-

Posts

209 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by genericDave

-

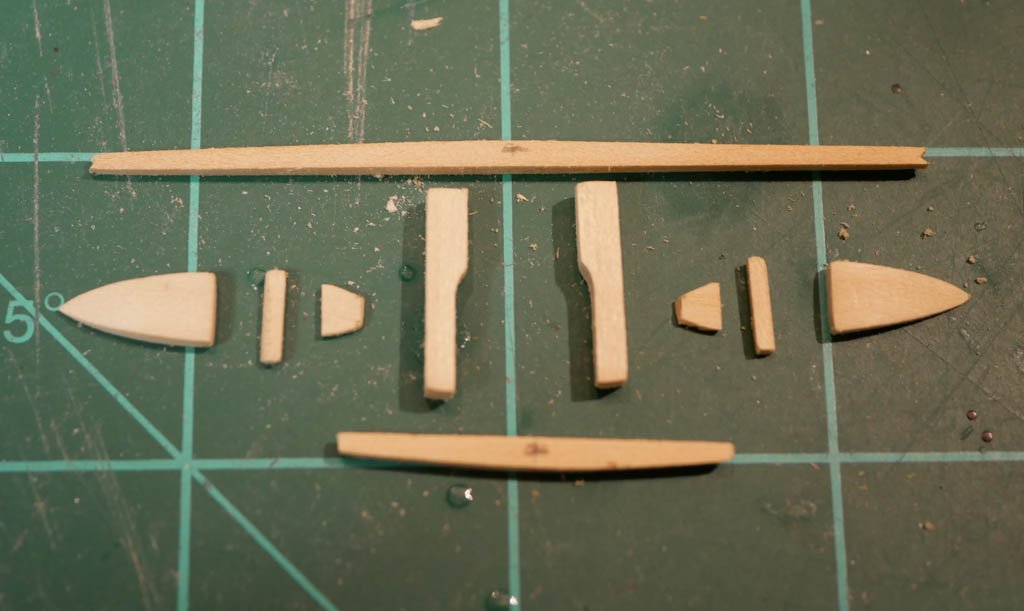

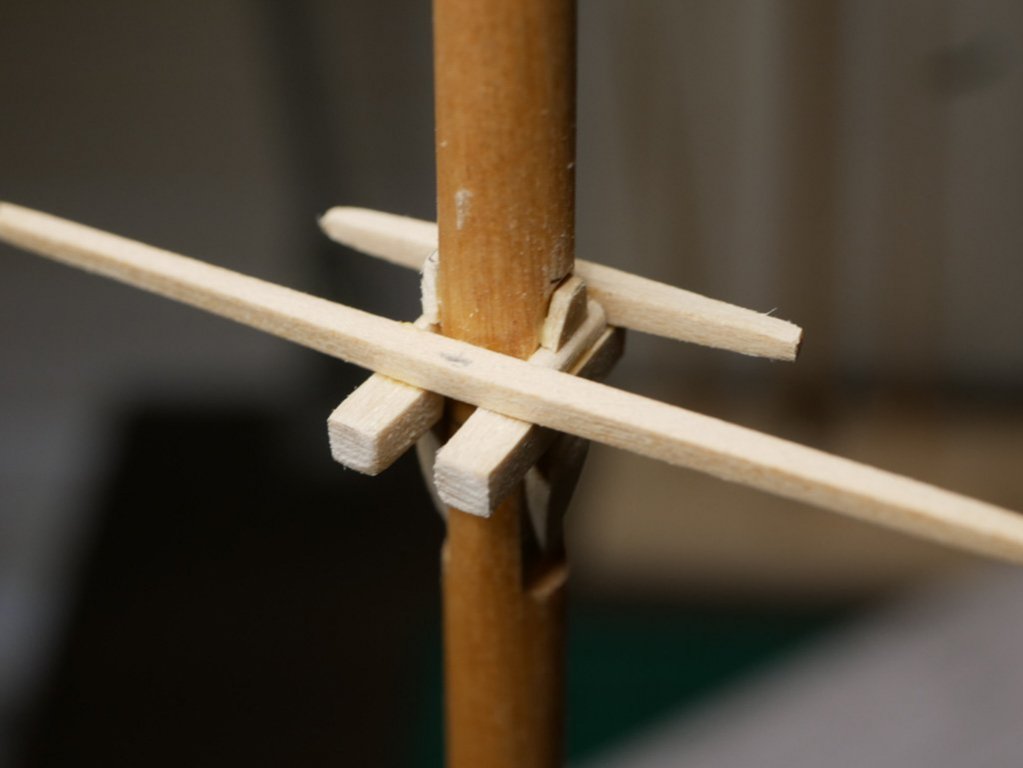

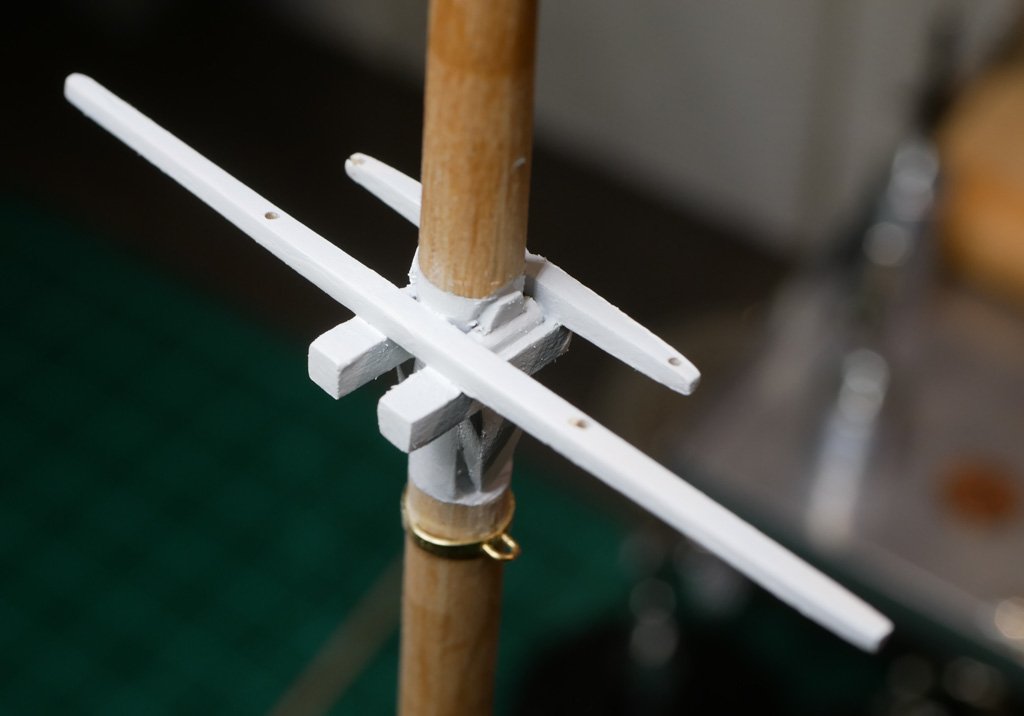

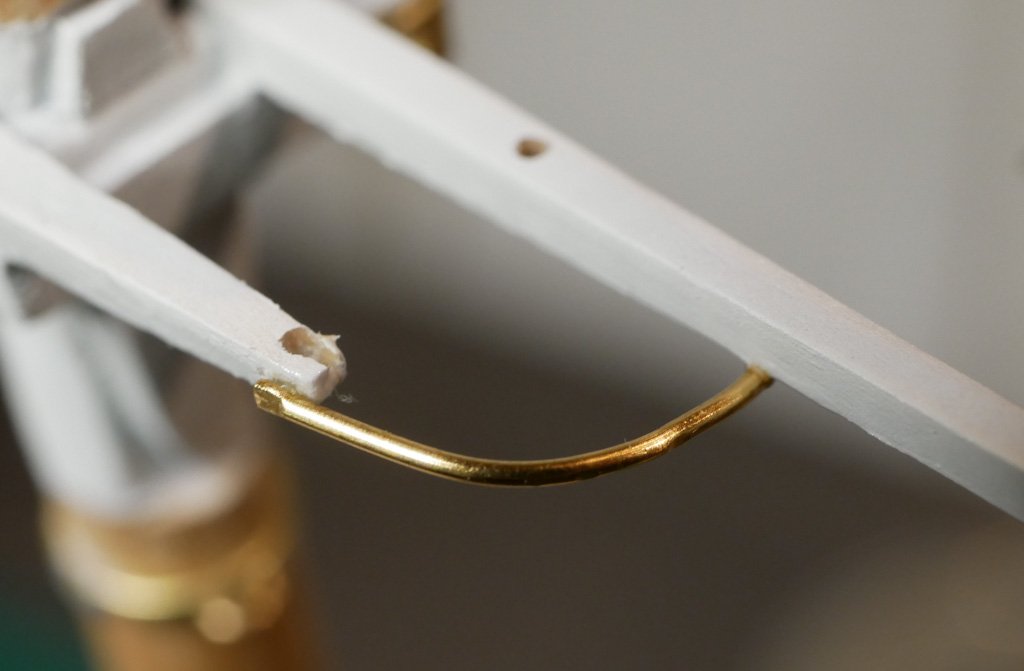

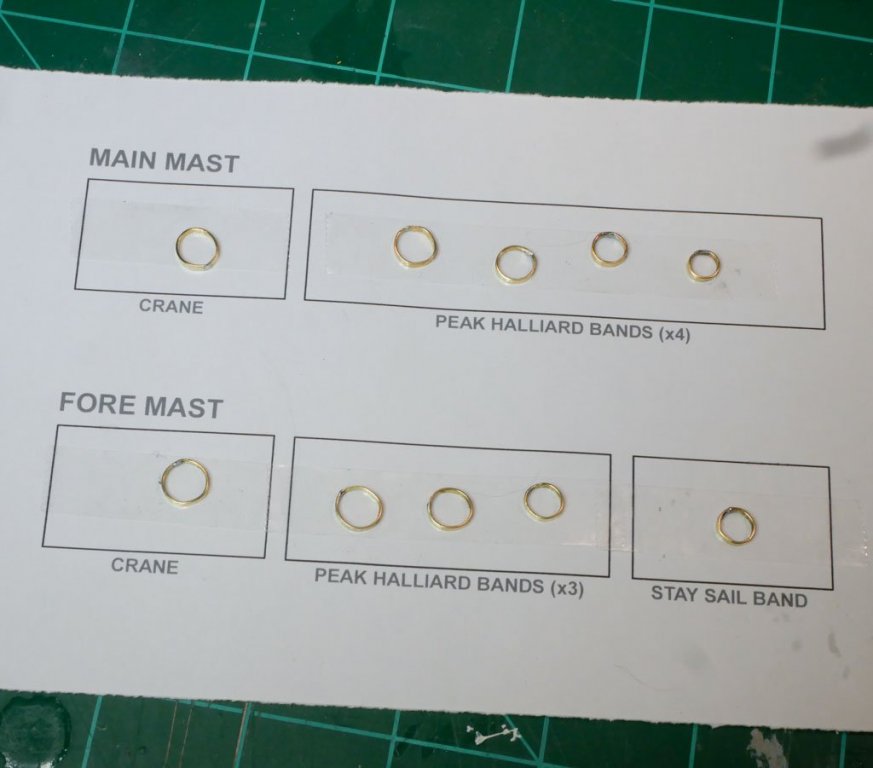

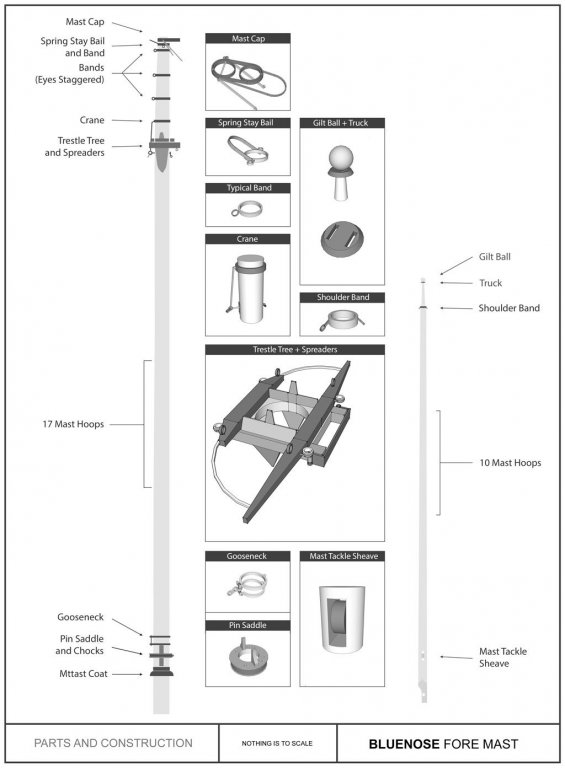

Lower Masts Moving on to the upper portion of the lower masts.... I added the band for the futtock shrouds on the main mast. I simplified it a bit because my 4 attempts to do it "correctly" failed miserably. After several hours, I decided to simplify it to just a band with some wire. Trestle Trees and Spreaders Next I moved on to the mastheads/trestle trees/etc. I've spent a good amount of time over the last few weeks drawing these in 3D (first in SketchUp, then as a way to learn TurboCad), so I had a pretty good understanding of their construction. Despite that, I managed to build them without the cross blocks. Oh well... I built out the trestle trees and spreaders for both masts, then painted them white. With the basic assembly complete, I moved on to all the metal work. I started with the iron gates that hold the heel of the top masts in place. I made these from brass strips, but soldered on some brass rod to simulate the connection points (which I imagine to be very similar to how the two parts of a door hinge are pinned together). Next up were the clips at the ends of the long spreaders. These were also made from brass strip, with a couple holes drilled in each side to simulate bolts. As I've done in other places, brass rod will be glued into the holes to form the actual bolts. The spreader bars were made from brass wire. I didn't bother trying to simulate the bolts on these...I just crunched the wire in a pair of pliers to flatten out the ends and glued them on. Moving on...the main mast has a couple 'shackles' that attach to the trestle trees, where the quarter lifts connect. I made these from brass strip, bent into a 'U' shape. I drilled holes for simulating bolts, and used my mill to make the strips a little more narrow where the quarter lifts will attach. Various eye bolts were installed per the plans. I ended up using eyebolts in place of the fairleads dictated by the plans. I wasn't confident that I could model anything remotely resembling a fairlead at this scale (at least nothing that would look better than an eyebolt). That pretty much completed the trestle trees, so I moved on to the bands. Mast Bands I made all the bands in one sitting, each one sized to exactly where it needed to go. Holes were drilled in each band using my little drill press (I'm getting really good at drilling precise holes in brass). The bands were then installed on