-

Posts

628 -

Joined

-

Last visited

About Worldway

- Birthday 10/30/1963

Profile Information

-

Gender

Male

-

Location

: Niagara Falls, Ontario, Canada

-

Interests

Driving my wife nuts. She suggested I get a hobby.

Recent Profile Visitors

-

Scottish Guy reacted to a post in a topic:

Are you an NRG Member???

Scottish Guy reacted to a post in a topic:

Are you an NRG Member???

-

Mr Whippy reacted to a post in a topic:

HMS Bounty by Steve 12345 - FINISHED - Billing Boats - 1:50

Mr Whippy reacted to a post in a topic:

HMS Bounty by Steve 12345 - FINISHED - Billing Boats - 1:50

-

I was wondering if you can help me.

The rigging knots for main gaff blocks going to the mast. I'm a relative beginner and can't find anything on the rigging of these. Can you help or do you have someone to recommend?

Thanks

Helmar Sowick

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

I was wondering if anyone uses hide glue or Old Brown Glue and what their opinion is of it. I did do a forum search on the topic and found a couple of older discussions but nothing current. I see that it is a reversible glue in the sense that parts can be unglued using heat and water. I thought that might be a benefit to someone like me who tends to do a lot of rework. I know there is a downside to hide glue, whereby it has to be heated. Apparently, and correct me if I’m wrong, Old Brown Glue is basically a hide glue that doesn’t need to be preheated. I also read that hide glue tends to shrink when drying effectively pulling the parts together tighter. Just wondering if this might be something worth considering.

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

GGibson reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

GGibson reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

-

bhermann reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

bhermann reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

-

AON reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

AON reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

-

Haliburton reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

Haliburton reacted to a post in a topic:

Bluenose by Worldway - Model Shipways - Scale 1:64

-

I thought I would shift focus and move on to sails for the time being. I had a friend give me the patterns for his Bluenose sails but they weren't the correct scale. I also wasn't sure if the kit provided me with enough material to make the sails; considering I will likely have to remake a few of them as a learning exercise. I went to our local Fabric shop and picked up some material that was similar to the material provided in the kit. I don't know if the material is to proper scale (thickness) but for now it will do. I also picked up some tracing paper and started tracing out the sails. I plan on photocopying the patterns before I attempt to use them. I have a feeling the copies will be needed. I have been loosely following Bob Hunt's practicum. However, with the Bluenose he does not cover the sails. His practicum is for a ship without sails. His series of practicums increase in skill level as the builder moves from one practicum to the next. With the Bluenose he didn't cover the sails as this practicum was designed for the beginner. Luckily I do have a couple of articles on sail making and, of course, I got all the information at my fingertips on this forum.

