-

Posts

1,653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hof00

-

Thanks Rob. I'll equip the Mainsail, Top-Sail and Topgallant Fore and Main with "Horses." 🙂 A question for you: Do you have a diagram/key for Running Rigging Fairleads associated with the Fore, Main and Mizzen Main Tops? (Platforms) I am trying to figure out if these were used for Sail Handling only or if Sheets, etc. utilized these, or, if they passed through the "Lubbers" hole in the Tops. Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi All, Small update. A little dull perhaps just some progress on Yards. Photos are more or less complete Topsail Yards. (These require the addition of Flemish Horses and a bit of paint touch-up here and there.) I think about one month for these three items. (I am trying not to be too "Precious" with the Yards otherwise I would never get them done!! 🙂) I am also still trying to decide which Yard were equipped with Flemish Horses. Opinion seems a little divided on the subject. (The advice that I have received is that only Top-Sail Yards were equipped with Flemish Horses. I wonder if this applies to the Mizzen Top-Sail Yard also? If anyone has opinions regarding McCay's Ships, I'd be very keen to hear them.) I also include a couple of photos of the next three Yards, Topgallant, Fore, Main and Mizzen. (I prepped all Yards some time ago except for Paint and attaching Blocks and other items, prepared also.) Anyway, that's me for the mo. Cheers.... HOF.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi All, A quick update tonight. Completed the Fore, Main and Mizzen Yard. (Main Course?) I am reasonably happy with the result although the process took me a little time to figure out an assembly sequence that seems to work for me anyway. (I guess the next 12 Yards will be practice enough. 🙂) I decided to blacken, (Paint) the Jackstays as they just didn't look right "Bright." (I have prepped all remaking Jackstays Black.) Footropes are 5.0mm below the Yard and are 0.15mm A/L "Waxed" Black Thread. (In the photo, the Footropes look a bit "Random," they look much better "Off Camera.") Stirrups are 4 X strands of Copper wire, (0.1mm?), twisted together with a 0.5mm loop in the end for the Footropes. Just a couple of touch-ups on these items that I have just seen!! 🙂 Tomorrow, I'll make a start on the Top-Sail Yards. These are, (Painted)), ready for thier "Furniture" which is also prepared. Thats me for the Mo. Cheers....HOF. Photo:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi Rob, Very Nice!! Thanks for your input, helps with the visualization. I made a "Dummy" Spar about the same as the Foretop. I can "Fiddle" with the Stirrups/Footropes without making mistakes on the prepared Spars. I am pretty sure that I have the Stirrups the correct length for the Top Sail Yards. The Main Yard Stirrups are going to need to be a millimeter or so longer as the Yard is thicker, anyway, consistency is what I'll be after. 🙂 Cheers and Regards, Harry.

-

Many thanks to you all!! I think I can move on a bit now. I am making up a "Test" Yard to gauge how different materials, (Thread/Wire), look and behave to avoid re-work on items already created. 🙂 Good to know a definitive answer regarding Flemish Horses. Cheers and Regards, Harry.

-

Hi All, Thought I'd pose a question regarding Footropes, Flemish Horses and Stirrups. I am currently building the 1/96 Mamoli Flying Cloud and in the process of building the Yards. The plans show Footropes and Stirrups but no Flemish Horses. I don't think that this is entirely correct. I have looked at various publications, Ship Modeling Simplified adv. that Flemish Horses were only installed on Yards that had Stunsail Booms fitted, other info is either very vague and one adv. that Flemish Horses were only installed on Top Sail Yards. Another question, is there a formula for the spacing of Stirrups over the length of the Yard or arbitrary placement? So, what is the answer? 🙂 I am hoping that someone can offer some "Seer" advice on the subject. I am also tossing up the practicalities of adding Flemish Horses if they are too small at 1/96. Many thanks in advance. Cheers....HOF.

