-

Posts

128 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by maturin52

-

Well, I fell completely off the map. I had some fairly major surgery back in November and spent a couple of weeks in hospital, and a month or more afterwards unable to work on my Bounty project. In the meantime, I had some computer problems, necessitating a hard drive wipe and OS re-install. Fun times! In any case, I'm back with the computer, running Windows 10 and liking it, but have been unable to access this site. (They don't respond to password reset requests.) I have been back at my shipyard, and have actually completed planking the hull and I am currently staining and varnish her. I am not thrilled with the result, but it's good enough for this point in my modelling career. I'll get some pictures posted in the next few days. Back on track!

-

And so the hull construction begins, and the dreaded plank-bending and fitting. I've read extensively on this site and other resources trying to find what method(s) work best, for most builders. It always comes back to a judicious combination of clamping, soaking, and heating. Attached is a stand-alone picture of the result I've achieved with ideas I've put together from my studies. First, the best tip I got was using the metal filler plates from old computers! I have several of them kicking around in storage, and as a result, several of these plates. You know the ones... the little pieces of metal that close up expansion slots that aren't being used. These are quite bendable, and can easily be twisted and bent to conform to quite complex shapes. So, having bent one of these to exactly replicate the needed curve for the bow, I then clamp the plank to the template, bending it only as much as it will bend without strain. Then I submerged the entire assembly in hot water - I use a spare paint-roller tray for this. After 30mins to an hour of soaking, I re-position and add clamps to increase the bend of the plank. This is repeated until the wood exactly conforms to the desired shape. Now I take the newly bent plank, still clamped to the template and slide it repeatedly over the barrel of a hot soldering iron, moving fast enough to prevent scorching, but slow enough to evaporate water from the wood and set the curve. I then left the whole works to dry completely, and the curve holds beautifully. This is a time-consuming process, but it promises to make the hull construction infinitely easier, much more accurate, and a lot of fun! Also, hopefully it will cut down on wasted material and putty!

-

Well, so much for keeping to a weekly update schedule. Although I've been managing to find time most days to do a little work on the Bounty, I've procrastinated about adding to this build log because much of the work was off-model, or was too transitional to show much of anything. Anyway, in the time since my last entry, I've planked and installed the main deck. I decided to go ahead with the nailing as specified in the instructions. I'm pleased with the results, and I'm displeased with the results - imagine that, mixed feelings. Contrary to some of the modelers posting here, I rather like the look of brass nailheads, fittings, and whatnot. To me, it looks like the ship is brand new, or is constantly kept shiny by a taut captain. It's likely less authentic that the blackened look, but for me, at this point in my ship-building career, bling is a good thing! The deck lined up with the masts and the pipes for the bilge pump (a 1/4" drill bit took care of notching the beams) but I do have a few issues with alignment of the edge of the deck and the rise of the hull, however, I have a plan! I shimmed the few spots needed roughly, and should be able to make any adjustments necessary with file and putty when planking the hull. That's the plan anyway. The planks on the stern are well underway, and I guess the next big project will be planning and executing the hull planking itself. I've been doing my homework, reading build logs, planking-how-to articles, and experimenting with scrap pieces. Time will tell. Here are a few quick shots of the progress to date:

-

Well, so far I've been keeping to the weekly update schedule. This week, I've completed the mid-deck partitions, stained the panels, varnished the whole works and installed them. I really liked the look in another build log of actually adding plants to the pot-racks in the aft cabin - I suspect that this would normally have been the Wardroom, but when the HMS Bounty loaded breadfruit plants in Tahiti, every possible square inch was taken over to provide room for as many bushes as possible (except Bligh's cabin, I bet!). I used pieces of scrap wood for the 'trunks', and picked up some model train "bushes' to make the foliage. I considered using beads to simulate actual breadfruit, but since juvenile plants were taken onboard, they wouldn't have been bearing fruit before they were all tossed overboard by the mutineers. I liked the size of the ringbolts and rings, so I went ahead and used them for the door hardware. Next are a couple of ladders, then I'll test fit the maindeck and make sure everything lines as it should. So far, so good. I'm really enjoying this build, and I'm in particular hurry to get to the hull planking. It will come soon enough!

