-

Posts

157 -

Joined

-

Last visited

Reputation Activity

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Mark,

Those two videos have the information I have been looking for all week. I was out of ideas on where else to look. I have begun both his and your builds but hadn't reached anything other than his mention of using a hair dryer. Without the video the information doesn't help someone as inexperienced as me. Your "tear aparts" motivated me to do my own. Thank you . . .

My home made jig gave me two planks with difficulty but Chuck's method for edge bending was as simple and easy as one could ever hope to find. After putting the wale plank and the one above it with two planks made from my jig I used Chuck's method and more easily made two more as seen below. I even went so far as to order some clamps identical to what he used.

The second and equally important thing was watching him illustrate implementation of his lining off. I did not do that the first time, even though I recognized its importance, I will definitely do it this time.

Respectfully and thankfully,

John Maguire

Seattle

-

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Mark,

Those two videos have the information I have been looking for all week. I was out of ideas on where else to look. I have begun both his and your builds but hadn't reached anything other than his mention of using a hair dryer. Without the video the information doesn't help someone as inexperienced as me. Your "tear aparts" motivated me to do my own. Thank you . . .

My home made jig gave me two planks with difficulty but Chuck's method for edge bending was as simple and easy as one could ever hope to find. After putting the wale plank and the one above it with two planks made from my jig I used Chuck's method and more easily made two more as seen below. I even went so far as to order some clamps identical to what he used.

The second and equally important thing was watching him illustrate implementation of his lining off. I did not do that the first time, even though I recognized its importance, I will definitely do it this time.

Respectfully and thankfully,

John Maguire

Seattle

-

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Mark,

Those two videos have the information I have been looking for all week. I was out of ideas on where else to look. I have begun both his and your builds but hadn't reached anything other than his mention of using a hair dryer. Without the video the information doesn't help someone as inexperienced as me. Your "tear aparts" motivated me to do my own. Thank you . . .

My home made jig gave me two planks with difficulty but Chuck's method for edge bending was as simple and easy as one could ever hope to find. After putting the wale plank and the one above it with two planks made from my jig I used Chuck's method and more easily made two more as seen below. I even went so far as to order some clamps identical to what he used.

The second and equally important thing was watching him illustrate implementation of his lining off. I did not do that the first time, even though I recognized its importance, I will definitely do it this time.

Respectfully and thankfully,

John Maguire

Seattle

-

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Mark,

Those two videos have the information I have been looking for all week. I was out of ideas on where else to look. I have begun both his and your builds but hadn't reached anything other than his mention of using a hair dryer. Without the video the information doesn't help someone as inexperienced as me. Your "tear aparts" motivated me to do my own. Thank you . . .

My home made jig gave me two planks with difficulty but Chuck's method for edge bending was as simple and easy as one could ever hope to find. After putting the wale plank and the one above it with two planks made from my jig I used Chuck's method and more easily made two more as seen below. I even went so far as to order some clamps identical to what he used.

The second and equally important thing was watching him illustrate implementation of his lining off. I did not do that the first time, even though I recognized its importance, I will definitely do it this time.

Respectfully and thankfully,

John Maguire

Seattle

-

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

First of all, thank you for the many LIKES, dear friends . . . .

Having said that, here I am back again - twice in the same day. Reason: problem solved!

I see all of you with your clever home made tools and jigs so I decided to begin by following your lead and try one myself. The advantage I found with this jig was that after clamping the concave side to the tile I could lay the movable piece on top of my plank during the bending push and by so doing it kept the plank from wrinkling as it was forced into its unnatural edge direction.

All the techniques with which I was unsuccessful seemed in my opinion to be tailored to normal bending and gave me no discernible relief when I used them for edge bending.

I opted to follow the lead of Mark and Chuck with plank lengths that in my case are only somewhat scale. Importantly, by having shorter lengths to attach I'll have more control in glue amount, taper, bevel and plank to plank tightness. I did the first attempt, which was removed, with full hull length planks and always felt that I didn't have the control that I wished for.

