-

Posts

465 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by *Hans*

-

Something that might be of interest to tell: Oak was never used for decks, because it becomes very slippery when wet. Pine etc. doesn't get slippery when wet. Therefore decks on model ships are always done in light wood.

- 305 replies

-

- utrecht

- statenjacht

-

(and 1 more)

Tagged with:

-

You can buy brass needles (I think these are from Prym) which are 0,3 or 0,4 mm thick. But I am not sure if they will be visible in the walnut.

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Tip - a very simple but effective way to do this is to use a black marker - with same effect

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Yeah, he is a bit desperate.... I think the Dutch lion was a bit more fierce in that days.

- 305 replies

-

- utrecht

- statenjacht

-

(and 1 more)

Tagged with:

-

- 305 replies

-

- utrecht

- statenjacht

-

(and 1 more)

Tagged with:

-

Piet, I made a few pictures (but unfortunately not of the Lion), can send them to you. Please have a look on my website (kolderstok.com) and reply via the given email on that site. I can send you the pictures then.

- 305 replies

-

- utrecht

- statenjacht

-

(and 1 more)

Tagged with:

-

If you want to make extra pieces of ornamentation you can take a medium thin thread (0,5 mm or so), make it stiff with some glue (white glue f.i.) and paint it afterwards in a gold or black or so. In this way you can add extra lines and so.

- 305 replies

-

- utrecht

- statenjacht

-

(and 1 more)

Tagged with:

-

Robin, are you planning to place part S (schot) later? Because the deck has to be planked up to this part and I noticed you haven't placed it so far.

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Owh - this is such a sad picture. I can still see the sole print of your boot on it!

- 305 replies

-

- utrecht

- statenjacht

-

(and 1 more)

Tagged with:

-

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Nicely done! What you can do is sand the upper planks back to a thickness of almost nothing and then you are close to the real ones.

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Btw - I know the guy who designed the Bronze hand canons (he did this especially for me) - so if you are really interested in them I can ask.

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Robin, just found your topic - thanks for posting. You've already done a very nice job!

- 91 replies

-

- kolderstok

- duyfken

-

(and 1 more)

Tagged with:

-

Rigging is fun. Have a look at drawing 2 of the Duyfken - but be careful - it might be scary....

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

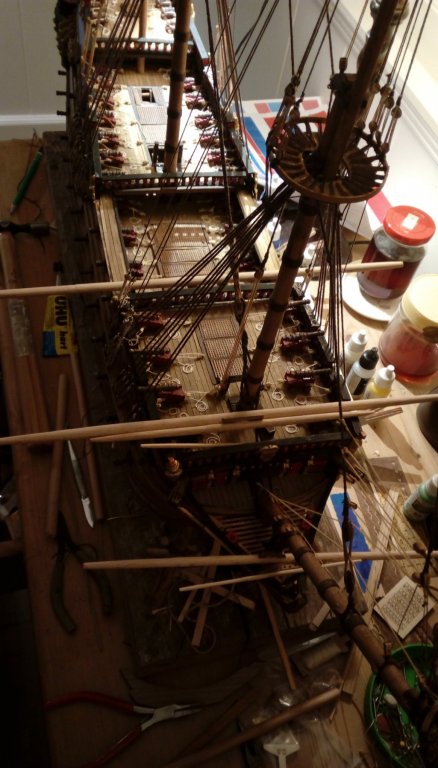

All you readers might have noticed this build is not really updated every week (or so). This is because I am very busy on creating the third model in my range of Dutch 17th century ships. This time I am building quite a big one: De Zeven Provinciën from 1665 - the flagship of Michiel Adriaansz. de Ruyter. I hope to start a build log on this one within short time, but as the plan is to launch her as a model kit end of this year (short before Christmas) this might take some more time. I am very occupied in finishing the model and preparing the box and her contents. A few pictures to give some more information: More info on http://kolderstok.com/zevenprovincien.en.html

-

Hi Anton, Here you can have a view on your next model :-) http://kolderstok.com/zevenprovincien.html Unfortunately yet only in Dutch. The English site will follow within the next days.

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

Try to find it myself as well last few days. But the only globe I found was this one: Isn't quite the same on the mantelpiece...

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

Nice globe you have! Is this still somewhere for sale? (btw - the ship looks nice as well)

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

Nice sculpting! What stuff do you use for this? Two component product?

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

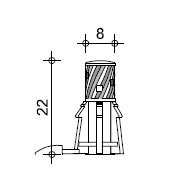

Nice details! To "cover" the gratings issue for the Batavia I suggest in the building instructions to cover some of the gratings with canvas. This is in fact just dark red painted cloth. And this is the drawing of a 17th century capstan - just as you have made it. I think yours is pretty correct.

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

Haha - nice! Please let him show his painting when he is finished!

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

Anton, I'm aiming for end of 2017 - but this might be optimistic.

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

-

OK - I am a bit further as seen on the picture. In the back you'll see the Dordrecht. And this is a part of the stern:

- 322 replies

-

- sergal

- sovereign of the seas

- (and 5 more)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.