-

Posts

3,175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glenn-UK

-

Build Log - Day 25 (7th & 8th Dec 2025) Task 45 – Main Rails Prep Work I am currently doing some more prep work this time related to the main rail patterns as it is important to get a good fit with these decorative patterns. When test fitting the main rail it can be seen that stern frame counters still need to be trimmed so they are flush with the end of the main rail. I marked the end position of the main rail pattern on the hull and then with the patterns removed, using some different grit sanding sticks, the stern frames were sanded to the marked lines. I did manage snap off the four dangly bits from the two rear window shapes on the right-hand main rail pattern when removing the laser char so it may take me a bit of time to sort out before that part can be fitted. After carefully removing the laser char the bow main rail patterns they were soaked in hot water and then clamped to my bending jig (see earlier posts regarding the jig). Once the patterns had fully dried (after 18 hours) they were test fitted and were a good fit. The next set of photos shows the test fit of the main rail patterns. They do look nice. I will have to trim the bow section of the lower main rail patterns, so they fit flush with the stem post. The bow gunwale patterns did need a slight adjustment to the curve at the bow end, so they accurately follow the curve of my hull. The patterns were soaked in hot water for 30 minutes and then clamped to get the required new curve. Once the clamps were removed I was happy with the fit. I also test fitted the midship and upper deck gunwales and I was happy with how they looked. I am also adding a slight lateral bend to the rear section main rail so it follows the curve of the hull, as can be seen below.

-

Build Log - Day 24 (5th & 6th Dec 2025) Task 44 – Painting The Hull The first task was to apply a WOP finish to the hull, inner bulwarks, stern counter and decks. I used a 50 / 50 mix of Rustins Clear Satin polyurethane and white sprit for this. Two coats were applied. Next the gunport oval openings were painted blue. Tape was attached to the inner bulwarks to prevent leakage. Next the hull was taped up so the blue band could be painted. I brushed on 4 coats of diluted blue paint. The tape was then removed and new tape added so the red paint band could be added. I brushed on 4 coats of diluted red paint. The lower stern counter was also painted blue. Photos Gun Ports Painted Hull taped and ready for the blue paint Hull after blue paint has been added Hull taped and ready for the red paint Hull after red paint has been added. Rails will be added which will hide and paint overspills between the colours. Stern counter painted. Rails will be added which will hide the paint overspills with the hull below the stern counter. Testing different wood-coloured paints which I might use on the hull. I am currently drawn toward the right hand walnut wood colour.

-

Build Log - Day 23 (3rd Dec 2025) Task 43 – More Prep Work I have now sanded the tops of the bulwarks level and did test fit the gunwales. All looks good. I did brush on some diluted wood filler around the curved sections that are not covered by the gunwales so the laminations between the layers will not be visible once painted. The gunport opening were also sanded smooth and coated with diluted wood filler so that, when painted, the laminations between the layers should not be visible. I copied this method from @DelF. I am currently waiting for a delivery of some Rustins Polyurethane clear satin varnish so I can apply a WOP finish to the hull before embarking on the painting tasks. I have also ordered some different coloured paints. Depending on the test results I might then paint the hull and inner bulwarks with a wooden paint finish. I also took the opportunity to test fit some of the deck items which locate in the various deck openings. Thankfully no problems detected. Photos Picture of the hull with some deck items, masts and bowsprit test fitted. Gun ports sanded and coated with diluted wood filler. Checking a cannon with a gunport Checking the bitts and mast on the upper deck Checking the cabin pattern, main mast and bitts Checking the foremast, bowsprit and bitts.

