russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

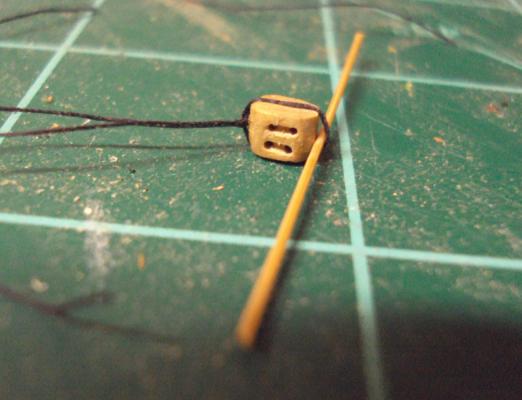

I know it has been a long time, but I am still working on this schooner. I had to take time to do all sorts of other projects including a large scale model restoration last year. In the meantime, I have been getting a few things done on this model, here and there. Here is where I am at right now. I am painting the bottom of the hull red. This has a several very thin coats and it will need a few more yet. I have the sails almost ready. I still need to attach the hanks for the forestaysail and the jib. The main and foresails are both ready to go on the masts right now. In preparation for rigging, I am making some blocks. Here is the double block for the main gaff halyard. Russ

-

Experience with BlueJacket metal toners?

russ replied to Cathead's topic in Metal Work, Soldering and Metal Fittings

I have used their Brass Black and Brass Brown. I work in a small shop just off the den and I have not noticed a lot of odor. I have applied with a brush and I have soaked. It will tone brass, copper, and aluminum. I have always used it full strength. Quite often it is necessary to apply the toner, wait a bit, rinse off, blot dry, and reapply, repeating until you get the depth of color you want. For small parts, I usually hold the piece with cross locking tweezers and brush on the toner, dunking in water and blotting on a paper towel each time. Using a toner takes some time and patience. It is not something to do if you are in a hurry. Russ -

-

That is about the smallest scale I would even think of trying to make such blocks. I have made them in larger scales with little difficulty. I use a 4" table saw with a zero clearance insert and the blade lowered to make the grooves on the inside face of the shell for the strop to fit into. Russ

-

Allan: What sizes are you looking at? Shell length? Scale?

-

Jud: I understood your idea, but I was saying that adding the glue to the thread before tapering makes it easier to do the taper. Russ

-

Jud: Stiffening the thread with glue before cutting the point will make it easier to cut the thread to a point. You need that stiff end to the thread to be able to cut the pointed end. Russ

-

I would use a small drill bit to drill out the hole in the gunport cover. Then, use some CA (super glue) to harden the very end of the thread so that it is very rigid. You can even use a hobby knife to cut along the edge of that hardened end to get the very end of it to a point. Then pass that pointed end through the hole in the gunport cover. Tie a simple overhand knot in the other end of the thread so that when you pull the thread through the hole, the knot acts as a stopper to hold the cover open. Russ

-

replacement for blacken it brass?

russ replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

Bluejacket Shipcrafters sells a Brass Black solution that I have used for years. It seems to be very good. Russ -

John: That deck looks great. Wonderful job. Russ

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

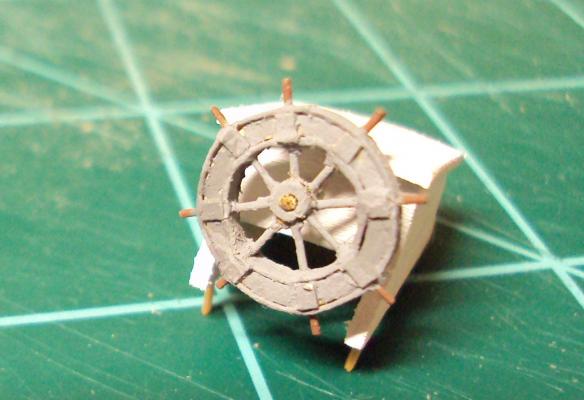

Martin: I freely admit that I could have made a better job of the wheel. Close up, the paint work should be better for sure. However, it is not too bad when you look at it from a distance. The boss and the rim are of boxwood. The rim piece was cut out and the inside section removed. Files were used to clean up the inner and outer surfaces. The spokes are of bamboo. Each spoke extends through the rim and then is cut off to form the handles. The outer and inner rims are of poster board, as are the pieces set onto the rim at each spoke. Russ

-

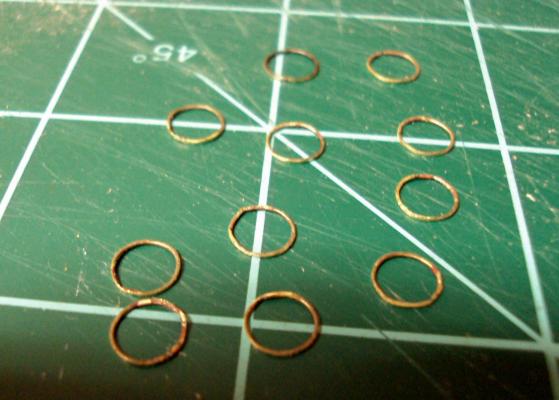

One challenge that I have been working on is the mast hoops for this model. At 1/48 scale, I have been trying to come up with a way to make them small enough to blend into the scale of the model. I need 22 hoops, 11 for both mainsail and foresail. Here is what I came up with. Brass wire is soldered into a loop and the piece cut off with a tail. The piece is then fitted over a dowel that acts as a jig to make sure that the hoop is circular and that it can be filed up with no problem. Once the tail is cut off, the hoop is filed to remove the evidence of the joint and then it is filed all around the outside to make that side somewhat more flat. The last thing will be to chemically tone them with Bluejacket's Brass Brown. Once sewed to the boltrope and in place on the mast, they should look enough like wood at this scale. Russ

-

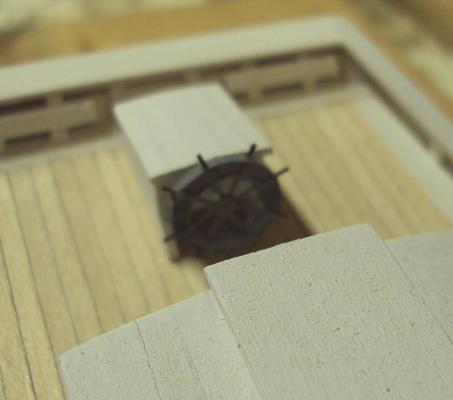

It has been a while since I had a real update, but it has been busy, both in the shop and out. Work gets in the way, but I have also had several commissions of late, some of which I will bring to your attention in time. Here is a look at the wheel. The close up looks rather nasty, but once it is on the deck it blends in quite well. Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.