-

Posts

143 -

Joined

-

Last visited

About fletch944t

- Birthday 11/03/1957

Profile Information

-

Gender

Male

-

Location

North Carolina

-

Interests

Woodworking, Guitars, Painting, and Golf

Recent Profile Visitors

-

JerseyCity Frankie reacted to a post in a topic:

USS Constitution by fletch944t - Model Shipways - Scale 1:76 - 1812 Era

JerseyCity Frankie reacted to a post in a topic:

USS Constitution by fletch944t - Model Shipways - Scale 1:76 - 1812 Era

-

Bill Tuttle reacted to a post in a topic:

Is there a better #11 blade handle

Bill Tuttle reacted to a post in a topic:

Is there a better #11 blade handle

-

dgbot reacted to a post in a topic:

Can i live without a BYRNES TABLE SAW

dgbot reacted to a post in a topic:

Can i live without a BYRNES TABLE SAW

-

MEPering reacted to a post in a topic:

USS Constitution by fletch944t - Model Shipways - Scale 1:76 - 1812 Era

MEPering reacted to a post in a topic:

USS Constitution by fletch944t - Model Shipways - Scale 1:76 - 1812 Era

-

MEPering reacted to a post in a topic:

USS Constitution by fletch944t - Model Shipways - Scale 1:76 - 1812 Era

MEPering reacted to a post in a topic:

USS Constitution by fletch944t - Model Shipways - Scale 1:76 - 1812 Era

-

riverboat reacted to a post in a topic:

Constitution by patrickmil - Model Shipways - 1/76th

riverboat reacted to a post in a topic:

Constitution by patrickmil - Model Shipways - 1/76th

-

roach101761 reacted to a post in a topic:

Is there a better #11 blade handle

roach101761 reacted to a post in a topic:

Is there a better #11 blade handle

-

GLakie reacted to a post in a topic:

Is there a better #11 blade handle

GLakie reacted to a post in a topic:

Is there a better #11 blade handle

-

Is there a better #11 blade handle

fletch944t replied to roach101761's topic in Modeling tools and Workshop Equipment

My review of surgical blades - so far. I ordered two different styles of scalpel handles and four different styles of scalpel blades to test as compared to Exacto blades. The scalpel blades I ordered were #10, 11, 22, and 25. The #10 & 11 scalpel blades are similar in style to the #10 and 11 Exacto blades and they fit the #3 scalpel handle. The #22 scalpel blade is similar to the #22 Exacto blade and fits a #4 scalpel handle. The #25 scalpel blade is the closest thing I could find to a #2 Exacto blade. It too fits the #4 scalpel handle. So, in all cases the scalpel blades are slightly more flexible than their Exacto counterparts. Sometimes I find that I like that and other times I prefer the stiffer blade. For me personally, I have small hands and I find that the scalpel handles feel better in my hand than the Exacto handles (regardless of which Exacto handle it is. The scalpel blades are very sharp and inexpensive. And finally, the blades don't slip - period. Often, if I find myself needing anything more rigid than the scalpel blade, I end up using a gouge or a chisel. However, having said that, I'll also say that I don't think I'll be abandoning my Exacto knives completely in favor of scalpels. I think I'll be using the scalpels at every opportunity simply because the blades are cheap and I can change them frequently without breaking the bank. But, I also know that there will be times that a very sharp, very rigid blade is called for and the scalpel blades just won't cut it (pun intended). So there you have it. My own impartial review of Exactos versus scalpels. -

dgbot reacted to a post in a topic:

Scroll saw

dgbot reacted to a post in a topic:

Scroll saw

-

I have a lot of power tools, including a scroll saw, and I use all of them on a fairly frequent basis. At the time I purchased my scroll saw, I felt I needed one right then but, I was short on cash at time. So, I bought a 16" Variable Speed Central Machinery Scroll Saw from Harbor Freight for $69. I bought it fully expecting to have to throw it away after a few months but, at that price I figured I could afford to throw it away and buy a better one when my pockets were a little deeper. To my surprise, it's been up the task for everything I've asked it to do. I guess if I were going to use a scroll saw more frequently than I do, I could see ponying up the bucks for the MicroLux or Proxxon scroll saws. But, since I only use it every couple of days, I'll keep using the CM scroll saw until it goes belly up.

-

robnbill reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

robnbill reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

-

Well Bill. All I can say is if my Connie turns out even close to yours, I'll be a happy camper. Incredible work. And again, thanks for all the help you've given me thus far. It has been invaluable.