-

Build Log - Day 22 (2nd Dec 2025) Task 42 – Laser Etched Decks and Inner Bulwark patterns It took a few attempts before I was happy with the dry fit of the lower deck inner bulwark patterns. I ended up taking about 1mm from the front edge and then I had to sand a bit from the bottom edge. When test fitting the patterns I used both the cathead and the oval locator plugs to check the alignment. The two laser etched deck patterns were then glued in place. I used some pins pushed through the eyebolt holes to make sure these patterns were aligned with the deck bases. When test fitting the upper deck bulwark patterns I noted, when properly aligned, there was a gap between the bottom edge and the deck in the mid-section. I did consider making some new patterns, but I decided to sit these patterns flush with the deck when they were glued in place. The lower deck inner bulwark patterns were then glued in place. I used the catheads and oval locator plugs to position these patterns before clamping. Once clamped the catheads and locator plugs were removed. Photos Lower deck trial fit with bulwarks Laser Etched Decks Fitted The next photos shows the mid-section gap when the upper deck inner bulwark is aligned. Upper deck inner bulwark glued in place, without the gap with the deck. The lower deck inner bulwark pattern clamped in place after gluing. The oval locators were removed after this photo was taken. You may also note that I have drawn and taped the preliminary water line The current build status

-

Build Log - Day 21 (1st Dec 2025) Task 41 – Prep for adding Laser Etched Decks and Inner Bulwark patterns It will take me a few days to complete the next task of adding the two laser engraved decks and associated inner bulwark patterns. The first task was to remove the bulkhead ears that protrude above the decks. These snapped of easily and the deck base was then sanded to remove any remaining excess bulkhead ear material. Once that was done, I did a test fit of the upper deck and bulwarks. Everything seems to be well aligned. Pins were also used to double check the deck was properly aligned with the deck base. Next I did a trial fit of the lower deck. This is a bit tighter and did require a little bit of sanding to ensure a good fit. Pins were once again used to double check the deck was properly aligned with the deck base. Using the same template used when bending the outer bulwark patterns the right-hand side inner bulwark pattern, after a 30-minute soaking in hot water, was clamped to it. Once it had dried out, I did a test fit. I will need to make some minor adjustments to this pattern to ensure it is properly aligned such as sanding a bit from the bottom of bow section of this pattern. I also need to add a chamfer to the leading edge, so it locks in with the stem post. I made a cardboard copy of the left-hand bulwark pattern to see what modifications, if any, would be required. The left-hand pattern, after soaking, was clamped to the bending template and will now be left to fully dry out overnight. Photos Upper deck trial fit with bulwarks Lower deck trial fit Pins used to check lower deck alignment Right-hand inner bulwark alignment. I need to sand a bit from the bottom of bow section of this pattern. I also need to add a chamfer to the leading edge, so it locks in with the stem post. Left-hand side card template test fit.

-

Build Log - Day 20 (28th - 30th Nov 2025) Task 40 – Completion of second planking I have now completed the second planking task. I am pleased with how the hull now looks, noting there will be a few areas to add some wood filler when it is time to paint the hull below the waterline. Photos Right-Hand Side Left-Hand Side Bow Stern

-

Build Log - Day 19 (26th – 27th Nov 2025) Task 39 – Start of second planking layer on left-hand side I am now working slowly and steadily with adding the second planking layer on the left-hand side. In the following photo I have completed the first banding section of 5 tapered planks around the bow. I am doing my best to match these planks up with the right-hand side. The next photo shows the first banding section around the stern After completing the first banding section I took some measurements and then added some tic marks for the remaining bow planks, as can be seen in the next photo. I used my digital callipers to help mark the positions. The next set of photos were taken after I had completed the second banding area. Now that I have completed the joint with the stern counter I will add some tic mark for the stern section for tapering.

-

Build Log - Day 18 (25th Nov 2025) Task 38 – Completion of second planking layer on right-hand side Following on from my last post in did not take me too long to complete the right-hand side second planking. My working method has evolved during this task. Using paper templates to get the right shape for the bow lateral band has certainly made a big positive difference. Also using a 4-butt shift pattern for the planking made the task much easier, especially with getting good joints with the stern counter and post. Although by no means perfect, I am pleased with how the planking looks and it is much better than any of my previous models. I am now debating whether to paint the section below the waterline white or to leave it with just a nice varnish. There is no need to decide just yet, and of course I will consult with my daughter-in-law before making a final decision. In the photos below I have brushed some water on the planking to give an impression of how it will look once varnished. It also highlights all the flaws. Photos The completed hull The stern area Midships, shows the 4-butt shift pattern Bow area

