-

Posts

161 -

Joined

-

Last visited

About rlwhitt

- Birthday 11/16/1960

Profile Information

-

Gender

Male

-

Location

Clemmons, NC

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Lt. Biggles reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Lt. Biggles reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Freebird reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Freebird reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Freebird reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Freebird reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

westwood reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

westwood reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

JohnB40 reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

JohnB40 reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

Jared reacted to a post in a topic:

USS Essex 1799 Frigate by rlwhitt - FINISHED - Model Shipways - 1:76

-

rlwhitt reacted to a post in a topic:

Mayflower by Tigersteve - Model Shipways

rlwhitt reacted to a post in a topic:

Mayflower by Tigersteve - Model Shipways

-

rlwhitt reacted to a post in a topic:

TRE KRONER 1742 by Beckmann - 3"/8' scale - Transom-Model

rlwhitt reacted to a post in a topic:

TRE KRONER 1742 by Beckmann - 3"/8' scale - Transom-Model

-

rlwhitt reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

rlwhitt reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

-

rlwhitt reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

rlwhitt reacted to a post in a topic:

Sloop Speedwell 1752 by Stuntflyer (Mike) - Ketch Rigged Sloop - POF

-

rlwhitt reacted to a post in a topic:

HMS Sphinx 1775 by Ronald-V - Vanguard Models - 1:64

rlwhitt reacted to a post in a topic:

HMS Sphinx 1775 by Ronald-V - Vanguard Models - 1:64

-

rlwhitt reacted to a post in a topic:

Concord Stagecoach by bobandlucy - Model Trailways - 1:12 scale

rlwhitt reacted to a post in a topic:

Concord Stagecoach by bobandlucy - Model Trailways - 1:12 scale

-

Inboard Details Been a while since last update, springtime diversions.... Anyway, been finishing up some details inboard. Mast and bowsprit stubs, knights, some deck rings, and all the pin rails with those period incorrect belaying pins I at least got some wooden ones to make them more reasonable than the brass ones included.

