-

Posts

1,484 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

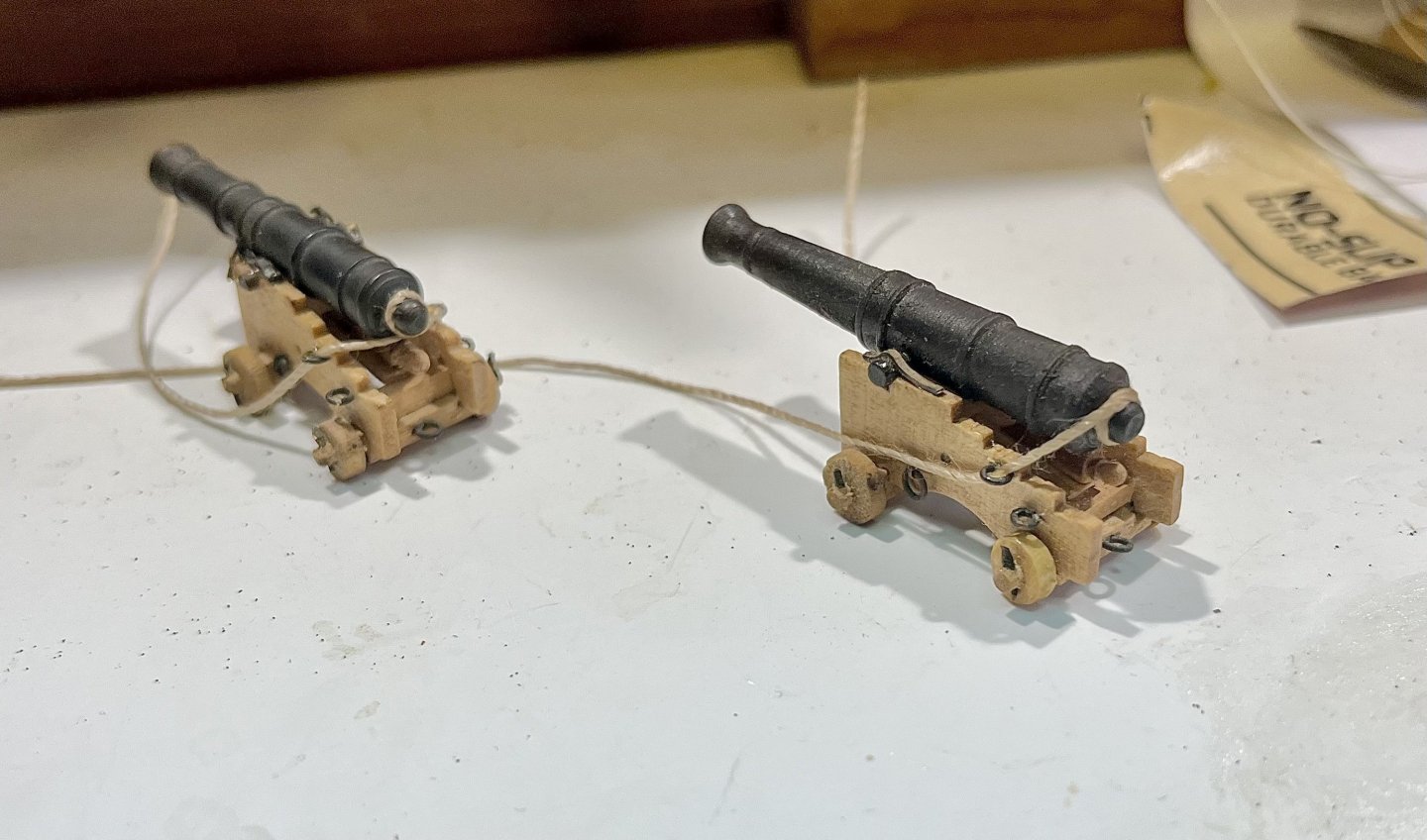

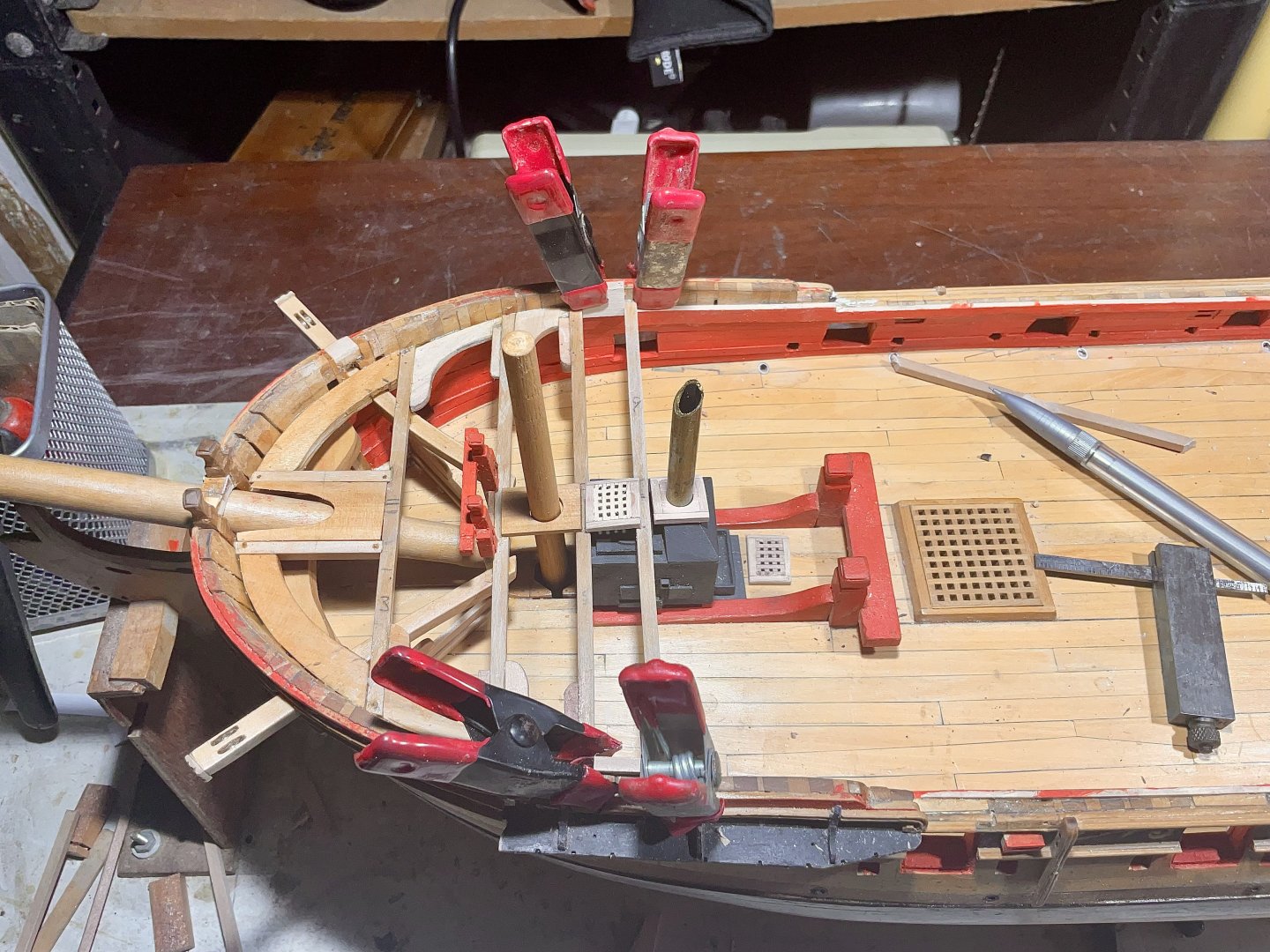

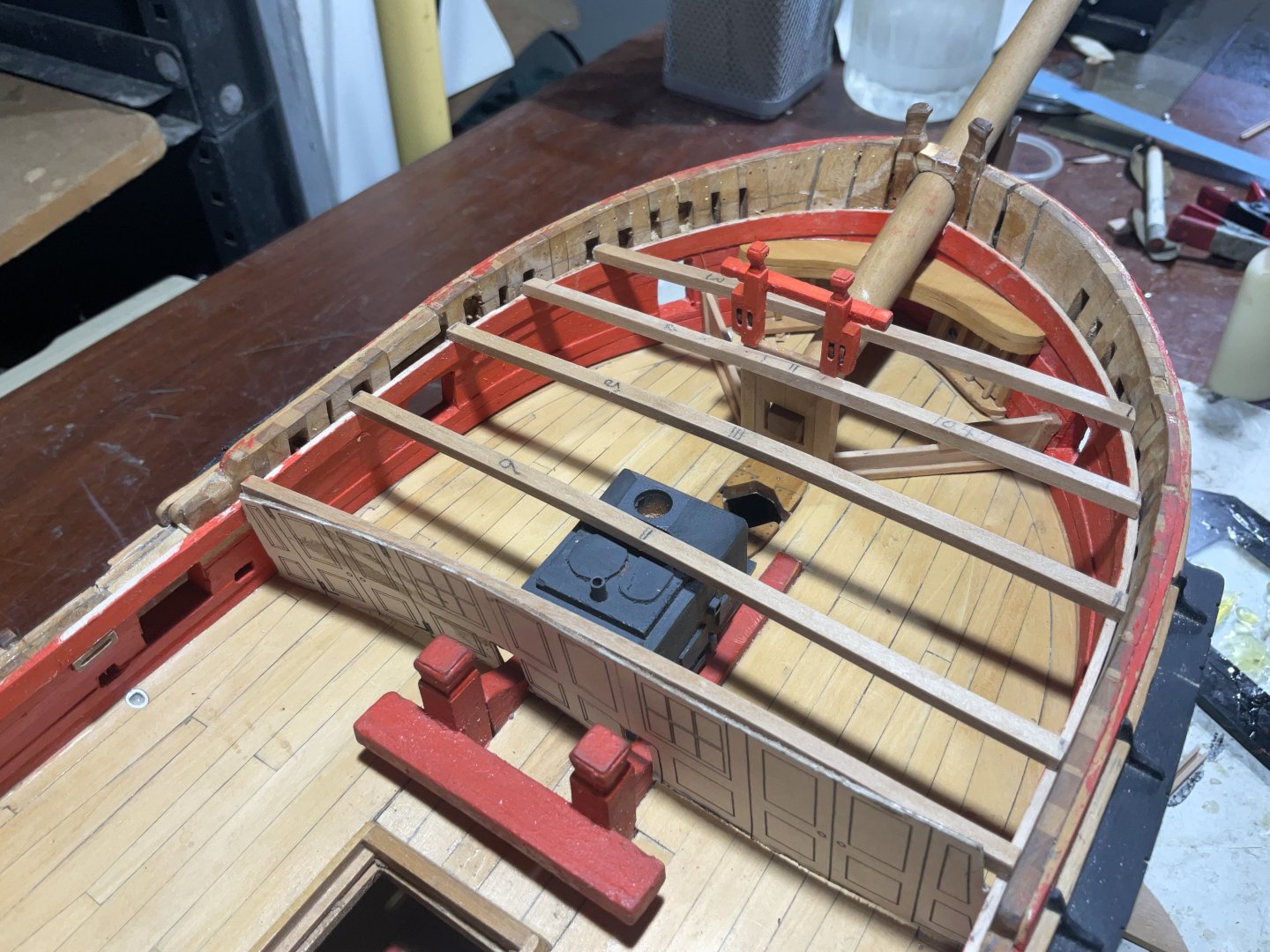

You are right and wrong. I wanted to install the cannon back from the gun port. That turned out to be an error as the aft train tackle ended up to close to the eye on the center of the deck. This was caused by the blocks being too long. I have now been able to reduce the hook down to about 5” while in real life it was probably 3” in length. I just cant make it smaller than this and even this method is a bit of a cheat as i had to remove the eye at the end of the hook. It will be better on the port side. In any case this will all be sealed up and no one will be able to see it, just you and me.