- 335 replies

-

- Constitution

- Mamoli

-

(and 3 more)

Tagged with:

-

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

-

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

-

Is there a better #11 blade handle

fletch944t replied to roach101761's topic in Modeling tools and Workshop Equipment

I may have spoken too soon. All of my newer X-Acto brand handles are single slot. I have an older handle that has an X-slot collet. However, I can't identify what brand it is. Funny thing is, the handle is close in size to all of my handles that accept a #2 blade but, the #2 blades are slightly to large to fit into the handle. As far as the single-slot X-Acto handles, while I've had a great deal of trouble getting them to grip the blades, it may be attributable to the fact that, having surgery on both wrists just prior to the end of last year, my grip is not quite back to full strength and I may not be able to tighten them sufficiently to properly grip the blades. However, having said that, one design improvement that X-Acto could put in to make this easier is to knurl both the tightening nut and the handle next to the tightening nut. What I find is that while I can grip the tightening nut, the handle slips in my fingers when trying to tighten the nut. I also took another look at the Harbor Freight "deluxe hobby knife" set again. While almost all of the knifes use a plastic collet, most of the collets tighten near the blade. However, on two of the handles the plastic collet runs inside the entire length of the handle and are threaded on the end opposite of the blade for a tighten nut. While I detest the plastic collets, these two handles in particular seem to have much less trouble holding the blade. -

Is there a better #11 blade handle

fletch944t replied to roach101761's topic in Modeling tools and Workshop Equipment

That's interesting Walter. I think I have some old X-Acto handles buried away somewhere and I do remember that the older handles have a single slot instead of the X slot on my current handles. I'll have to give them a try (assuming I can find them). -

fletch944t reacted to a post in a topic:

Is there a better #11 blade handle

fletch944t reacted to a post in a topic:

Is there a better #11 blade handle

-

Is there a better #11 blade handle

fletch944t replied to roach101761's topic in Modeling tools and Workshop Equipment

For me, the answer to these two questions does not shed any light on the problem nor reveal a solution to the problem. Regardless of how I hold the knife or what I'm using the knife for, the X-Acto handles currently on the market don't grip the blades very well. -

Is there a better #11 blade handle

fletch944t replied to roach101761's topic in Modeling tools and Workshop Equipment

I did a similar thing yesterday Phil. Except on eBay. I bought 2 stainless #3 handles and 2 stainless #4 handles. 100 each of the #10, #11, #22, and #25 blades. Total was $30.15 with free shipping. The reason I bought 2 of each handle was so I could keep a #10 and #11 in each of the #3 handles and a #22 and #25 in each of the #4 handles. That way I won't have to be changing blades all the time. We'll see how it works out. -

Is there a better #11 blade handle

fletch944t replied to roach101761's topic in Modeling tools and Workshop Equipment

I bought the Harbor Freight "deluxe hobby knife" set and it's completely worthless IMHO. In fact, the Harbor Freight handles are actually worse than the X-Acto handles at gripping a blade. To the point of being dangerous. That being said, I too am not happy with the way the #2 and #11 X-Acto handles grip a blade. I'm constantly having to tighten them as well. I think I'll give the scalpel route a try. -