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

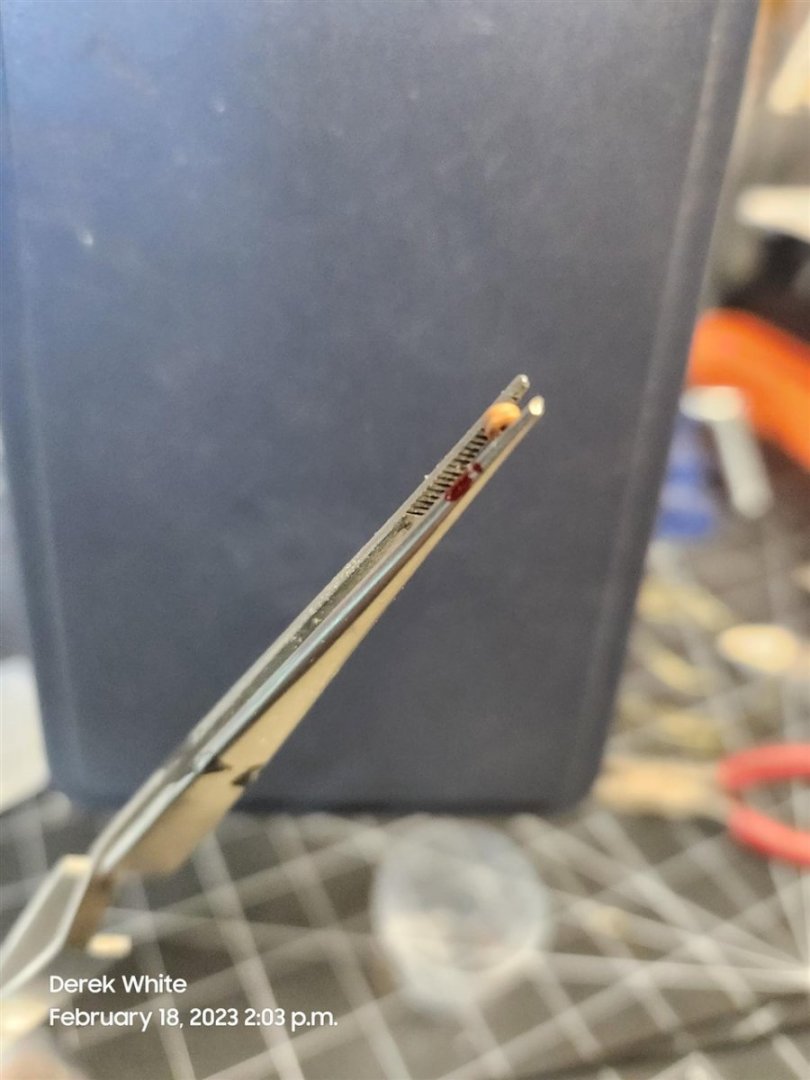

Started today working on the fore gaff. The kit comes with laser cut jaws. I used the material originally supplied to assemble the dories as shims to center the jaw on the gaff. Once assembled, I set this aside to let the glue dry. I wanted to finish the bowsprit, or at least paint it and install it so I could eventually install the traveler block. I originally installed the two strips of wood on either side of the center line of the bowsprit but was unhappy with how it turned out so I removed them and tried again. In removing them, I did a little damage but I think I cleaned it up OK. I contemplated scrapping and starting over again but decided it wasn't necessary. While studying the drawings I discovered that I had yet to install the deadeyes on the ship's rails. So I wrapped them in the 0.014" dia wire. It was a little fiddly but went pretty well non the less. I had some issues drilling holes and installing them properly. I purchased a set of micro drill bits off Amazon and found "a deal". However, they weren't the best quality and they broke pretty quickly. So I started drilling with the correct size, broke it, switched to another size, broke it, etc. etc. Also, because I hadn't installed the main rail and monkey rail with the accuracy required, I couldn't install the deadeyes in the proper locations on the external edge. As such, I'm not sure if I will add the metal straps below the deadeyes. It won't align properly and think it would look worse instead of adding more realism to the finished model.