the masts. No glue was necessary since the bands fit nice and snug. I drilled through the holes into the masts, and glued in the assorted eyebolts. Gluing those eyebolts in place should give me the little extra bit of stability. Spring Stay Bail The spring stay bail was added, made from some brass strip and eye bolts. All that's left on the masts is the mast caps. But I'll take a short break (this post is getting long), then I'll post again with the mast caps!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Bob - That's a good idea! I've got a couple left over. I'll try to get those cleaned up, stained and installed before I move on.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

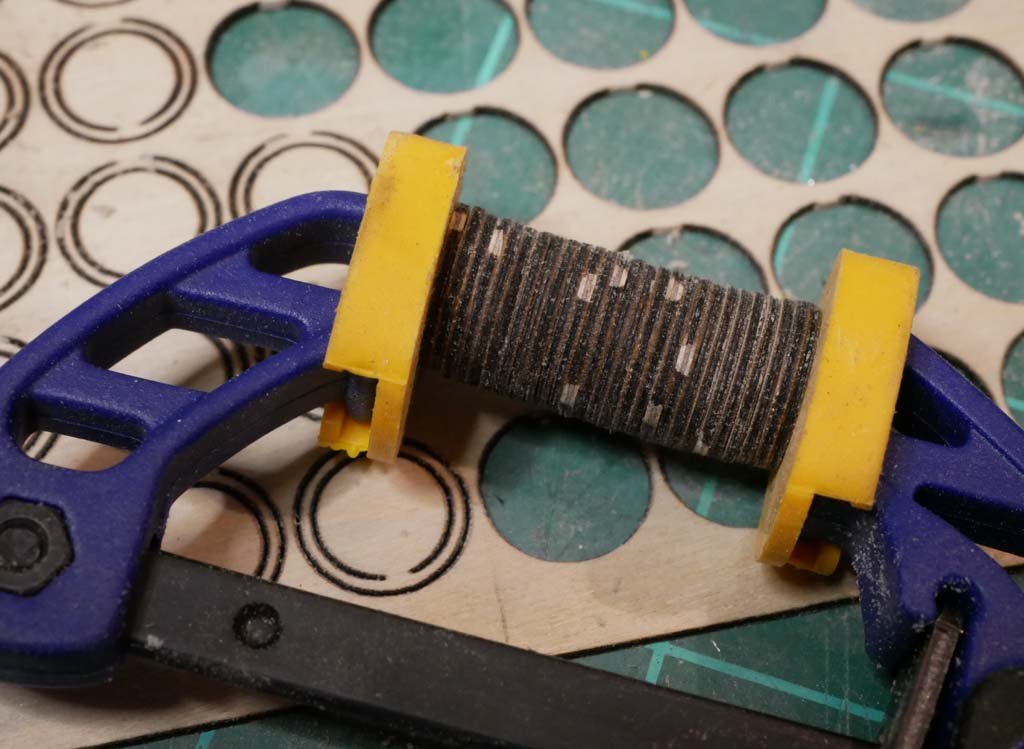

Mast Hoops Finally finished all the mast hoops. These things are tiny and fragile. I managed to only break one in the process. The kit provides 2 sizes of mast hoops as laser cut parts. I only did the larger size for now, since those are what I need to continue working on the lower masts. I sanded the top/bottom faces before I removed them from the sheet. Then I cut them loose, but left the inner circles attached. This made them a little more sturdy while I sanded the outside edge. To make sanding the outside easier, I clamped a bunch together and went at the whole set with a foam sanding stick. Then I cut the inner parts free and started sanding the inner edge. This won't be very visible, but I'm concerned that if I don't get rid of the laser char it will leave marks on the mast. I did these in groups of 3-5, holding them up on my bench while I sanded the inside edge with a foam sanding stick. Once I had all 37 sanded (20 for the main mast, 17 for the fore mast), I dipped them in some stain. I'm staining them a medium brown to match the roofs and trim on the deck structures. That should also make them stand out a little from the masts, which are stained a very light brown. I was also able to run by the hobby store this week and get some thin brass sheet material. This stuff is 0.003" thick, so it can be easily cut and bent. I used this to replace the metal sheet at the bottom of the main mast that I had previously made with copper tape. I wasn't happy with that bit of copper since everything else on the ship is brass. I think it looks much better. I simulated the bolts/nails by just punching tiny holes, then rolling the holes flat again. I think these would have been too small to try and glue in wire. With luck I'll be able to dive in into the more exciting parts of the lower masts this weekend...bands, cranes, caps and trestle trees.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Robert! I'm happy with the metal work as long as I don't look too closely

