-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by jburchfield1@wowway.com

-

-

Well, on a temporary hold as far as planking goes.

Found out the my house wiring is too old to use a blow dryer (can you believe that). Guess I've only got 14 ga wiring with a max watt load of about 1550 or so. Smallest blow dryer I've been able to find needs 1875 so it would overheat the wiring.

So I ordered on of those plank bending tools by Amati. Supposed to get it on Wednesday. That'll let me bend on the face without water. Guess I'll just have to let them dry overnight for the edge bends.

In the meantime, I think I'll start working on the mast's and stuff. No bending necessary!

-

Hey Geoff,

Thanks for the info. I'll look into that.

-

-

Hey Bob,

That piece of glass you were using in your first pictures of edge bending - is that "armored" glass?

Did you make that or buy it?

-

Well, tried to start planking today and knocked that darn transom off again.

Shaped 5 of the oars while I was waiting on glue. Used a sponge sanding pad to round the handles. Worked like a charm.

Guess I'll start planking tomorrow.

-

Dremel makes router attachements if anyone is interested, (and didn't already know).

Reasonably priced and would give you a perfect rabbit with just a little practice.

-

-

-

Well, fairing the hull wasn't as scary as I thought. Got that all done, and ready to put the transom on and then try my hand at some planking.

Pray for me?

-

Yeah, I'm using Titebond for everything. Only used CA to add supports to top of bulkheads.

Got the structure solid enough that I can actually fair the hull by sanding horizontally instead of vertically. Much easier and faster. Got one side done already.

But keep those tips/tricks coming.

-

Thanks for the tips Mike. I'm nervous about planking but at the same time excited to see how I can do.

-

-

Good to know, thanks. Could have made a mess.

Guess I need to learn to silver solder.

-

I was just doing some reading ahead while waiting on glue to dry and came up with another question.

Can parts that have been CA'd together be blackened?

I know you would have to clean them before gluing because the acetone would dissolve the glue but can you then blacken them or must they be painted.

-

I just hope I can come even close to this on mine. Just now putting in bulkheads.

I've got Bob F's link bookmarked AND I've got Chucks tutorial on planking. Got my fingers crossed.

-

This may sound like sarcasm but I promise you it's not.

Good thing you mentioned to use an up and down stroke. I really never even thought about them breaking when going the other way.

-

- alde, Ryland Craze and mtaylor

-

3

3

-

K, I've looked and looked and can't find........

Is there a thread, tute, or something on fairing the hull after the bulkheads are installed?

-

One thing that I have picked up is the need for clamps, clamps and more clamps. I bought 4 dozen 3/4" clamps so hopefully I'm set for those.

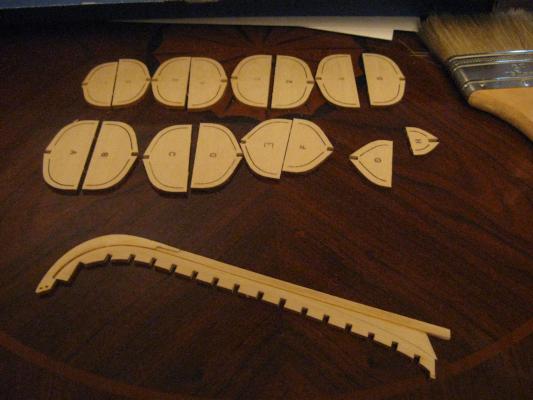

I've started on the keel section now, but still working on getting a camera so that I can post pictures in by build. Soon, I hope.

-

I was just doing some research on the web and found this:

Looks like the same stuff, removes with mineral spirits so could be thinned with the same if necessary.

Pretty cheap too!

Think I'll get some and try it when I get to a rigging point.

And it appears my "fears" about gluing the knot are basically unfounded so another point cleared up for me.

Thanks for your responses.

-

K, I asked this question elsewhere and have not yet received a response. Maybe here.

How (or maybe what) glue is used to "set" the knot on a line that has been treated/soaked in bees wax?

Doesn't the wax prevent the glue from penetrating?

Total newbie here so don't yell please.

-

K, went shopping today and got my "toy" tools, glue, etc.

Got everything de-charred (don't know if that's a word or not but............) and already broke the transom, gotta be more careful with that sharp x-acto blade. It's ok though, I just went and bought a sheet and re-cut it. Will be starting on the keel bevel tomorrow morning so.......

Just a small note about me. I tend toward perfectionism but I'm not a really sensitive person (people who know me call me Spock). I want to learn to do this the best way possible. If ANYBODY sees ANYTHING that is wrong or could be done a better way, don't even hesitate to tell me. You don't even gotta be polite as far as I'm concerned. Don't just let it slide. I promise I will not be offended.

-

Since I am starting the Longboat as my first ever build (as I see others are), I have also bookmarked this thread.

Excellent guide for those of us totally inexperienced at this craft.

If you are not/have never been a teacher - you do it very well.

-

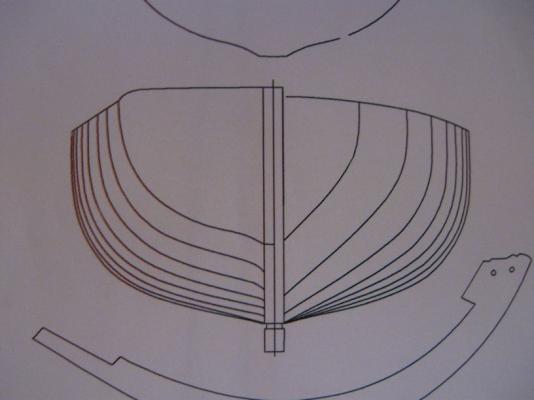

18th Century LongBoat by jburchfield1 - Model Shipways - 1/4" scale - SMALL - 1st ever build

in - Kit build logs for subjects built from 1751 - 1800

Posted · Edited by Pops

Mike - I thought about using the bulkheads as a "frame" by clamping the planking to them.

BUT, doesn't that risk getting enough moisture into the bulkheads (from the wet planking strip) to risk warping/swelling?

Alistair - (or anybody) is their such a thing as "overbending" or does the "snap back" of the strip keep that from occuring?

Maybe I'm just overthinking this and just need to jump in, as it were?