-

Posts

104 -

Joined

-

Last visited

About stripehunter

- Birthday 05/20/1977

Profile Information

-

Gender

Male

-

Location

Lancaster, PA USA

Recent Profile Visitors

-

Scottish Guy reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

Scottish Guy reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

Bill Morrison reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

Bill Morrison reacted to a post in a topic:

USS CONSTELLATION by Tschiller - Artesania Latina - Scale 1:85 - Kit Bashed back to 1797

-

SUBaron reacted to a post in a topic:

Swift 1805 by stripehunter - FINISHED - Artesania Latina - 1:50 - first build

SUBaron reacted to a post in a topic:

Swift 1805 by stripehunter - FINISHED - Artesania Latina - 1:50 - first build

-

I have this kit in my closet for the future if i can ever get myself back into modelling. This kit is a bit odd as there are some major features that dont seem to belong to either version of the connie. Since you are going back in time this might not be much use to you but i have a bunch of pics taken from a modellers perspective of interest of the late version down in baltimore. https://modelshipworld.com/topic/15595-reference-photos-from-vist-to-uss-constellation-in-baltimore-md/?tab=comments#comment-484865

-

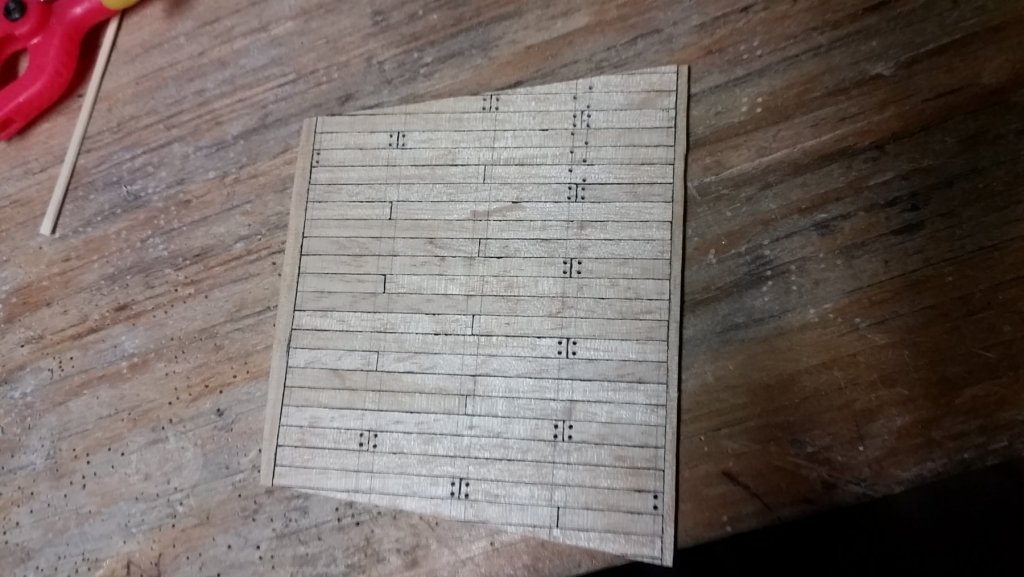

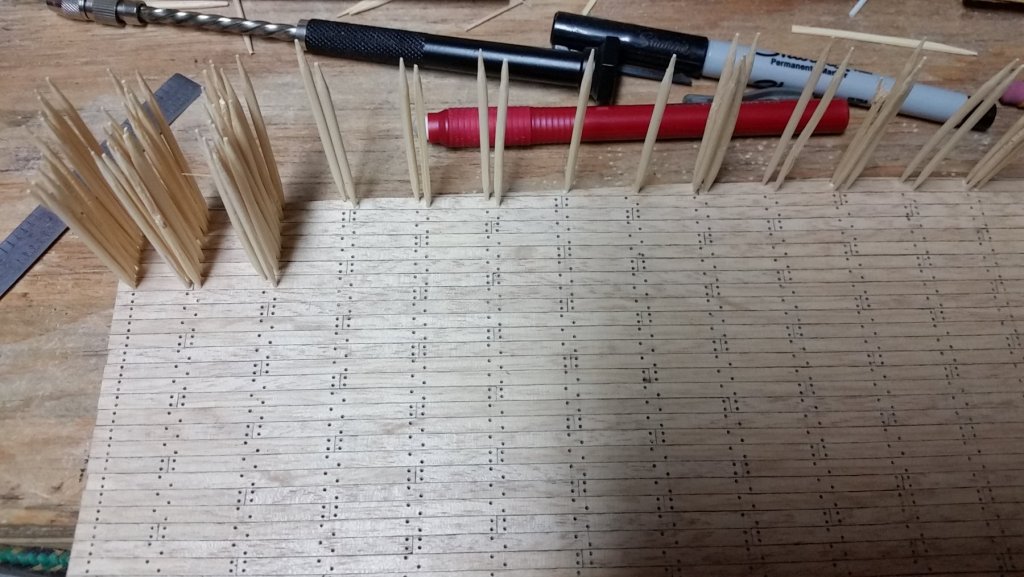

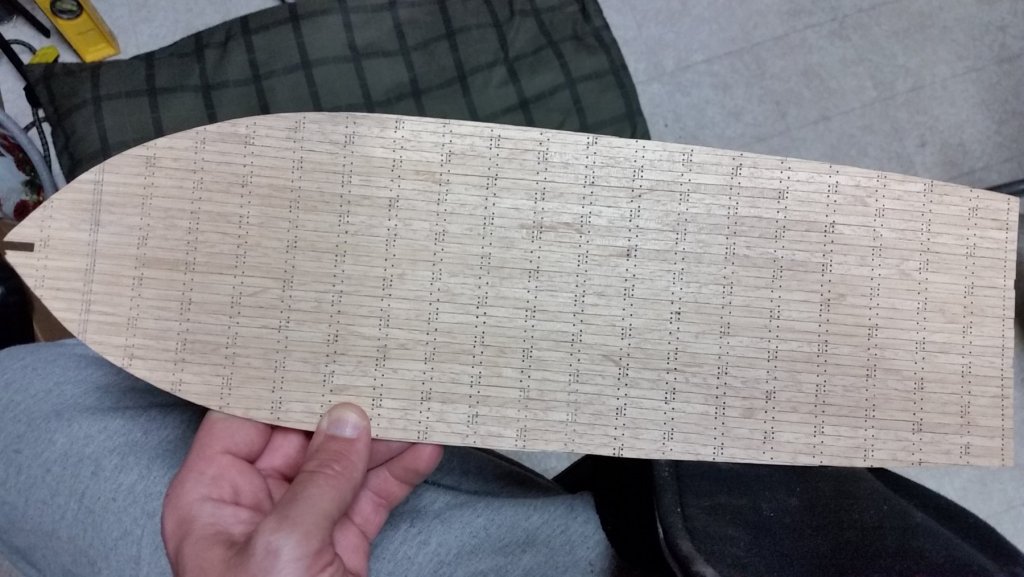

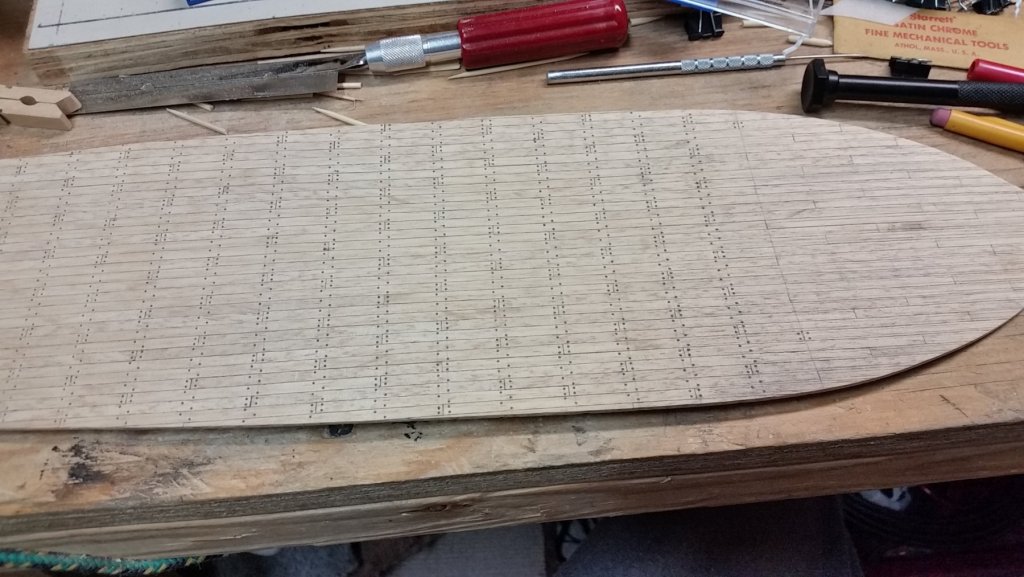