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

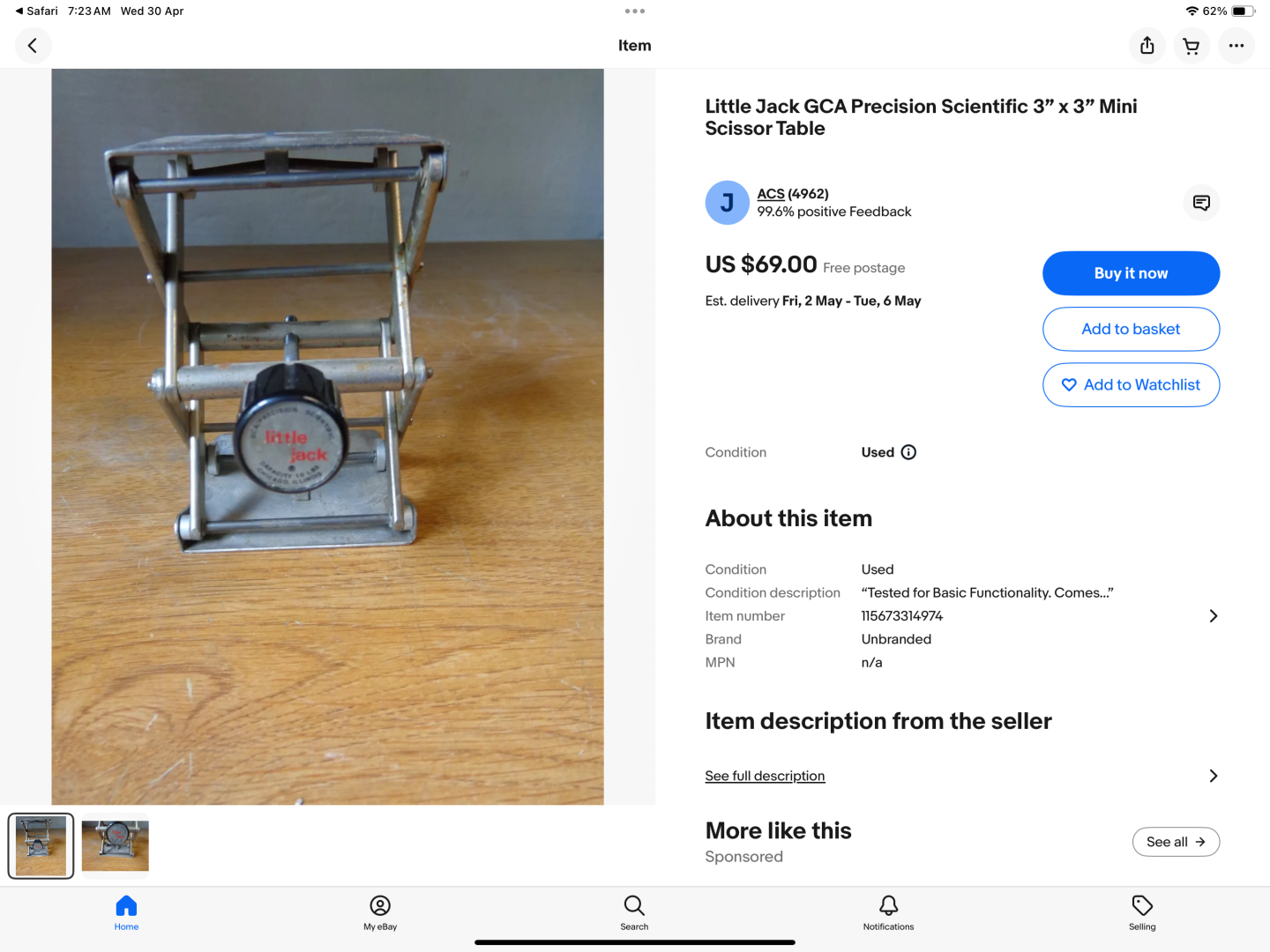

I was struggling with the adjustment screw on my Preac as it kept changing caused by the vibration of the saw and the slackness of the adjustment screw, so i have ordered a jack and hope this will keep the adjustment more stable . I remember someone making an external adjustment screw for the Preac but cant remember where or how it was done. These steam gratings are so small that i ended up making them solid instead of removable. Pity. If the jack works ill try again but wont get it for 2 weeks when Susan returns from NY.