-

Build Log - Day 17 (23rd -24th Nov 2025) Task 37 – Plans to complete 2nd planking on right-hand side Work is progressing with adding the second planking to the right-hand side. I have now reached the stage where the final two / three runs are required. The following is a photo of the current build status. There is some glare reflection from the lights as I took these pictures in the evening with my LED spotlights. I have now started work on adding the next plank, and in the next photo I am using a spare piece of planking material to gauge the shaping of the final bow plank. The next photo shows the stern area, the pencil line shows where the final two planks will fit. There is a bit of damage to one of the stern planks, I am not sure what happened there. In the next photo I am checking that two full planks will fill the gap. However, when checking the midship section the gap is approximately 2.5 plank widths, which is a bit frustrating. In the next photo I am checking where the gap is back to 2 plank widths on the bow. My plan, to complete the planking is try and leave a rectangular 2mm shape for the final midship infill.

-

Build Log - Day 16 (20th – 22nd Nov 2025) Task 36 – Adding one planking layer I thought I would share, in detail, the method which I am now using to fit the second layer of planks. Step 1 – Creating a paper template for the lateral bend A piece of paper is folded underneath the plank. I then use a pencil to trace the required bend, as shown in the photo below. Next I cut along the pencil line and this becomes the template for the lateral bend. Step 2 – Tapering the plank Using the various bulkhead measurements taken when creating the banding areas, I use my digital callipers to mark the required widths. You will note, in the photo below, I also have a guide plank to indicate the positions of the various bulkheads. Step 3 – Lateral bend of the plank Once the taper has been applied the plank is then laterally bent. The paper template is used to set the required curve, as shown in the next photo. Water is brushed on to the plank and a hair dryer is used to apply the heat. Step 4 – Test Fit Once the plank has been bent as per the template it is test fitted. As can be seen in the next photo the plank sits flush with the previous plank without any force added. The plank is then cut to the required length as per the 4-butt shift pattern. Step 5 – Gluing the plank Glue is applied to the hull, using the following attachment to the super glue container. This attachment has proved to be an invaluable asset in this respect. I brush some water on the underside of the plank to aid the adhesive with the ca glue. The plank is then carefully fitted, working from the stem post. I am happy with how this plank (still damp) looks, once glued in place. Step 6 – Midships Plank The midships plank is cut to size, a slight bevel is applied to the top edge. Glue is then added to the hull before the damped plank is fitted. The red arrows shows the 4-butt shift joints. Step 7 – Stern Post Plank This is the plank that takes the most effort to fit. With the plank in position, as shown below, the underside is marked where the sharp bend to the lower stern counter pattern starts. The bend area is then wetted and a bend applied. I usually start with a gentle manipulation with my hand to get the start of the bend. Next I use a bottle to complete the task. A hairdryer is used when the plank is being bent around the bottle. The bent plank fit is then checked, as shown below. The bend looks OK. The pencil dot is where the plank need to terminate with the stern counter. Using the pencil mark on the plank I use the following template to cut the correct angle. The next photo shows the stern post plank prior to fitting. The dampened plank is then glued in position. This time I work from the stern post to the midships to ensure I get a good join with the stern counter. Apart from one plank (red arrow), where I worked from midships to stern counter when the plank was fitted, I am really pleased with how the joints with the stern counter looks. As can be seen in the final photo of this post the remaining stern counter gap to fill is exactly one full planks width which is ideal.