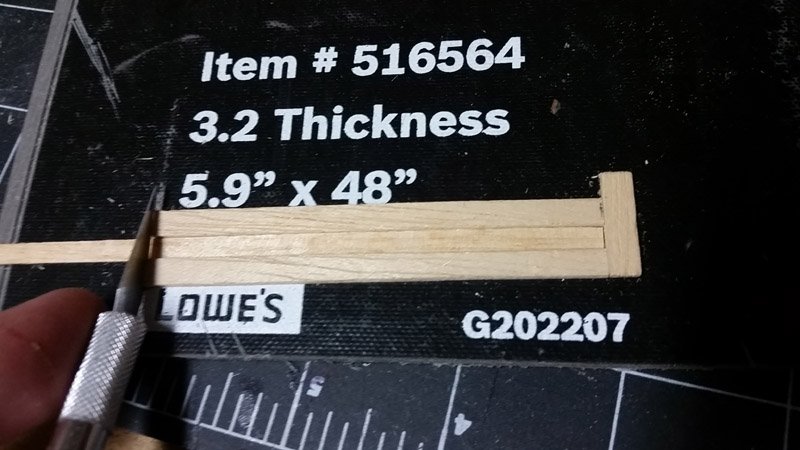

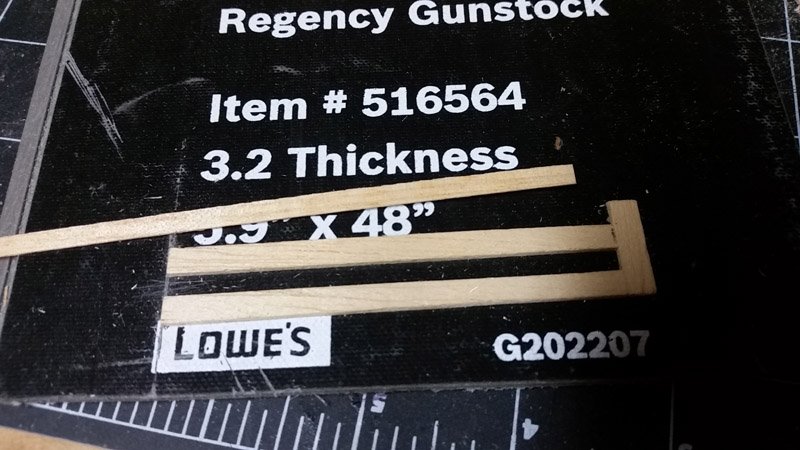

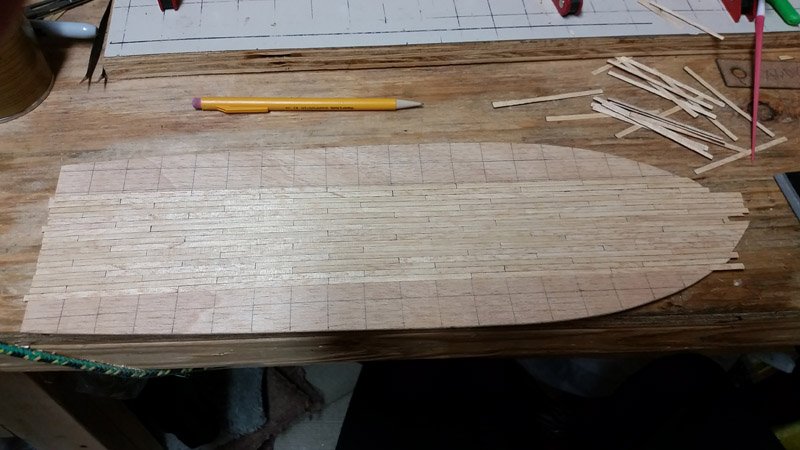

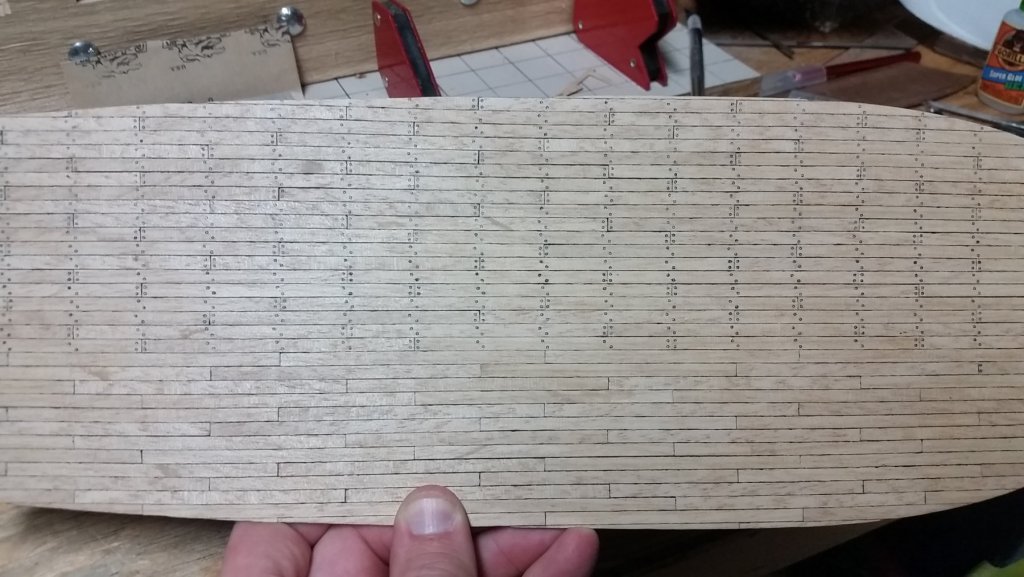

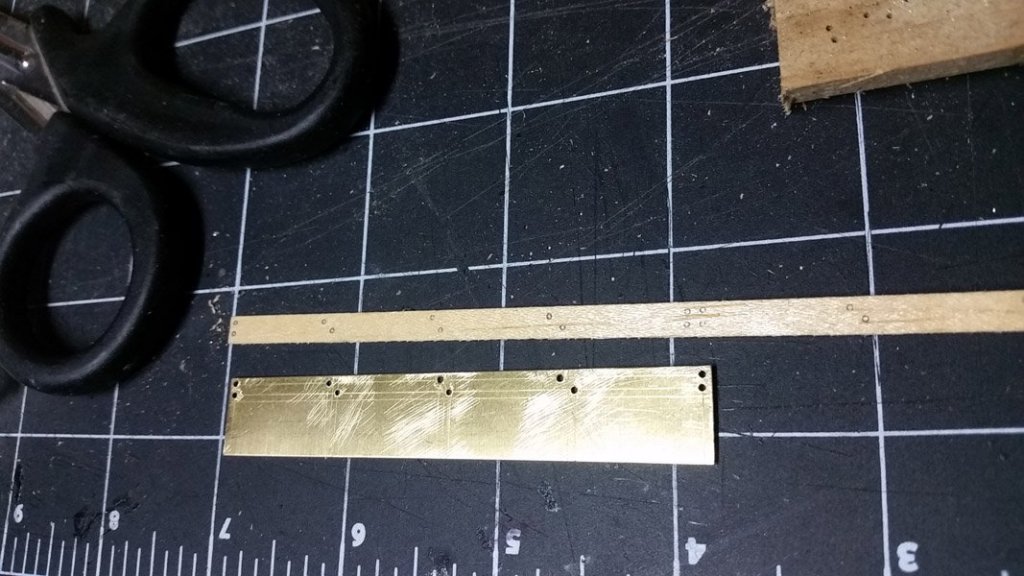

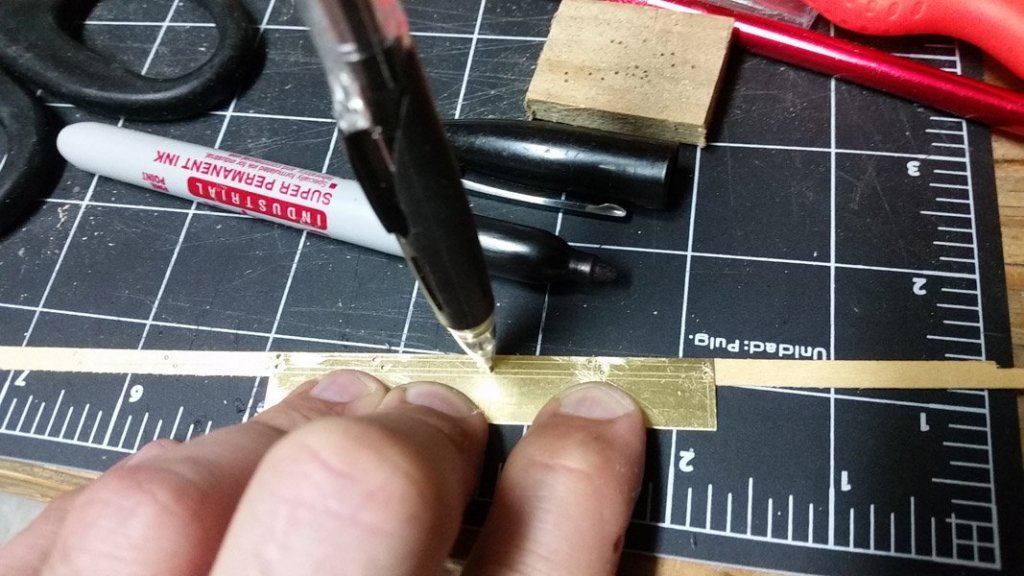

A pic of the final version of my drilling template. I would draw a line across the deck at the butt joints, then center the 4 hole pattern on that over a butt joint at opposite ends of the deck and drill. Then i'd draw two lines through all the holes. To drill the remaining holes i'd center the holes in the pattern over these lines, then center the plank edge under the reference holes, hold down and drill. I tried tracing out lines and drilling free hand, but even after starting with a sharp point i found the template to be quicker and more consistent. I started toothpicking with bamboo. First area confirms i got exactly the effect i was going for. Very subtle but noticeable at the same time.