- 1,127 replies

-

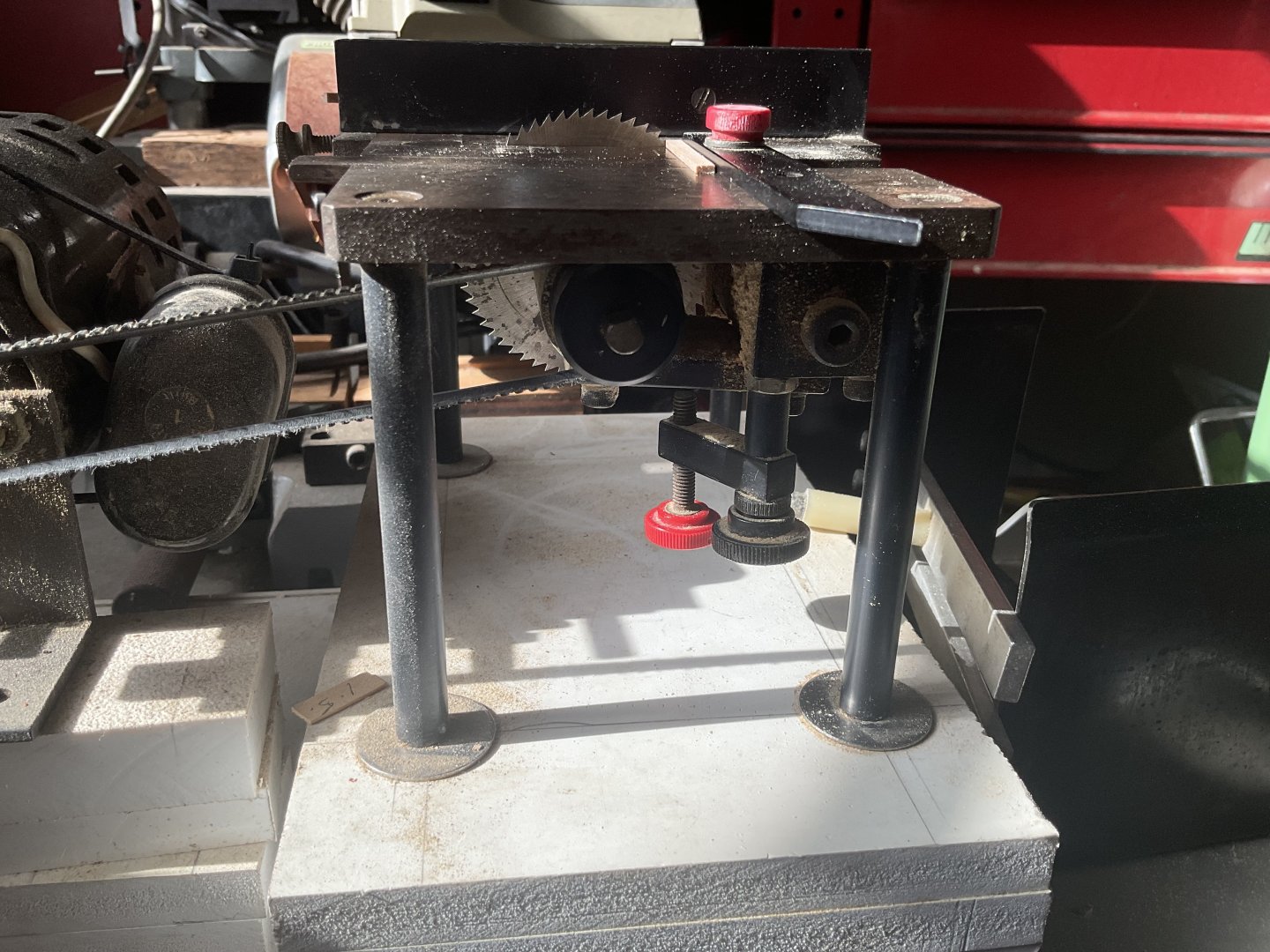

I needed some more wood do out to the outside workshop to cut some stock and almost had an issue. So decided to make a rip jig for this saw. Strange as I never cut up small stock on this saw always on the Proxxon. Here is the jig I made using Green heart and Juniper wood .i should have done this a long time ago. Its nice to be able to make your own tools.

- 1,127 replies

-

Hi Tom David does not like power tools while Greg is like me and loves them. You will see this demonstrated in book 3 of the Swan Practium . Having said that David’s approach is to learn carving skills using gouges . I found that to work at this scale and the size of the cathead it was easier to use my Turbo carver to carve the diamond shapes. David would definitely disagree and use a v shape gouge to achieve the same result. I will continue to practice using the gouges but have no issue using power tools to achieve the end result. Sorry will not see you this year, my next visit is in December as we are planning white Christmas in upstate NY.