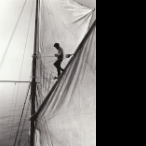

Below is the wale plank and the first plank above it. Those are the two most difficult. On my hull, they can only lay flat and fair if they are edge bent.

Continuing to plank upward will only require slight edge bending.

Planking downward will only require tapering.

Again, thank you for your many advices. Also, I am going to look closely at Chuck's videos.

Now back for an edit after getting into just the first few minutes of Chuck's video and I see the easy way to do it . . . . Wow!

Respectfully,

John

-

John Maguire got a reaction from cristikc in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from cristikc in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

First of all, thank you for the many LIKES, dear friends . . . .

Having said that, here I am back again - twice in the same day. Reason: problem solved!

I see all of you with your clever home made tools and jigs so I decided to begin by following your lead and try one myself. The advantage I found with this jig was that after clamping the concave side to the tile I could lay the movable piece on top of my plank during the bending push and by so doing it kept the plank from wrinkling as it was forced into its unnatural edge direction.

All the techniques with which I was unsuccessful seemed in my opinion to be tailored to normal bending and gave me no discernible relief when I used them for edge bending.

I opted to follow the lead of Mark and Chuck with plank lengths that in my case are only somewhat scale. Importantly, by having shorter lengths to attach I'll have more control in glue amount, taper, bevel and plank to plank tightness. I did the first attempt, which was removed, with full hull length planks and always felt that I didn't have the control that I wished for.

Below is the wale plank and the first plank above it. Those are the two most difficult. On my hull, they can only lay flat and fair if they are edge bent.

Continuing to plank upward will only require slight edge bending.

Planking downward will only require tapering.

Again, thank you for your many advices. Also, I am going to look closely at Chuck's videos.

Now back for an edit after getting into just the first few minutes of Chuck's video and I see the easy way to do it . . . . Wow!

Respectfully,

John

-

John Maguire got a reaction from WackoWolf in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from WackoWolf in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

First of all, thank you for the many LIKES, dear friends . . . .

Having said that, here I am back again - twice in the same day. Reason: problem solved!

I see all of you with your clever home made tools and jigs so I decided to begin by following your lead and try one myself. The advantage I found with this jig was that after clamping the concave side to the tile I could lay the movable piece on top of my plank during the bending push and by so doing it kept the plank from wrinkling as it was forced into its unnatural edge direction.

All the techniques with which I was unsuccessful seemed in my opinion to be tailored to normal bending and gave me no discernible relief when I used them for edge bending.

I opted to follow the lead of Mark and Chuck with plank lengths that in my case are only somewhat scale. Importantly, by having shorter lengths to attach I'll have more control in glue amount, taper, bevel and plank to plank tightness. I did the first attempt, which was removed, with full hull length planks and always felt that I didn't have the control that I wished for.

Below is the wale plank and the first plank above it. Those are the two most difficult. On my hull, they can only lay flat and fair if they are edge bent.

Continuing to plank upward will only require slight edge bending.

Planking downward will only require tapering.

Again, thank you for your many advices. Also, I am going to look closely at Chuck's videos.

Now back for an edit after getting into just the first few minutes of Chuck's video and I see the easy way to do it . . . . Wow!

Respectfully,

John

-

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

First of all, thank you for the many LIKES, dear friends . . . .

Having said that, here I am back again - twice in the same day. Reason: problem solved!

I see all of you with your clever home made tools and jigs so I decided to begin by following your lead and try one myself. The advantage I found with this jig was that after clamping the concave side to the tile I could lay the movable piece on top of my plank during the bending push and by so doing it kept the plank from wrinkling as it was forced into its unnatural edge direction.

All the techniques with which I was unsuccessful seemed in my opinion to be tailored to normal bending and gave me no discernible relief when I used them for edge bending.

