-

Posts

1,553 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by G.L.

-

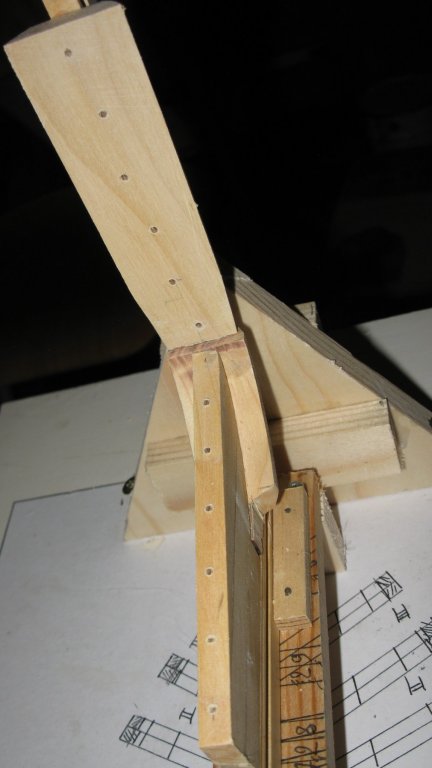

4.3 I have made a wooden box of which the inner dimensions are the sizes of an A4 paper. The paper with the glued frame parts fits in it. On top of the wooden frame parts I glue the original frame plan and cover the hole with a plank of A4 size and lay some lead weights on it. There is space for three frames in the box. Next day I have a strongly glued piece with the frame drawing on both sides which make it easy to saw the frame and to sand the sides and the bevels with the drum sander. After being sanded, I treenail the frame.

-

4.2 I use the carbon copy to glue the first layer of the frame on with rubber cement. Between the joints of wood pieces I put wood glue. On that layer I lay once again a carbon paper and exactly on top the frame drawing and press trough the outline of the frame. This time the copy is made on the wooden layer.

-

Part 4: Making the frames 4.1 I can start to make frames. I must make thirty frames, that can take a while. The frames of a Flemish fishing vessel ware made in two layers with some eight to eleven different pieces of oak. I will try to explain my method. Probably there will be other and better ways, but this method suits me. I first lay a A4 format paper between two layers of carbon paper (typewriter era) in such a way that both sides of the paper touch a carbon side. Then I lay the frame drawing (also A4 format) on it and take care that the two papers are exactly on top of each other. When that is done I press trough the frame drawing with a fine embossing pen. The result is a copy of the frame drawing on both sides of the paper.

-

3.15 The sternpost and the stem are consolidated on the keel with steel straps. I do not know the term in English. I make them from a plate of brass. I am not used to work with metal. I sawed the pieces with the fret saw. The stem pieces are curved and the stern pieces in a hooked shape. To obtain identical couples of straps I solder them together before filing them. After being filed they can be loosed from each other by heating the soldering.

-

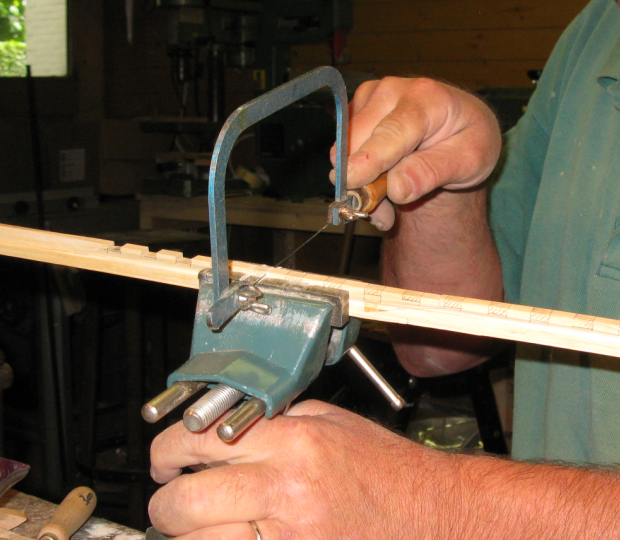

3.12 I wait until the cut off stems become yellow (takes some months) and saw them between the knuckles into hollow pipes. The pipes can be split easily into sticks with a knife. A little tic on the knife with a hammer may help. Split the sticks further as close as possible to the needed diameter for the treenail.

-

3.8 Determining the shape of the knee is a little more difficult as for the apron because the knee is round. I take for the upper shape the lower profile of the apron and for the after shape the profile of the first station. I use the sand disk to give the knee shape mostly at random between the two profiles.

-

3.2 I made the keel, the stem and the stern simultaneously but I will deal with one after the other in this report for clearness' sake. The keel is made in two parts with a keyed hook scarf in the middle. I saw the scarf with the fretsaw. The scarf is keyed with two wedges. The two parts of the keel are glued together. Once dry, I saw the wedges along the keel and sand them.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.