-

Posts

7,755 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CDW

-

F-86F-30 Sabre by Egilman - Kinetic - 1/32nd scale

CDW replied to Egilman's topic in Non-ship/categorised builds

Man, that looks good. Very very good! You hang in there and take care of yourself first. We are all pulling for you EG. -

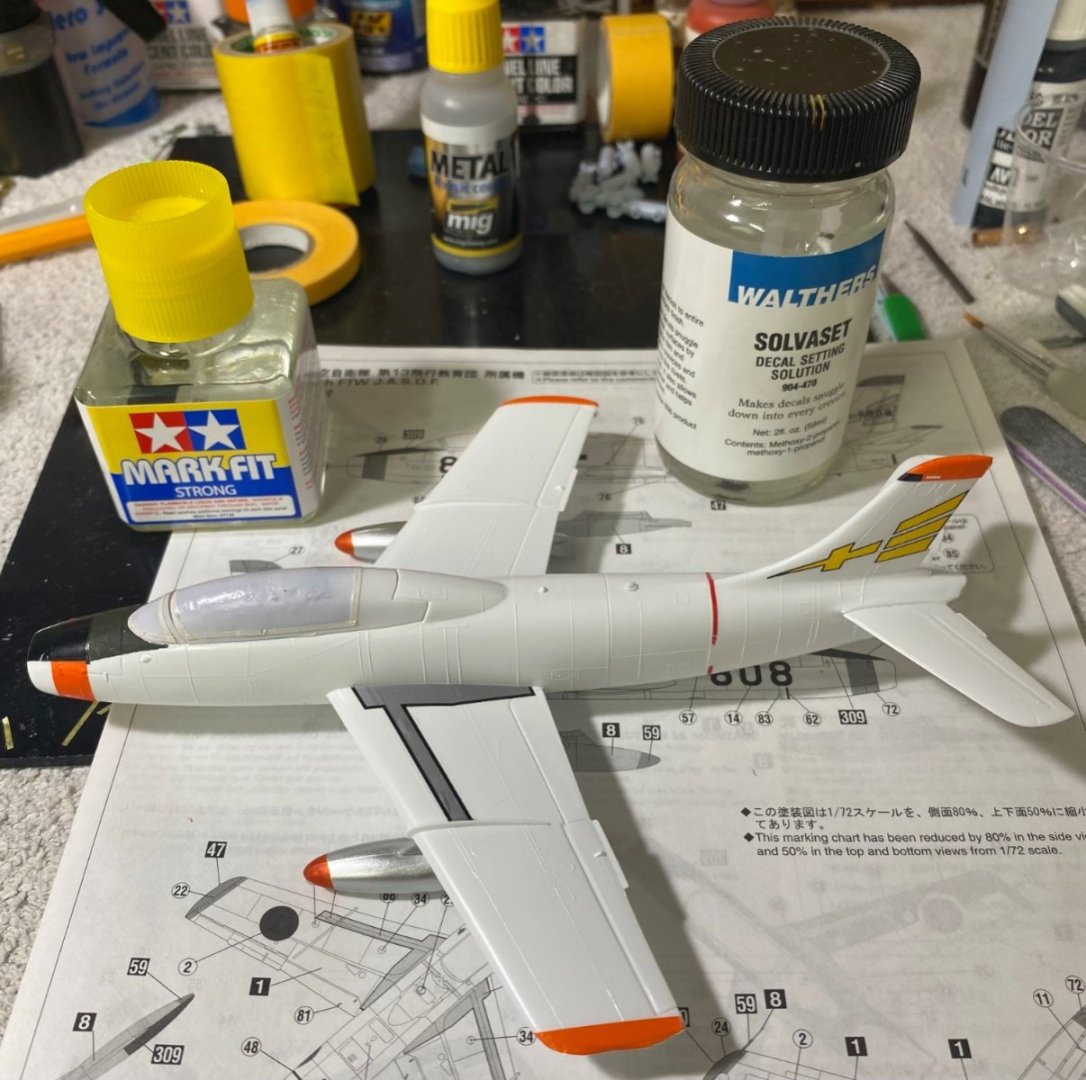

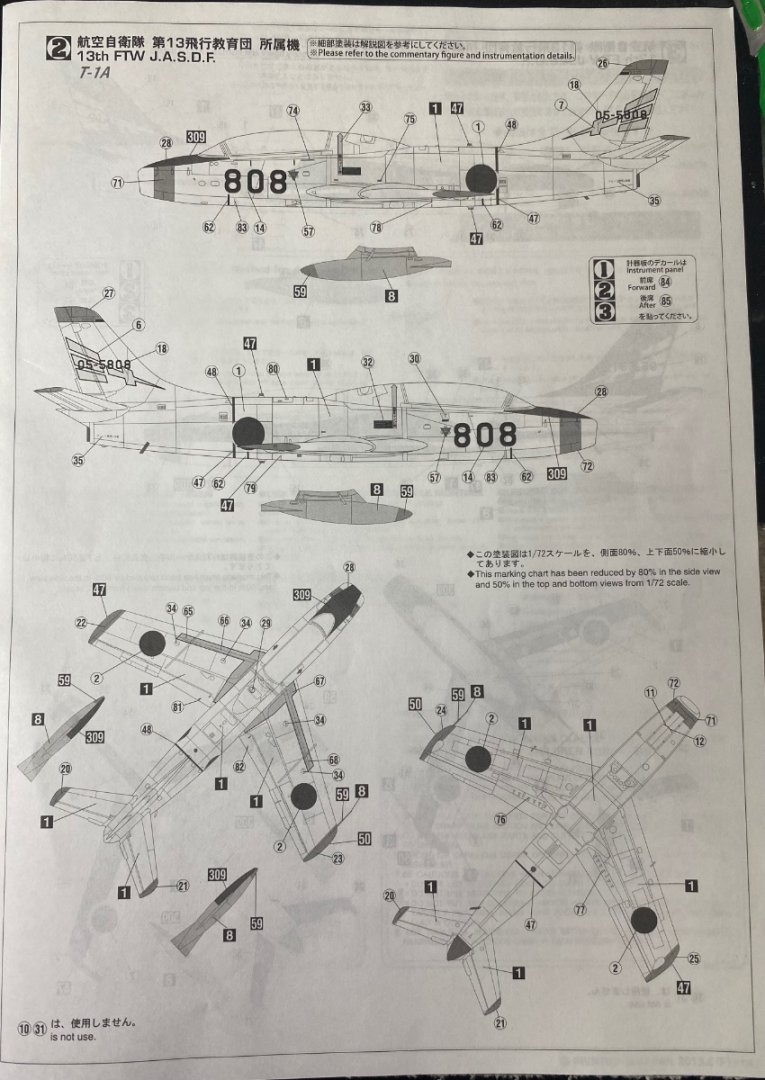

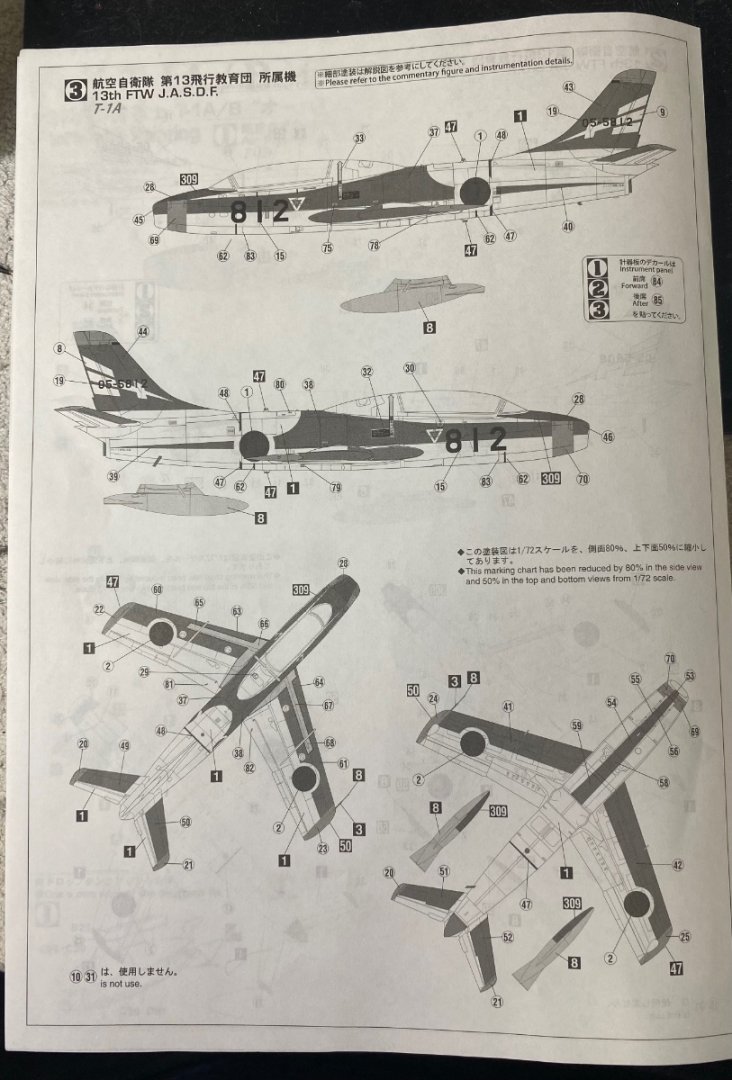

Decal work in progress. One thing that can be frustrating are the way decals behave from one manufacturer to another. Totally different. Some decals will require a mild solvent to help them settle into place, or none at all. Some will require a strong solvent or something in between. There is even inconsistency in the same kit brand from one kit to another. All this demands a varied selection of decal solvents on hand and experimentation to see which one is required. From experience, I can tell you it’s similar to carpentry, you can cut more off but you can’t add on. So it’s best to start with a milder