-

Build Log - Day 13 (19th Nov 2025) Task 35 – Banding Preparation After fitting the first 3 full width planks and the garboard plank I was left with a gap of 80mm to fill at the midships, which would require 20 x 4mm planks to fill. I think it will be a good idea to split the infill area into 4 bands, with each band comprising 5 planks. I took some measurements and then calculated the planking requirements. as follows: Stem Post BK 1 BK 2 BK 3 BK 4 BK 5 BK 6 BK 7 BK 8 BK 9 BK 10 BK 11 BK 12 Length To Fill 40mm 48mm 65mm 74mm 80mm 80mm 80mm 80mm 80mm 76mm 74mm 74mm 74mm Band Width 10mm 12mm 16.5mm 18.5mm 20mm 20mm 20mm 20mm 20mm 19mm 18.5mm 18.5mm 18.5mm Plank width 2mm 2.4mm 3.3mm 3.7mm 4mm 4mm 4mm 4mm 4mm 3.8mm 3.7mm 3.7mm 3.7mm I made a couple of paper templates, one for the bow area and one for the stern area. I added the required curve to the bow section template which will help with the lateral bend. Using a spare piece of 4mm planking material I made a bow plank (from bulkhead 4 to stem post) and a stern plank (from bulkhead 8 to stern post) using the above table measurements and templates as guides. I was happy with how they both looked when test fitted. The test planks, when held against the hull, both appeared a good fit, therefore I can now proceed with planking the first banding section. Photos The paper template is being checked in the photo below. I took my time to get the right shape for the top edge. The bottom edge and drawn planks could have been neater. The stern template. I did make a hash of cutting the bottom edge. I also did a test the template around the stern counter as would like to fit two planks to the outer edge before the planking has to rotate so it terminates with the bottom edge. I did purchase a set of proportional dividers to help with tapering the planks. It has been correctly set in the photo below. Test lateral bending of tapered bow plank, using the template as a guide. Test fit of the test plank, looks OK, noting it was not colour matched.

-

Build Log - Day 12 (15th – 18th Nov 2025) Task 31 – Second Planking Preparation Before commencing with adding the planks there was a bit of background work required. I had decided to use a 4-butt shift pattern for the second planking. With reference to the information contained in Longridge's book Anatomy of Nelson's Ships I created the following plan contained in the attached pdf file. 001 4 Butt.pdf This a sequence that repeats and works as follows: a) First plank has been positioned with the reference bulkhead b) The second plank start point is then 2 bulkheads to the right of the first plank. c) The third plank start point is then 1 bulkhead to the left of the first plank. d) The forth plank start point is then 1 bulkhead to the right of the first plank. e) the firth plank start point is then 2 bulkheads to the left of the first plank. f) Repeat the above sequence a) to e) When looking at both @James H and @DelF build logs it appeared that the first three planks were not tapered around the bow. I test this out and concluded I could follow suit without any issues. When looking at the kit supplied Lime planks there is quite a bit of colour variation between them. Therefore as I proceed to fit the planks I need to colour match the planks with the bulwark as far as it practical, noting this becomes less of an issue below the waterline as the hull will be painted white. Task 32 – Adding the first plank After selecting the first plank it is test fitted in the rabbet and a line is drawn so it follows the curve of the stem post. Following the information provided by @Chuck lateral bending method I set about working out the central point of the U-shaped bend. The plank brushed with water and clamped. A hairdryer was then used to apply heat. The first planking layer (right and left sides) was then glued to the hull. Task 33 – Adding the next two planks It was then a case of cutting planks to the required lengths for the 4-butt shift pattern and gluing them to the hull. Task 34 – Garboard Plank Noting that 24 planks / side would be required, and as 3 planks had already been fitted below the bulwark I thought it would make sense to add the garboard plank which would then leave 20 planks to fill the gap. This would make it easy to split this area into 4 planking bands, width 5 planks per band. I took my time to get the required shape around both the the stem and stern post. I also worked out the required plank start positions for the 4-butt shift pattern, based on pattern created by first three planks. Photos In the photo below I an checking if three full width planks can be fitted around the bow, not colour matched. In the next photo I am checking the colour match of first plank with the bulwark, it looks good. The next photo shows marking the plank for rabbet so it follows the curve of the stem post The next photo shows the central lateral bend point, which is where the widest gap is Lateral bending of the first plank (left and right) First plank has now been fitted, and the 4-butt joints can be seen Checking the second plank fits, also checking it is aligned with the required bulkhead line. Cutting planks method. This tool give a nice shape cut. I do give the cut edges a very light sand. Second planking layer completed, I am using acetone and water to clean the planks to remove excess glue. The 4-butt pattern can be seen. Third planking layer completed, so far so good. Garboard plank - stem post Garboard plank - Stern post