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

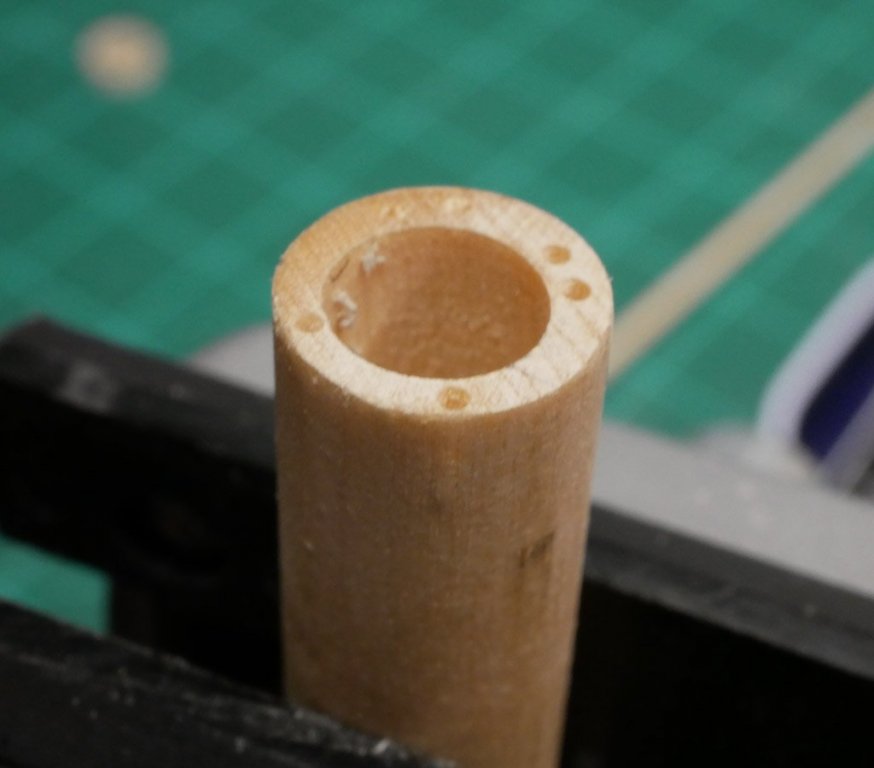

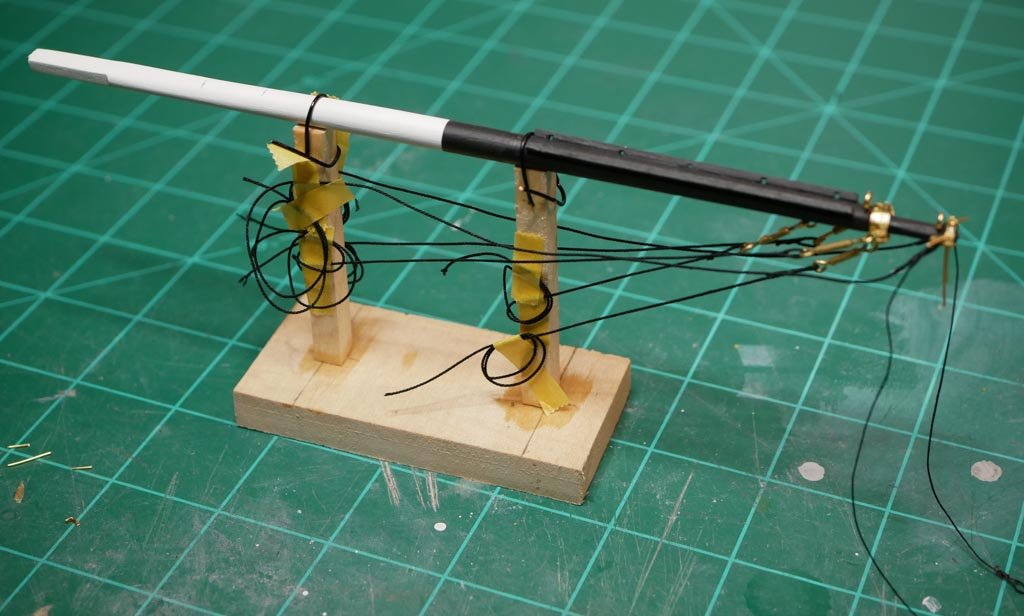

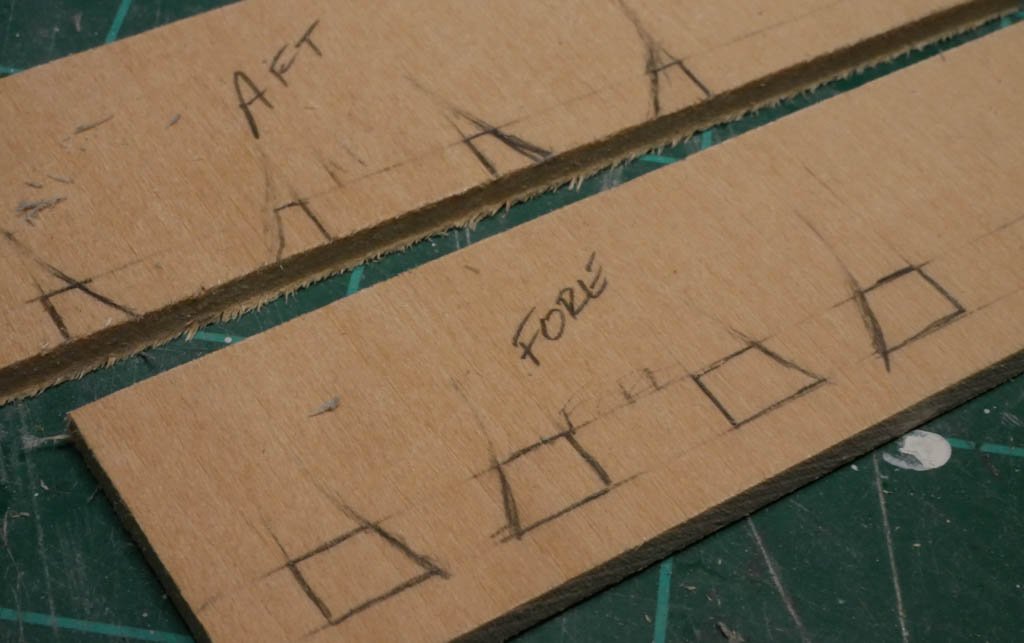

Masts I've made some progress on the masts. After spending a week or two going through all the plans for the masts, the various parts, and all the rigging that touches the masts, I finally felt confident that I understood everything. I decided to work on the fore mast and main mast at the same time since they are nearly identical. I started by cutting the masts to length, cutting the tennons to fit the holes in the deck, and doing all the tapering. The tapering was pretty easy - the lower masts are straight on one side and tapered on the other three sides. I only tapered them from the trestle trees and up since the taper on the rest was very, very slight. I also cut and tapered the top masts. The top masts were tapered on all sides, so I stuck them in the lathe and used sandpaper to shape them. These got a good sanding, then I stained them. The plans call for it being 'natural', but I used a light stain on the deck and I want these to match. So they got a good coat of stain and were placed in a little stand I made to dry. For the mast fittings, I decided to work from the bottom up. For this first part, I'm going to build out everything up to where the first mast hoops go, then I'll stop and work on mast hoops for a while. Pin Saddle and Boom Rest So, the first things to make are the pin saddle and boom rest. These are nearly identical. They only differ in the chock placements and the use of belaying pins on the fore mast. The kit provides some laser cut pieces for this. However, I really wanted to add the 'recessed metal band' detail indicated on the plans, and I didn't think I'd be able to pull that off using the kit's parts. I decided to go a completely different way. I started with a dowel rod that had the same diameter as the pin saddle and boom rest. The masts at this spot are 5/16", so I used a 5/16" drill bit and my drill press to put a hole straight through the dowel rod. Next I drilled the holes for the belaying pins on the pin saddle. This is easiest to do now before I start making the cut for the recessed band. Once that was done, I stuck the dowel into the rotary vice on my Proxxon mill. I used the mill to carve away a recessed area for the metal band. Then I cut the end free with a razor saw. I repeated this process for the boom rest (but without the holes for the pins) and did a quick test fit on the mast. Then I cut and shaped the 8 chocks (4 for the fore mast, 4 for the main mast) and glued everything in place. I masked off everything higher up on the masts, and give these areas a good airbrushing with white. I used some 1/64" thick brass strip to form the metal bands. The strips were bent around the recessed area, then secured with a short brass rod that runs through holes in the band. I also installed the belaying pins on the pin saddle. Gooseneck Next up was the gooseneck. For this, I made two metal bands by folding over some brass strip and drilling a hole through them. I ran some brass rod through the holes to form the joint on the back of the band, then shaped the rest to form the parts that go around to hold the rest of the gooseneck assembly. The gooseneck has a uniquely shaped ringed piece held between the two bands. It has one horizontal ring that attaches to the gooseneck, and two vertical rings (one for the fore boom, and one for a tack line). I wanted this piece to be pretty strong since it will hold the fore boom. I decided to make it out of some thicker brass I had laying around. I started by drilling a couple holes in the brass. Then I stuck it in the mill and 'eyeballed it' to mill it into the general shape. I left a thin 'stem' coming off the back that I bent around to form the ring that connects to the gooseneck. All the parts for the gooseneck were ready... The bands were glued in place, then brass rods were added to hold the connector, which holds the oddly shaped ring piece. That piece moves freely, which I think is the point of the assembly. Metal Sheet As a final step, I added the metal sheet to the main mast. I'm leaving all the metal work on the ship as brass (since paint comes off brass too easily, and I'm horrible at blackening), so I really wanted that metal sheet to be brass. However, I didn't have any suitable brass for that on hand, so I used some copper tape I had lying around. I'll probably check my local hobby store for some brass that I can swap out for this metal sheet (I'm not happy with this one spot of copper on the ship). And now I'm done with the lowest parts of the mast. Next I'll work on making the mast hoops so I can drop the required number in place before adding the trestle trees.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Nirvana - Sure, I can send over the SKB files, as long as you promise not to judge me on the quality of the models You can get the model here. Note that the scale of individual parts (and the pieces that make up those parts) is not at all accurate. I was primarily just trying to figure out how the parts go together. There's also a lot of places where the model is 'hacked', with lines in wrong places, incomplete shapes, etc. Dave B - I never thought I'd use the mill as much as I do, especially since I have a small one that can stay set up all the time. Just did the tenons for the masts with it - they came out perfect and only took a minute or two!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