-

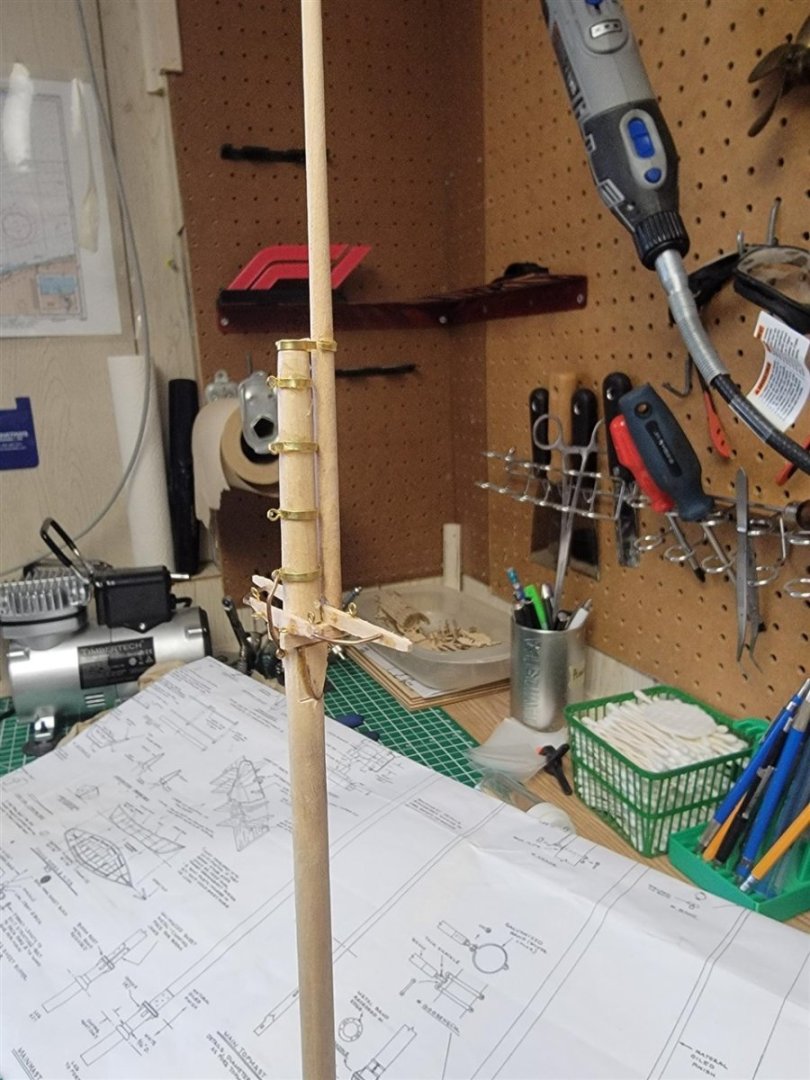

Today I finished up the main mast. For the chafing piece for the boom jaws, I had a piece of brass tubing that I cut to length and slid on the mast. I installed the 4 chocks, cutting pieces out of 1/16" x 1/8" basswood. I also made sure I installed the mast hoops first. I found that the quantity of mast hoops I had didn't total the same quantity that shows on the drawing. Not sure what to do, I simply divided the total quantity by 2 and used half on the main mast and will put the other half on the foremast. Hopefully I can make it work from there. The drawing shows a white band at the bottom of the mast called a Canvas Mast Coat. I had some spare fabric and cut a strip to suit and glued it on. I still haven't permanently installed the main mast. Probably won't until all the masts, booms etc are done. I think I will work on the bowsprit or the fore boom and gaff before tackling the foremast.

-

It's been quite a while so I thought I would offer a brief update on the progress of my Bluenose. I can say that progress has been very slow however I have not abandoned the project nor do I plan to. I keep getting sidetracked but always seem to gravitate back to the shop, and I can say that my interest in ships and ship history hasn't diminished. I have projects in mind that I would like to do in the future but am determined to finish the ones I have started and abandoned. I have 3 other ships in the drydock that I would like to finish first before I tackle anything new. At one point I thought about finishing the Bluenose without the sails but quickly decided that the sails are one of the recognizing features of the Bluenose. I was fortunate enough to have a friend give me his patterns for the sails so should make that task a little easier. I have pretty much finished the deck complete with the 8 dories normally carried when she was used as a fishing vessel. I've yet to lash them down. The main mast is almost complete. It's not permanently mounted yet but it's close. I plan to start on the foremast shortly. As previously reported, the dories and the crates/barrels are 3D printed. Although not authentic, I think the crates/barrels add a little to the deck. I will still add to this build log as I progress. I hope that I will post more often in the future and hopefully have the Bluenose complete in a timely manner.