-

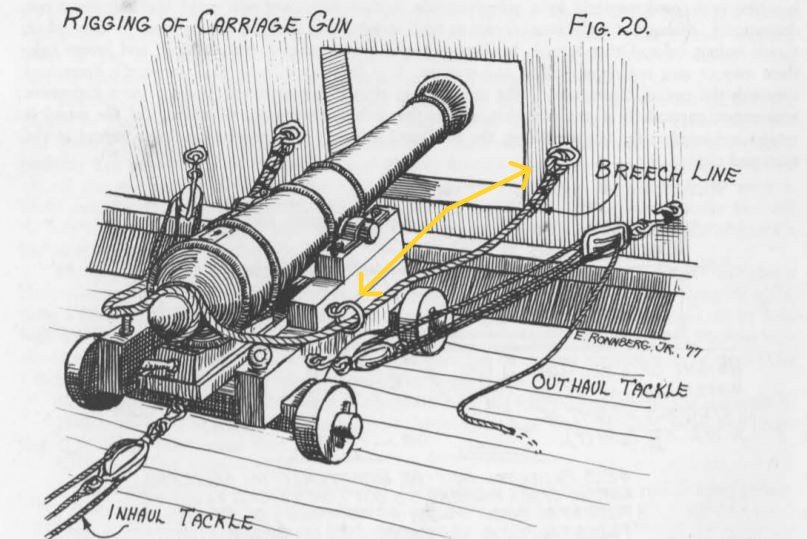

After a bit more experimentation with the cannon I have come up with the following. I drilled a small hole in the side panel for the breech line rigging ring. I then made an ring attachment hook and attached the kit supplied ring to it. The hook for the ring maybe needs to be a tad smaller. I have also added a smaller eyebolt for the outhaul rigging. I think this cannon looks much better now and I know what is required when I assembly the 6 off production cannons. I did add a coat of Iron Work Black paint to the cannon. The following pictures show my rejected attempts. I did not like the look of the outhaul tackle kit supplied eyebolt in the following photo, it looks way too big I did use a smaller eyebolt in the next photo and it does look Ok, but I just felt the overall thickness of the eyebolt material was no right. I tried a small eyebolt to hold the breech ring in the next photo, does not look right.

-

I have built one of the ships cannons. I did not encounter any problems when assembling the various parts. The most time consuming aspect was removing the laser char from the cannon side edges and wheels. I have not done a brilliant job of the removing the char from the ships wheels but I think they look reasonably OK. I did use a top end of a belaying pin to add a handle for the quoin. I think the handle looks OK. Should I paint the quoin black, thoughts anyone? I did try a method used by @DelF on his build whereby the cannon wheels were pushed on to a tooth pick which was then placed in a lathe. The char could then be sanded as the wheel was rotated. I did try this on a spare wheel but I ended up taking too much material of the wheel so I decided to abandon that method. The cannon was then place on the deck. I will probably add the breech line and I might also add the inhaul tackle. I have no plans at the moment to add the outhaul tackle however as I would need to modify the cannon to take a second eyebolt. When looking at the breech line rigging it passes through a ring located on the cannon side and are then seized to an eyebolt located on the bulwark, as can be seen below. I did a test fit of the kit supplied eyebolt. It does look large and clunky in my opinion. It also looks like the one required for the outhaul tackle. There is no provision for adding the breech ring. Referring to @DelF build log post he drilled some additional holes in the carriage for provision of the breech rings. I will follow his lead in this respect. The following photo is from DELF's post and shows his cannon. I have not, as yet, modified the cannon as per the previous photo in the following tests. Next I tried a smaller eyebolt (from by collection of unused kit parts from previous builds together with a kit supplied ring. This does look a bit better and is currently my preferred option. The eyebolt still looks a bit big so I will try to fashion a suitable ring holder. I did try a few different options as shown below. Another type of eyebolt with a larger ring. The ring definitely looks oversized. I also tried a smaller ring with a different eyebolt. This is a possible option, but the eyebolt is still a bit to large. I am planning to use 0.75mm natural thread for the breech line. so I thought I would test the two different rings with the breech line thread. Based on this test I will use the smaller ring. To allow for the right amount of cannon recoil the breech line should be 3 x barrel length. I will use this as a guide when I get ready to add the rigging. I would welcome any thoughts / comments on any of the above.