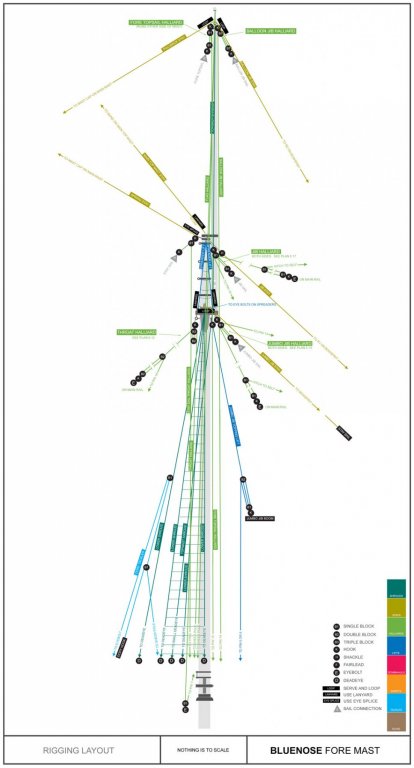

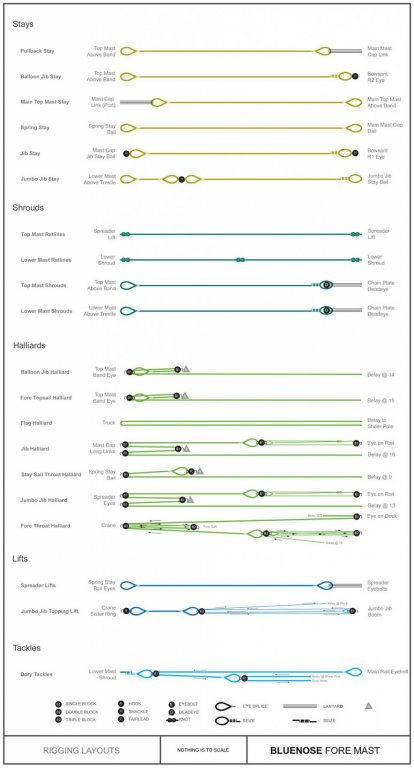

Mast Planning Over the last few days I've been knee-deep in fore mast details. I decided that before I do any work building the masts, I want to fully understand every part and how the assorted rigging gets attached. This led me to doing various drawings of everything. I'm sure experienced modelers just know this stuff, but I'm still new to all this, so having to draw everything out really helped me to understand how everything was constructed and rigged. I thought I'd post a few of the drawings. Be aware that nothing is to scale - I was only trying to map out the general construction and rigging. I started by drawing up the fore mast (lower and top masts). I mapped out all the various parts that need to built. I used SketchUp to model the individual parts (not all accurate, but close enough that I understand the construction). That gave me a pretty good idea of all the metal work, and all the possible places that rigging might be attached. My next step was to take this and draw on all the rigging. This was fun (really, it was). I got all the lines on there, but the various hardware (blocks, hooks, etc) aren't exact. I decided to leave those kinds of details for another drawing since this one was getting cluttered. I color coded all the different types of lines. Since I did this in Photoshop, I can easily turn off groups of layers to hide/show various types of lines. Once I had a good idea of all the rigging on the fore mast, I made a spreadsheet of all the lines and figured out the size of rope to use, etc. All that was left was to figure out the exact hardware and runs of each line. I followed the general concept I used for the bowsprit, where I listed out each run and illustrated the various details. There were a lot of revisions to this one, and I had to consult other sources for some of the details. For example the throat halliard wasn't detailed enough in the plans to figure out exactly how it runs, so I had to consult Chapelle. It is still a work in progress, and will likely be refined/updated as I go. But I think this gives me enough of a roadmap that I can start building the fore mast. All this is overkill...but as someone who knows very little about real ships and rigging, forcing myself to map everything out has really helped me to understand how everything comes together. There were many things that I would have done wrong if I hadn't gone through this process (and probably several things I still have wrong!) I'm out of town this weekend, but I think I've got everything ready to start actually building the fore mast when I get back next week!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

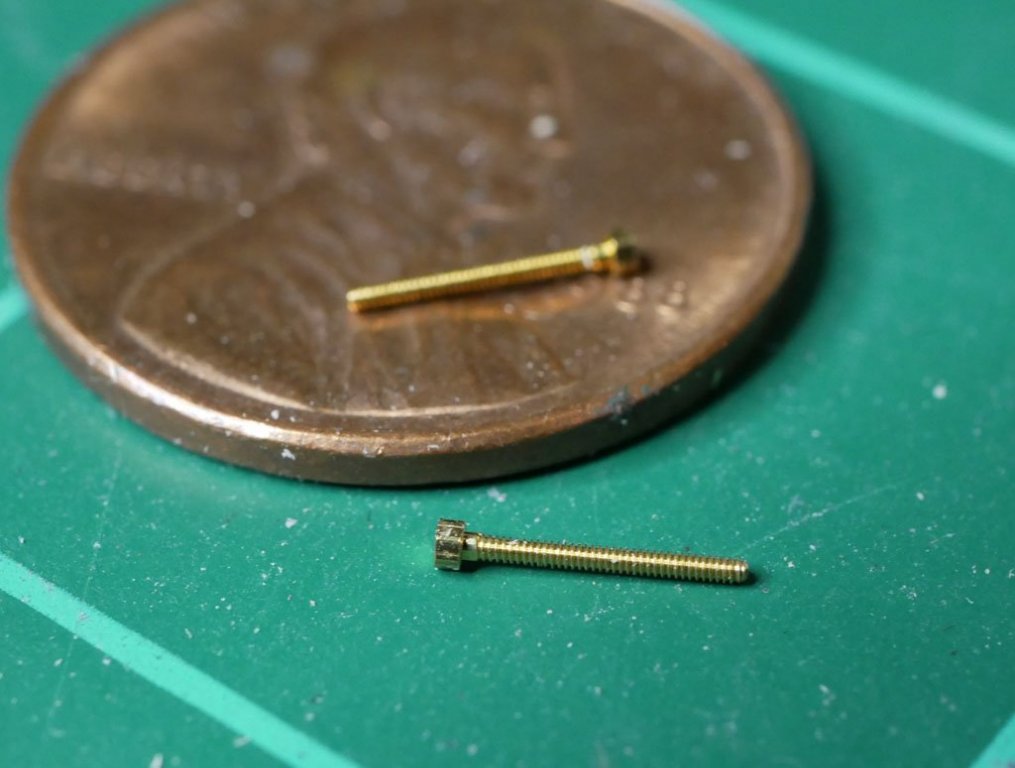

Nirvana - of course you can steal it That's why we all post here, right? I'm so in love with these little bolts that I'm planning on ordering more and using them for anything that requires a 'pin'. I also discovered that they offer nuts that fit these bolts, so I'm going to order some of those too. If I can actually screw those on, the nuts will let me 'lock in' a pin while retaining the ability to remove it later. Fright - Thanks!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

