-

Posts

157 -

Joined

-

Last visited

Reputation Activity

-

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

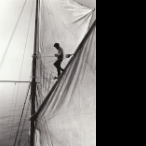

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from zoly99sask in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from zoly99sask in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from DocBlake in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from Piet in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

John Maguire got a reaction from Piet in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

Beautiful . . .

-

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mtaylor in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from mrshanks in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from Rainbow in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Rainbow in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you folks for the many LIKES . . . .

Amati supplied small 4 mm pieces to go between the forward frames that would define the bearding line. In their construction manual it could be seen that planks making the extreme curve close to the bow had flat spots between the frames that were the result of them not following a rounded lay.

I opted to use balsa fillers in lieu of the supplied components. Initially I tried to economize on the amount of balsa by cutting it cleverly but I wasn't clever enough so with version 2.0 ended up using full rectangular inserts.

The following day I chewed up the overhang to the extent possible with a small grinder, then using a sanding block and 60 grit paper worked the port side down to shape.

Another day and both sides are complete.

Now I get a nice rounded fair lay with test planks. The balsa at the absolute front area will need tweaking where the planks would meet the stem but I'll deal with that at that time. I don't want to do it now and accidentally remove too much balsa.

Respectfully submitted,

John Maguire

Total Time 108 hours (I am slow)

-

John Maguire got a reaction from GuntherMT in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from GuntherMT in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from slow2cool in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from slow2cool in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from CaptainSteve in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from CaptainSteve in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you Brian, Mark, Doc & Joe.

I am more verbose than most Joe because I am both slower and since I lack experience I am trying to show all the nitty gritty in hopes that one of you will catch me before I get way beyond my ability to reasonably recover.

The pictures in the manual show walnut but the supplied wood is far from that quality. I do not know what it is other than soft.

Edge bending to achieve a result similar to spiles took me a week of reading and finally Chuck's video to understand. Reading and doing are two different things . . . .

The uppermost strake seen forward in the following photos is the wale plank. I extended it one more piece aft, leaving one section to go. Learning from your build Mark, when I joined the piece to the wale plank I laid another alongside temporarily to assure the transition would be straight and unnoticed. Slight bending downward will take place beyond.

I also like the layout seen in the second group of pictures from the previous post. It seemed to embody the lessons so many have written, but I wanted to present it for opinions in case I was blind siding myself.

Today, for future reference, I carefully traced both sides of all four banding planks onto the hull, then tic'd off the uppermost band from my arbitrary 0 frame to the stem. I will end up with approximately 3/4 plank width there.

Here is another view further forward.

Before extending the wale strake I needed to finish planking the transom because the finish planking should overlay the transom edge.

I also had seam blackening for unknown reasons that I have seen others remark about. I am experimenting with an idea that I hope will prevent it. Chuck Passaro, in his CHEERFUL build makes a point of mentioning not using edge glue. He has as you know pencil blackened the edges to simulate tar. If he can get along without edge glue I plan to try it also. My two forward hull strakes and the entire transom are carefully fit with beveled edges and forced tight fits and so far they are clean. Fingers crossed.

Respectfully,

John

-

John Maguire got a reaction from Elijah in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

John Maguire got a reaction from Elijah in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

Beautiful . . .

-

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Continuing with the previous post, this line out scheme began with the mid strake positioned at plank 14, midway between the wale and keel, but rather than routing it forward at frame midpoints it was run strictly by eye, offered into what looked fair taking into account the wale and the keel. Strakes to define all four bands were run this time.

Strakes in each band are always wider than half plank at the stem. I see no issues, so far, at the stern.

I would appreciate as many opinions as possible.

Respectfully,

John

-

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Jack12477 in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

This is the first to two consecutive posts, each describing a planking possibility. Kindly give opinions.

I am considering a different way than Chris's instruction on how to plank REVENGE. To do as he suggests begins with the wale plank, laid on approximately parallel to the deck sheer. Planks below the wale would then follow a path similar to this picture.

Looking at Chuck Passaro's CHEERFUL and studying his edge bending technique invites the thought of edge bent spile like planks where aft and particularly forward they more nearly parallel the wale as well as the keel. I am bending the planks as seen below to prevent wrinkling. Though Chuck has bent his dry, I found my wood cracked. Wetting it for a couple of minutes in hot water prevented that. I plan to further explore with boiling water. Once bent, I put the jig in the freezer to hasten cooling.

As I began to line out the hull, two possibilities presented themselves. I plan to post twice - once for each of the possibilities that I investigated.

I used actual planks to define four bands. This enable me to more clearly visualize the actual fair lay and in particular what would happen at the stem.