-

Build Log - Day 12 (14th Nov 2025) Task 27 – Stairs to Main Cabin The next major task will be to add the second planking. Before starting this time consuming task, I decided to have a few days doing some other tasks. I really like the curved stairs to the main cabin so thought it would be a nice easy build task. The parts were removed from the sheet and the laser char removed from the stair edges. As each rung was removed, I annotated their positions on the underside. With the two sides glued into the base the top and bottom rungs were fitted to ensure the sides correctly aligned. It was then a case of added the remaining rungs in turn. The completed assembly was then test fitted and it slotted in place perfectly. I then assembled the two ladders which are used to access the aft deck from the lower fore deck. Task 28 – Binnacle This was another easy build. The parts were removed from the sheets and the PE parts was glued in place. Next the bottom, middle and top shelves were fitted to the side patterns. The front and rear patterns were then glued in place, and clamped whilst the glue was curing. Task 29 – Catheads The two catheads were test fitted and I was pleased that these parts passed through the hole(s) in the hull. Task 30 – Rudder The outer patterns were glued to the rudder. The rudder was then test fitted. Photos Main cabin stairs parts are ready to be assembled A quick check that the base pattern fits in the slot in the lower deck. The two sides have glued to the base pattern and two rungs are being used to ensure the sides are correctly aligned. Adding the rungs, one at a time. The completed stair assembly. A final test fit, I really like this ladder. Test fit of the two fore to aft ladders Binnacle parts ready to be assembled Framework assembled Front and back panels glued in place and clamped. The completed binnacle, noting chimney and eyebolts will be added later. Catheads test fit, noting the bulkhead ears prevent checking installation from deck for the time being Rudder with outer patterns fitted and laser char removed. And a test fit of the rudder, looks good. I have also marked the hull in readiness for the second planking. I am planning to install the hull planks, using a 4 butt shift pattern. The hull has been split into 3 bands, with 8 planks per band required at the midships. I have ordered some proportional dividers which I will use to taper the planks from midship to bow.

-

Build Log - Day 12 (11th - 12th Nov 2025) Task 24 – Keel and Stem Post Pattern After confirming I was happy with the rabbet that is formed when the outer patterns for the keel and stem post were test fitted, they were glued then in place. Locating tabs are provided with the kit to ensure these patterns are correctly aligned. In the build manual the stem outer patterns were added after the bulwark outer patterns had been fitted. I thought it would be better to fit them prior to the fitting the bulwark patterns so I could utilise the rabbet to help hold the bulwark pattern in place. Task 26 – Stern Counters As detailed in my previous post I did prebend the lower stern counter pattern to follow the curve of the stern frames which was then glued in place without any problems. The upper stern counter pattern also required a slight bend so it would lie flat with the stern frames. A camphor was added to the bottom edge of this pattern for a better fit with the lower stern counter. Task 26 –Outer Bulwark Patterns As highlighted in my previous post I did use a cardboard template to determine if I needed to trim the actual bulwark patterns. Using the template as a guide I sanded the bow edge of these patterns and then did a test fit. I repeated this process a few times until I was happy with how the patterns were lining up with the hawse holes and cathead opening on the hull. The patterns were then soaked in hot water for 30 minutes and clamped in place on the hull. They were left for 24 hours to fully dry out. The bent bulwark outer patterns were then test fitted, using pins and the kit supplied gunport templates to check the alignment. Everything looked good. I drew a line along the bottom edge so I know where to add the glue. Glue was brushed on the hull and then working from the bow the patterns were inserted in the rabbet and then aligned with the two hawse holes and cathead opening. A clamp was used to hold the pattern in place and then pins were then inserted as then patterns were aligned with the gun port and window openings. Clamps were added to hold these patterns in place. Photos Lower and upper stern counter patterns have been fitted and sanded to shape Bulwarks soaked and clamped to hull Hawse and cathead openings look good Test fit using pins and gun port jigs. Bulwark patterns glued in place Post Gluing - Bow Alignment looks good Post Gluing - Gun port openings look good Post Gluing - window openings look good