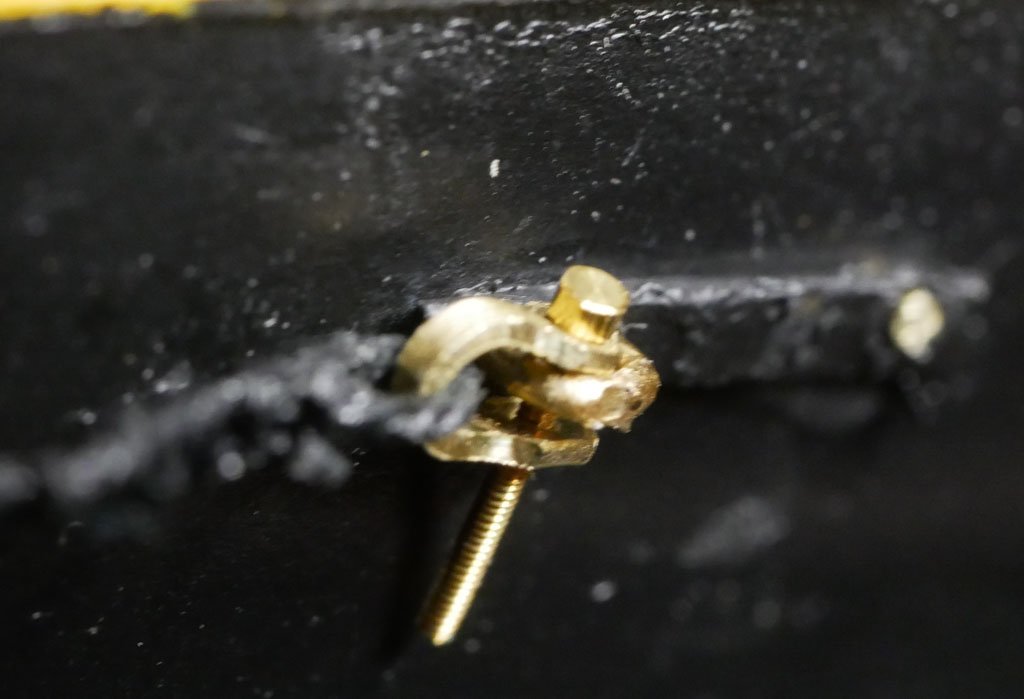

Brass Bolts So I finally got around to checking the mail today, and my brass bolts from Model Motorcars arrived. I ordered these hoping they would work as shackle pins for rigging. They work great! I got two sizes (0.5mm and 0.6mm), and the larger size seems to work best. I made the holes in my shackles using a #69 drill bit, so these these things are tiny. As you can see, they've got a perfect hex-shaped head, and they're threaded. The threading gives it a little 'grip' in the shackle, and so far they are holding firmly without any glue or soldering. Since they are brass, they match perfectly with all my metal work (all done in brass), and they are easy to snip to length with a pair of shears. Here's one in a shackle on the bowsprit, trimmed. These things look so much better than the metal stuff I made myself! And here's one connecting the guy line to the hull, before it got trimmed... Anyway...if you're looking for a simple solution for shackle pins, these work great. And they weren't too expensive...it was $5.00 for 20. Ok...now I've got to get back to analyzing the plans for the fore mast and re-drawing all the various pieces to be sure I know how they're assembled and what they do...

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks everyone! I try not to go overboard on detail in my posts...but I do get carried away! To help limit my over-posting I started a blog when I began this build, and it is now up to 90 articles. The post there about the bowsprit was even MORE detailed (It actually took up four articles...basic construction, turnbuckles, eye splices, and rigging). I'm also getting close to 3,000 photos of my Bluenose build on my computer - might have to invest in more storage! I do find that knowing I'll have to explain myself keeps me honest while I'm working. I'm less likely to take a shortcut if I know I'd have to admit to it. When I started building ships a couple years ago I never would have thought that posting here would have such an impact on my process. I'm moving right on to the masts. Tonight I've cut the dowels for the fore mast, fore top mast, main mast, and main top mast. I've milled the base of the fore mast and main mast to fit into the slots in the deck, and I'm working on building a board to hold the masts while I work on them. Just for fun I taped the top masts to their respective lower masts and put them on the ship...this thing is going to be tall when its finished!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