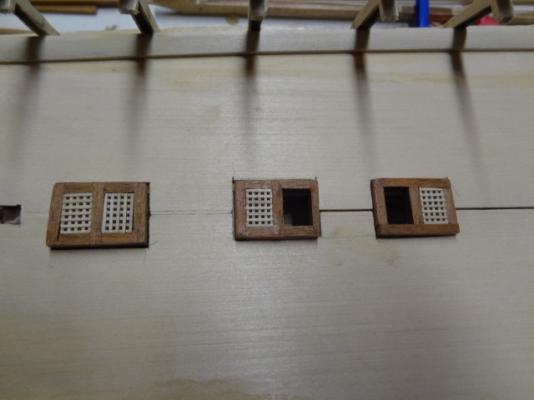

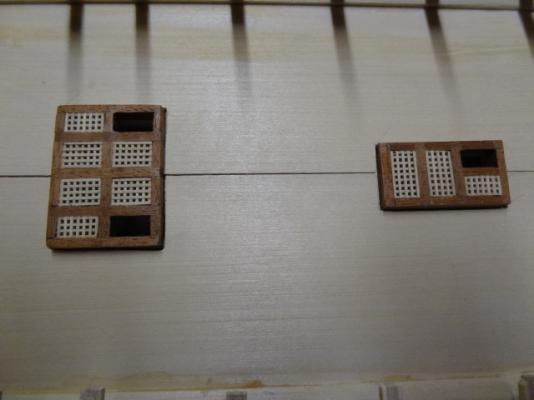

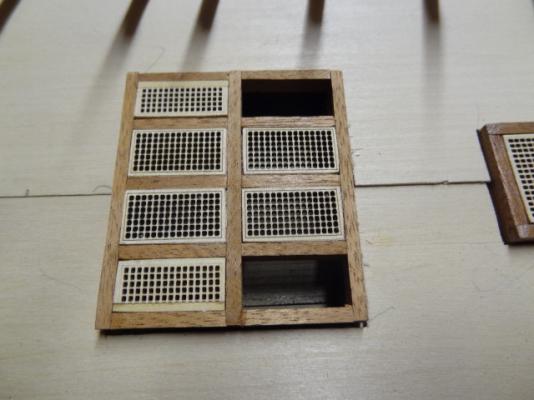

It's been sometime since I've posted but, the last few weeks haven't been a complete waste. Just to give you a little history, it WAS my intent to construct the gun deck hatches using the same grating provided in the kit. I wanted the grating on the gun deck to appear identical to the grating on the spar deck. So, I contacted Model Expo and ordered two extra sheets of the grating sheet provided in the kit. As you can see from the previous pictures, I was already well into constructing the gun deck hatches using the kit grating. After constructing all of the gun deck hatch coamings, I started locating them on the gun deck and came to a disturbing realization. That being that the gun deck hatches were entirely too large. I knew when I made the decision to go this route that the hatches were going to end up being larger than they should be. This was due to the fact that even using the smallest gratings available in the kit, the hatches would be larger than scale - even cutting some of the gratings down to a smaller size (which I didn't want to do). But, I made a conscious decision to go ahead and give it a shot. Well, had I gone through with the plan, there would not have been enough room for all of the gun deck hatches and it would have crowded other equipment on the gun deck. So, I reluctantly went back to the drawing board on the hatches. I had previously printed copies of all of the Constitution deck arrangements from the Plans CD. And, I already had measurements of the gun deck hatches which I had converted to scale by comparing the main hatch measurements from the CD and the MS plans to get a conversion factor. This is how I knew my original hatches were going to be larger than scale. So, I ordered boxwood grating material from Model Expo (1mm grating holes) and fabricated all new hatch coamings and gratings for the gun deck. This also required me to cut new sub-flooring for the gun deck and rework the hatch support framing. As a side note, I'll be using the same grating material on the spar deck in place of the grating provided in the kit (again for consistency in appearance). I've also completed the gun deck waterway, attached the waterway to the gun deck sub-floor, and painted the waterway. You won’t see it in the pictures yet, but I’ve also started planking the gun deck. One of the reasons that I decided to install planking over a basswood sheet sub-floor is so that I can plank the gun deck sub-floor with it removed from the model. I did this because I thought it would make the job of planking easier, especially with regards to using scale length planks. One problem that it does create is that the center line plank on one half of the sub-floor must overhang slightly to ensure the seam between the sub-floors is properly concealed (assuming all goes according to plan). So, here are the pictures of the progress thus far. I’ll post pictures of the deck planking when I’ve made enough progress to take some decent pictures.

-

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

-

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

-

While I've had very little time to work on the model this week, I've made some minor progress. I finished another one of the gun deck hatches and I finished the fore-most scuttle. As far as I can discern, I have three more gun deck hatches to complete (unless I've missed a hatch or scuttle somewhere). Then I'll be able to start working on the gun deck planking. I've yet to apply the acrylic satin sealant to the larger hatch or the scuttle. That's why the middle hatch is darker in appearance than the other two.

-

Hi Jon. Bob's Practicum will serve you well. IMHO it is a must have for folks, like you and I, who don't have a huge amount of experience with plank on bulkhead modeling. However, also realize that frequently there is more than one way to accomplish a task and sometimes it may be easier for you to do something your own way than it might be following the practicum to the letter. I have found that to be true on several occasions with the practicum. Just realize that this is YOUR build, not Bob's build and you can do whatever you want. I'm very early in my build and I've already made a ton of mistakes and broken a lot of stuff that I had to fix. I was honestly petrified getting started on my build. However, I quickly learned that every mistake is a learning experience and that every mistake is fixable. I've also come to realize that your skills as a modeler will develop quickly once you start and you'll find yourself making fewer and fewer mistakes as time progresses. Good luck on your build.

-

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

fletch944t reacted to a post in a topic:

USS Constitution by robnbill (Bill) - FINISHED - Mamoli - 1:93 kit - First Build - Bashed

-

Thanks Patrick. The only place I plan to do any of the berth deck is for the hatches that will have at least one opening with a ladder going down. For example, the next hatch aft which is directly below the aft end of the spar deck main hatch will have two ladders going down. So, I'll try to model some berth deck planking there. However, the forward-most hatch on the gun deck is really just a scuttle. So, I'll have a hatch and hatch grating there with black paneling underneath. As soon as I finish all of the hatch coamings for the gun deck and cut the sub-floor panels to accommodate them, I'll start planking the gun deck. I need to do that so that when I get one of the 24 pound long guns put together I can set it on the gun deck to determine the appropriate height of the gun deck ports.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.