I opted to follow the lead of Mark and Chuck with plank lengths that in my case are only somewhat scale. Importantly, by having shorter lengths to attach I'll have more control in glue amount, taper, bevel and plank to plank tightness. I did the first attempt, which was removed, with full hull length planks and always felt that I didn't have the control that I wished for.

Below is the wale plank and the first plank above it. Those are the two most difficult. On my hull, they can only lay flat and fair if they are edge bent.

Continuing to plank upward will only require slight edge bending.

Planking downward will only require tapering.

Again, thank you for your many advices. Also, I am going to look closely at Chuck's videos.

Now back for an edit after getting into just the first few minutes of Chuck's video and I see the easy way to do it . . . . Wow!

Respectfully,

John

-

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

First of all, thank you for the many LIKES, dear friends . . . .

Having said that, here I am back again - twice in the same day. Reason: problem solved!

I see all of you with your clever home made tools and jigs so I decided to begin by following your lead and try one myself. The advantage I found with this jig was that after clamping the concave side to the tile I could lay the movable piece on top of my plank during the bending push and by so doing it kept the plank from wrinkling as it was forced into its unnatural edge direction.

All the techniques with which I was unsuccessful seemed in my opinion to be tailored to normal bending and gave me no discernible relief when I used them for edge bending.

I opted to follow the lead of Mark and Chuck with plank lengths that in my case are only somewhat scale. Importantly, by having shorter lengths to attach I'll have more control in glue amount, taper, bevel and plank to plank tightness. I did the first attempt, which was removed, with full hull length planks and always felt that I didn't have the control that I wished for.

Below is the wale plank and the first plank above it. Those are the two most difficult. On my hull, they can only lay flat and fair if they are edge bent.

Continuing to plank upward will only require slight edge bending.

Planking downward will only require tapering.

Again, thank you for your many advices. Also, I am going to look closely at Chuck's videos.

Now back for an edit after getting into just the first few minutes of Chuck's video and I see the easy way to do it . . . . Wow!

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, Joe, Don & Mark,

Thank you for your thoughtful advices.

Yes, I did the original "first" planking in this area but it was as much a hassle as I am having now and the seams are not finish quality. I could not achieve really finish grade seams.

Pictures that I displayed a few posts ago show where I was headed this time with the final planking and the results were not suitable. With the first planking, glueing the couple of inches closest to the stem was done with medium viscosity super glue. It seems like every place I did that there were black seams. Probably a coincidence. Additionally, the seams were not furniture tight. I was fighting the wood.

I have been scouring You Tube videos for the past two days to no avail. Thank you for the Chuck related videos. I just saw that post and will look. I soaked some planks in alcohol all night then wrapped one in a wet cloth and microwaved it, first for three minutes with no good results, then for five minutes. No help.

I tried hot air and it did nothing on either of the two types of wood that I have. In the photo below you'll see a piece of the wood used for the first planking that I experimented on with hot air this morning and broke it.

I made a jig with the approximate shape that I want and by putting the smaller part of the jig on top of my plank I was able to keep the planking from twisting as I forced it into the concave shape of the jig. I ran hot air over it later to try to dry out the wood. I'll leave it for awhile before releasing the clamps.

Could it be that this wood is of so little mass that it does not retain interior heat after trying to steam it in a wet rag inside the microwave oven?

I am thinking next of trying boiling water for an hour or longer.

Here is what I just did. You can see the tape pattern beside it and to the side is the piece I broke when I tried hot air.

Respectfully,

John

-

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

First of all, thank you for the many LIKES, dear friends . . . .

Having said that, here I am back again - twice in the same day. Reason: problem solved!

I see all of you with your clever home made tools and jigs so I decided to begin by following your lead and try one myself. The advantage I found with this jig was that after clamping the concave side to the tile I could lay the movable piece on top of my plank during the bending push and by so doing it kept the plank from wrinkling as it was forced into its unnatural edge direction.