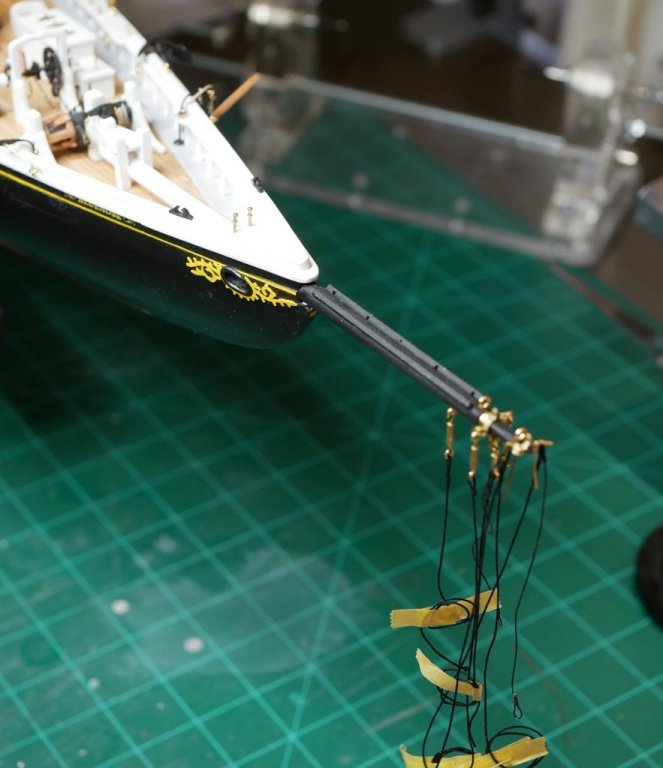

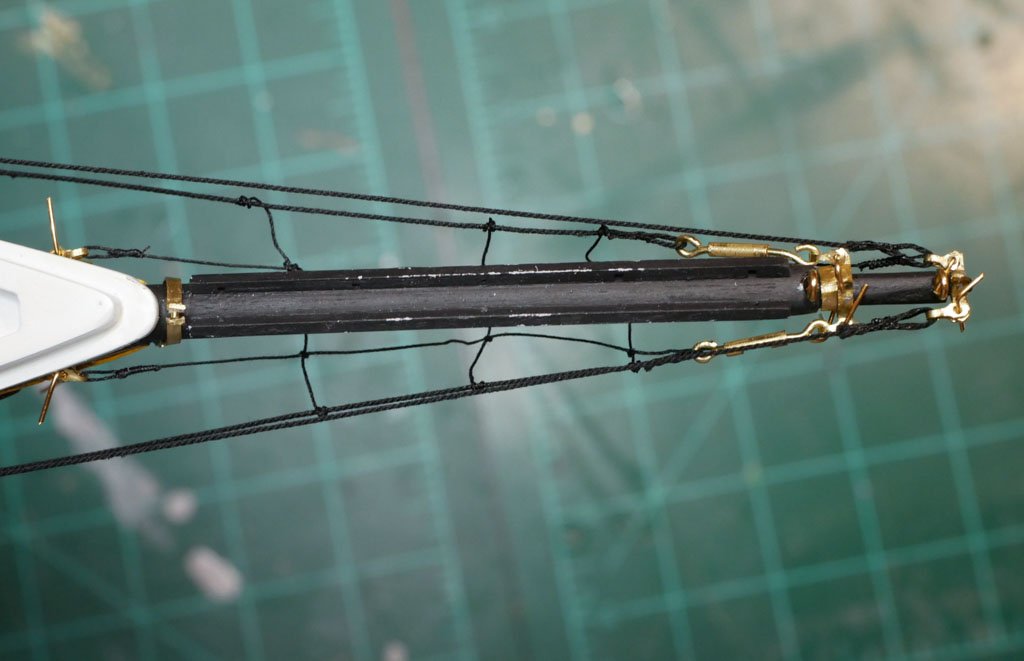

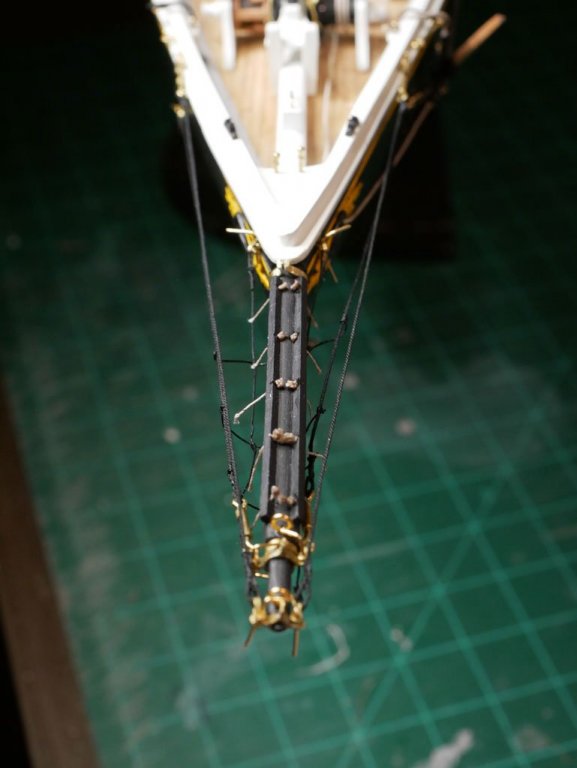

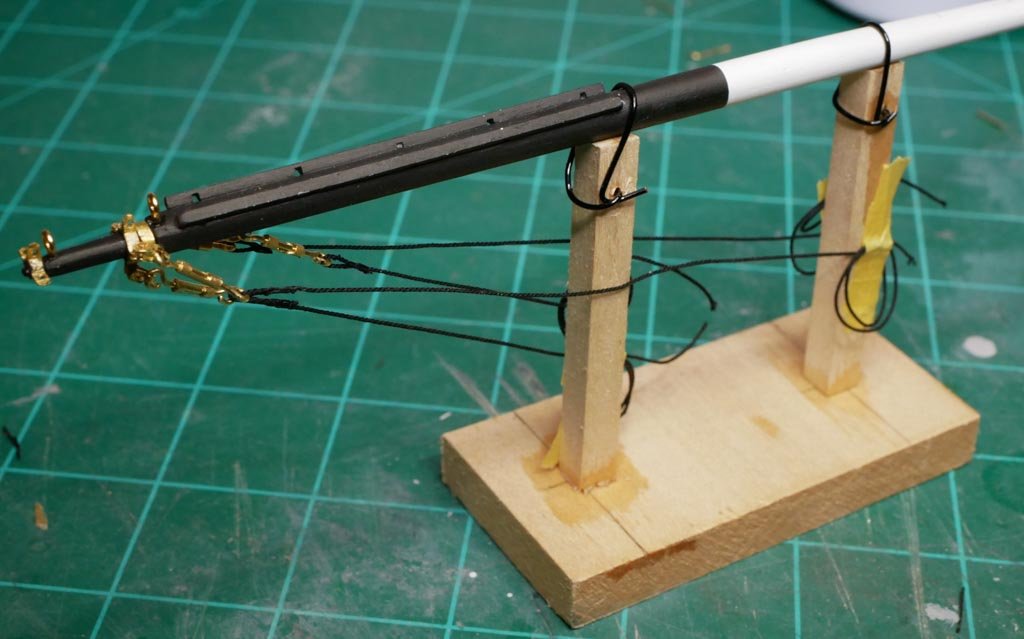

Mounting the Bowsprit Hopefully my last bit on the bowsprit... I rigged everything I could with the bowsprit off the ship. I got the backropes, guy lines, and bobstays attached to the bowsprit. I ended up pulling out the pins I made for the shackles and replacing them with bigger pieces of wire. This keeps those shackles removable for now, which will come in handy. I've ordered some really tiny brass bolts, so I'll wait until those arrive and see if they work for pins - if not I'll try making some. In the meantime, ignore the big pieces of bent wire holding shackles in place. I made the foot ropes and attached them while the bowsprit was off the ship, but they ended up being the wrong length once I got everything installed, so I pulled them off and remade them. (Removable shackles came in handy there.) Next the bowsprit was installed. Obviously this is pretty easy - it just slides into place. Gammon Iron I made the gammon iron from a piece of brass strip. I folded it in half and drilled a hole near the fold, then glued a brass rod in the hole (as a bolt), and cut the fold off. Now It looks like two pieces. I bent it to the right shape and drilled the other holes for the bolts into the hull. Jumbo Jib Traveller Block I made the jumbo jib traveller block from a piece of strip wood. It was carved to the right shape, and the bottom was shaped to match the curve of the bowsprit. From the plans, it was a little difficult to quickly tell exactly how the jumbo jib boom connects on there without more digging - it might be a ring - so I left the wire unglued for now. That gives me options when I go to hook up the boom - just pop out the wire if something needs to slide on there. Rigging Next I started in on finishing up the rigging. I started with the backropes. These are attached to staples that go into the rail. The staples were installed, and the lines were attached. Thanks to Brian's advice I'm slowly getting better at eye splicing. However, I did find it easiest to tighten the line, mark the length, then remove the line from the ship and do the final eye splice with the rope off the ship. (Another way that having the shackles removable helped.) I just found it easier to mess with the rope and do the wrapping when I didn't have to worry about holding it in place. My lines could have been a little tighter, but this worked pretty well here. I don't think I'll be able to get away with that on the masts, where I'll need the tension on the lines to be more precise. Hopefully by then I've got a lot more experience with all this stuff and securing the lines is easier. The guy lines and bobstays were also installed similarly. The plates were mounted to the hull, hardware installed, then the rope was measured, removed, spliced, and reinstalled. Most of this went pretty quickly since all the hardware was made in advance. Each eye splice got easier and easier. Footropes Once all those lines were finished up, I tried the footropes again. This time I got the length right. The stirrups gave me some trouble. My first attempt didn't turn out well, so I pulled all the knots apart and removed them. Originally I tried running each stirrup from one side to the other, tying each knot (guy - footrope - footrope - guy) as I went. I found it very difficult to keep the right amount of slack between each guy/footrope while also getting the knots tight. For my second try, I tied the stirrups to the guy lines on both sides first, being careful to leave the stirrup hanging just right so it hit the footropes. I found this to be much easier, since it was just 1 knot controlling the amount of slack instead of 3. Then I went through with some black thread and tied the stirrups to the footropes. They didn't turn out perfect, but I think I can live with it. I plan to keep an eye on it over the next week or so, and if they bug me too much I'll pull the guys and footropes off and redo them. I think I'll be able to live with them. Finally, I cut, tied and installed the jib stops using some tan rope. Those were easy...not much to say about them. So, the bowsprit is now built, installed, and rigged. I learned how to eye splice (thanks!), learned how to make turnbuckles and shackles, and got more comfortable with understanding the rigging plans. I *think* I'm ready to tackle the fore mast.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

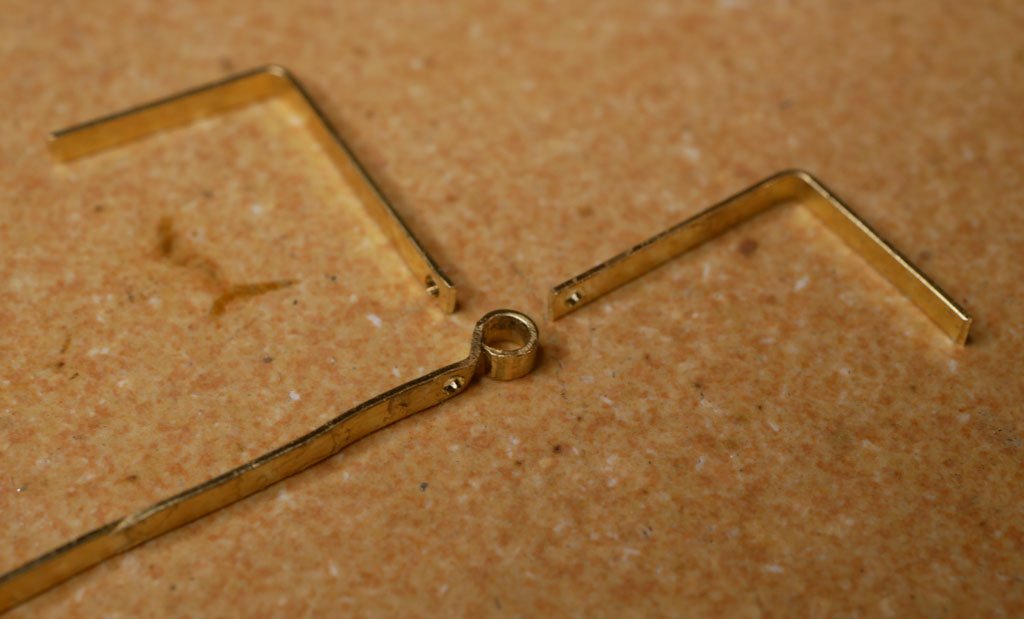

...so about those shackles and turnbuckles.... Shackles I made a bunch of shackles from brass wire, and they looked fine. But when I tried to use one on the ship, it was way too big and out of scale. To make it smaller, I had to switch to thinner wire, and I wasn't happy with how those looked. This photo is of one of the smaller shackles that is about the right size, but ugly... So, I decided to take a different approach. I have a lot of 1/64" thick brass strip lying around, so I took a stab at making shackles out of that. I determined the size I wanted the shackles to be before being bent, and marked that out on some scrap wood. I glued a brass strip down and used my drill press to put in a bunch of holes. I'm doing all the drilling and milling before I cut the individual shackles, so right now I'm working with one long strip that will turn into a bunch of different pieces. The holes were positioned so they will end up at both ends of each individual shackle. Next I moved the board to my mill. I used the mill to take off a little bit of the brass strip between each pair of holes. I did this on both sides so that the body of each shackle was narrower than the ends. I didn't get too precise with this - just eyeballed it. Then I pulled the strip off the board and cut the individual shackles apart. Now I had a pile of flat little brass pieces. They looked pretty rough at this point. Using round nose pliers, I bent each one into a 'U' shape, and they suddenly looked like pretty decent little shackles. They ended up working great. While they look rough when they're flat, you don't notice the imperfections once they're bent. I tried a few different ways of making them, but the process above was the only one that produced usable results. I'll need more shackles for other parts of the rigging, so maybe I'll be able to refine this process a bit as I go. Turnbuckles For turnbuckles, I considered ordering some, but it gets expensive really fast. I don't really care if they are 100% accurate, but I wanted something more than just wire. I wanted to try and reproduce the basic look of actual turnbuckles. I have a fair amount of brass tube left over from making my pintles and gudgeons. The tubing is about 1/16" in diameter, and the opening is just the right size to fit the brass rods I have. I started by using my mill to carve away part of the brass tube to create an opening. Because of the size, I'm only doing this one side - I'll just try to make sure that's the side that faces outboard and gets seen. Next I cut some pieces of brass rod and made rings on end. I stuck those through the tubes. Finally, I trimmed the rods to the right length and bent them to create the ring in the other end. On most of them, the tube fit tight enough that it didn't slide around. On the few that did move a bit, I just roughed up the brass rod with a file, and slid the tube over the rough spot. That seemed to create enough friction to hold the tubes in place. No glue, no soldering. So, now I had staples, links, shackles and turnbuckles. Everything I needed to start rigging, which brings me to the point where I posted my update above.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