-

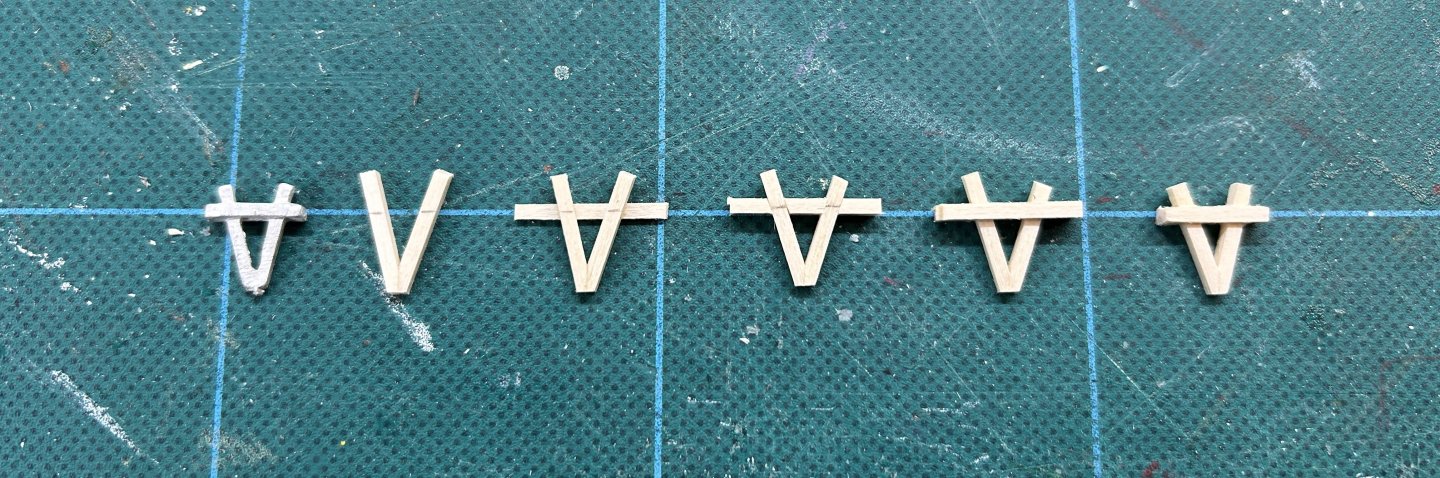

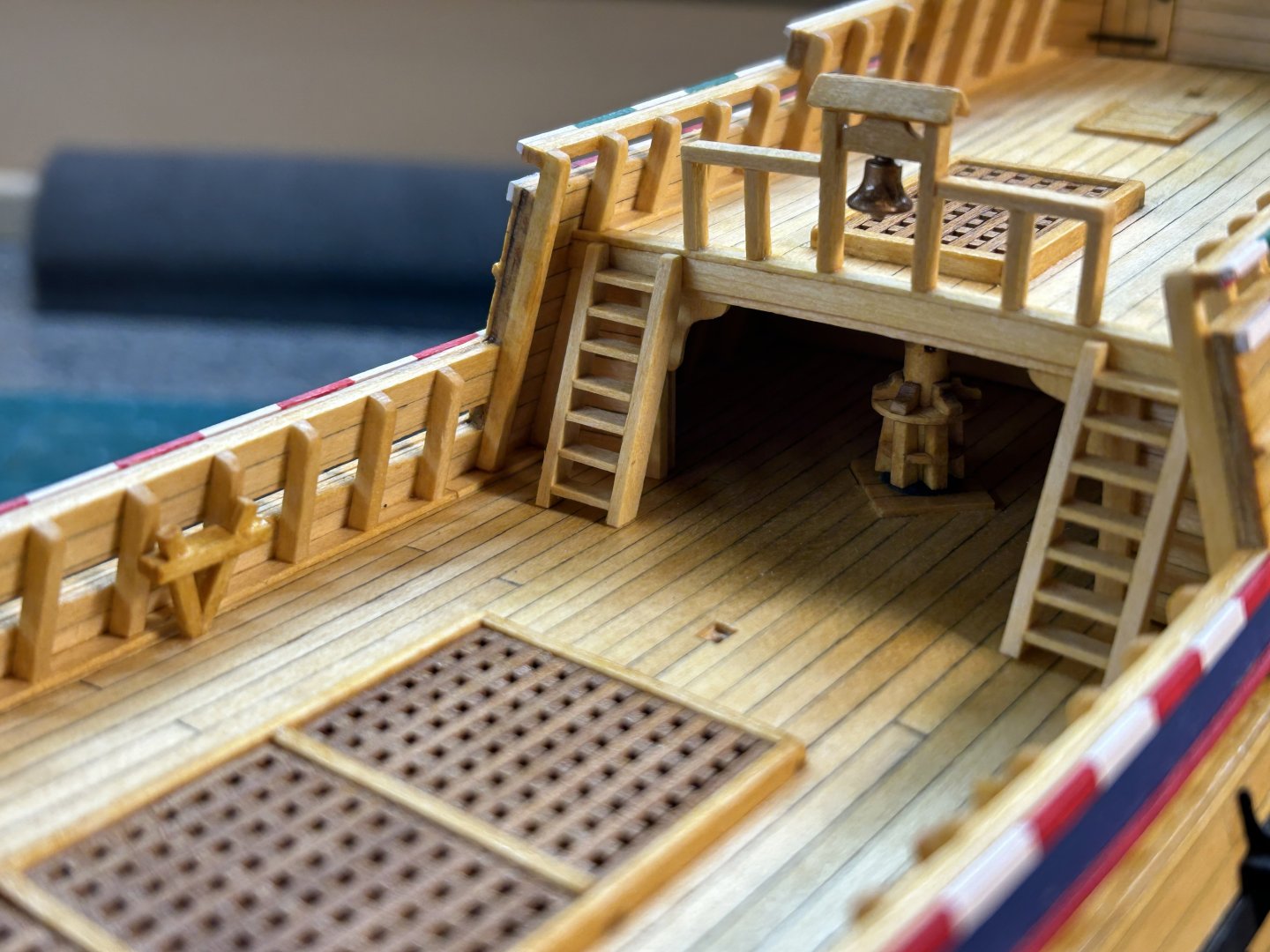

Kevels and other Inboard Bits Moving inboard to some of the items to finish here. There are 8 "Kevels", which are basically very large cleats for belaying ropes, attached to the stanchions. On the original Mayflower there were probably only these and railings themselves for securing various rigging ropes, as it would have predated the use of belaying pins. The kit comes with some pins as well since these exist on the Mayflower II replica. I suspect that they were used to make managing the ropes a bit easier for the modern sailors of 1957. As for the Kevels, the kit is supplied with Britannia metal ones, and as with all such items are just so-so, and quite beg to be remade from wood as I have done here. Here is a picture of the metal exemplar, along with the scratch made ones in various stages. Left to right we have the metal one, then a simple "V" made from 1/16" square stock and marked at the point where the horizontal bar will go. Then the bar is made in layers, starting with a 1/32" x 1/16" strip on the back, with 1/16" square angle cut fillers, followed by another 1/32" thick strip. Finally, the ends are all trimmed and the overall thickness of the horizontal bar is reduced a bit. Here we have some shots of ladders, railings, belfry with a britannia metal bell, and some of the mounted kevels. And an overall shot of the whole so far, on it's new stand.

-

That's truly a set of stunners B.E. Man that Indy is a beast, but also a beauty as well. I hope to do Sphinx one day but I don't think I'd ever have room for its big brother.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

To Rig or Not to Rig ...that is the question. Actually, it's not normally much of a question for most people, for a subject like this. Hull only is usually seen only in later subjects where it makes more sense once the admiralty style of modelling became a thing. Not so much for models like this. For that reason, I had originally intended to mast and rig this one, making it probably my only one that I'd fully rig. As I've alluded to in my prior build logs I don't like doing masts and rigging. Yes, odd choice of hobby for that predilection, huh? I've been dreading the job and have decided to be the oddball and make a hull only Mayflower. But so be it - I'm here to enjoy myself and dread the thought of the next few months of not enjoying the build - so I'll be stubbing the masts and bowsprit and calling it a day, moving on to more interesting projects (for me). I admire all you guys that enjoy and do so well with the rigging part, and I enjoy looking at them, just not the doing.