All the techniques with which I was unsuccessful seemed in my opinion to be tailored to normal bending and gave me no discernible relief when I used them for edge bending.

I opted to follow the lead of Mark and Chuck with plank lengths that in my case are only somewhat scale. Importantly, by having shorter lengths to attach I'll have more control in glue amount, taper, bevel and plank to plank tightness. I did the first attempt, which was removed, with full hull length planks and always felt that I didn't have the control that I wished for.

Below is the wale plank and the first plank above it. Those are the two most difficult. On my hull, they can only lay flat and fair if they are edge bent.

Continuing to plank upward will only require slight edge bending.

Planking downward will only require tapering.

Again, thank you for your many advices. Also, I am going to look closely at Chuck's videos.

Now back for an edit after getting into just the first few minutes of Chuck's video and I see the easy way to do it . . . . Wow!

Respectfully,

John

-

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, Joe, Don & Mark,

Thank you for your thoughtful advices.

Yes, I did the original "first" planking in this area but it was as much a hassle as I am having now and the seams are not finish quality. I could not achieve really finish grade seams.

Pictures that I displayed a few posts ago show where I was headed this time with the final planking and the results were not suitable. With the first planking, glueing the couple of inches closest to the stem was done with medium viscosity super glue. It seems like every place I did that there were black seams. Probably a coincidence. Additionally, the seams were not furniture tight. I was fighting the wood.

I have been scouring You Tube videos for the past two days to no avail. Thank you for the Chuck related videos. I just saw that post and will look. I soaked some planks in alcohol all night then wrapped one in a wet cloth and microwaved it, first for three minutes with no good results, then for five minutes. No help.

I tried hot air and it did nothing on either of the two types of wood that I have. In the photo below you'll see a piece of the wood used for the first planking that I experimented on with hot air this morning and broke it.

I made a jig with the approximate shape that I want and by putting the smaller part of the jig on top of my plank I was able to keep the planking from twisting as I forced it into the concave shape of the jig. I ran hot air over it later to try to dry out the wood. I'll leave it for awhile before releasing the clamps.

Could it be that this wood is of so little mass that it does not retain interior heat after trying to steam it in a wet rag inside the microwave oven?

I am thinking next of trying boiling water for an hour or longer.

Here is what I just did. You can see the tape pattern beside it and to the side is the piece I broke when I tried hot air.

Respectfully,

John

-

John Maguire got a reaction from CaptainSteve in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from CaptainSteve in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, Joe, Don & Mark,

Thank you for your thoughtful advices.

Yes, I did the original "first" planking in this area but it was as much a hassle as I am having now and the seams are not finish quality. I could not achieve really finish grade seams.

Pictures that I displayed a few posts ago show where I was headed this time with the final planking and the results were not suitable. With the first planking, glueing the couple of inches closest to the stem was done with medium viscosity super glue. It seems like every place I did that there were black seams. Probably a coincidence. Additionally, the seams were not furniture tight. I was fighting the wood.

I have been scouring You Tube videos for the past two days to no avail. Thank you for the Chuck related videos. I just saw that post and will look. I soaked some planks in alcohol all night then wrapped one in a wet cloth and microwaved it, first for three minutes with no good results, then for five minutes. No help.

I tried hot air and it did nothing on either of the two types of wood that I have. In the photo below you'll see a piece of the wood used for the first planking that I experimented on with hot air this morning and broke it.

I made a jig with the approximate shape that I want and by putting the smaller part of the jig on top of my plank I was able to keep the planking from twisting as I forced it into the concave shape of the jig. I ran hot air over it later to try to dry out the wood. I'll leave it for awhile before releasing the clamps.

Could it be that this wood is of so little mass that it does not retain interior heat after trying to steam it in a wet rag inside the microwave oven?

I am thinking next of trying boiling water for an hour or longer.

