samueljr

Members-

Posts

339 -

Joined

-

Last visited

-

samueljr started following Proxxon DB-250 lathe extension bed , HM Cutter Cheerful 1806 by Chuck - FINISHED - 1:48 scale - kit prototype , HMS VICTORY 1765 by albert - 1/48 and 7 others

-

Jorge Hedges reacted to a post in a topic:

Queen Anne Style Barge c. 1705 by samueljr - FINISHED - Syren Ship Model Company

Jorge Hedges reacted to a post in a topic:

Queen Anne Style Barge c. 1705 by samueljr - FINISHED - Syren Ship Model Company

-

samueljr reacted to a post in a topic:

Medway Longboat (1742) 1:24 by gjdale - Finished

samueljr reacted to a post in a topic:

Medway Longboat (1742) 1:24 by gjdale - Finished

-

Sorry Bob (Let's not hijack Wayne's thread) Wayne, I actually did drawings of the masts and yards based on Prebele's notes/logs . I don't know if I have them anymore Sam

-

Bob Sorry about the "under development again" line that was / kinda an inside joke when I put it on m y profile. I was doing some design work for a couple of different manufacturers on spec. I've got to take that thing off. I did want to do ESSEX larger but my bosses wanted it at 1:76 (scale conversions) were just a pleasure to do - lol Sam

-

The scale was requested by Eric Snow (who was managing ME at the time) It is the same scale as the CONSTITUTION. He felt the same scale would (obviously) give a sense of size and proportion to a contemporary vessel and might even spur multiple purchases - Sam Cassano Jr Wayne, the kit is based on the original launch appearance so the best source of masts & yard sizes would be Prebele's notes / logs that list them. After that you've got to decide what year / era you're going to present and research to that time frame as there were considerable changes made to the rig as was the actual appearance and armament Sam

-

I've added two like new condition AOS book titles to my library reduction sell-off THE NAVAL CUTTER ALERT THE SHIPS OF CHRISTOPHER COLUMBUS Each is in like new condition Each is $35.00 plush shipping or both for $60 plus shipping Other titles can be found on my earlier thread I'm also adding the entire runs of MODEL SHIP BUILDER and SHIPS IN SCALE magazines PM me with questions or order(s) I'll be updating the list next week Thanks - Sam

-

SCUPPERS

samueljr replied to samueljr's topic in Building, Framing, Planking and plating a ships hull and deck

To everyone who responded - THANKS! I've been experimenting with a few different solutions and I'm leaning towards the less is more philosophy. The scupper lining is a great detail if subtle enough - too much and it looks like a gaping hole in the waterway. I'm either going to go with Druxey's acrylic paint solution (thanks David) or just a thin paper for for the lip. The issue other than size is the consistency of the shape. Thank's again to everyone Stay well Sam -

Hi I'm working on a commission project in 1/4" scale and am looking for a good treatment/method of the internal lining of the scuppers. I've got (I think) the exterior discharge under control but am looking for the inboard / intake (waterway) side. I recently saw a thread where the builder did a nice job of it and I can't remember the thread. It wasn't focused on the scuppers, it was just one of the details illustrated. Any help and/or direction would be appreciated. Moderators, if this should be in on deck thread please move Thanks! Sam

-

First off I'd like to thank everyone who inquired and purchased books - THANK YOU! Attached is the remaining inventory - still some really great titles available. I'm running a special sales promotion - spend $20.00 dollars and get your choice of any $5.00 book for free (just pay s/h charges). Spend $35.00 or more and get your choice of any two $5.00 books for free (just pay s/h charges). Book selection is based on availability - first come - first sold. Please PM me with any questions Thanks again - Sam BOOK INVENTORY 111219.pdf

-

I've got a number of projects in front of me and have come to the realization that the library I've accumulated is no longer necessary. The books are "graded" on the scale used by Amazon (I've tried to be as objective as possible). The prices listed do not include shipping as I'll use the least expensive method dependent on weight. distance. etc. Just as an FYI - Live in Western New York State I can accept paypal Please PM me with any questions. Thanks! - Sam BOOKS FOR SALE AMENDED 101819.xlsx

-

samueljr reacted to a post in a topic:

Medway Longboat 1742 -1/2" scale by Rustyj - FINISHED

samueljr reacted to a post in a topic:

Medway Longboat 1742 -1/2" scale by Rustyj - FINISHED

-

Thank you to all for the "likes" through the project and for the words of encouragement. It's not always easy (or comfortable) not following the crowd. Michael, I am an unapologetic kit basher and have several on my work bench in various states of completion. I just don't know where I'm headed next. Also I've been given the opportunity to throw my hat in the kit design ring (again) by one of the Manufacturer/Sponsors of MSW. I've stated the initial beta testing of bulkheads )so far - so good) and will know in the near future if we're going to move forward with the project. Sam

- 47 replies

-

- queen anne barge

- syren ship model

-

(and 1 more)

Tagged with:

-

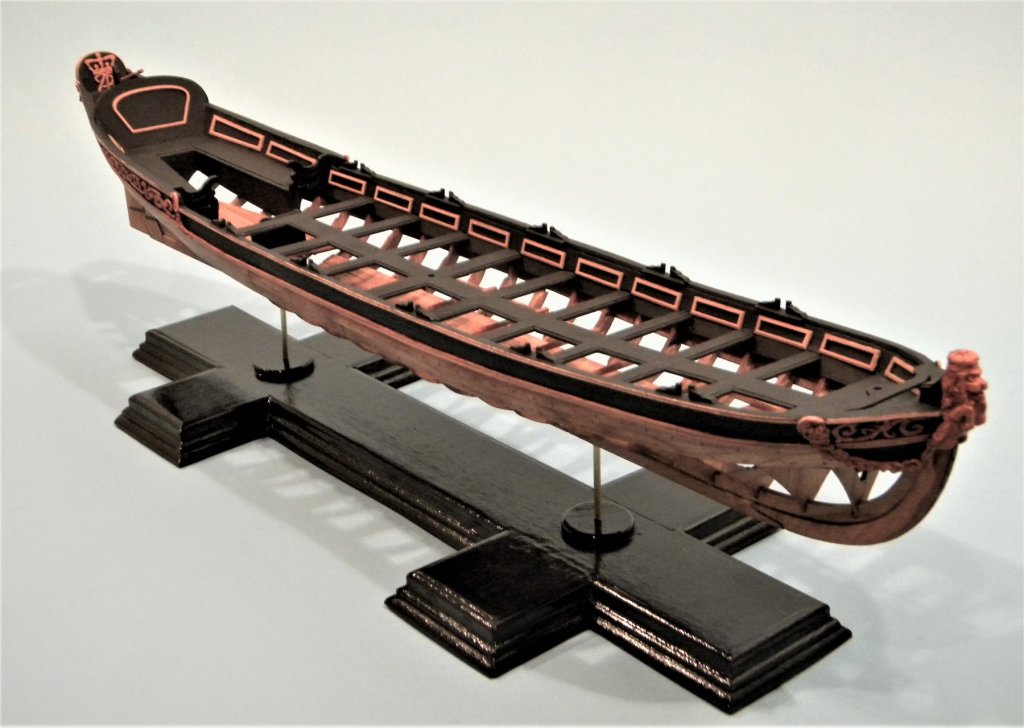

Well this is it. The BARGE is complete and on it's permanent base. For my purposes as I've said there will be no flags, sweeps or internal decorations. Thanks to everyone for checking in. On to the next project ............................................

- 47 replies

-

- queen anne barge

- syren ship model

-

(and 1 more)

Tagged with:

-

Good morning Russ Thank you! The build is done except for the base which I'm just starting to construct. I'm actually happy with the overall appearance given my goal from the outset. Once it's mounted I'll break out the camera and take a few pics. The phone I'm using is picking up a lot of red. Here's a little better shot of the figure head. It's about 2'-08" in scale. It's a little taller than I set out for but it looks proportionally right. My wife wants to know why it's tongue is sticking out? LOL! Are you going to be able to make the February meeting in Rochester. Sam

- 47 replies

-

- queen anne barge

- syren ship model

-

(and 1 more)

Tagged with:

-

Figure head and additional scroll added. The only item left is the tiller (it's been turned, I'm deciding how to finish it) There will be no frieze inserts, flags or oars on the build. Only a simple base.

- 47 replies

-

- queen anne barge

- syren ship model

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.