-

I'm going to use the planking as supplied in the kit. A while back I purchased a plank-bending tool sold by Artesenia Latina which is designed to bend thicker planking by crimping. I've seen a few how-to demos on Youtube, and I'm hopeful that it will be answer... still a ways to go before arriving at that point, however.

-

Hi guys.... I too am building the AL Bounty kit, as a few of you know, having visited and kindly commented on my own log. I too own a wonderful little Papillon; her name is Winnie and she has blessed my wife and I for more than 7 years now. Three guys building the same ship, and all owning Papillons. Spooky, ain't it? My enjoyment and success with this kit would be greatly diminished if not for these build logs and the wisdom contained in them. I never begin a new phase without checking to see what my fellow shipwrights have done at the same stage.

-

Well, I've managed to get a lot more done that I had anticipated. All the lower deck are installed, and to my mind, it looks infinitely better that the wide open lower deck provided for in the basic kit. It's also a lot of fun to look at a particular structure and know that it was a scratch-built addition. I'll be doing more of those as I go along, thanks in no small part to inspirations found in these build log. What a wonderful resource, it's so great to get feedback and advice from others who share the same passion!

-

As mentioned above, I've decided to follow others and add the missing partitions to the lower deck. I measured and constructed 5 walls for this purpose. I used 50mm pieces of wood to build up these structures, put in several framed doors, and planked the works with the same material used for the decks. Here's the results, though they still need to be sanded, trimmed and varnished.

-

I really like the idea of adding cabins to the lower deck... I was surprised that the kit did not include them. I printed a copy of the work bryanc posted, and will be using that as a guide for my own creations. Thanks, Bryan! I have plenty of leftover bits and pieces fro earlier kits, so it should be an enjoyable challenge. Never throw wood away, not even the sheets the parts are cut out of! Work is coming along on the well, and the cabins will be next.

-

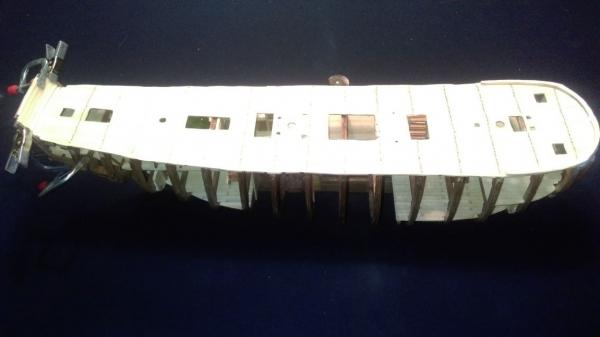

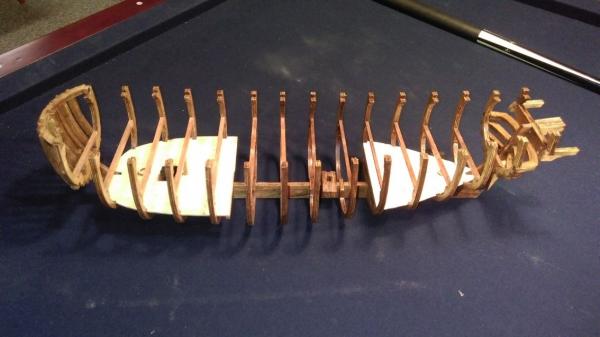

I'm going to try and add to this build log weekly, assuming there is progress to report. I'm on the site much more often than that, however... I've been developing the routine of looking at other build logs before moving on with each step. So... the hull framing is complete, and the lower deck sections are varnished and installed along with the mid-deck support beams and the false keel. I am very pleased with the way all the pieces fit together, and what I have so far appears to be a solid foundation for what is to come.

-

I've progressed to about Step 4 in the instructions - true to form for AL, the instructions are a little cryptic, but between them and this site, I'm confident that all will be well. I discovered on previous builds that it's a good idea to sand the black laser residue from the edges of the precut pieces, as this only way paint, stain, and glue will adhere properly. I stained and varnished all the plywood pieces (American Walnut), and varnished the crossbeams and floor surfaces. So far, so good....