Here is what I just did. You can see the tape pattern beside it and to the side is the piece I broke when I tried hot air.

Respectfully,

John

-

John Maguire got a reaction from GuntherMT in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from GuntherMT in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, Joe, Don & Mark,

Thank you for your thoughtful advices.

Yes, I did the original "first" planking in this area but it was as much a hassle as I am having now and the seams are not finish quality. I could not achieve really finish grade seams.

Pictures that I displayed a few posts ago show where I was headed this time with the final planking and the results were not suitable. With the first planking, glueing the couple of inches closest to the stem was done with medium viscosity super glue. It seems like every place I did that there were black seams. Probably a coincidence. Additionally, the seams were not furniture tight. I was fighting the wood.

I have been scouring You Tube videos for the past two days to no avail. Thank you for the Chuck related videos. I just saw that post and will look. I soaked some planks in alcohol all night then wrapped one in a wet cloth and microwaved it, first for three minutes with no good results, then for five minutes. No help.

I tried hot air and it did nothing on either of the two types of wood that I have. In the photo below you'll see a piece of the wood used for the first planking that I experimented on with hot air this morning and broke it.

I made a jig with the approximate shape that I want and by putting the smaller part of the jig on top of my plank I was able to keep the planking from twisting as I forced it into the concave shape of the jig. I ran hot air over it later to try to dry out the wood. I'll leave it for awhile before releasing the clamps.

Could it be that this wood is of so little mass that it does not retain interior heat after trying to steam it in a wet rag inside the microwave oven?

I am thinking next of trying boiling water for an hour or longer.

Here is what I just did. You can see the tape pattern beside it and to the side is the piece I broke when I tried hot air.

Respectfully,

John

-

John Maguire got a reaction from Elijah in Independence 1775 by DocBlake - Artesania Latina - 5/16" scale.

John Maguire got a reaction from Elijah in Independence 1775 by DocBlake - Artesania Latina - 5/16" scale.

Nice, Doc . . .

-

John Maguire got a reaction from Elijah in Independence 1775 by DocBlake - Artesania Latina - 5/16" scale.

John Maguire got a reaction from Elijah in Independence 1775 by DocBlake - Artesania Latina - 5/16" scale.

Doc,

Good to see some work again here. Its fun to see how quickly you experienced folks get through the first planking.

I wish I had found the Gast Haus when I was building the Mequon site.

Respectfully,

John

-

John Maguire got a reaction from CaptainSteve in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from CaptainSteve in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you for the many LIKES and advices for staining. I am unable to identify the wood type. Don Robinson, Denis or Marten, could you please identify the specie?

Well, today I decided my work was unsatisfactory. Look at this.

And this . . .

So, I spent the afternoon with #60 sandpaper and ground back down to the glue boundary.

Now for reconstruction, here is a photo of the plan. Look to the relative position of the lower wale. The manual calls for a strake in the position of each wale and they call it a wale plank. Later in the build they instruct the builder to add a wale on top of the wale plank. So, to recap, the first task is to lay the wale plank. Please observe its position relative to other prominent features.

In the next picture you'll see I have heavily marked the wale position so that I can use Dan's "cover it with tape" scheme and be able to see the line through my tape. I then took a long 5mm plank and correctly positioned it below the gun ports and let it run with its natural flat lay against the hull. Notice please how it travels upward approaching the stem, contrary to the plan.

In the following picture you will see a completed REVENGE where the builder seems to have done exactly what is demonstrated in my prior photo. It is a beautiful model, by the way.

Now, back to the Builders Manual. In this photo they attach the wale strake, then on the next strake below it they begin to taper. My problem is that I can't attach the initial wale plank the way Chris did because of compound curvatures. He is a magician.

Here is another view of the correct position.

And finally, the next picture is the best available that illustrates the compound nature of the plank.

Do any of you have a technique to bend planks in unnatural directions? Not only the bend, but when you study this last picture it can be seen the plank needs to be longer on the top edge than on the bottom edge. I did this before, but not well and that is part of why I removed my last weeks work.