-

Many thanks Rob. I built the Mantua/Sergal Cutty Sark, (On this site), a few years ago, this now seems much simpler, (The Cutty that is), due to the bigger scale. 1/96 is much more challenging. Anyway, the answer to you question regarding Sails, no. 🙂 Bare Bones will do nicely. Incidentally, I have an A/L 1/84 Cutty in the cupboard with sails. After the FC I might be tempted.... Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi All, Bit of an update seeing that it's been a few weeks.... Working on Spars, Blocks and Hooks tiring to get my "Recipe" correct for these items. 🙂 I have completed Block installation for the Mainsail yards. For the Blocks that attach directly to the yards I first made up "Pigtails" with the Block siezed to one end using a "Slidey" Siezing secured with a dab of CA. I then wrapped the "Pigtail" around the Yarad and used the same Siezing to secure the Block and "Pigtail." After much Gnashing of teeth and brow beating the method works for me, a little more work but the results are more acceptable than other methods attempted. I also utilized the Jack Stay installation to line up Blocks along the center of the Yard. (Blocks for Boom and Gaff a similar approach for Block installation. The Stunsail Booms are not yet glued in position as I need to develop a method for Footropes and Stirrups. While I experiment, it will be nice to remove any "Clutter." (I have some ideas for Stirrups and Footropes.) I took some time to have a think about Hooks for Blocks and Rigging and developed a simple Jig to create 5.0mm Hooks. (I need quite a few of these as I am thinking that allot of the Running Rigging will eventually be secured to "Hooked" Blocks with Eyebolts on the Deck.) Next was to think about attaching the Hooks to the Blocks.... These Blocks require a Becket, no problem to create these but I was disappointed with the result after tying the Siezing on the "Hook" side of the Block. (Even with 0.15mm Rigging Thread, the result was disappointing.) I decided to resort to 0.4mm Black "Art Wire" More acceptable results and much easier. Next tasks: Stirrups and Footropes Topsail Yard Furniture That's me for the mo. Comments/suggestions always welcome. Cheers....HOF. Photos:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

I sincerely hope that you have enough material(s) in your kit. As you may have read in my log, I was rather frustrated by the lack thereof in mine. Take care of the small components as I found that there were just enough.... I am finding, at this juncture, that there are not nearly enough Blocks, I am glad I have plenty from other builds. Cheers....HOF.

-

Nice Build!! I really like the color scheme. Cheers.... HOF.

- 68 replies

-

- Sanson

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Hi Rick, Thank you for your kind comments, appreciated. Regarding Chain Plate lengths, I'll definitely have a look-see. I do think that it's a little too late to adjust the lengths. (They are quite a bit shorter when the bottom Link of the Shroud Chainplate is held on the Wales.) I will have a wee break from proceedings while I ponder suggestions by yourself and Rob. (Maybe do some Yard and Mast work? 🙂) Comments and suggestions very welcome thank you. Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi Rob, Thanks for the "Heads-Up." I am aware of the Double Channel set-up used. The Kit does not supply secondary Channels. The do however instruct the modeler to install a 2.0mm? strip to represent the secondary Channels. Yup, I have been thinking about these items and am considering "Scratching" something. (It's not too late, the Channel Caps are not fixed yet, just pinned. 🙂) Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

