-

Posts

916 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by aydingocer

-

END OF BUILD DAY 5. 1,5 hours today. 17,0 hours into build in total. This is the status at the end of DAY5 .Thanks for watching.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

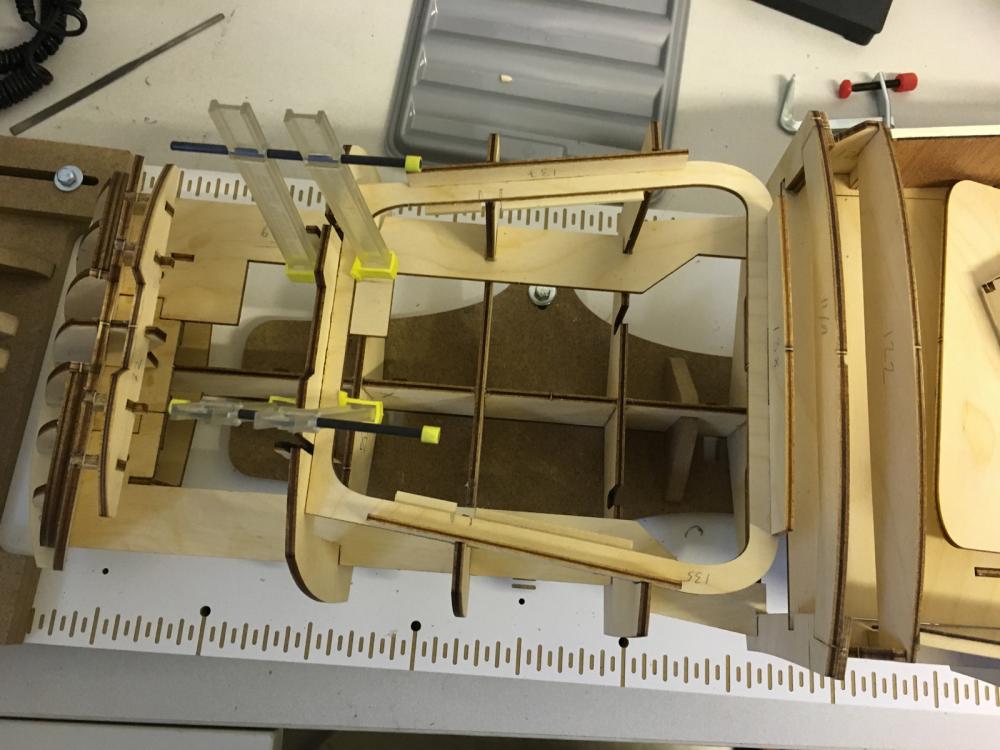

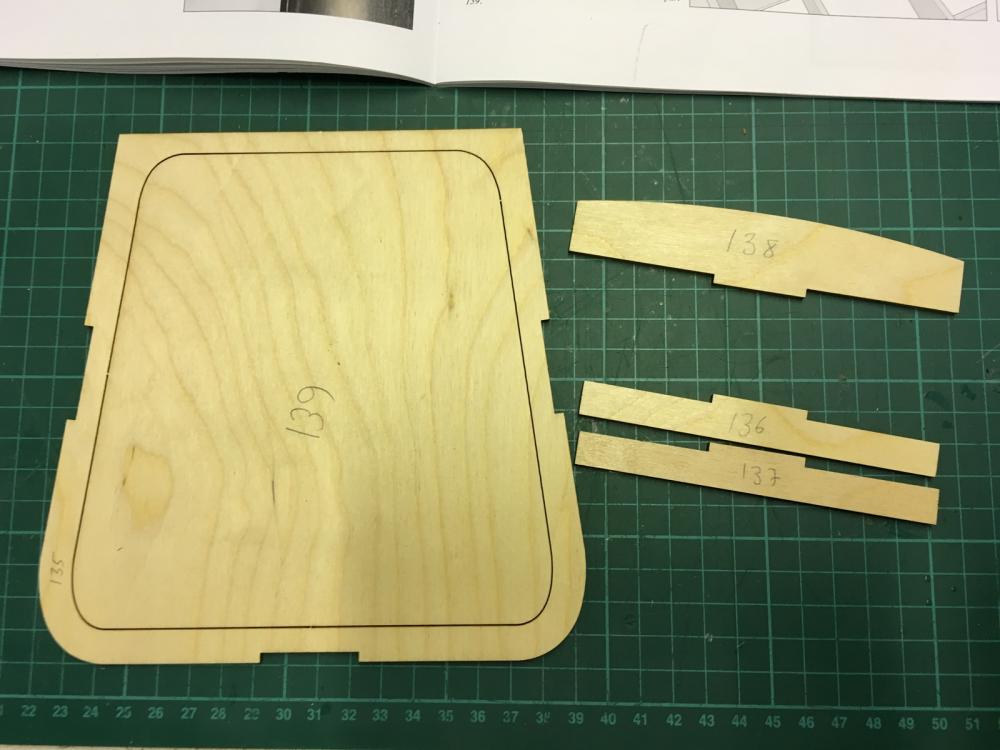

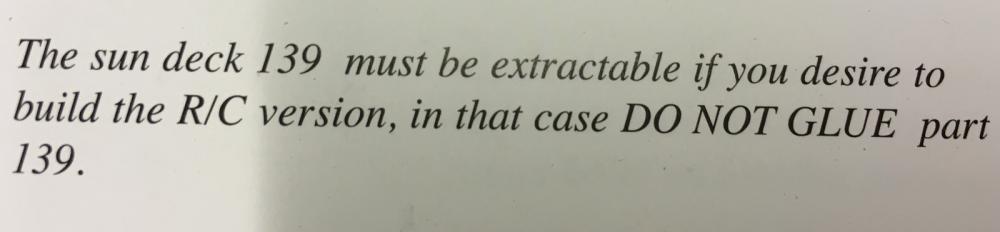

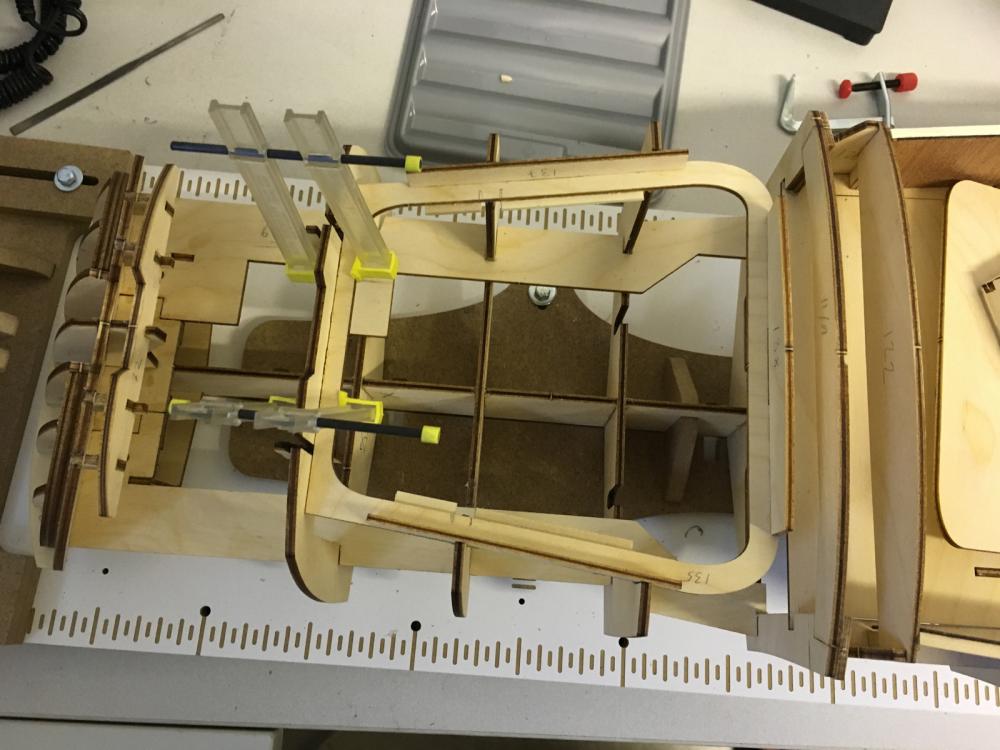

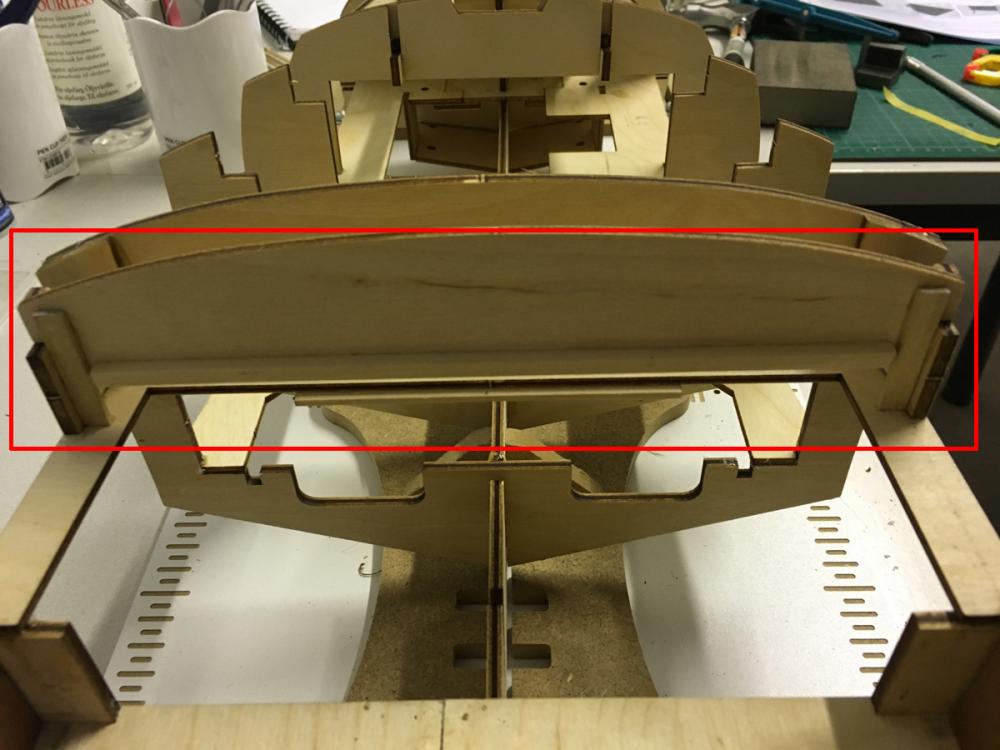

Sun deck. The lid (Part 139) will stay removable for R/C option: The parts: Assembly: Supports from 2x6mm lime strip. Use plan to cut to the size: Dry fit the sun deck to its place before installing the support strips to ensure that they don't hit the frames. Supports installed: Sun deck dry fitted to place: Closed the lid temporarily: Remember to scrape off any glue residues for smooth fit of the lid: Sun deck glued in place:

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

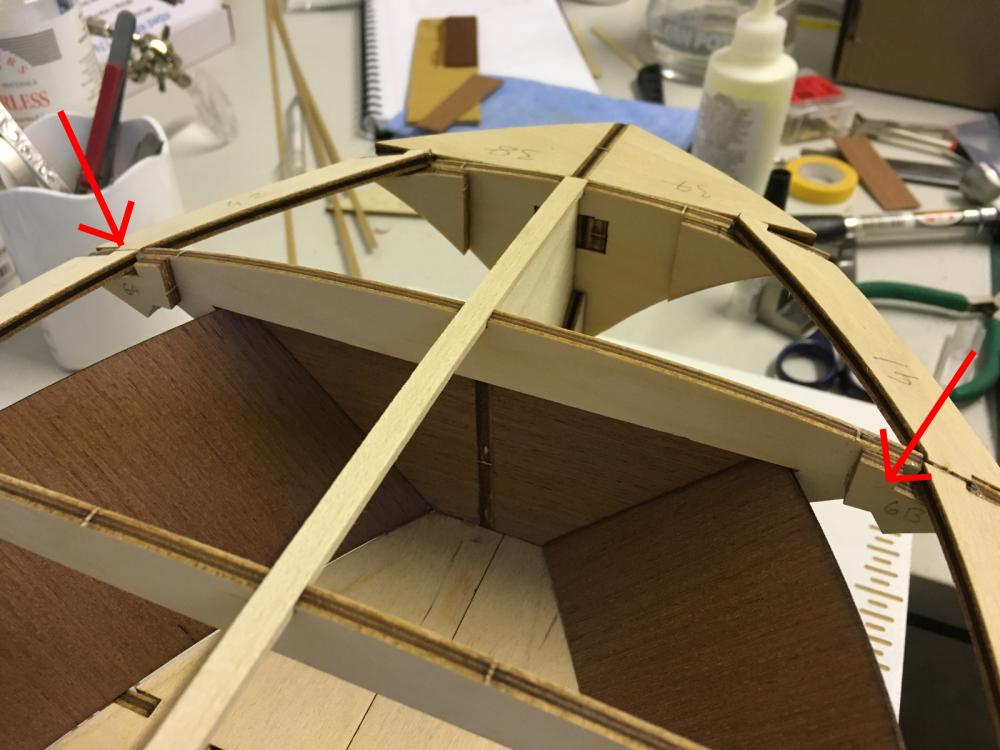

Moving on to next. Front light housings: While checking the installation location, I noticed with a panic that I had glued the reinforcements of the frame 6 in wrong side . They should be in the front of the frame, not at the back. But looking ahead in the manual I figured out that this should not cause any problem in the future so I let them stay. No need to rip them and glue to the other side. Front light nests are in place:

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

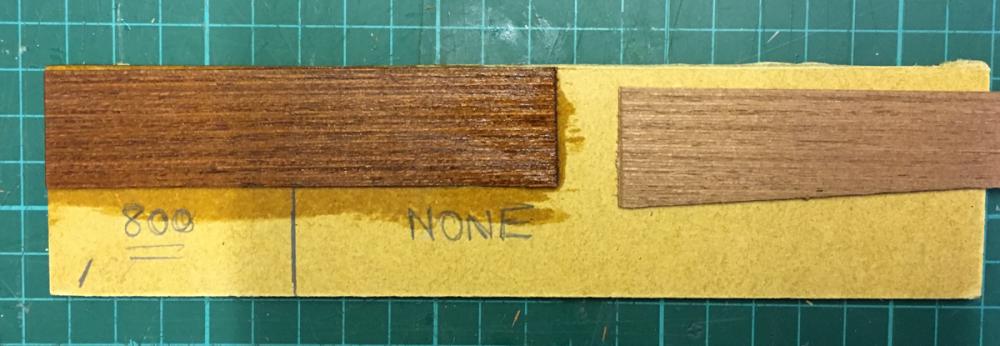

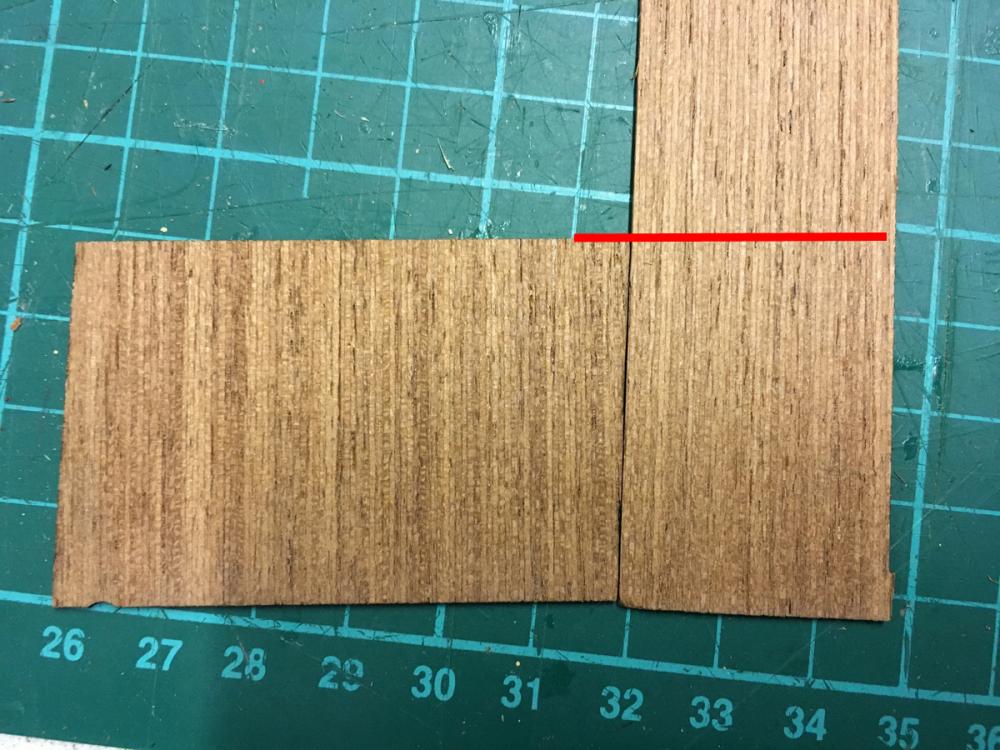

BUILD DAY 5. HULL CONSTRUCTION CONTINUED As I mentioned above, I am skipping the upholstery step for now and continuing with the next steps. But before moving ahead, I wanted to try varnishing on a piece of scrap mahogany. The mahogany plates on the interior of the hull (as seen in the earlier photos) are a bit tricky to sand, therefore I wanted to test if primary sanding actually will make any significant difference after heavy varnishing (I am thinking of all in all about 10 layers). The mahogany veneer is also very good quality and pretty smooth, that sanding may not be necessary at all. We'll see. Most of the mahogany veneer you see in the earlier photos in the interior will be either hidden under a hood or hardly visible thrgguh the seats so if I can save some sanding it will be good. For this purpose I prepared the following test piece: Mahogany veneer, left half sanded with 400 grit and right half not sanded at all. The rightmost piece is a control piece to see the difference between varnished and dull surface. This is right after the 1st layer: I use genuine boat varnish:

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

Hi Yves, At first I thought so, looking at the labor spent on those seats, but I confirmed it with the sales guy on snmodels.com, who is an authorized dealer of Amati and actually is located in the same town as Amati. Second, the photo on the kit box has similar fabric seats. One guy from another forum who built it wrote also that the seats came in the box like that. So it is quite possible. Also this upholstery kit costs around 150€ if you want to buy it separately and it is expensive. I was thinking also to run stitches on a piece of white fabric (or leather) and cover the seats with it. Though they look great, one problem is, though, that the stitches are too big for a 1:10 scale model. Even if they are, say, 1.5mm size (probably the smallest you can make using a sawing machine, it would correspond to 15mm in full scale which would not be so realistic in my opinion.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

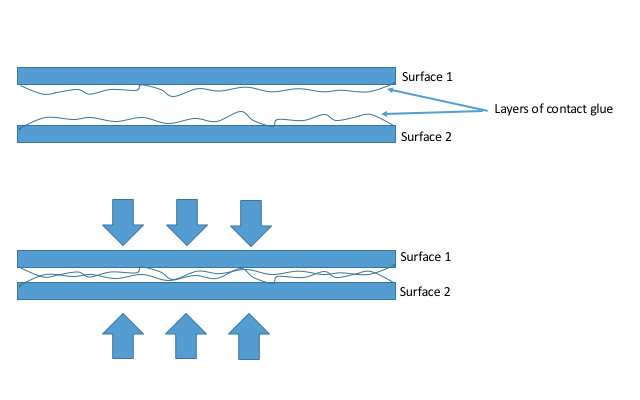

Thanks for the tip Keith, I'll try that. Actually now you've mentioned using CA like a clamp, I remembered using the similar technique for planking: using CA in intervals between the wood glue to work like a clamp in tricky areas. Thanks for reminding it. And Moxis, using real leather would be great. I just ordered faux leather from eBay and will see when it arrives. Overall I think that I will skip this upholstery work for the time being (mainly due to varnishing work ahead) and handle it as a mini-project of its own, peacefully. Because that will make the main difference between a cheap look and expensive look I have somewhat concerns with contact glue. I used it a lot in my other projects, such as loudspeaker cabinets and I have experience of using it in large surfaces. A small surface like this one would be a challenge combined with the very high make-no-mistake factor of using the contact glue. In addition, due to the nature of the contact glue which works by sticking to each other, there is always a layer of glue between the surfaces no matter how much you press. With one side being soft material like leather, I wonder how smooth the result will be: But anyways, I will just try several options as a side-project and see. By the way, Amati has apparently updated this kit recently. I bet that many things are for the better, but I have to say I am pretty disappointed with the upholstery kit. Looks like in the earlier editions the seats came like this. Great looking with real fabric and stitches, colors etc (photo credits hobbiesguinea.com): What I have is these plastic marshmallows (photo credits snmodels.com): I somehow understand manufacturer's concern. They might have gone better solution against water splashing on those seats while it is running on water, sacrificing the looks. (I also have to mention my great thanks to an Alberto from snmodels.com who explained this to me on online chat and provided photos. Great customer service even though I am not a customer yet, but this way I definitely will be) Now I will look around for any shops which still have the old version of the upholstery kit.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

I found these DC-FIX self adhesive leather-effect sheets. I may try those as a replacement to the stock leather-like sheets. I will post once I've done that. I also ordered a few A4 size white and turquoise faux leather sheets from eBay. Will test all of them peacefully and decide.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

Thanks Antony, It just so happens that I have some free time in these days, so I take advantage of them.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

END OF BUILD DAY 4. 1,5 hours today. 15,5 hours into build in total. This is the status at the end of DAY4 .Thanks for watching.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