Spile? When I lay out tape on the hull - flat - as per Dan's suggestion to Mark and then remove and study the tape trace laying flat on the table it looks to me to be a spile candidate because the shape is so irregular and represents the width of at least three planks. However, if the wood can be turned to wet spaghetti that would sure be easier.

Please dear friends weigh in with your opinions.

Respectfully,

John

-

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, I am enroute to checking out Chuck's edge bending right now - thank you.

Don, you are very observant - because the ship is upside down I put the plank on the wrong side of the line to make photography better. Repositioning it will not make the kind of change necessary. Can you please look at your kit Don and identify the wood I am using?

Respectfully,

John

-

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you for the many LIKES and advices for staining. I am unable to identify the wood type. Don Robinson, Denis or Marten, could you please identify the specie?

Well, today I decided my work was unsatisfactory. Look at this.

And this . . .

So, I spent the afternoon with #60 sandpaper and ground back down to the glue boundary.

Now for reconstruction, here is a photo of the plan. Look to the relative position of the lower wale. The manual calls for a strake in the position of each wale and they call it a wale plank. Later in the build they instruct the builder to add a wale on top of the wale plank. So, to recap, the first task is to lay the wale plank. Please observe its position relative to other prominent features.

In the next picture you'll see I have heavily marked the wale position so that I can use Dan's "cover it with tape" scheme and be able to see the line through my tape. I then took a long 5mm plank and correctly positioned it below the gun ports and let it run with its natural flat lay against the hull. Notice please how it travels upward approaching the stem, contrary to the plan.

In the following picture you will see a completed REVENGE where the builder seems to have done exactly what is demonstrated in my prior photo. It is a beautiful model, by the way.

Now, back to the Builders Manual. In this photo they attach the wale strake, then on the next strake below it they begin to taper. My problem is that I can't attach the initial wale plank the way Chris did because of compound curvatures. He is a magician.

Here is another view of the correct position.

And finally, the next picture is the best available that illustrates the compound nature of the plank.

Do any of you have a technique to bend planks in unnatural directions? Not only the bend, but when you study this last picture it can be seen the plank needs to be longer on the top edge than on the bottom edge. I did this before, but not well and that is part of why I removed my last weeks work.

Spile? When I lay out tape on the hull - flat - as per Dan's suggestion to Mark and then remove and study the tape trace laying flat on the table it looks to me to be a spile candidate because the shape is so irregular and represents the width of at least three planks. However, if the wood can be turned to wet spaghetti that would sure be easier.

Please dear friends weigh in with your opinions.

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, I am enroute to checking out Chuck's edge bending right now - thank you.

Don, you are very observant - because the ship is upside down I put the plank on the wrong side of the line to make photography better. Repositioning it will not make the kind of change necessary. Can you please look at your kit Don and identify the wood I am using?

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you for the many LIKES and advices for staining. I am unable to identify the wood type. Don Robinson, Denis or Marten, could you please identify the specie?

Well, today I decided my work was unsatisfactory. Look at this.

And this . . .

So, I spent the afternoon with #60 sandpaper and ground back down to the glue boundary.

Now for reconstruction, here is a photo of the plan. Look to the relative position of the lower wale. The manual calls for a strake in the position of each wale and they call it a wale plank. Later in the build they instruct the builder to add a wale on top of the wale plank. So, to recap, the first task is to lay the wale plank. Please observe its position relative to other prominent features.

In the next picture you'll see I have heavily marked the wale position so that I can use Dan's "cover it with tape" scheme and be able to see the line through my tape. I then took a long 5mm plank and correctly positioned it below the gun ports and let it run with its natural flat lay against the hull. Notice please how it travels upward approaching the stem, contrary to the plan.

In the following picture you will see a completed REVENGE where the builder seems to have done exactly what is demonstrated in my prior photo. It is a beautiful model, by the way.