-

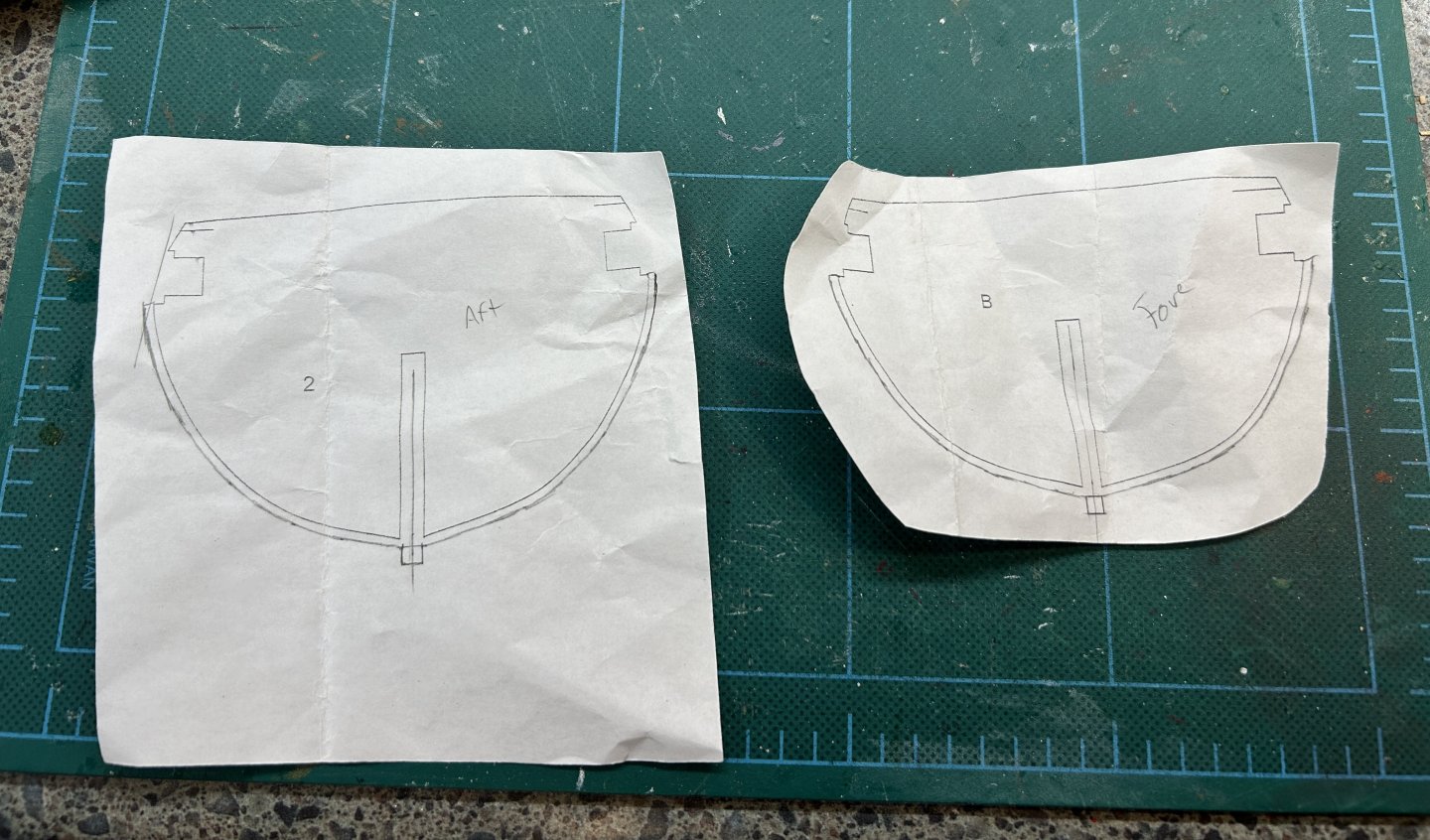

Display Stand A brief diversion from the build... Oddly, there's nothing provided in this kit for mounting, so you'll need to provide either a pedestal or cradle type mounting of your own. I prefer the latter, so I scratched one. I started by picking 2 appropriately spaced bulkheads from the plans and cut out the part images, then traced a keel and planking line onto them to get a shape pretty close to the actual. Then I cut that out and transferred the outline (with a little space to account for felt padding) to some card stock and then sort of came up with a reasonable shape for the rest of the cradle parts. Then I used that to trace onto some 1/8" basswood sheet, cut them out along with some horizontal spacers and glued it all up. I've added some felt temporarily, which I'll remove when I get ready to finish/paint. The felt is some adhesive backed sheet I got at the craft store, 0.99 per sheet that'll last a long time! Cut, Peel and Stick - nice and easy. Finished cradle: I'll probably mount that to a baseboard, and while I was at Hobby Lobby found that they have a nice selection of inexpensive pine craft boards, ready to use. This one was just the right size and was just $7! So if you don't feel the need for a fancier species of wood, this is a good source if you have one nearby.

-

Outboard Details Finishing up some items on the outside, so that's basically done save for mounting the lower deadeyes to the channels and the anchors (last). Overall shots from the front and rear showing catheads, chesstrees, channels, port hinges, flower stern decor, and rudder/tiller arm. One note about the rudder. The instructions call for the typical way of using brass strips and wire for the pintles and gudgeons, but I have been going against that grain on mine and use thick card stock and tiny dowels instead. I find this much easier to work with. If it's painted there's not really a difference in appearance. Another thing to note that the instructions mention using the plans to cut things like cathead and chesstree pieces from stock. They are in fact provided laser cut, though oddly only one cathead part! Luckily there is plenty of extra stock on that sheet to trace and cut another one. A word about port lid straps/hinges. I cut thin strips of card stock and glued them to some medium sized black rigging rope with CA to form a "hinge pin", and then used some slightly open tweezers to press fit the card stock down around the rope to make the hinge profile shape. Finally I cut the rope almost flush to the edge of the strips. I did this in groups of 4 on one length of rope to get consistent length and placement. I wish I had taken pics of this process. Once cut, I CA'd the strip with the "hinge" on the back at the top of the port lid. Since it's all painted black it looks pretty decent at this scale.

-

HMS EURYALUS by Matiz - FINISHED - scale 1:56

rlwhitt replied to matiz's topic in - Build logs for subjects built 1801 - 1850

This is truly master class stuff here. I'm at once inspired and humbled when I see things like this. Just WOW!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.