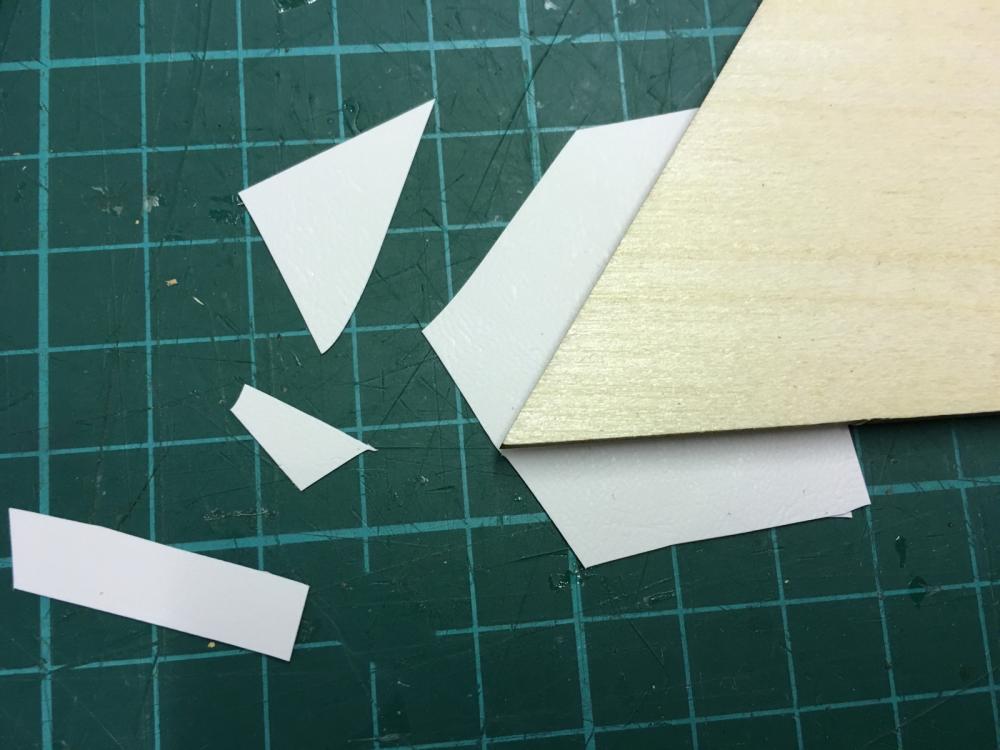

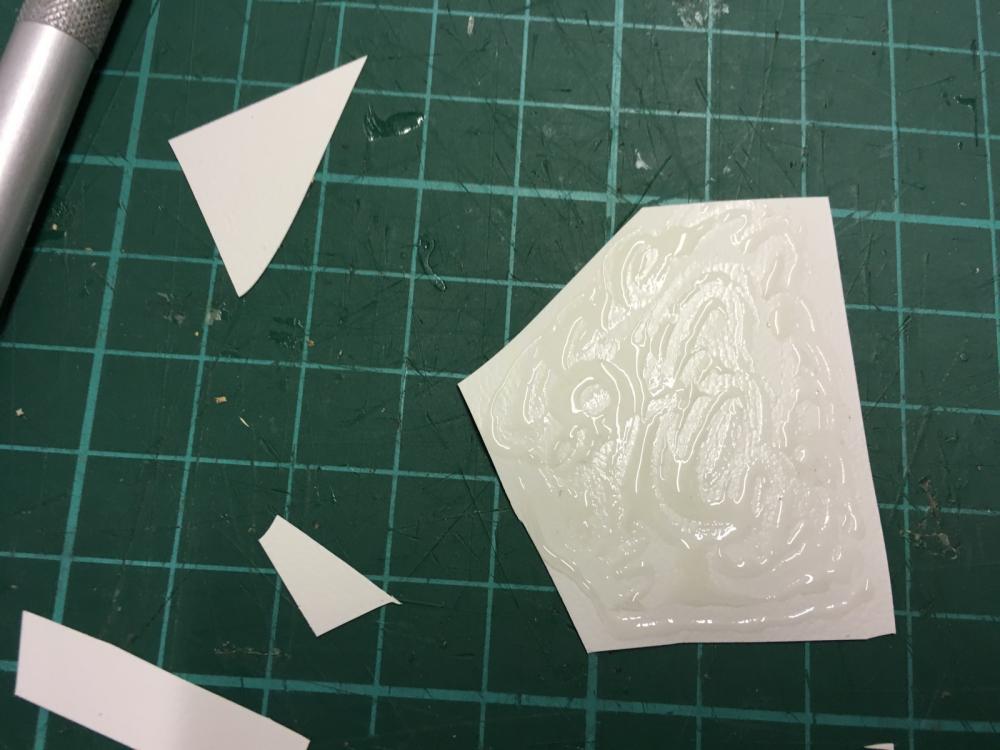

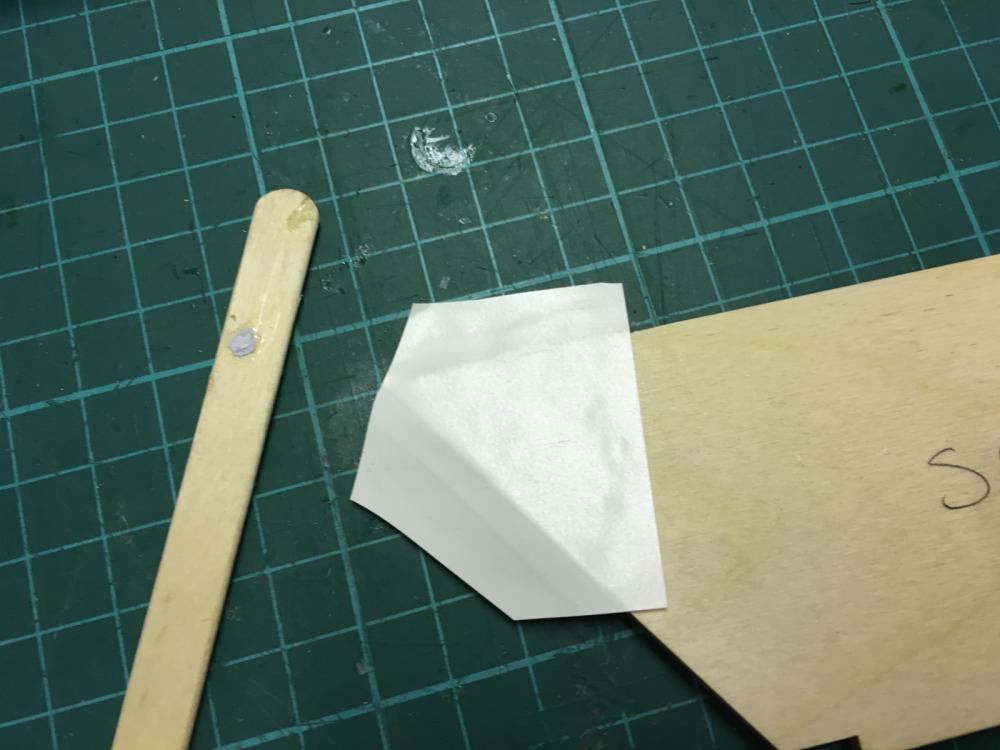

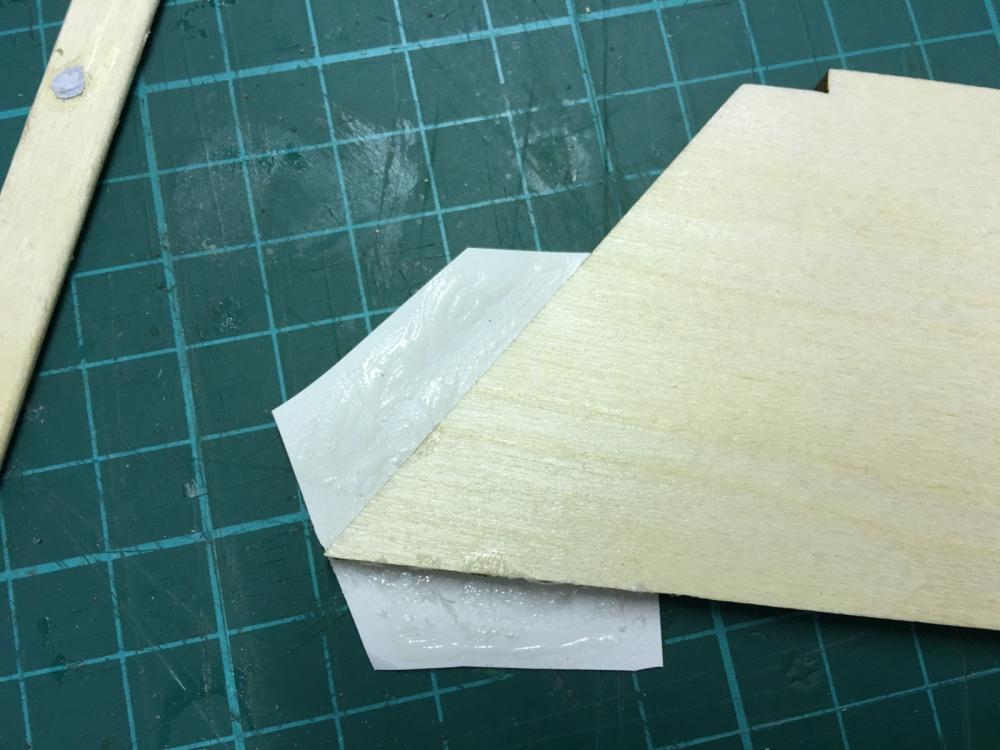

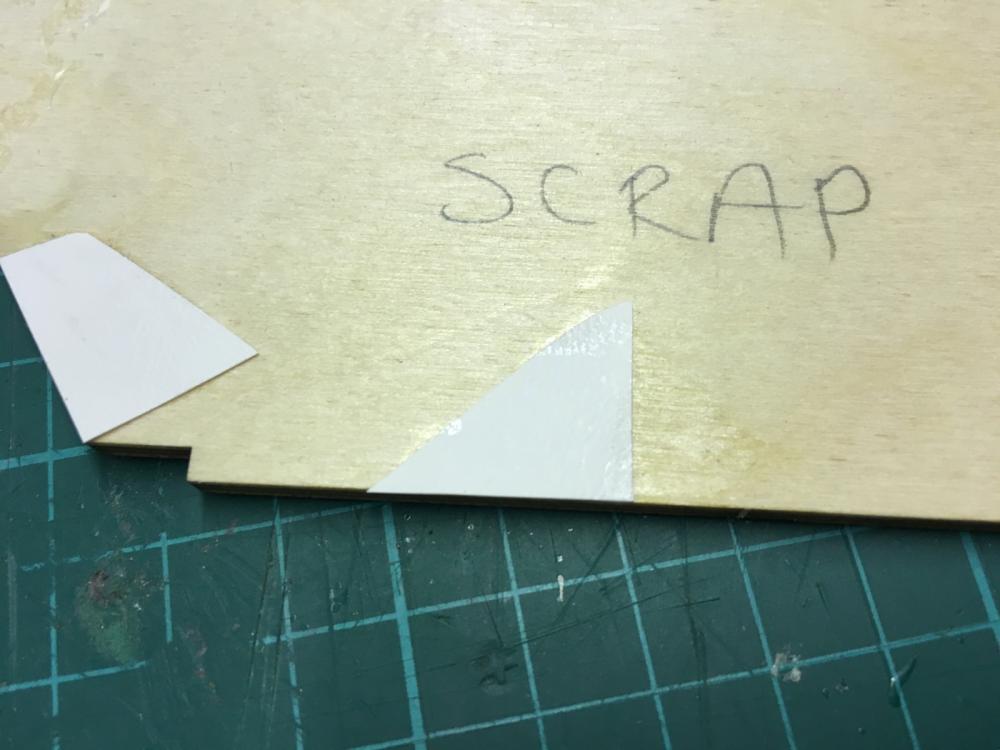

And now I turn the page of the manual only to find out that I have to stop for today: Looks like it is time to apply some lacquer which I wasn’t expecting to come this quick. Well, actually the instructions are not calling for it just yet. According to the manual it is time to apply the “leather-like material” (that’s what the manufacturer keeps calling it throughout the manual) inside the cockpit. It sounds however wiser to apply the lacquer inside first in order to eliminate the risk of spilling lacquer on the upholstery. I saw in another build log in another forum that the builder applied water proof lacquer all around inside, I think that’s what I will do. So I’ll go and buy a boat grade lacquer tomorrow. I also checked this “leather-like” material. It is totally plastic and feels a bit tricky to fold in the corners. I decided to try on a piece of scrap and first results was not promising: Cut a test piece: Apply glue (trying with UHU Hart just out of curiosity): Put on the plywood, swipe with a piece of stick applying pressure: However it didn’t seem to work. There came air bubbles and eventually the glue came loose: Then I tried with CA (super glue), which seemed to work well, except that the residues left stains here and there. Have to be very careful if I choose to use CA. . It seems very tricky and make-no-mistake task to successfully apply the upholstery to the entire cockpit. Right now I think this will be my plan: - replace the leather-like plastic with thin faux leather sheet. It would look more realistic and be easier to work with. - cut identical pieces from a very thin veneer (or from acetate sheet) using the plan sheets as guide - glue the faux leather peacefully on these pieces - and finally glue them in their places on the cockpit Or any suggestions? So, next, I will lacquer the interior and move on to the next task until I do the shopping above.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