This is the FIRST of the two posts and shows one of the explored possibilities.

I began by choosing the widest frame amidship. My 4mm planks will require 28 strakes to go from the lower edge of the wale (reference) plank to the keel. In the next photo the mid plank is shown. The strake is laying fair through the position for the 14th plank, half way between the wale and the keel. Looking at the two frame positions forward can be seen a pin hole at each representing the mid point between the wale and the keel.

This mid band strake was positioned at the stern to be the last strake approaching the post that is in a rounded position. The next plank would parallel the vertical part of the stern.

The mid point strake, already edge bent, continues forward half way between the wale and the keel. It can be seen converging with the wale in the next two pictures.

At this point the plan to divide each frame into four equal widths began to look like the stem area was not going to work out well. The equal division of each frame into four equal width bands sounded reasonable but in reality I don't think it works. Should it if spiled?

I went on to a modified proposal that can be seen in the next post.

Respectfully,

John

-

John Maguire got a reaction from Canute in Armed Virginia Sloop Patrick Henry by DocBlake - FINISHED - Lauck Street Shipyard - Scale = 1/32 - POF Admiralty Style

John Maguire got a reaction from Canute in Armed Virginia Sloop Patrick Henry by DocBlake - FINISHED - Lauck Street Shipyard - Scale = 1/32 - POF Admiralty Style

The cannons are exquisite, Doc . . .

-

John Maguire got a reaction from slow2cool in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

John Maguire got a reaction from slow2cool in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

Beautiful . . .

-

John Maguire got a reaction from slow2cool in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from slow2cool in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Continuing with the previous post, this line out scheme began with the mid strake positioned at plank 14, midway between the wale and keel, but rather than routing it forward at frame midpoints it was run strictly by eye, offered into what looked fair taking into account the wale and the keel. Strakes to define all four bands were run this time.

Strakes in each band are always wider than half plank at the stem. I see no issues, so far, at the stern.

I would appreciate as many opinions as possible.

Respectfully,

John

-

John Maguire got a reaction from slow2cool in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from slow2cool in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

This is the first to two consecutive posts, each describing a planking possibility. Kindly give opinions.

I am considering a different way than Chris's instruction on how to plank REVENGE. To do as he suggests begins with the wale plank, laid on approximately parallel to the deck sheer. Planks below the wale would then follow a path similar to this picture.

Looking at Chuck Passaro's CHEERFUL and studying his edge bending technique invites the thought of edge bent spile like planks where aft and particularly forward they more nearly parallel the wale as well as the keel. I am bending the planks as seen below to prevent wrinkling. Though Chuck has bent his dry, I found my wood cracked. Wetting it for a couple of minutes in hot water prevented that. I plan to further explore with boiling water. Once bent, I put the jig in the freezer to hasten cooling.

As I began to line out the hull, two possibilities presented themselves. I plan to post twice - once for each of the possibilities that I investigated.

I used actual planks to define four bands. This enable me to more clearly visualize the actual fair lay and in particular what would happen at the stem.

This is the FIRST of the two posts and shows one of the explored possibilities.

I began by choosing the widest frame amidship. My 4mm planks will require 28 strakes to go from the lower edge of the wale (reference) plank to the keel. In the next photo the mid plank is shown. The strake is laying fair through the position for the 14th plank, half way between the wale and the keel. Looking at the two frame positions forward can be seen a pin hole at each representing the mid point between the wale and the keel.

This mid band strake was positioned at the stern to be the last strake approaching the post that is in a rounded position. The next plank would parallel the vertical part of the stern.

The mid point strake, already edge bent, continues forward half way between the wale and the keel. It can be seen converging with the wale in the next two pictures.

At this point the plan to divide each frame into four equal widths began to look like the stem area was not going to work out well. The equal division of each frame into four equal width bands sounded reasonable but in reality I don't think it works. Should it if spiled?

I went on to a modified proposal that can be seen in the next post.

Respectfully,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Thank you for the many LIKES, dear friends . . .

Joe, I appreciate you taking the time to comment. At this point in time I have only edge bent two planks with Chuck's method. I bent to the point where I felt safe, then clamped and applied heat. There was very little spring back when I released the clamps after cooling. I found that I could further bend at that point and repeat the process.

I just spent part of the last two days hand sanding the planks previously glued to the stbd side of the ship. Boring. The port side had been stripped earlier.

The builders manual instructs the constructor to attach the wale plank as described a couple of days ago and then continue planking as seen in the photo below.

Instead, I am going to line off the hull in standard fashion and use Chuck Passaro's edge bending technique to plank parallel to the lower run of the gun ports. That should produce an appearance similar to his ship CHEERFUL. I prefer that appearance.

