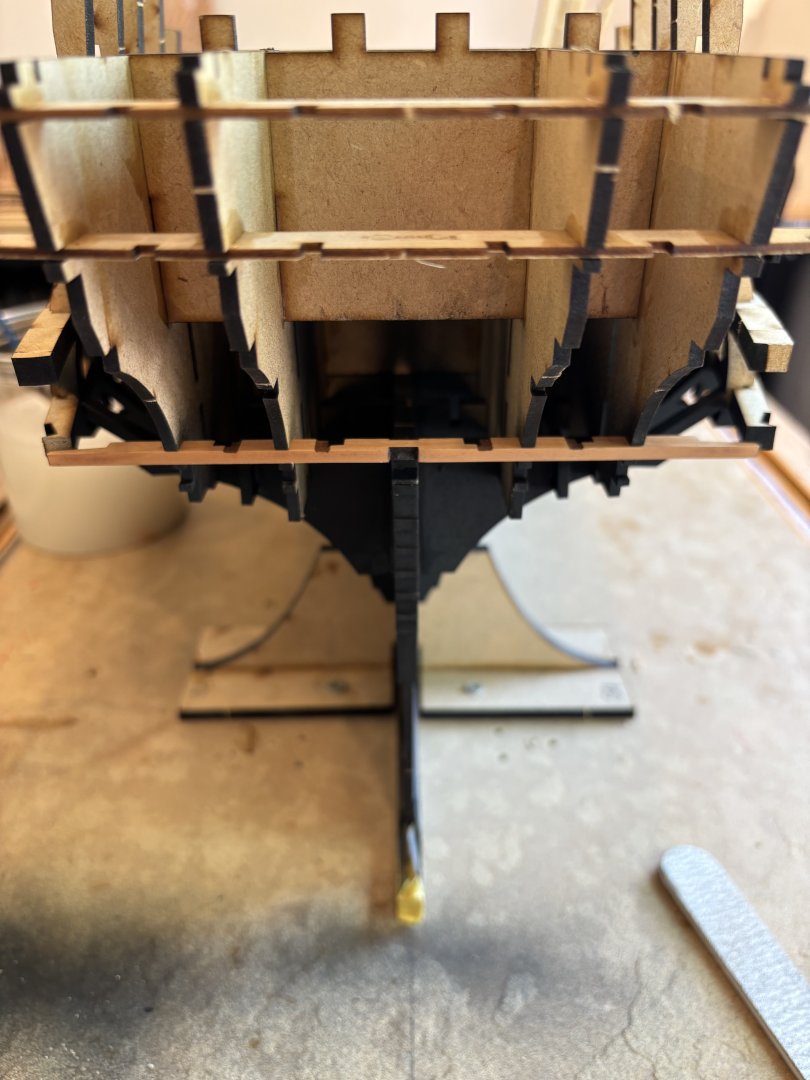

Here are the upper frame locator pieces, two mdf parts on each side that get clipped into the former at the bow and then into grooves on each bulkhead, I used a few rubber bands and some clamps to keep them securely in place while the glue dried. Now that these have been installed I need to start masking off the keel and other parts so I can paint the former and all bulkheads flat matt black below the level of the gundeck so nothing can be seen behind the framing, or at least make it as invisible as possible.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.