-

Build Log - Day 12 (11th - 12th Nov 2025) Task 25 – Keel and Stem Post Pattern After confirming I was happy with the rabbet that is formed when the outer patterns for the keel and stem post were test fitted, they were glued then in place. Locating tabs are provided with the kit to ensure these patterns are correctly aligned. In the build manual the stem outer patterns were added after the bulwark outer patterns had been fitted. I thought it would be better to fit them prior to the fitting the bulwark patterns so I could utilise the rabbet to help hold the bulwark pattern in place. Task 26 – Stern Counters As detailed in my previous post I did prebend the lower stern counter pattern to follow the curve of the stern frames which was then glued in place without any problems. The upper stern counter pattern also required a slight bend so it would lie flat with the stern frames. A camphor was added to the bottom edge of this pattern for a better fit with the lower stern counter. Task 26 –Outer Bulwark Patterns As highlighted in my previous post I did use a cardboard template to determine if I needed to trim the actual bulwark patterns. Using the template as a guide I sanded the bow edge of these patterns and then did a test fit. I repeated this process a few times until I was happy with how the patterns were lining up with the hawse holes and cathead opening on the hull. The patterns were then soaked in hot water for 30 minutes and clamped in place on the hull. They were left for 24 hours to fully dry out. The bent bulwark outer patterns were then test fitted, using pins and the kit supplied gunport templates to check the alignment. Everything looked good. I drew a line along the bottom edge so I know where to add the glue. Glue was brushed on the hull and then working from the bow the patterns were inserted in the rabbet and then aligned with the two hawse holes and cathead opening. A clamp was used to hold the pattern in place and then pins were then inserted as then patterns were aligned with the gun port and window openings. Clamps were added to hold these patterns in place. Photos Lower and upper stern counter patterns have been fitted and sanded to shape Bulwarks soaked and clamped to hull Hawse and cathead openings look good Test fit using pins and gun port jigs. Bulwark patterns glued in place Post Gluing - Bow Alignment looks good Post Gluing - Gun port openings look good Post Gluing - window openings look good

-

Build Log - Day 11 (8th- - 10th Nov 2025) Task 19 – Sanding and Filling The hull was sanded smooth, tapering the plank depth in the the dead area toward the stern post. I then brushed some water on the hull which helped to highlight gaps and depressions. Wood filler was applied and then, when set, the hull was sanded smooth again. Water was brushed on the hull once again which did show there were still some depressions. I highlighted these areas with a pencil and then filled them with wood filler. Once dried the hull was given another sand. It looked and felt smooth. It also looked Ok when water was brushed on. Task 20 – Lower Stern Counter The lower stern counter needs to be bent to follow the curve of the stern frames. The pattern was soaked in hot water for 45 minutes and then strapped to bottle. The bottle had a very similar shape to the stern frame. And just like @DelF the pattern cracked along one of the lasers etched lines. As this pattern will be painted it should not be a problem. Task 21 – Stern Post The three outer patterns were glued to the stern post and once set the stern post was glued to the hull. Task 22 – Keel and Stem Post Pattern Test Fit The outer keel and stem post outer patterns were test fitted so the rabbet could be checked. Using a test plank, I was happy with the rabbet. Task 23 – Test Fit Outer Bulwark Patterns The outer bulwark patterns were test fitted. They looked good and aligned perfectly with the gun ports and window openings. As they had not been bent around the bow it was not possible to check the alignment with the catheads and hawse holes. With the patterns slotted in the rabbet it did appear they were not aligned. However, when I made a cardboard template using everything did align up perfectly. As the template is not as thick as the actual pattern it might mean a simple bevel will be required. Most testing required to make sure I can make the right adjustment to the actual patterns. In the build manual it does state that: “Some adjustment at the bow may be needed as we’ve left a little extra material to allow for variations. Photos The first photo shows pencil marks where there are some depressions. The stern area. The completed hull after the first planking had been sanded smooth. Bending the lower stern counter pattern, the crack along one of the laser etched lines can be seen. The stern post has been glued in place. The keel outer pattern have been test fitted. The outer patterns have been test fitted to the stem post. The outer bulwark patterns test fitting The bow section of the outer pattern does not seem to align. Using a template of the outer bulwark pattern.