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

Hello Mark and welcome

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

Worldway reacted to a post in a topic:

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

-

Worldway reacted to a post in a topic:

HMS Speedy by David Lester - FINISHED - Vanguard Models

Worldway reacted to a post in a topic:

HMS Speedy by David Lester - FINISHED - Vanguard Models

-

Hi Per, I got the STL file for the dory from Thingiverse. The link to the file is https://www.thingiverse.com/thing:236917 I scaled it and made multiple copies for the same print using my slicer program. If you're not familiar with the site, they have thousands of files you can download for free. I also got the barrels and crates from the same site.

-

I've spent some time printing new dories for the Bluenose along with some crates and barrels to add to the deck. The dories I had printed at my local library were a little on the large side and had a lot of supports added. I found that, because of the relatively small size, they didn't need any supports therefore didn't need any cleaning up. Of course they will still need to be painted and have some details added but it's a good start.

-

As an FYI, I have had an order in with Sig Mfg which has been backordered for over 2 months. I have been in contact with them and am told that it's because of boats unable to unload. As of November 17th they were still waiting for the shipment. I don't have a definitive date yet but have asked them to keep it on backorder as I'm in no immediate rush. I should mention that they have been fantastic to deal with and have replied to me promptly and courteously.

-

Thanks Per. I pick up the printer on Saturday and will spend the better part of the weekend getting familiar with it. I'm looking forward to using it. I plan on also downloading Fusion 360 so I can develop my own files (hopefully). If I can master this fast enough I may go back in my Bluenose build and 3D print some of the Britannia fittings which didn't turn out so well and reinstall them.

-

Alan, according to the library's web site they use PLA plastic filament (Polylactic Acid). It's quite rigid. The detail wasn't too bad and was good enough for what I needed. As a side note, I broke down and bought a 3D printer. I ended up buying the Creality Ender 3 2V. I looked at resin printers but figured I would get more use out of a filament printer as I wanted it for a lot more than just modelling. Plus I don't have to deal with possibly dangerous chemicals. We'll have to talk some day soon so I can see what your 3D printing experience has been like and perhaps compare notes. Luckily, our IT department at work has a printer and has offered to help me plus there is a lady at work who uses one extensively in a side business she has and has also offered to help me. David, I happened upon the library's website and noticed they did 3D printing so I thought it might be a good solution. Like you, I hated trying to put the dories together and eventually I gave up with a pile of scrap. I wasn't going to add the dories to the Bluenose until I saw the library's site. I found a file on Thingiverse which I rescaled and emailed to the library. I had no idea if I was sending them the correct file or if the scale would show up correctly or if I nested the duplicates properly. I talked with one librarian who runs the printer and she looked at everything I sent her and told me it was fine. I was happy with the results. I had a quick look at the website you suggested and will definitely be spending more time there, not just for the sails but for other build aspects as well. As far as sails go, I met up with Alan a few weeks ago and he was showing me a sail he made with silk span and I was very impressed with the results. So I'll be experimenting with it as well. So many options. John, I'll be happy to help as much as I can as I'm sure anyone on MSW would. However, I'm a beginner and am learning as I go as this is only the second build I've done.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.4b9546914df2c235b4fe82d7c03670bd.jpg)

PR.thumb.jpg.cdbcbd0745b65f4cb15bf7c9b4841198.jpg)

PR.thumb.jpg.967a2e6d4eea89d5840e6195ad53590d.jpg)

PR.thumb.jpg.a21097616acc1de13718f5ce1a36ac43.jpg)

PR.thumb.jpg.f9b0b35a789451cdbc2a559d82fe15b8.jpg)

PR.thumb.jpg.f64a982311fe09476f24bb32c8e99b9a.jpg)

PR.thumb.jpg.82ce2cd1204976d881cec2ab360f31fa.jpg)

PR.thumb.jpg.5a264481ac209bff45a08e2e8ae507c1.jpg)

.jpg.d149f30489bd3712ba9caebac06e08f0.jpg)

.jpg.40b75159514a576c6eb654c8b4a749dd.jpg)