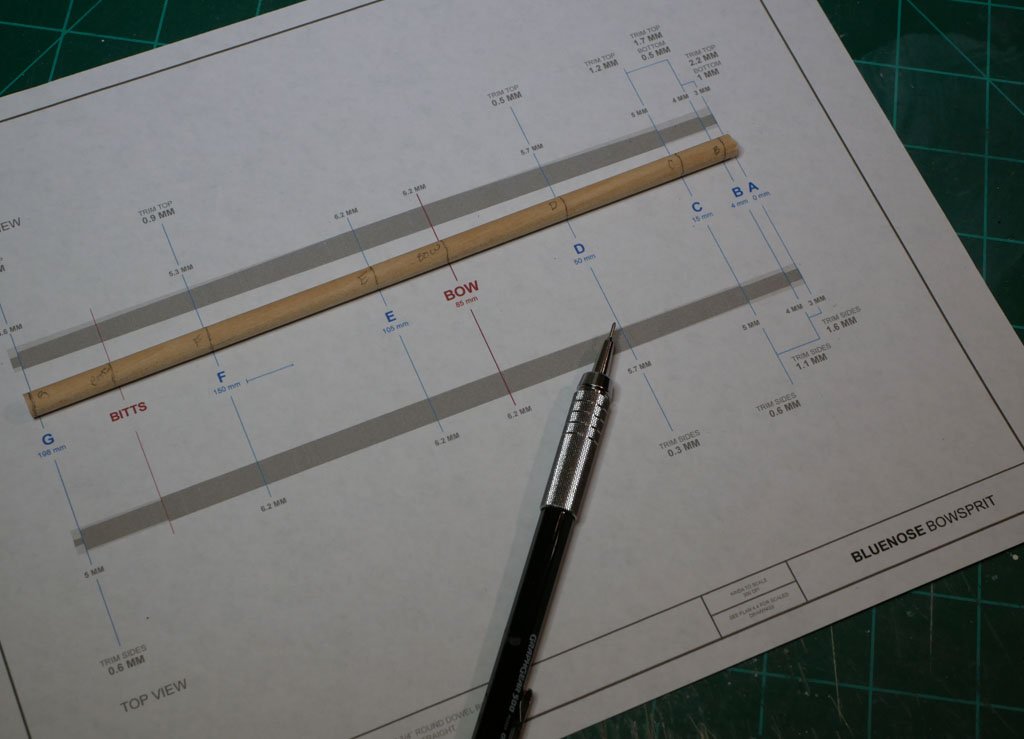

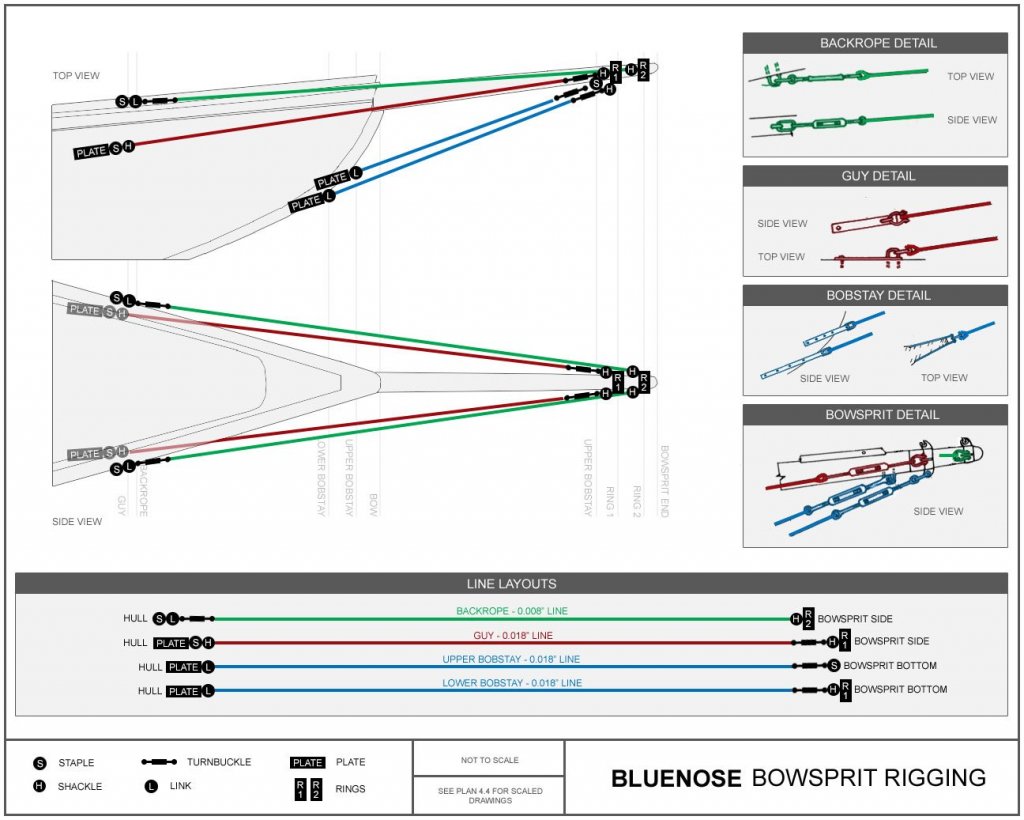

Bowsprit Ok - the bowsprit is done! I posted a quick update before, but now I'll go through what I actually did. Since the bowsprit uses several things that I'll be doing a lot more of (tapering, making hardware, rigging), I thought I'd explain how I did everything so you more experienced folks can point out where I could have done things easier or better. Since it might get a little long, I'll probably break it up into multiple posts. So here we go... I decided to tackle the bowsprit before the other masts/booms/etc, and see it all the way through rigging because it gives me a chance to get my feet wet with a variety of things that'll be doing on the other masts/booms. I definitely learned some lessons. Tapering the Bowsprit The first step was to actually build the bowsprit itself. The bowsprit on the Bluenose is tapered, but the tapering is only on the top and sides. The bottom is straight. So I can't just stick it in a drill/lathe and sand away. To help get the tapering right, I drew up a model of the bowsprit at actual size and marked a bunch of reference points. I figured out how much needed to be trimmed off each side at each point. Next I stuck the dowel rod in my mill and cut notches at the correct depth for each reference point. While I had it in there, I also squared off the rear end. With all the reference notches in place, I started sanding with a sanding block to give the bowsprit the tapering. The notches made this pretty easy - I just sanded a smooth line from one low spot to the next. Jib Stop Rails I made the rails for the top from some strips of basswood. They were cut to length, then I used the mill to cut out the spots where the jib stops will go. Bands While the bowsprit's paint was drying, I started in on the bands. I made these from 1/64" thick brass strip. I soldered on pieces to form the rings. My soldering skills are not great, but I managed to get these made pretty easily. (And apparently I did a decent enough job that they held throughout rigging - no problems with the soldered-on rings breaking off). The bands were installed onto the bowsprit along with the eyebolts and staple depicted on the plans. Planning for Rigging Next up was the rigging. I decided to do as much of the bowsprit rigging as possible before installing the bowsprit on the ship. This seems to be the method many prefer, so I thought I'd give it a try. I didn't do that on my first build because I was concerned about getting the length of the lines right (and not running out of rope). But for the Bluenose, I'm replacing all the kit's line with rope from Syren Ship Model Company, so I can always order more if I need to. Since I'm determined to do the rigging more accurately this time, I decided I needed a better understanding of all details before I start. I'm not familiar enough with all the normal lines and parts to be able to quickly glance at the plans and know what should be done. So, I spent some time making my own rigging diagrams based on the plans. These are fairly simple, and definitely overkill for the bowsprit, but they helped force me through the process. I made another sheet that shows the footropes. (I did that one separately so I could better visualize the stirrups.) As part of these plans, I mapped out how everything was connected and all the parts required. I also figured out which sizes of rope would get used for each line. I made a bunch of staples and shackles pretty easily from wire. Nothing too exciting there. However, the turnbuckles and shackles required more work...