Edge bent planks similar to this, which he advocates in lieu of stealers and drop planks, seem to make that possible.

Amati provides 4mm finish planking while specifying 5mm. That of course makes no difference, but I plan to mill 5mm wood and paint it black for the wales. The wales will to some degree not be parallel to the hull planking at the bow and stern, only midship. I believe I have seen that on other ship builds. The 5mm width ought to work well in contrast to the 4mm planking that it overlays.

Now to study lining off . . .

Respectfully submitted,

John

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Mark,

Those two videos have the information I have been looking for all week. I was out of ideas on where else to look. I have begun both his and your builds but hadn't reached anything other than his mention of using a hair dryer. Without the video the information doesn't help someone as inexperienced as me. Your "tear aparts" motivated me to do my own. Thank you . . .

My home made jig gave me two planks with difficulty but Chuck's method for edge bending was as simple and easy as one could ever hope to find. After putting the wale plank and the one above it with two planks made from my jig I used Chuck's method and more easily made two more as seen below. I even went so far as to order some clamps identical to what he used.

The second and equally important thing was watching him illustrate implementation of his lining off. I did not do that the first time, even though I recognized its importance, I will definitely do it this time.

Respectfully and thankfully,

John Maguire

Seattle

-

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

John Maguire got a reaction from Elijah in REVENGE by John Maguire - Amati/Victory Models - build in the Cougar Mountain Shipyard

Brian, Joe, Don & Mark,

Thank you for your thoughtful advices.

Yes, I did the original "first" planking in this area but it was as much a hassle as I am having now and the seams are not finish quality. I could not achieve really finish grade seams.

Pictures that I displayed a few posts ago show where I was headed this time with the final planking and the results were not suitable. With the first planking, glueing the couple of inches closest to the stem was done with medium viscosity super glue. It seems like every place I did that there were black seams. Probably a coincidence. Additionally, the seams were not furniture tight. I was fighting the wood.

I have been scouring You Tube videos for the past two days to no avail. Thank you for the Chuck related videos. I just saw that post and will look. I soaked some planks in alcohol all night then wrapped one in a wet cloth and microwaved it, first for three minutes with no good results, then for five minutes. No help.

I tried hot air and it did nothing on either of the two types of wood that I have. In the photo below you'll see a piece of the wood used for the first planking that I experimented on with hot air this morning and broke it.

I made a jig with the approximate shape that I want and by putting the smaller part of the jig on top of my plank I was able to keep the planking from twisting as I forced it into the concave shape of the jig. I ran hot air over it later to try to dry out the wood. I'll leave it for awhile before releasing the clamps.

Could it be that this wood is of so little mass that it does not retain interior heat after trying to steam it in a wet rag inside the microwave oven?

I am thinking next of trying boiling water for an hour or longer.

Here is what I just did. You can see the tape pattern beside it and to the side is the piece I broke when I tried hot air.

Respectfully,

John

-

John Maguire got a reaction from mrshanks in Armed Virginia Sloop Patrick Henry by DocBlake - FINISHED - Lauck Street Shipyard - Scale = 1/32 - POF Admiralty Style

John Maguire got a reaction from mrshanks in Armed Virginia Sloop Patrick Henry by DocBlake - FINISHED - Lauck Street Shipyard - Scale = 1/32 - POF Admiralty Style

Doc or Brian,

Do you use the metal cleaner first? I have used JAX with mixed results and crusting. Is that because I did not use the chemical cleaner you mention first? Once clean, what are the ranges of time that you use for JAX application?

Doc, your work continues to be stunning. I wish I had a sense of wood colors similar to yours. Are you able to produce a picture of your cannon axle pins to the deck? The axles and wheels are soooooo small . . . .

Respectfully,

John

-

John Maguire got a reaction from mtaylor in Armed Virginia Sloop Patrick Henry by DocBlake - FINISHED - Lauck Street Shipyard - Scale = 1/32 - POF Admiralty Style

John Maguire got a reaction from mtaylor in Armed Virginia Sloop Patrick Henry by DocBlake - FINISHED - Lauck Street Shipyard - Scale = 1/32 - POF Admiralty Style

The cannons are exquisite, Doc . . .

-

John Maguire got a reaction from Canute in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

John Maguire got a reaction from Canute in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

Beautiful . . .

-

John Maguire got a reaction from mtaylor in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

John Maguire got a reaction from mtaylor in Licorne 1755 by mtaylor - 3/16" scale - French Frigate - from Hahn plans - Version 2.0 - TERMINATED

Beautiful . . .