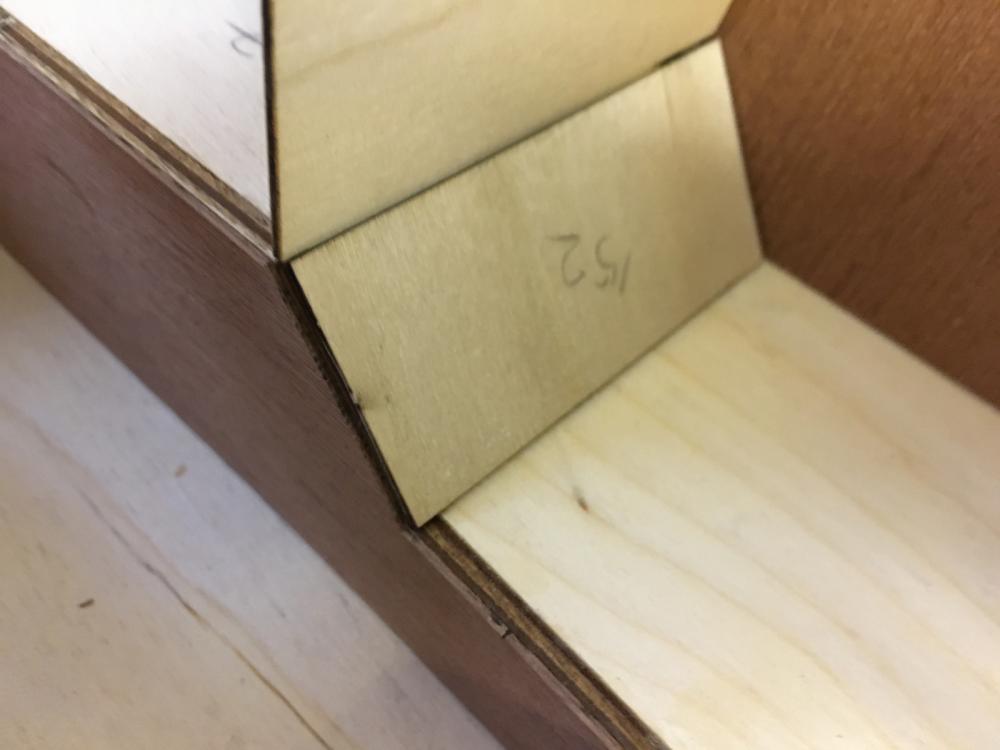

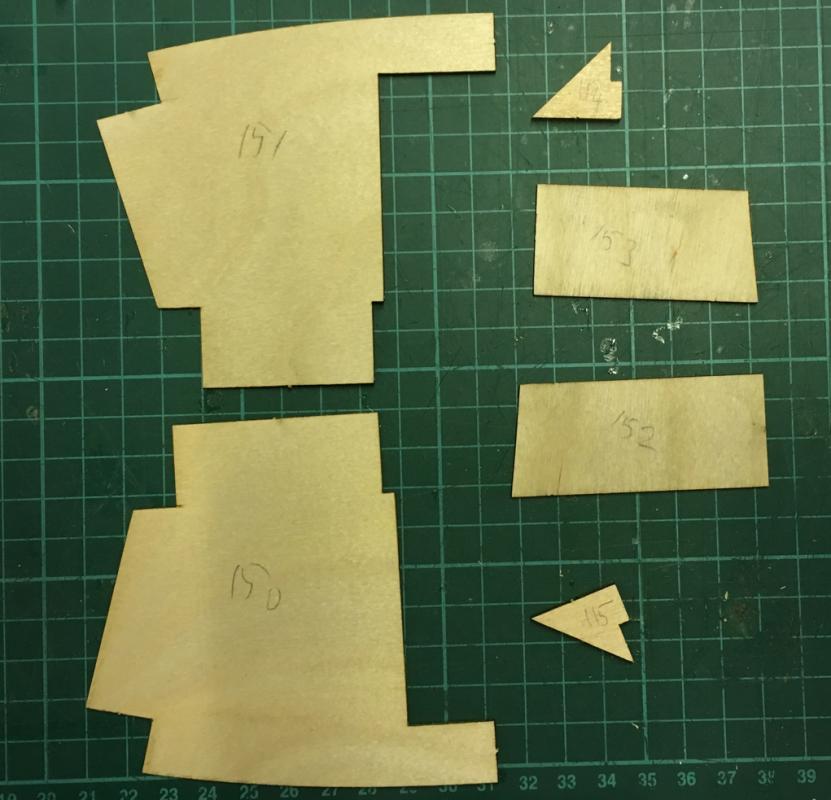

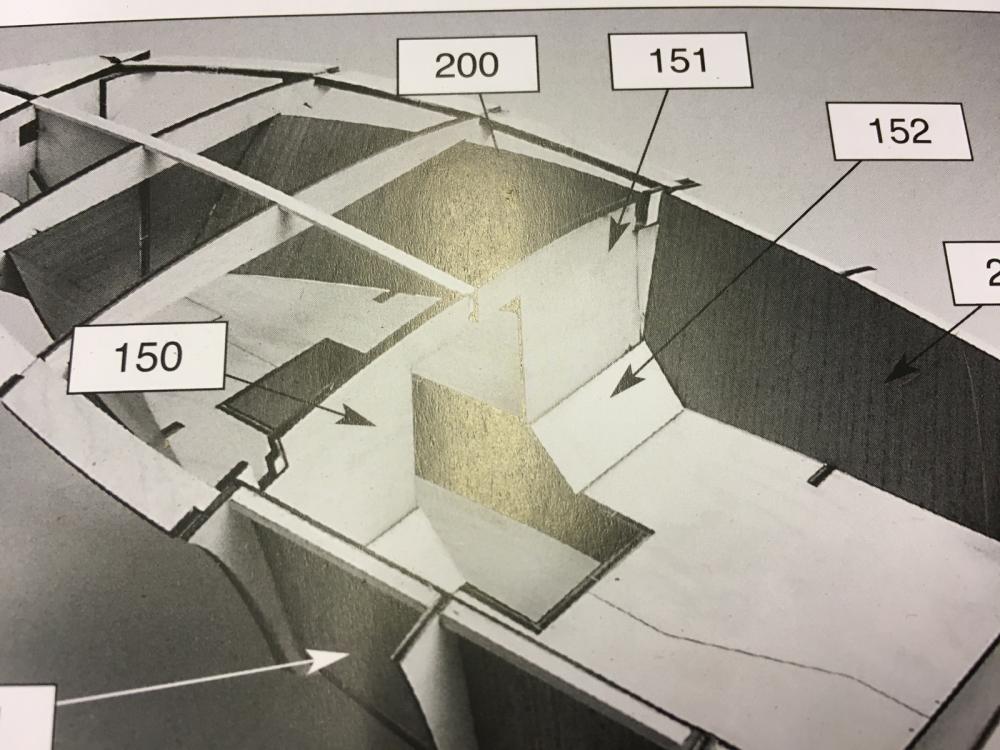

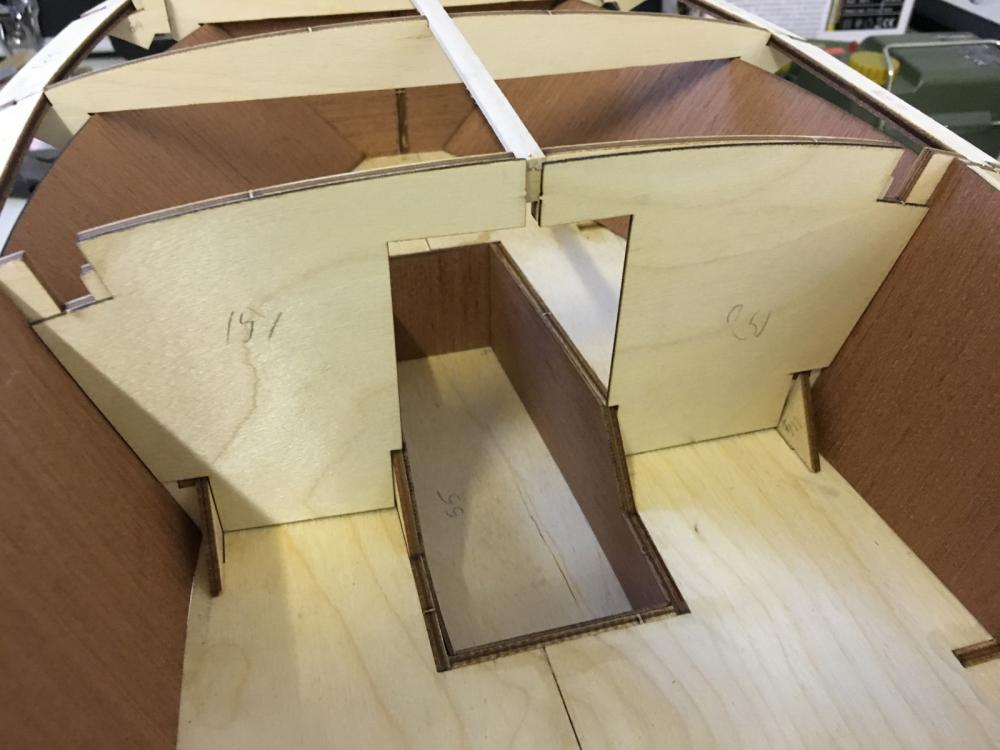

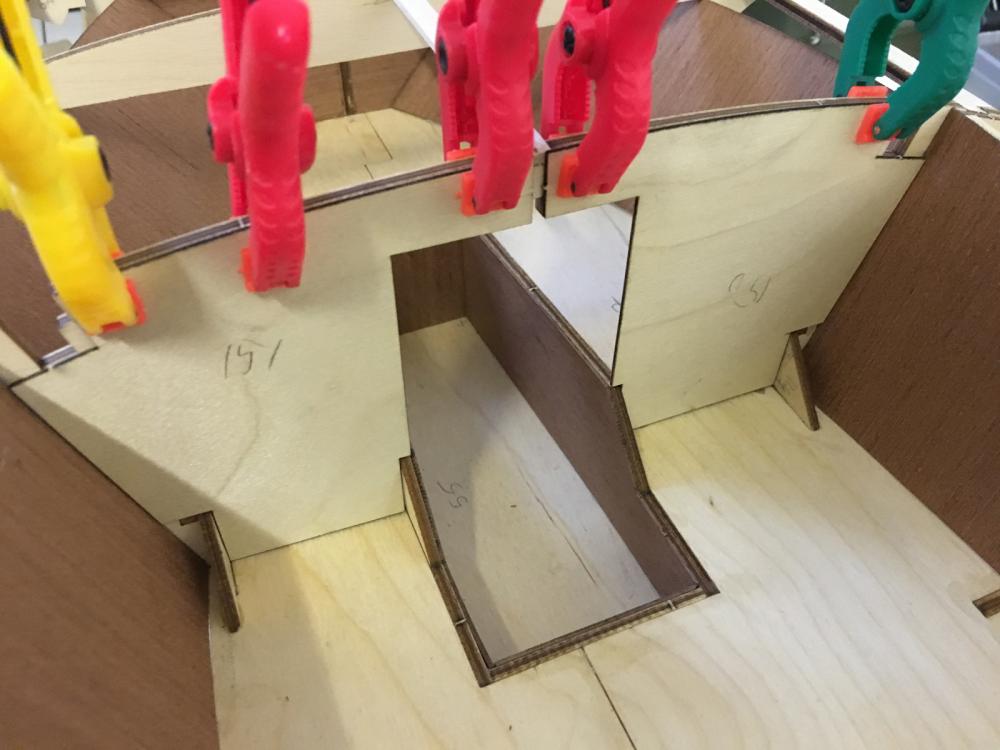

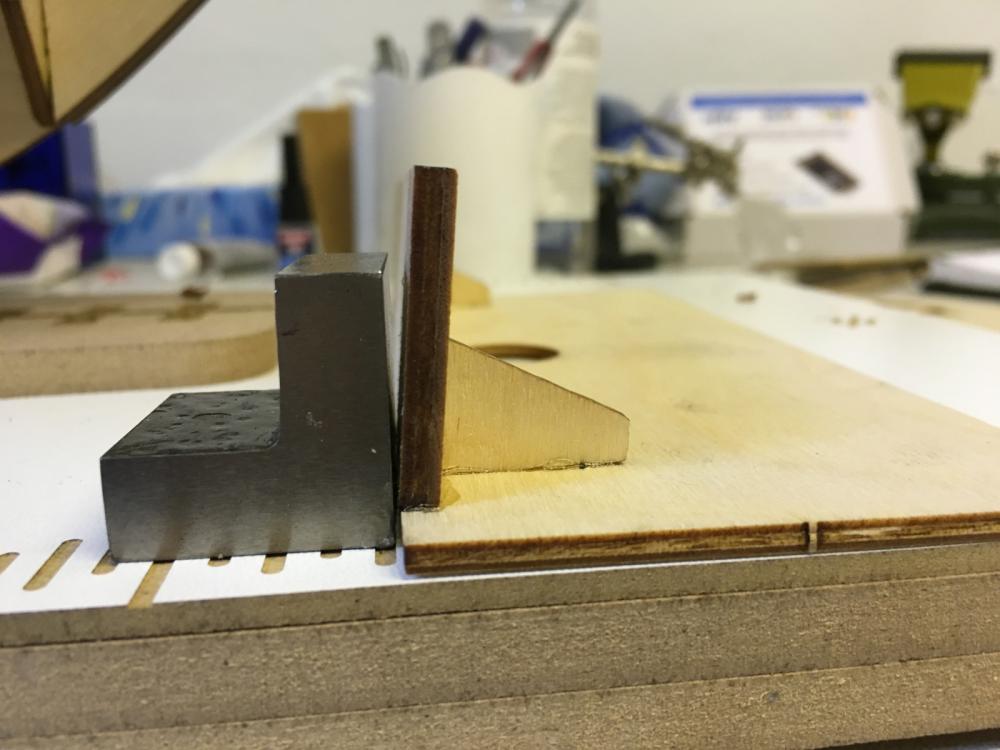

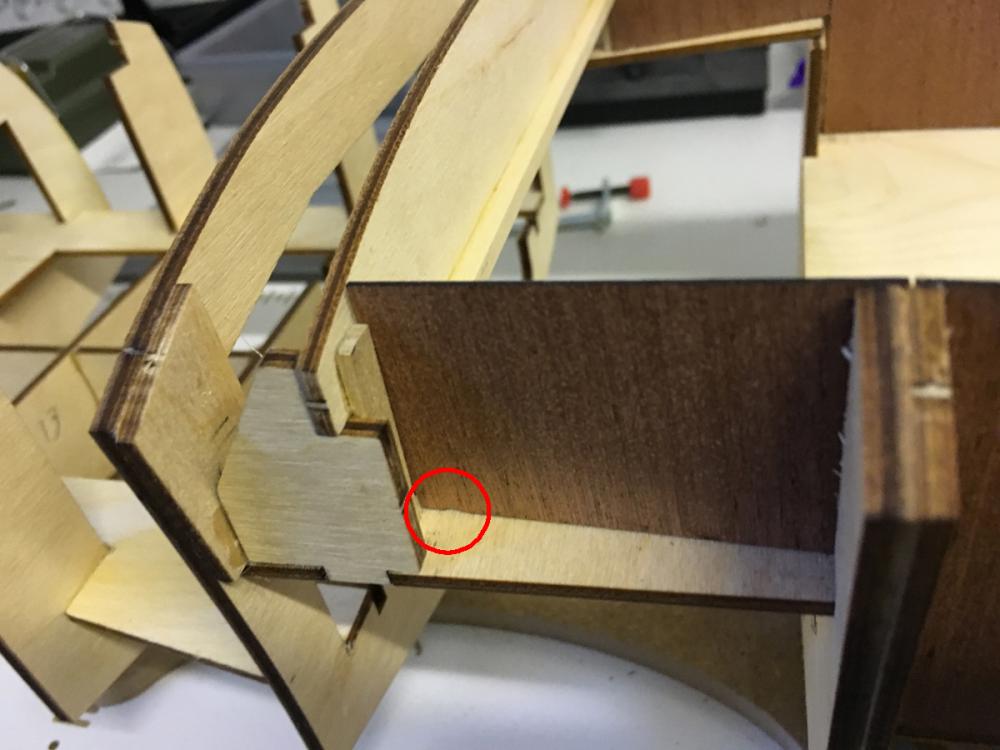

Parts 152 and 153 are the footrests which will be glued inclined. I used a piece of scrap wood (no glue) ensure that the triangular parts which will hold them dry at identical angle. According to the specs the footrests are not flush with the mahogany plank (in this photo it is the plank on the left side. Similar thing is for the other footrest). They stop at the end of the plywood allowing the edge of the mahogany plank to show.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