Now, back to the Builders Manual. In this photo they attach the wale strake, then on the next strake below it they begin to taper. My problem is that I can't attach the initial wale plank the way Chris did because of compound curvatures. He is a magician.

Here is another view of the correct position.

And finally, the next picture is the best available that illustrates the compound nature of the plank.

Do any of you have a technique to bend planks in unnatural directions? Not only the bend, but when you study this last picture it can be seen the plank needs to be longer on the top edge than on the bottom edge. I did this before, but not well and that is part of why I removed my last weeks work.

Spile? When I lay out tape on the hull - flat - as per Dan's suggestion to Mark and then remove and study the tape trace laying flat on the table it looks to me to be a spile candidate because the shape is so irregular and represents the width of at least three planks. However, if the wood can be turned to wet spaghetti that would sure be easier.

Please dear friends weigh in with your opinions.

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you for all who have looked in and posted LIKES.

Thanks Mark, yes, I see what you say. I am trying to tighten things up moving forward.

The wood itself, even if perfectly fit, is in my opinion too light in color. It is not the walnut described in the manual. Overall, the planking so far as well as the first layer is sufficiently tight that it does not need sanding sealer to further tighten and bind it, although I have put it on, followed by sanding.

At this point I think I want to use walnut stain to darken the wood. Should I plan to use Minwax "wood prep for staining"? Am I correct to think it enables the stain to color evenly? Do you think it will disguise my flaws? Should sanding sealer go on first or would it keep the Minwax wood prep from soaking into the wood?

Too many questions - sorry . . .

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Seven strakes on each side now . . .

Question please: some of the separations between planks, though very tight, have black lines for reasons that I don't understand. This supplied wood is light in color and not to my liking so I have been thinking I'd stain it, possibly dark walnut. In your experiences, do you think there is a reasonable expectation that the stain will neutralize that effect?

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Capt. Steve, WW & Doc. Also thank you for the many "Likes".

Another productive day at the Cougar Mtn. Shipyard. I think it was Martin who said planking between the Wales is a bit finicky - or something to the sort. Wrong dear friend - it is very finicky. The wood just doesn't want to bend that way. To do it otherwise would be to have the wales sharply swing upward approaching the stem and converge. The manual, box pictures and my sea eye wants to see the Wales run parallel to the deck and be evenly separated for their length. The only way to do that is to torture the wood. But, having said that the worst case is the so called wale plank that will be covered by the lower wale. In the photo, it is the lowest strake. Each plank above that becomes slightly less tortured. I have four in place on each side now, moving in the upward direction and the fifth and beyond look to be straight flat easy runs. I don't look forward to returning to bend a lower wale to shape, especially considering that it will need to have been tortured in the wrong direction and remain stable in shape so that it can be painted before glueing in position. Help. What is an effective way to bend wood the "wrong way"? Maybe a couple of minutes of steam isn't enough . . .

Here is a quick peek at the stbd side before clean up.

The port side, my learning side, was done first and does not have furniture quality seams between the planks. I have mixed some saw dust with watered down PVA and we'll see if I did a good job with the witches brew tomorrow when it gets a little sanding. Now it looks pretty messy.

Moving upwards from these four planks looks straight forward. No weird bends or torture.

In the downward direction I experimented by laying a plank adjacent to the lower wale plank and tracing a line with a pencil on the hull from bow to stern. I then moved the plank down to that line and did the same thing plank by plank moving towards the keel. They end up pretty much parallel to the keel, so hopefully the worst is over.

Thank you for looking in.

Respectfully,

John

-

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, I am enroute to checking out Chuck's edge bending right now - thank you.

Don, you are very observant - because the ship is upside down I put the plank on the wrong side of the line to make photography better. Repositioning it will not make the kind of change necessary. Can you please look at your kit Don and identify the wood I am using?

Respectfully,

John