-

Build Log - Day 10 (7th Nov 2025) Task 18 – First Planking Completed I have now completed the first planking. For the most part I am pleased with the result. The hull now be sanded and filled in readiness for the second planking. I will take great care to make sure the second planking above the water line is as neat as possible. I may try to follow the example shown in @DELF build log and go with fitting scale plank lengths. The planking below the waterline will be painted white so the planking will not be seen. Photos The completed hull.

-

Build Log - Day 9 (4th – 6th Nov 2025) Task 17 – First Planking Continues I have been making slow but steady progress with the first planking. I am pleased that I have now completed the planking to the transom area and I am pleased with the result. This area will need a little bit of sanding and filling. I have now started to plank upward from the keel and I have 6 planks to fit per side to complete the first planking. Before moving on I measured the unplanked distances to check the required tapering, which confirmed there were only 6 more planks per side required in the central section. The tapering requirements from bulkhead 4 to bulkhead 1 for the remaining planks was not greatly different to my original measurements which was pleasing. Photos The first two photos shows the planking up to the transom. I was pleased I was able to make the sharp bend. For the really sharp bends I used steam from a boiling kettle which proved to be very effective method. The next photo shows the bow, the planking is more or less even on both sides. When working on one of the lower planks I decided to add a stealer but I had a senior moment which you can see in the photo below. No idea what I was thinking. Thankfully normal service was resumed when I added the next plank, this time with a correct stealer added.

-

This post details the method I am currently using to add each plank. Step 1 - I take two planks, one for the right-hand side and one for left hand side and I mark the position bulkheads 1 - 4. Using my digital calipers I then mark the require plank width at these bulkhead positions. Step 2 - I draw a line between the marked taper points, as can be seen below, and then using a craft knife the taper is cut. Step 3 - With the two planks held together I ensure there the tapers are the same. Step 4 - The two planks are then laterally bent. Water is brushed onto the planks which are then clamped. Hot air is used to dry the planks from a hairdryer. Both planks are bent at the same time. Step 5 - The laterally bent planks are then test fitted and can be adjusted if necessary. In the photo below the angle for the stem post is being checked. Step 6 - With the plank held in position I add an alignment mark, usually on bulkhead 6, which I use when I am ready to glue the plank in place as I tend to work from the center outward adding pins left and right alternatively. Step 7 - Next I find the point where the plank bends around the stern which also requires a slight twist. Step 8 - Next I work out where the sharp bend is required to fit toward the transom. Step 9 - With the plank brushed with water the required bend toward the transom is made. I do this by gentle manipulation with my hands and using the hair dryer. Step 10 - Glue is then added to all the bulkheads and to the edge of the last fitted plank. I also add a bit of glue to both the bow and stern end of the plank. The plank is then aligned with the mark and pinned in place. Step 11 - I continue to add the pins, alternating between left and right of the first pin. In the next photo the first three pins have been added. Step 12 - Once all the pins have been added I do check everything looks Ok. Step 13 - The two planks have now been added, one to each side.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.