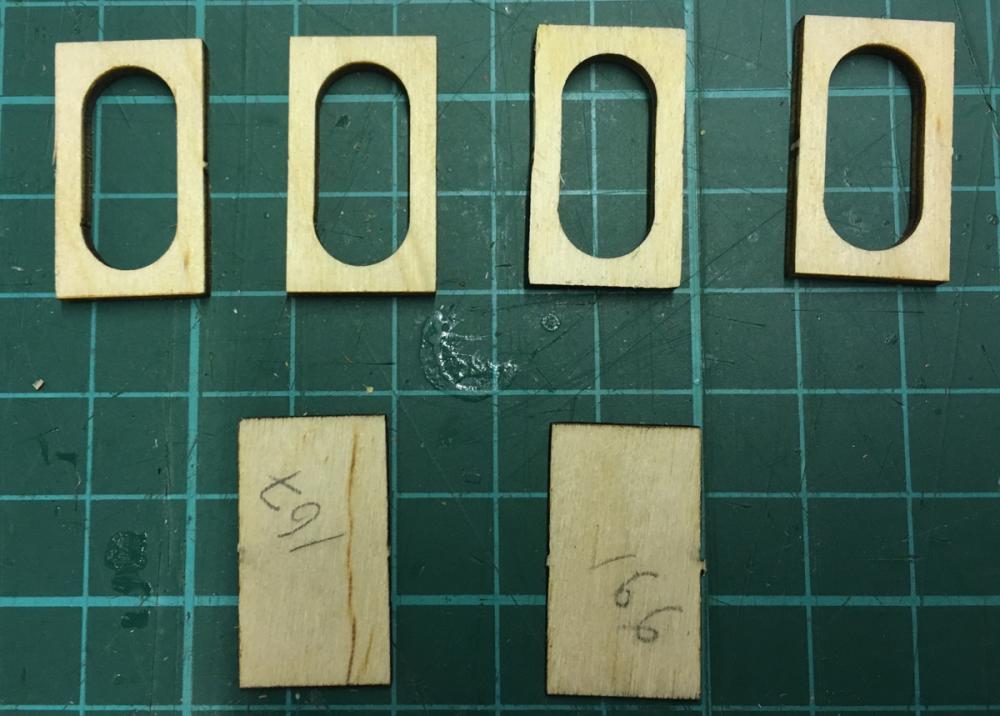

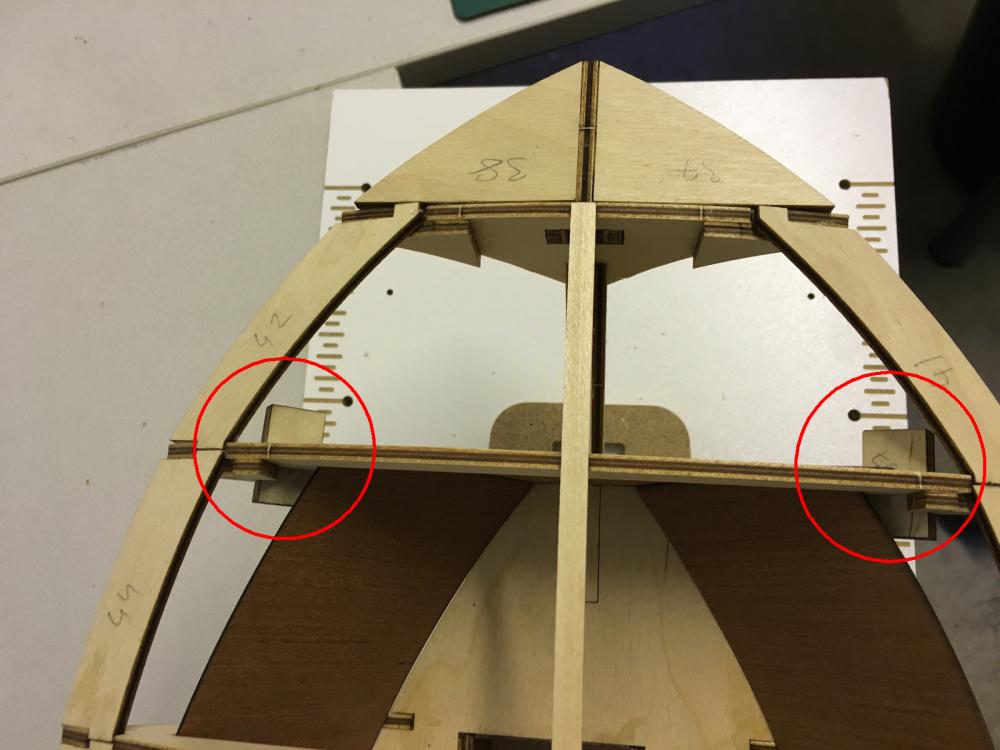

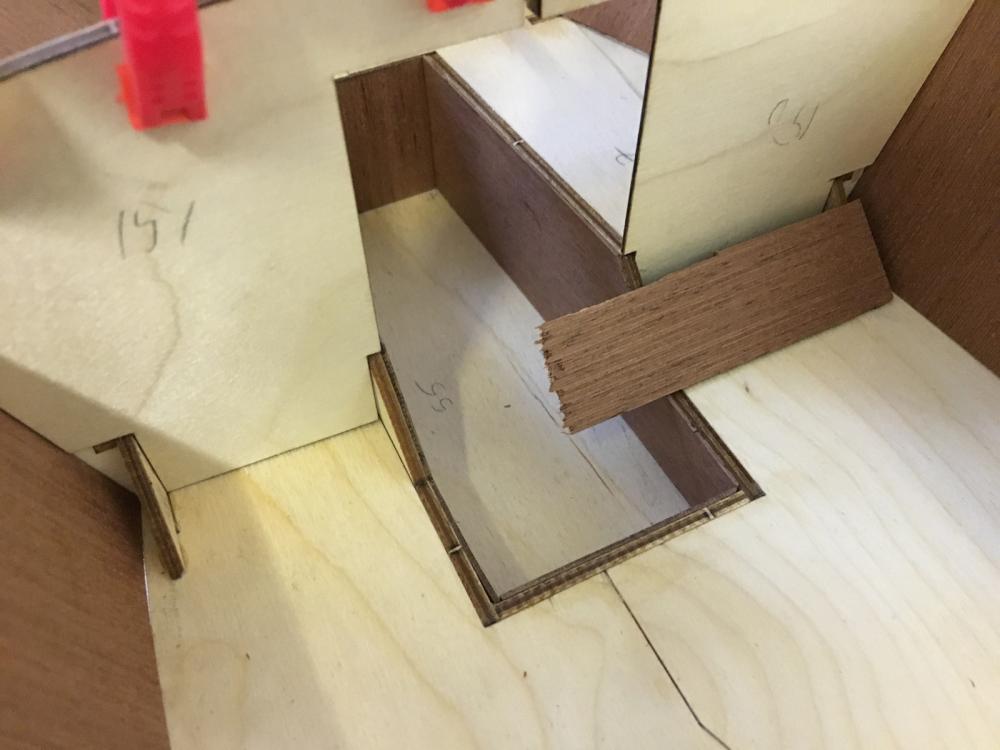

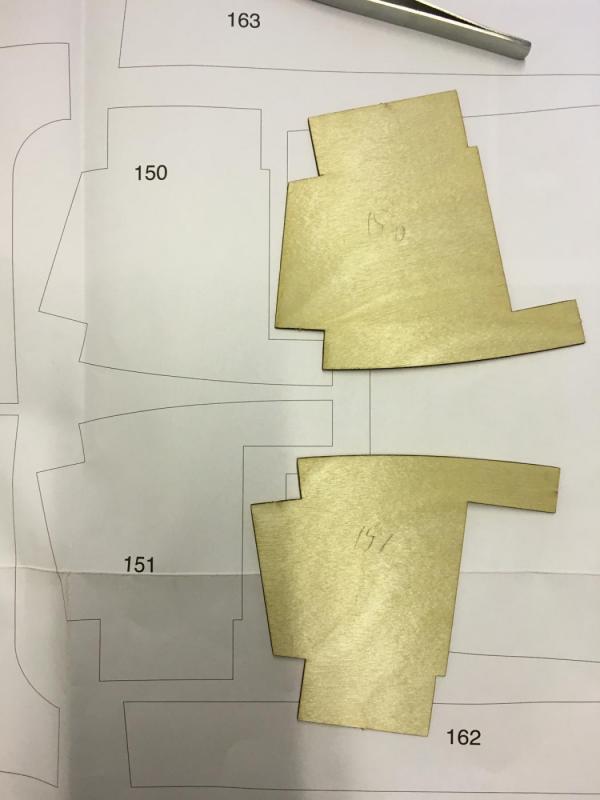

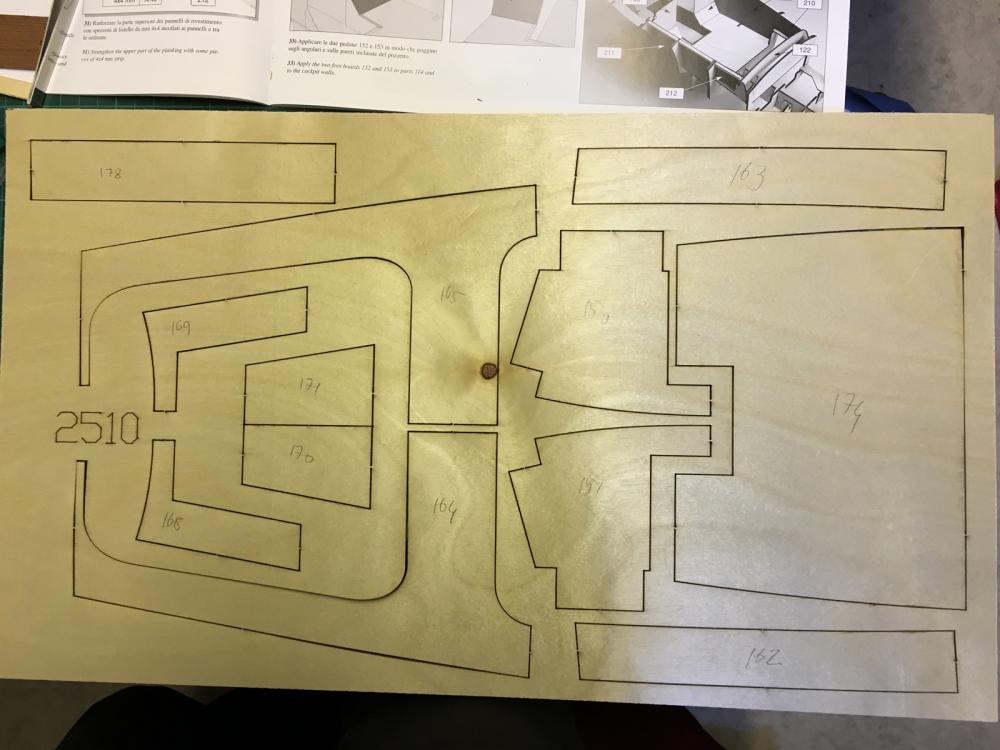

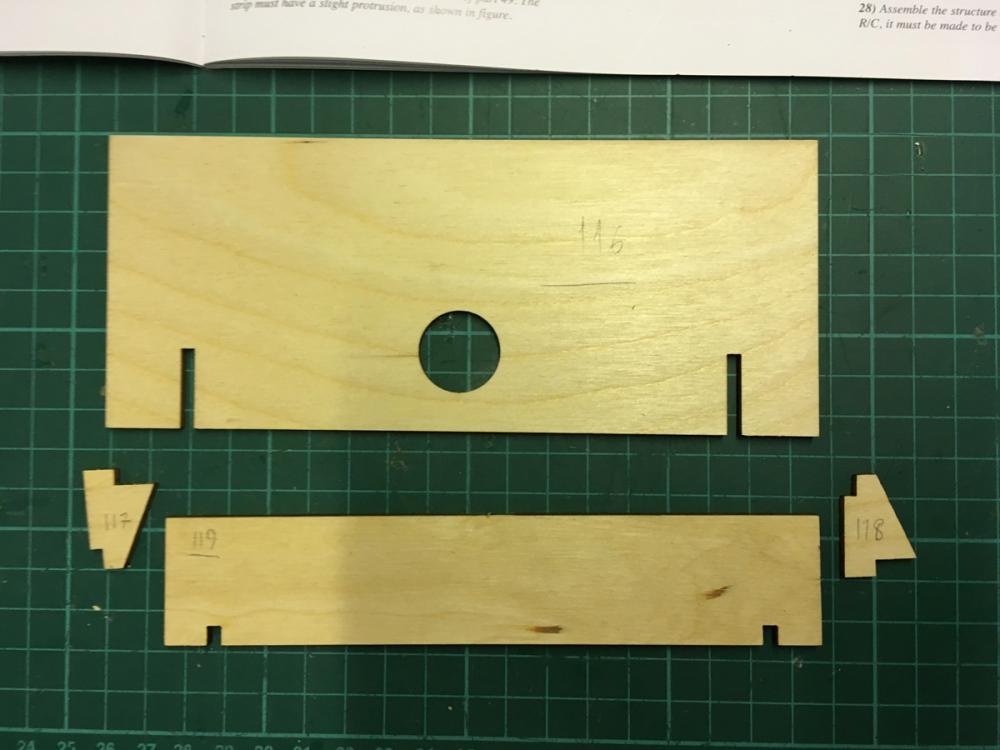

Cockpit cover parts from the sheet above. Here during dry-fit I noticed a mistake in the instruction manual. Parts 150 and 151 are labeled wrong in the photo in the manual. They should be vice versa. Otherwise they won’t fit. Or the numbering in the plan sheet is wrong, whichever. Well, this is the 2nd error in the instructions which puts me to 2-1 lead in the mistakes against the manufacturer!

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

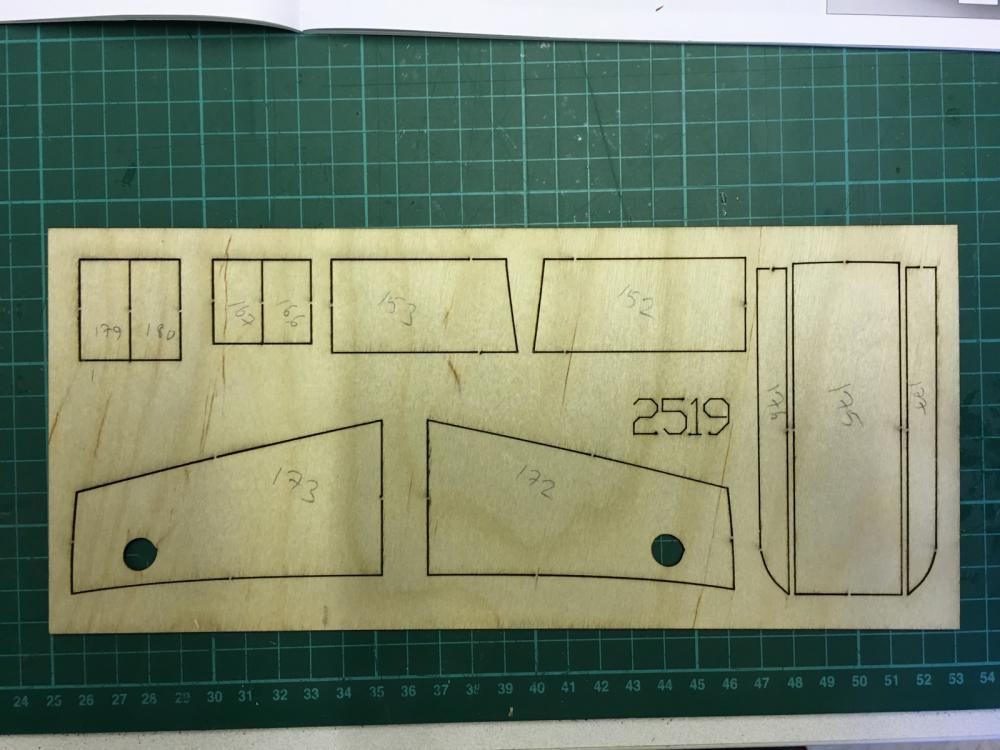

1mm high quality birch veneer sheet containing the parts for covering the hull’s plywood at more visible parts of the boat:

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

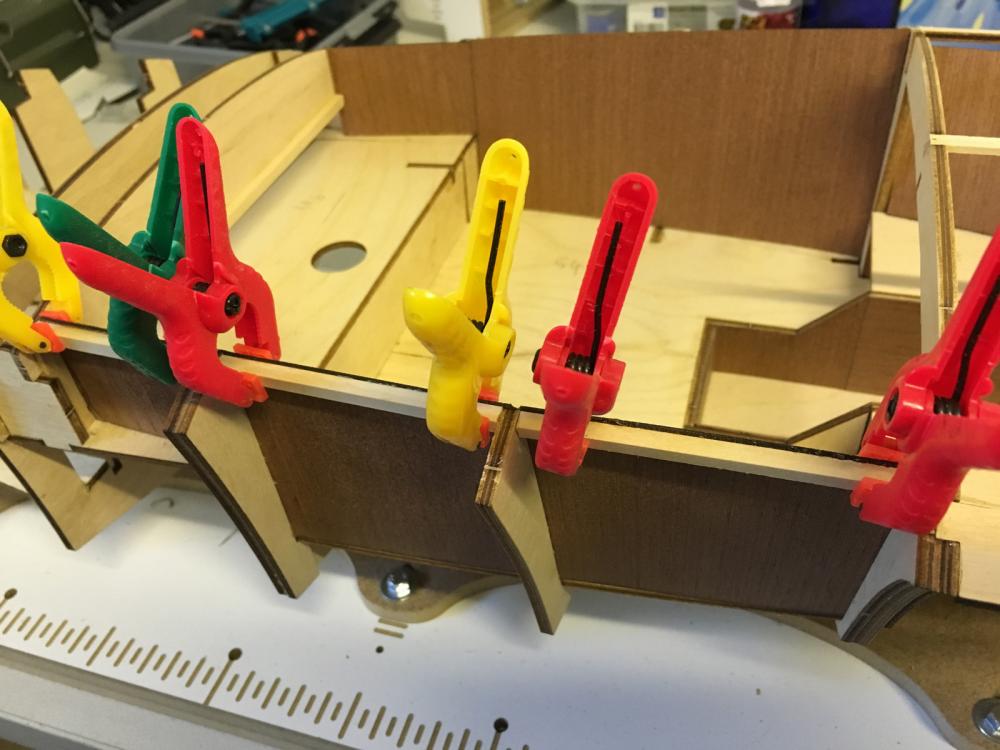

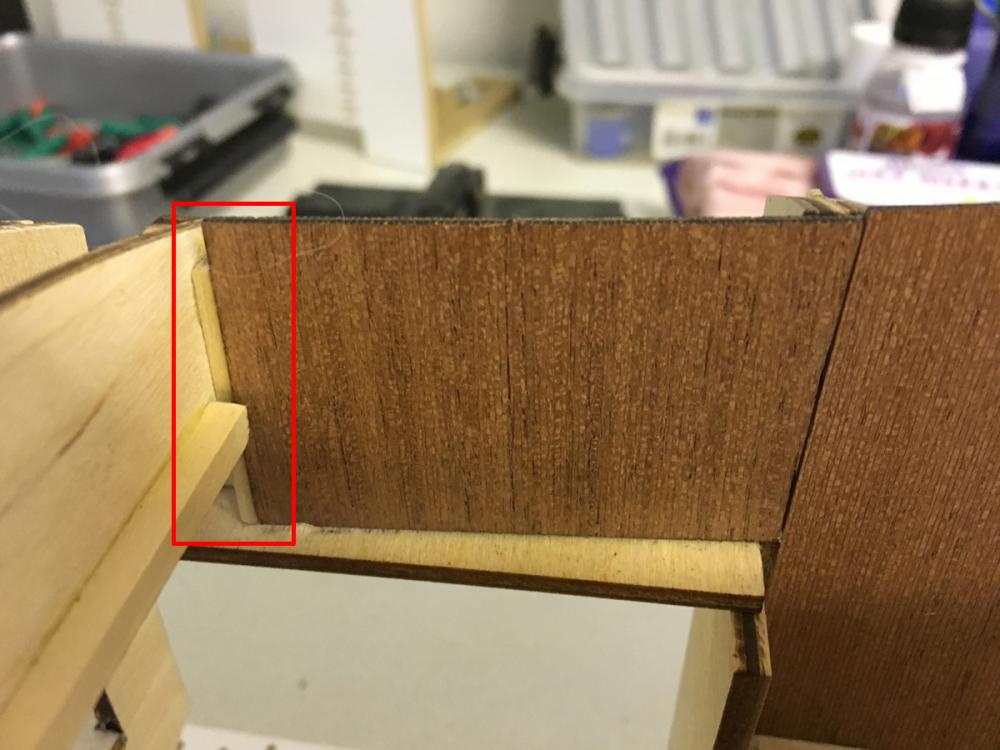

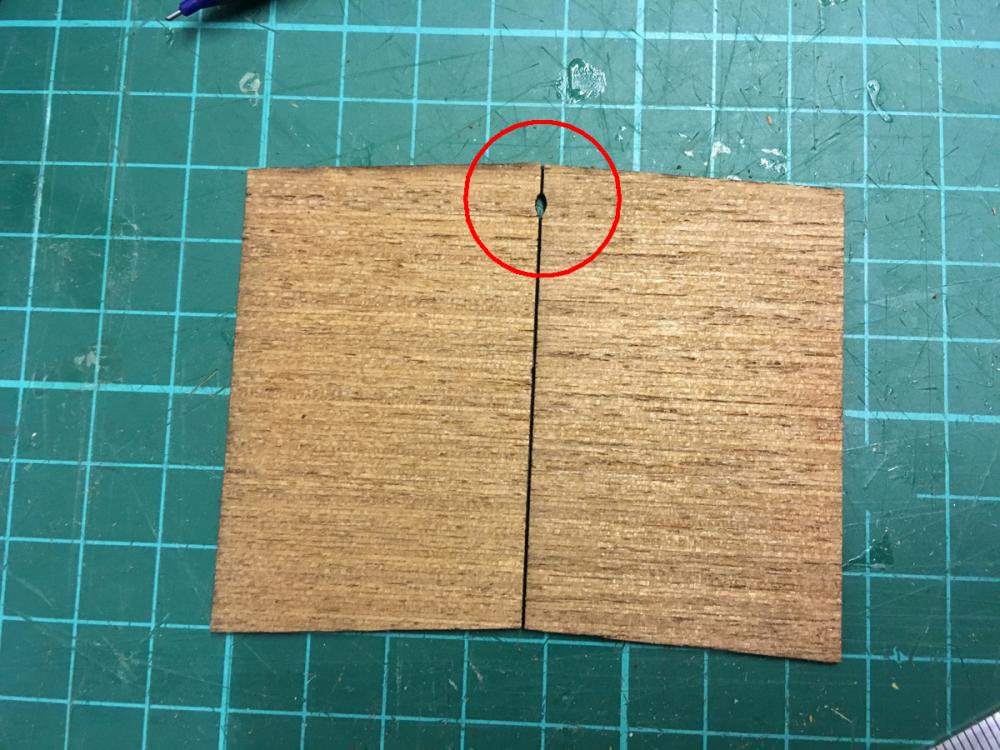

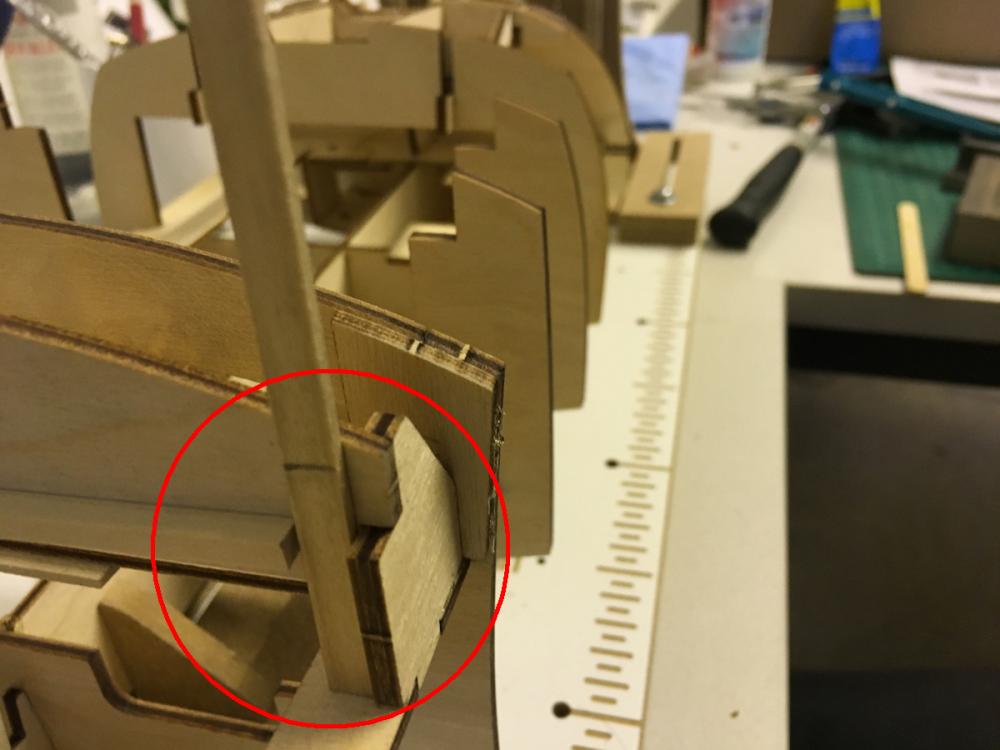

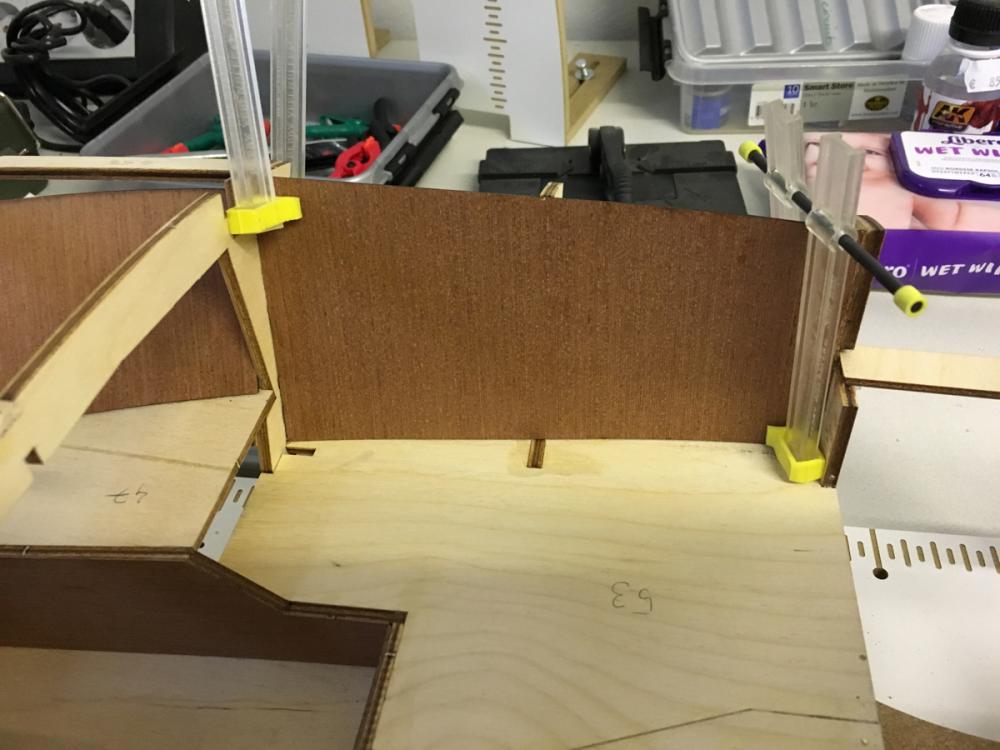

The rear seat panel, which I soaked and clamped yesterday to get it flat, is flat now and ready to be assembled. Note that the two pieces are not aligned vertically: The rear seat panel is in place. It is not glued to the place since it has to be removable (pulling by the help of the hole in the middle) to access the R/C compartment: From top: And from bottom:

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

BUILD DAY 4. HULL CONSTRUCTION CONTINUED Today I had to stop earlier than I was planning for the reason I will tell later (nothing bad).