solvent solution first then move on to a stronger one if needed. But don’t count on that same solution working for the next model. Each decal sheet seem to have their own characteristics. This one required the strongest solvent in my inventory, the Walthers Solvaset. My last model, the Airfix kit, worked just fine with Tamiya Markfit strong. Solvaset can damage some decals beyond salvage, so like I said before, start with a mild solution first then work your way up to a stronger one if needed.

-

Thanks EG. I guess the Japanese needed to exercise their engineering skills after a long hiatus, but they sure do look a lot like Sabres to me. Maybe there are subtle differences in angles of incident, centers of gravity, things like that, which would be hard to detect with the naked eye. The history I read remarked on their good stability for pilots in training, so maybe they concentrated their efforts to make the Sabre design more pilot-in-training suitable. They stayed in service a long time.

-

I think you are stating a fact concerning the size of the sprue gates. It’s been my experience that limited run kits have in common, large sprue gates. I often use a razor saw to cut the parts away from the sprue leaving a small portion to trim and file away to smooth it all out. The surface detail on this model looks good. It appears the fuselage halves join along the center/sides of the model? How is that fit. Will sanding or filler be required?

-

https://finescale.com/product-info/kit-reviews/2015/05/wolfpack-designs-t-2c-buckeye Above is a link to a FineScale Modeler review of this Buckeye kit. No mention of whether it’s a rebox, so I guess it’s safe to assume it’s Wolfpacks own mold but we know what they say about assumptions. ps I picked up the paint I needed to start this build. Will finish the pair of Fuji Trainers first.

-

Martin B-26B Marauder by CDW - FINISHED - Airfix - 1:72 Scale

CDW replied to CDW's topic in Non-ship/categorised builds

Thanks for the nice comments. That glass looks good from six feet…just right

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)