- 1,127 replies

-

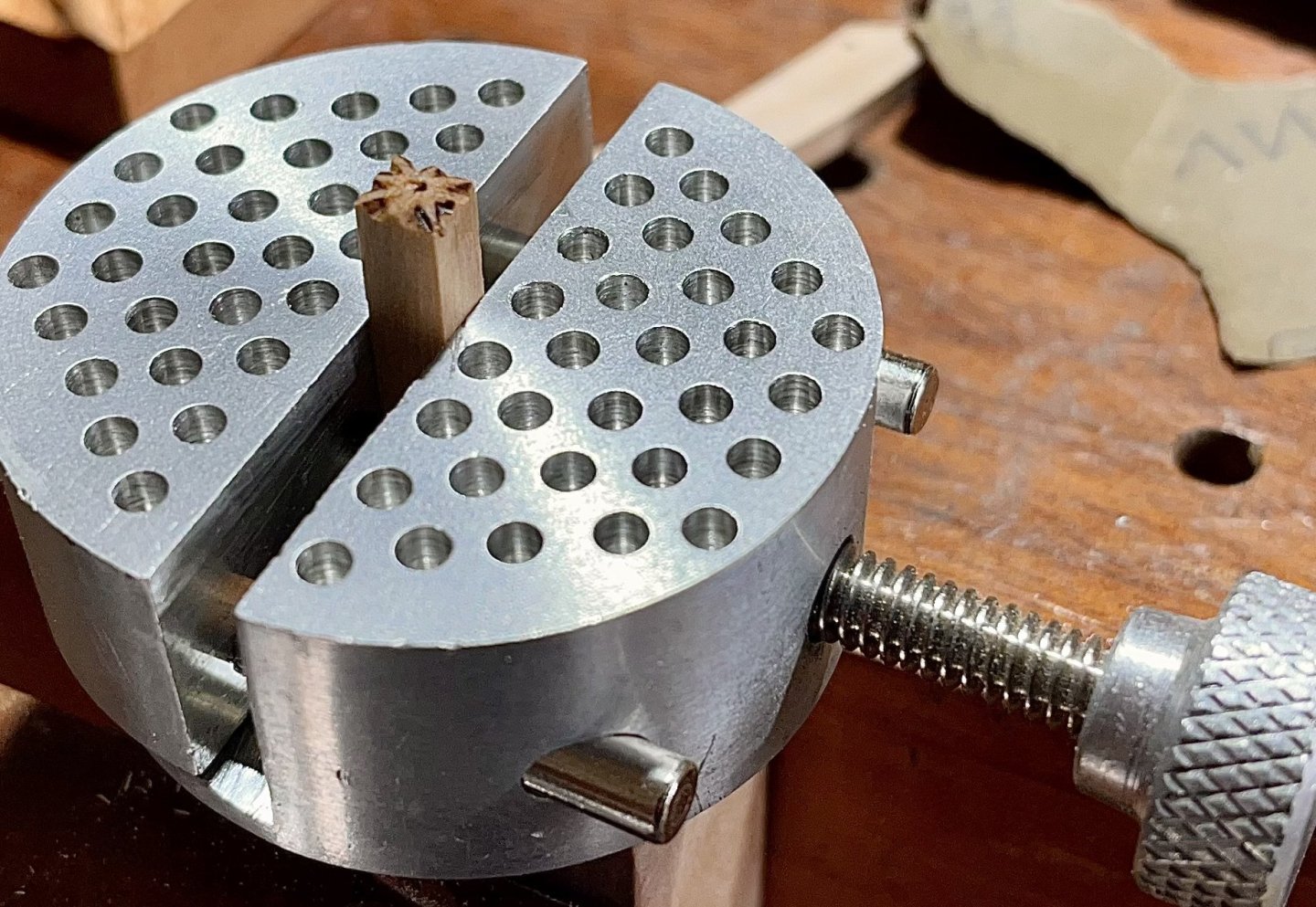

I had a lot of trouble holding the piece and made up this one from a Jewlers hand clamp . It worked great and since I already had it, the price was right.