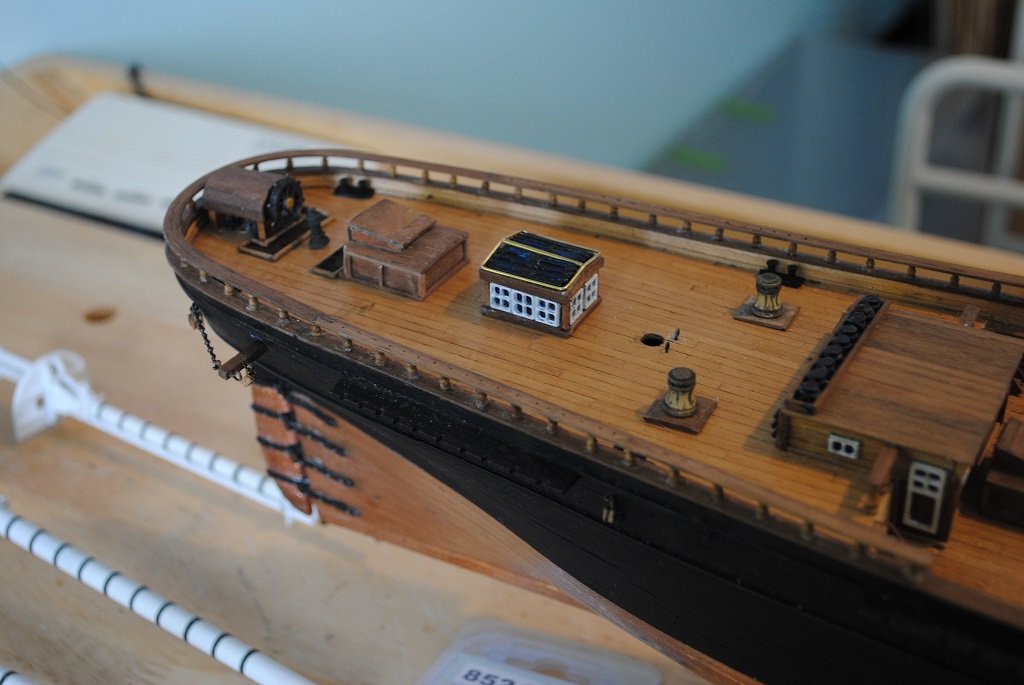

Hi All, Time for a small update: For some time, I have been struggling with tying my Stropped Blocks on to my first Yard, Fore Main Course. Several attempts later I think I have the correct "Recipe", one that seems to work for me anyway. I will post my fourth attempt after the Blocks are on.... 🙂 One of my issues was lining up the Blocks along the length of the Yard. I have some 0.5mm Brass Rod on order for the Jackstays, my plan is to utilize these to assist. Anyway, I digress, I decided to make my own Binnacle, the Kit supplied one was a "Later" 19th Century, Similar to a small pillar. Photos show my second attempt. I turned a Bell, also my second attempt as the first was way too large. I added "Brass" Caps to the Vertical Capstans. The material is actually Gold Bare Metal Foil but I think it does the job. This morning, I decided to have a bash at mounting the Chain plates. For the Channel Capping I cut 1.5 X 1.5 strips, pinned middle and both ends. Photos show unpainted capping strip. This will be painted Black before affixing. Anyway, that's about it for the day. Cheers.... HOF. Photos:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