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Brian, Thanks for those photos! That seems like a very straight-forward way to make these. I had been assuming that I shouldn't wrap an eye splice, but if that is typical, that makes this much easier (and better looking!). Trying to find info on how eye splices are done **in model ship building** has been a great example of how this hobby can be tough for someone without much experience. I'm sure many modelers who have been at this for a while take eye splicing for granted, but for someone relatively new to the hobby, it has been really difficult to find information on the 'correct' (or at least 'acceptable') way to do it. All my research on eye splices led me to info on doing eye splices on actual rope, which obviously isn't easy/possible at this scale. I looked through the various books I have, and didn't find any info. I did a search on the forum and found 18 pages of results - but unless I was ready to dig through tons of build logs (I wasn't), there wasn't a topic that seemed to address this. Sometimes it is these 'basic' techniques that us newbies really need some help with, and your photos really helped! I've got to make a few more shackles before I can finish up the remaining lines for the bowsprit, but once I get those knocked out I'll give your method a try!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Brian - Thanks for the suggestion! That sounds a lot easier than what I was trying to do (actually splitting the rope open and threading it through itself). Doug - I've been struggling quite a bit with brass myself I'm learning as I go, and most pieces are a lot of trial and error. I have a bunch of pictures of the process for these parts that I should be able to get up in the next couple of days. With the pieces for the bowsprit, I used my drill press, soldering iron, and Proxxon mill quite a bit. The bands were made from 1/64" thick, 1/16" wide brass strips. The eyes on the bands were made from the same strip and soldered on. The turnbuckles were made from 0.062" diameter brass tube, and I used the mill to cut away one side. Then I ran some 0.032" diameter brass rod through it and shaped the rings at each end. It looks good from one side, but the other side doesn't have the opening (I wasn't able to cut that on both sides without the tube becoming too weak in the center). I'm trying to keep the turnbuckle openings turned outboard so they look better. The turnbuckles aren't perfect, but I think they look better than I could have done with other methods. The shackles gave me a lot of trouble. I made some from brass wire and was really happy, until I went to put on one and realized they were way too big. I made smaller ones that were closer to scale, but to get the size right I had to use thinner wire, and I was concerned about it holding. What ended up working for me was to use the 1/64" thick, 1/16" wide brass strip. I marked a length of about 8mm, used my drill press to put holes in each end, then used the mill to carve out the sides so they were narrower. The piece was then bent over some round nose pliers to make the 'U' shape. To make the pin for the shackle, I took some 22 gauge brass wire and flattened one end using some pliers, then bent that end over and trimmed to form a little 'lip' at one end. I dropped that through the shackle and gave the lip a tiny dot of CA glue to hold it in, then trimmed the other side to length. Without a mill, I think shackles could still be made this way - just clamp the strip down and use a needle file to make the sides narrower (doesn't take much).

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Bowsprit Busy few days, and I'm supposed to stop working on my ship (or doing ship related things on the computer), so I'll just post a quick status update, and I'll catch up on the details later... I've been working on the bowsprit. I ended up making 2 because I wasn't happy with the shape of the first one. I've started rigging it, which has been 'fun'. I took a LOT of shortcuts with rigging on my first build (basically just tied all the lines off), and I'm trying to do a better job with this one. Of course the first four lines I run require an eye splice, and I don't know an easy way to do those. Lots of brass pieces had to be made for the end of the bowsprit. Everything was made from brass strip and brass wire. Hoping I can get the remaining rigging prepped over the next few days so I can get this installed.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

The dories are done! And I'm not kidding, oar am I? (Sorry - I've been saying 'dory', 'kid' and 'oar' way too much the last week or so). The remaining dories were finished up over the weekend. It didn't take long, just a lot of repetitive work to cut the rails, drill all the holes for the pins, cut+install the pins, and add splash rails and rope. They aren't perfect, but I'm pretty happy with them. I think they did turn out better than I was expecting, and certainly better than I could have made with the kit's parts. With the dories completed, I turned my attention to the two kids. These little racks will hold the two stacks of dories on the deck. Each kid is made from two long rails with a couple cross bars. I cut the 4 rails to length and notched them where the cross bars will hit. The cross bars were made from the same material. They were cut to length, then all the parts were pinned onto a build board and glued together. To make the angled pieces that will support the dories, I used a contour gauge to get the shape of the dory hull at each of the cross bars. I transferred this to some sheet wood and used that to mark off the pieces. There are two pieces for the bow and two for the stern (x2 since we have two kids). These were cut on my Proxxon scroll saw, cleaned up, and glued into place. While the stain was drying on these, I turned my attention to the oars. I decided to only make 4 oars - two for each stack of dories. Obviously they would have carried more, but I think if I tried to show the actual amount, you'd just see a pile of oars instead of the detail in the dories. I made the oars from some strip wood. I cut several lengths of wood and clamped them together. I marked the shape of the handle on one side, and filed them down to rough in the shape of the handle. Since they were clamped together, I was able to do all of them at once. Then I removed them from the clamp and did the rest of the shaping by hand with sandpaper. The handles were rounded off and the blade was shaped. Once I was happy with the shape, I stained and painted them. My color scheme wasn't based on any actual research - I just went with something I thought would look interesting. Suddenly, I had all the pieces I needed to put these on the deck. I decided that I didn't want to just tie them down. I wanted to be able to remove these if needed once I start rigging. So, I made a set of 'S' hooks from brass wire and seized them to some tan rope. I sized the ropes so they hold the dories firmly, but are still loose enough that I can unhook the ropes and remove the dories. Finally, the dory kids were glued onto the deck and the dories and oars were put in place. I haven't actually glued the oars in - they are just sitting in the dories at the moment. I've got some small buckets on order, and I want to see if the dories look good with a bucket in each one - that may impact how I arrange the oars. I'm also waiting on a couple more styles of wooden barrels. According to my list of stuff to do, I think I'm done with everything on the deck and below. I *think* I'm ready to start in on the masts!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Elijah! I've been following the progress on your new build - you're off to a great start!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Update on the dories... I've got all 4 dories built, but only one is "finished". I found that it was easiest to cut all the pieces for the 4 dories at once and do the basic assembly and painting in an 'assembly line' process. However, once it gets to adding the rail and final details...that takes some work. So I'm doing the last few steps one-at-a-time. I decided to make the thole pins from brass rod and leave them unpainted to match the rest of the metal on my build. These should probably be blackened, but since I'm leaving all the other metal pieces as raw brass, I think it makes sense to leave these as brass as well. Compared to the prototype, I used thinner stock for the seat support rails and for the seats themselves. I also positioned them lower, which should help to keep things nice when stacking these on the deck. The rail on the one finished dory was made from 1/64" thick sheet material. Obviously the dories aren't finished and I haven't built the racks to hold them, but I think they are looking good sitting on the deck!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Fright - thanks! I'm trying But this is only my second build, so it is still a learning process! Dave B - I did see very similar barrels on yours! These are from Model Expo / Model Shipways, and are the 17mm tall versions. They look very similar to yours (obviously you painted the bands). I'm fairly happy with the size, but I'm considering ordering some at the same size from other vendors to see if I can get some that aren't so dark. I'd like to have something fairly light and unfinished that I can stain to match the color scheme of my build. Lacy J - I just wandered over to your build log, and if you're over-thinking things...keep doing it! You're build looks great! I especially like that you took the time to do the coamings for the deck structures and plank around them! Are you building that out as the Bluenose II or the Bluenose I (I noticed your log title says the 'II'). I've been a little jealous of those who build the Bluenose II, because there are tons of photos of that ship since it's still out there. (If I were building mine out as the Bluenose II, I would have already convinced my wife to make a trip up there!) Jond - Thanks for the detail on the chain box! I've considered grabbing those plans a few times, but I think it would send me down a rabbet hole The Model Shipways plans don't actually show the location of the chain box on the deck, but they have a drawing of the box itself and they show it as a more squared-off box, so I went with that. On the chain and winch, it probably would have been more accurate to use chain for the anchor and wrap that around the winch, but I liked how the rope contrasted against the hull. I justified it to myself using some notes on the MS plans. I knew when I added it that I was wrapping it around the wrong side of the winch, but I think crossing it over to the 'rope side' would have looked a little funky. If this were my 4th or 5th build, I'd try to be more accurate, but as my second build, as long as I'm happy with the look, I'll take it On the barrels, I've had hard time finding good information. I know the Bluenose did store most of its barrels horizontally on a rack, but it did have those rings on the cabin for securing barrels. I wish I had the skill to build my own barrels, but since that would be a little much, I'm trying to source some pre-made barrels that will look 'good enough'. I think the size on these is right, but I'm not happy with the finish.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Work continues on my dories. I've got one completely finished, and the other three are built, but need their rails, splash rails, etc. installed. As a diversion, I've been looking into sourcing some barrels. I've seen some builds that build a structure to hold barrels (which looks amazing), I've seen some that add barrels tied to the cabin, and some that don't use wooden barrels at all. I'm not really wanting to build a structure with barrels, but I'd like to tie a few to the cabin. I bought a few different sized wooden barrels from Model Expo, and they arrived today. I think the size looks OK, but I'm not happy with the finish. They are pretty dark, and I'd like something a little more 'raw' that I can stain to better match the colors on the ship. So...a few questions for those Bluenose experts out there... Do these barrels look about the right size? Am I horribly out of scale? Does anyone have a good source for wooden barrels that are unfinished, ready to be stained?

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Russ! I've just started working on the 4 'real' dories, and I'm feeling hopeful that they will turn out usable!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Bob! I was actually looking at your build log the other day to see how you handled the dories...now I know why they were missing

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Do I Use Primer?

genericDave replied to CKNavy's topic in Painting, finishing and weathering products and techniques

I haven't used a sanding sealer, but I pretty much always use a lacquer based primer on everything I'm going paint, but I think it depends on the effect you're looking for. I use acrylic paints (water based), and find that without a primer, the paint tends to raise the wood grain a bit. So, things that are painted without primer look very 'wood-y' and show their grain. When use primer (and sand after the primer dries), I get a much smoother finish (often showing no wood grain). I like that really smooth look so I always use primer. The primer I use is Tamiya Liquid Surface Primer (grey), and it goes on very thin. So thin that it won't fill any holes, and any defects in the wood still show up. Since it is lacquer based it is a bit of a pain to clean up (can't be cleaned with water), but the results I get are worth it. I used it on the hull of my Phantom and Bluenose builds, but I think it really comes down to personal preference.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.