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

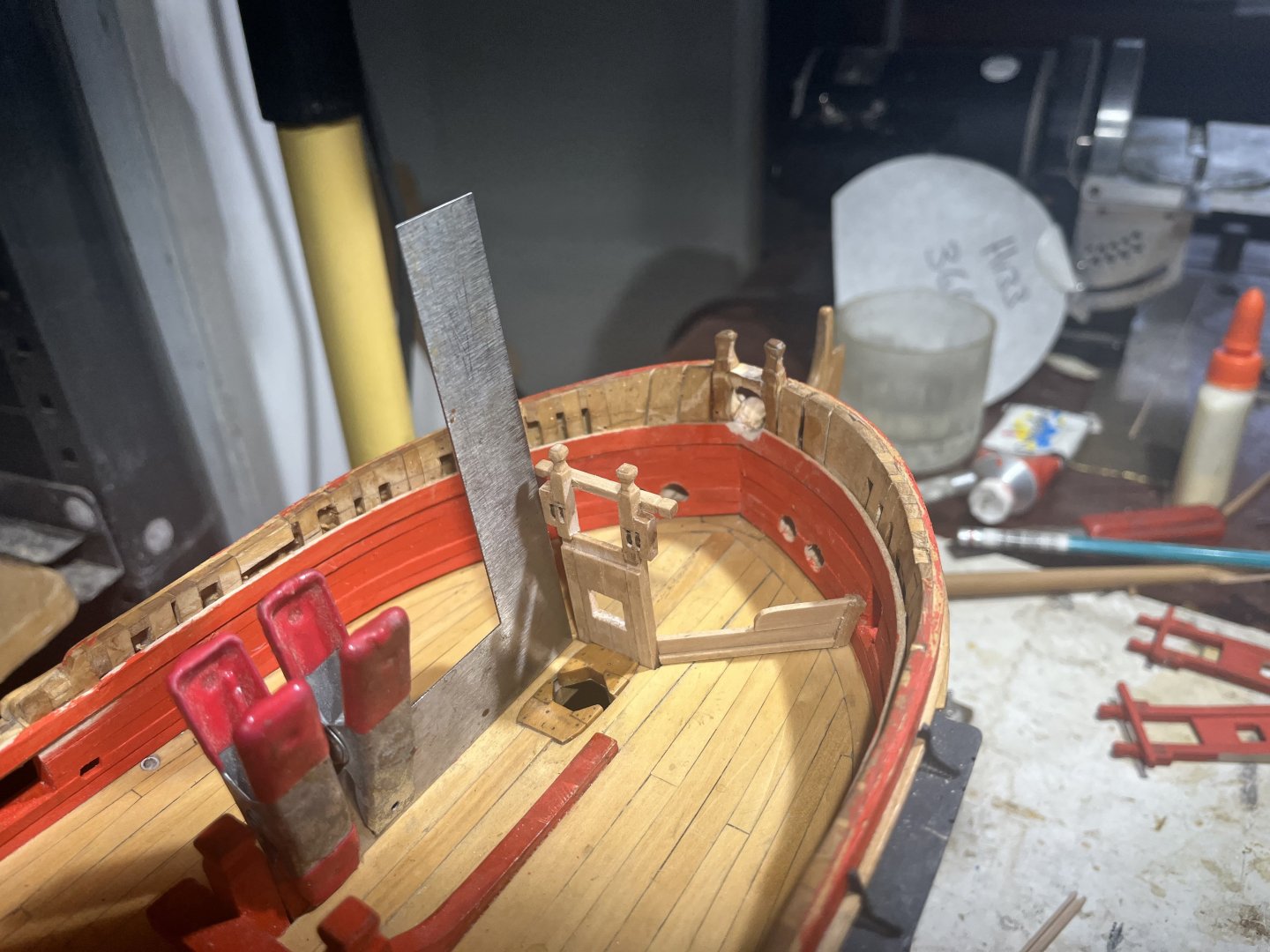

Catheads installed. That was brutal. I will have a lot of repairs to do to the moulding and the paint job. Easy fix its just a pain in the ace.

- 1,127 replies

-

Haha Alan it a wonderful learning curve. The sad thing is that much of what we learn gets lost for those who will follow. I have a written log that records many of my challenges so that when i get asked why i did what i did i and can find the answer. It is also why i have no fear of showing my mistakes in my videos.

- 1,127 replies

-

The bowsprit angle on the plans is 23degrees and my model is 21. So it is closer to the top of the stem than it should be. I have tried to change it but its not possible now. This will give me some issues with the figure head if i ever figure out what mine should look like. Right now i do not plan to put one as i have no idea what a THORN figure should look like. I will still carve one when the time comes though.

- 1,127 replies

-

You are correct about the bitt but not sure how i would get that measurement. Its not stuck yet and i will see how i can figure that out. The slope on the main deck is very slight.

- 1,127 replies

-

- 1,127 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.