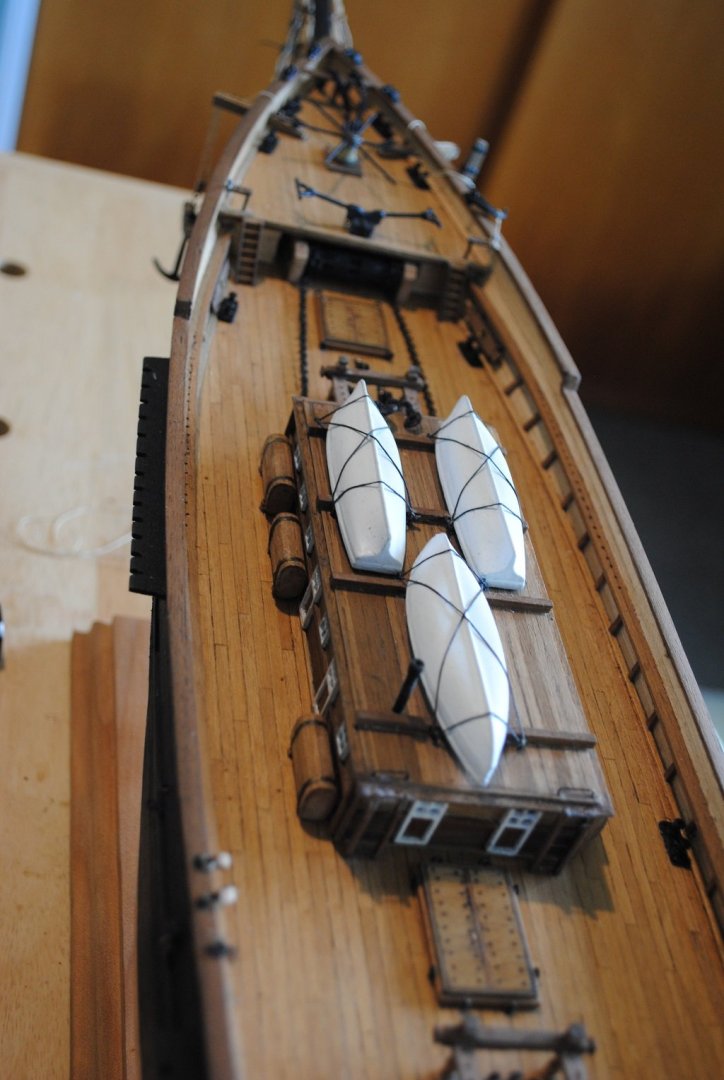

Hi All, Time for a small update.... Fitting of Deck Funiture progresses, only a few Deck Eye Bolts yet to place and a couple of Blocks on the Aft side of the Catheads. Thanks to @petervisser for his suggestion on Anchor Stowage. (I have done one up and one down.) I removed the Focsle Mooring Bitts in order to be a little more accurate with the Capstan placement, I also decided to install Capstan Bars for a little added interest. (Vertical Capstans are A/L as the kit supplied ones were pretty nasty.) I made up a couple of Gratings, one in front of the Ships Wheel and one for the Aft Companionway. The only things left unattached at the mo. are the Vertical Capstans and the Skylight structure/block. The Skylight continues to be a point of indecision for me as I am not happy with the way the Roof Windows look. (Photos show structure with a Brass frame around these and one without for comparison, feel free to comment. I have a couple of ideas yet to represent these Roof Windows a little better perhaps? (I might just be better to leave well alone.... 🙂)) Shroud Chainplates and Deadeyes assembled, (No photo sorry), and I'll assemble the Backstay Chainplates soonish. The Chainplate material is a "Soft" white Metal, and I overstressed a couple of these so had to replace with ones made from Brass wire. I think that's it for the mo. If I remember anything else, I'll update. Apologies for a couple of "Out of focus" pictures but I think that you'll get the idea. 🙂 Cheers....HOF. Photos:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Thanks Peter, I'll have a look. Many thanks. Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi All, Small update: Progressing with Fittings, I realized the Anchors were not correct, the kit supplied Anchors were "Admiralty" pattern, i.e.. Anchor Stock was a bar not a wooden Stock. What made things difficult, the Bar was cast as part of the Anchor. I had a look on-line, Model Expo sold the correct size and pattern, (Corel?), but the shipping was just way too expensive. So, making my own Stock and some careful surgery seemed the only course of action. I was reasonably happy with the results.... (Photos) Prior to this, the Anchor Chain/Cable/Spurling holes drilled on the Deck, Chains fitted to the Capstan and installed. (Kit supplied Hawse/Spurling fittings would not accommodate the Chain Diameter, so I found suitable replacements in my parts boxes.) This morning, I fitted the Anchors/Chains, but I have not determined how to mount/tie them to the Hull sides. Plenty of time.... 🙂 Cheers....HOF. Photos:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi Gentlemen, My name is Harry. (Taranaki) I have been knocking around for quite a few years on this site. You will find very good advice and comradeship here no matter what ship you are modeling. Nice to have some fellow New Zealanders on board!! 🙂 Cheers....HOF.

-

Hi All, Not much of an update but update, nonetheless. Poop Boomkins installed. These were a bit of a bother to install although I thought that I had mitigated any issues prior to installation. I am pleased that they are done, I feel I can now move on with remaining Deck fixtures. Cheers....HOF. Photos:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Thanks Peter, Appreciated. Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi All, Small Update.... @rwiederrich Rob had stated a few posts back that my Bowsprit Shrouds were terminated too far aft on the Hull. I needed a second opinion so reached out to Mr. Scott Bradner who advised that this was correct. So, armed with this knowledge I decided to "Adjust" the Shrouds. (I think I am a little happier with the result.) I have to polish the Copper again, too many grubby finger marks.... (Thanks, Rob, I just needed the second opinion.) Hopefully things are a little more accurate. Cheers....HOF. Photos:

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi Ian, Thank you for your consideration, appreciated. 🙂 Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Thanks Ian, The answer is no I don't. It is something that I have thought about Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Thanks Rick, Bowsprit/Jibboom was better the second time around.... 🙂 I had to glue the Bowsprit into its location as it kit does not allow enough penetration into the Hull. (I prefer Rigging to hold things in place, not in this case though.) I am working my way slowly with this one, My Cutty was easer at 1/78 scale. Once firmly located, it is not so much of an issue to tension things. (And, I ran out of kit supplied Chain, not surprising as this kit is more than a little "Light" on materials. It is fortunate that I have a few meters of the correct size chain in hand. 🙂) Cheers and Regards, Harry.

- 199 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.