-

Welcome to my build log for the HMS Bounty from AL. This will be my forth ship model and my second build log. I built Billings Bluenose many years ago when I was living in Halifax, NS. It was fun to be able to go downtown and board the actual ship in question to check details. That model got damaged over the years in a couple of moves, general decay, and the attentions of a cat. When I retired a while back, I stripped her down to the hull and rebuilt her. That's all it took, I was hooked and back into the hobby in a big way. I then built AL's HMS Bounty's Jolly Boat - a picture of the finished boat appears at the top of my King of the Mississippi build log. The riverboat was my 3rd kit, and I was very pleased with the way it turned out. I was less than diligent about the log, however, and much of the process was unrecorded. I'm starting this with the intention of being more organized. My thanks to all the other contributors on this site; your pictures, comments, and hints are invaluable.

-

I've been following your build with interest, as I've recently begun work on the same kit. I'm about a week in, and enjoying it so far. I'm not surprised at your observations regarding the instructions; this is my 3rd Artesania Latina kit (HMS Bounty Jolly Boat and the King of the Mississippi), and those kits were the same. I have learned with the Riverboat to rely heavily on these build logs. I'm looking forward to following along with your work, and I'll start my own build log, probably later on today. I do have one for my "King of the Mississippi, but I got really slack about posting photos, but at least I did post some shots of the completed model. Mike McMullon, St. Charles, MO (username: maturin52)

-

I've been exteremely bad at posting build pictures. However, I have been better at working on the ship herself. It's FINISHED. I've taken a few pictures of the finshed project. I'll have to wait until tomorrow to post them, as the files are too large as they stand. I'll resize them and get them up here tomorrow, along with a few comments on the experience. My next project was delivered by UPS this afternoon, Artesania Latina's HMS Bounty - 1783. I'll take a few days to clean up mywork area, sort and store leftover bits and pieces, and start all over again. I can't wait. OK, here are my remaining photos. I've stuck pretty closely to the build as in the instructions. The only real addition I made were a couple of coils of rope on the foredeck where the lines for the gangplank are. I'm pleased with the overall result, and I'm looking forward to returning to square rigs and to starting a new Build Log. Mike St. Louis, Missouri

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

The second deck has been finished and installed. and the cabins for the 2nd deck are under construction. I've just got a new phone, whith a higher resolution camera. I'm going to have to work with the images a bit more to bring down the file size some more, these are well over 1 meg each.

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks for the heads up, I'll check that before gluing up. Did you fix it byrelocating the 3rd deck openings?

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

The second deck is planked and the rubbing strake is installed. Next step will be to clear coat it, and then to continue working on the second deck cabins. Thanks for the input on picture size, Phillip, I've tried your suggested size here, and I think it looks good. Mike

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

The hull is complete, and the Engine Room and the Boiler Room have been put in place. Despite sketchy instructions, I figured out the stabling boxes and the supports for the bars to the livestock area. Progress is being made! I've been purposely using low resolution images to keep the file size down. Should I use higher resolution to improve detail?

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

The hull is finished at last. I wanted a bit of a distressed look, so I worked a bit with the stain and then covered the whole thing with two coats of polyurethane. I like the result. The lower deck structures are almost ready to install, so hopefully things will move along a little quicker now. In any case, there's no rush!

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

Finally have the hull and deck planked and now starting to finish the hull. My plan is to put 2 coats of stain on the hull and the 2 coats of polyurethane over hull and deck.

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

You seem to have addressed an issue that I've just across. I'm fabricating the swinging doors for the engine room on the lower deck. The instructions say to use 1x4 stock for the frames, but I find that that width covers far too much of the actual door panels. Did you use differnet stock? Did you rip the 1x4 to 1x2 or something in that range? maturin52

-

I'm in the early days on this kit. Thanks for all your photos, they are of GREAT help in my decision-making processes. I've been woking on the hull planking for about 2 weeks, but the end is in sight!

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

This is my last completed project: HMS Bounty's Jolly boat by Artesenia Latina. I am now working on the King of the Mississippi by the same company. Figured out low res mods so the pics aren't so huge. I've been working on the hull for a while now. It's a time consuming process! Does anyone have any closeups of the "stabling boxes"? The pics in the instructions are very unclear!

- 12 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.