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

END OF BUILD DAY 3. 5 hours today. 14 hours into build in total. This is the status at the end of DAY3 .Thanks for watching.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

This piece came around 1mm too short, because of the adjacent sheet (on the right) which I had to trim. This will most probably not even going to be visible, but just to be a good sport, I measured and cut a thin strip from a scrap mahogany sheet and glued it in place to close the gap: Watching the direction of the grain :

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

Thanks Per! It is also exciting to know being watched ))

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

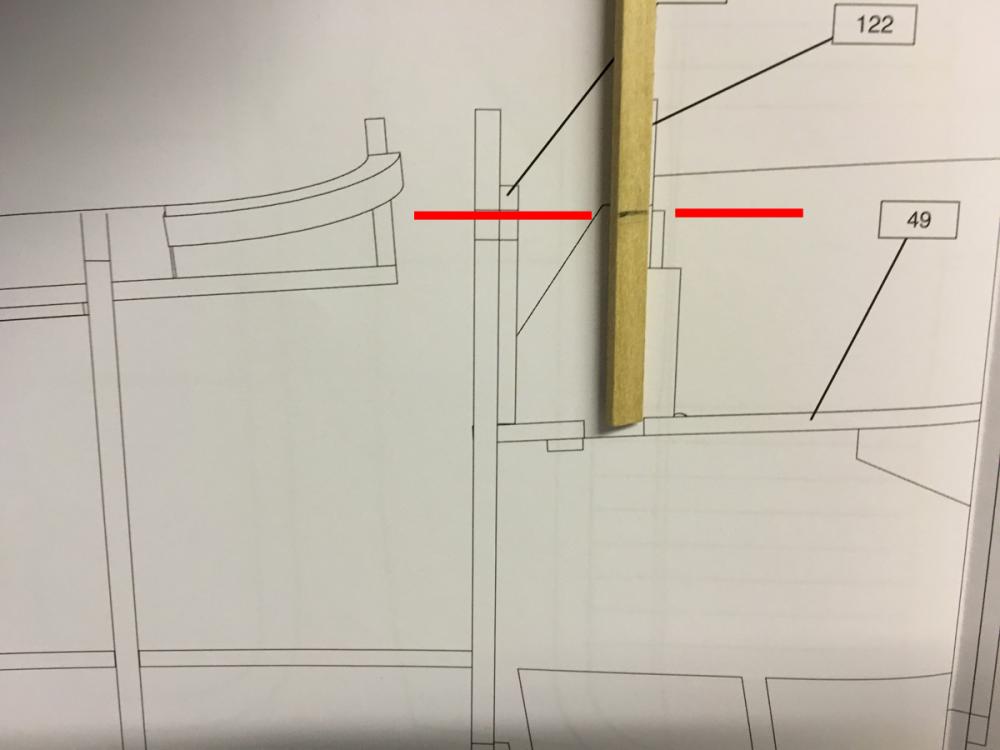

More lateral planking. Note that the parts have small groove at one end. It is essential to pay attention to orientation of the parts: Measure 2x6mm strips to act as spacers to above parts, using the plan sheet: Spacers glued in fornt of the support piece (which was temporarily fitted above - in the photo with masking tape):

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

More lateral mahogany planking sheets. I had to trim some 1mm for a perfect fit. Dry fit: Measure the trim: Trim (about 1mm): Glue in place: Repeat the steps for the other side.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

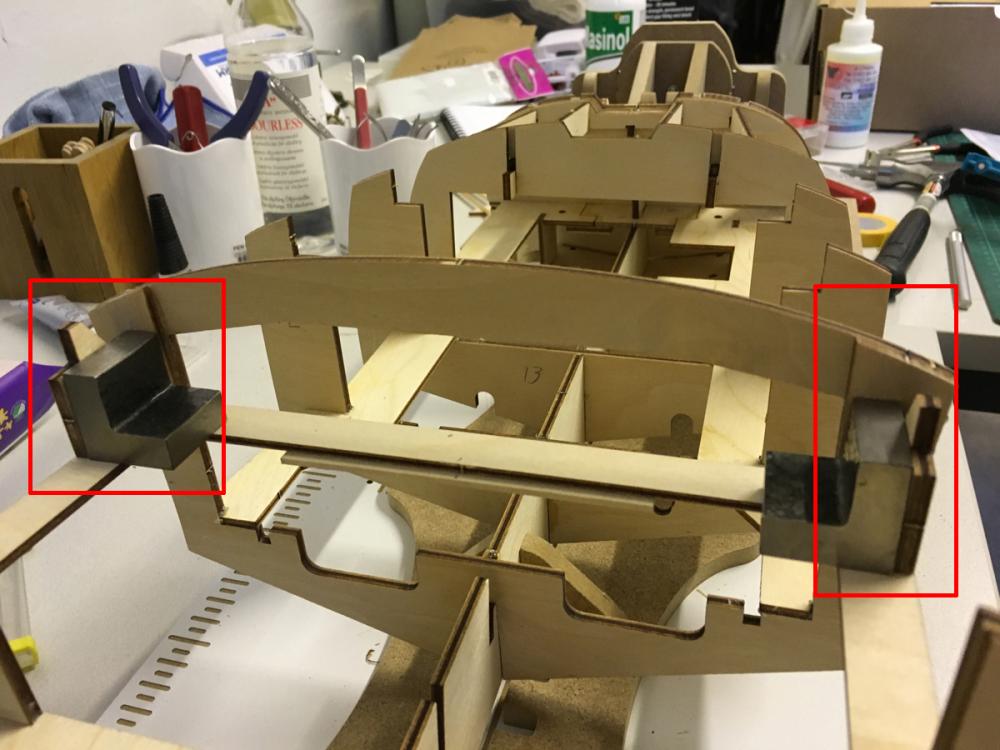

Side supports for the backseat. The small metal squares which I had bought (from micro-mark.com if I remember correct) help well in these kind of tight places to ensure the right angle. A 4x4mm lime strip to reinforce the back support for the seat. Temporarily dry-fitted until the whole thing is glued in place:

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

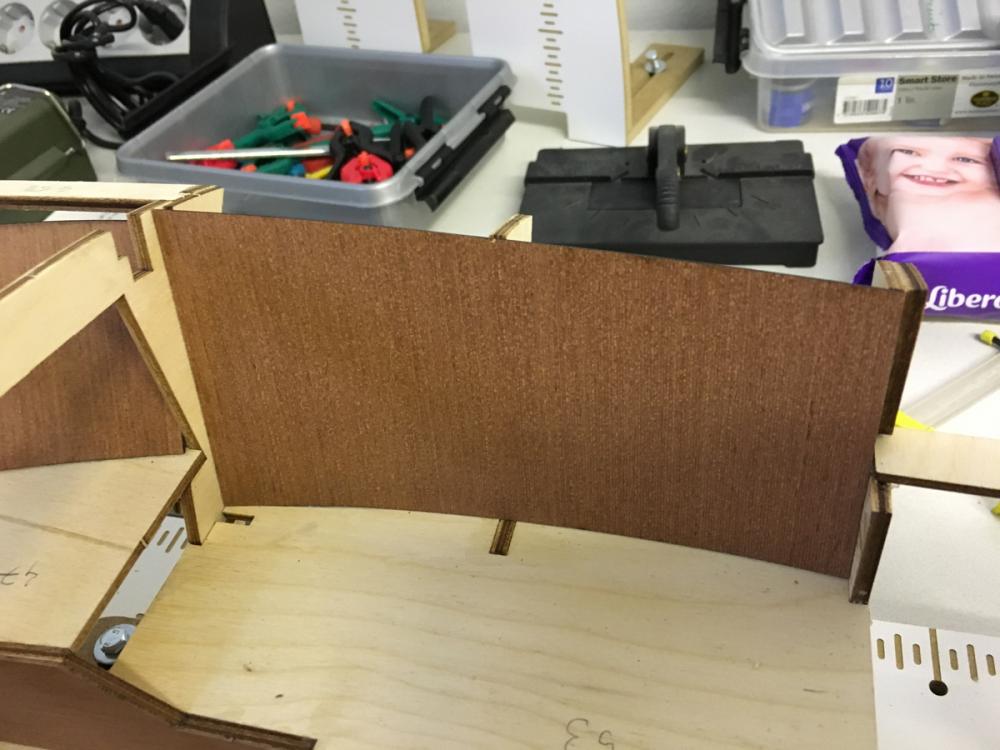

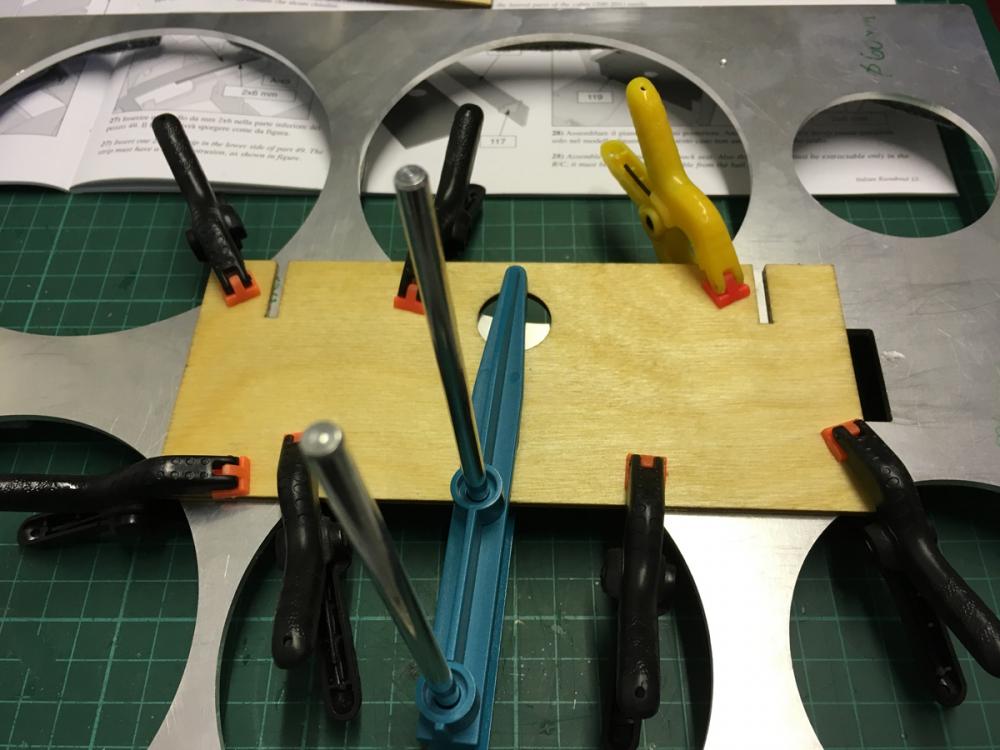

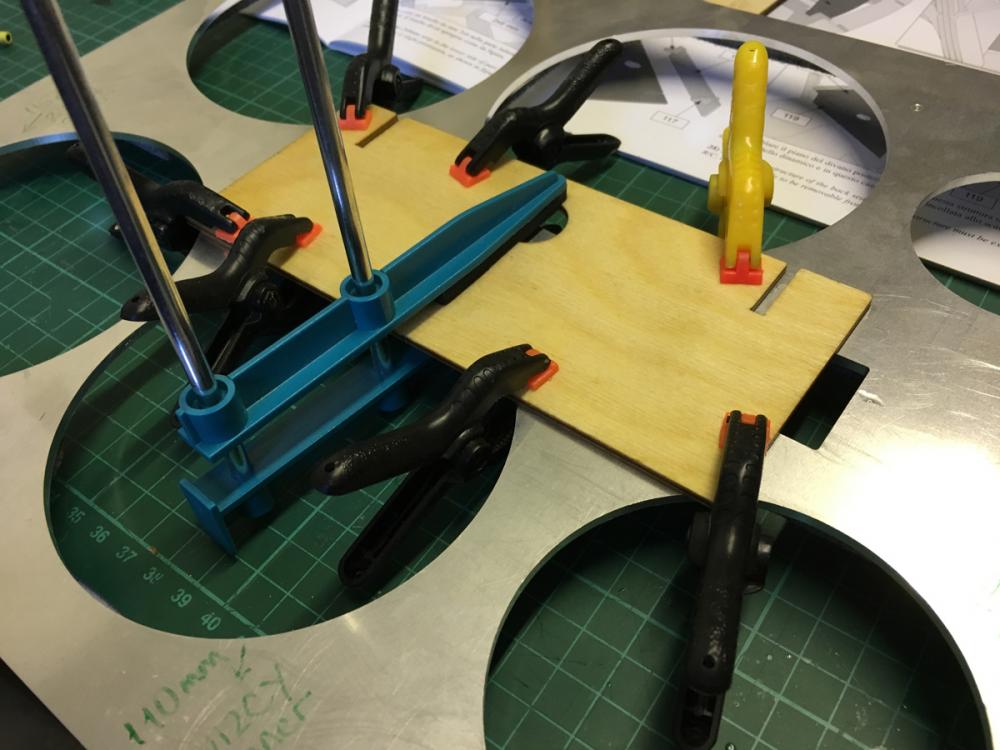

The backseat. This is also one of the pieces which should be left removable if R/C option is used. I noticed that the part 116 was not perfectly flat. It was a little bit warped (about 1mm). It would look ugly if I use it just like that. For this reason I soaked it in water for a while and fixed it with clamps on an aluminum jig which I had lying on my shelf for other project. I will wait until tomorrow hoping that it flattens. If it won't, then soak it longer time and maybe use hair dryer while it is clamped.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.