-

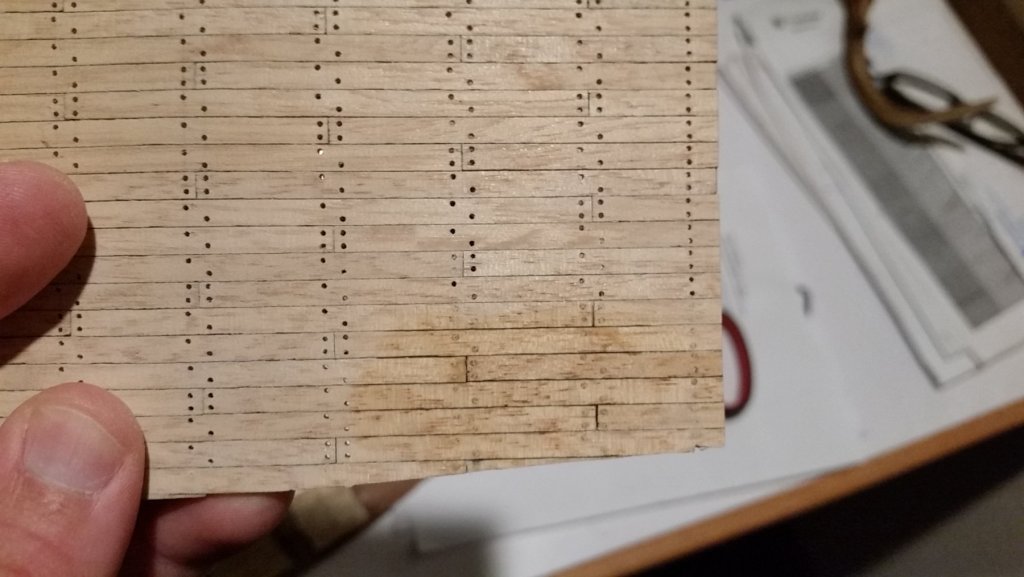

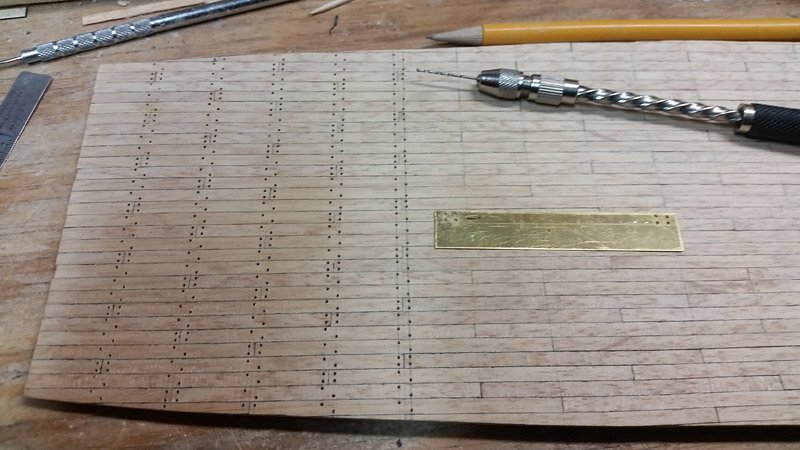

A sports injury wrecked my shoulder so ive not been able to work for some time. I finally got all the holes on the main deck done. Will start plugging them soon. The templates i was using for drilling my holes were of very thin brass. As I used them for drill guides, the bit would ovee time enlarge the holes in the template. I replaced it a couple times before finally using some much thicker brass. Getting the holes lined up and drilled in the thicker brass was a challenge in its own right but finally got it done. Then i immediately made a duplicate to use as a master if i need to redrill another. Another thing i did with the new template was to include holes for referencing it. All i need to do now is line up the plank edge seems under the holes on both ends and i know its centered properly.

-

Been getting some work in. Not much progress, but up to about 1000 holes. Admiral was giving me some fresh orders while i was drilling, and i accidentally made a 4 pattern where there should have been a two pattern (after this pic was taken). Oops. Going to leave it as is and hope i can cover it with a cannon or something. As subtle as the nails will be i doubt it will be noticed by anyone but me. Tried lining off and freehanding the holes, but i find my brass strip templates to be quicker and more accurate. I drill two four patterns at butt joints on far ends of the deck then line through the holes. Then just center the lines under the holes of my template. Problem is the holes wear larger as i drill and i need to keep making new templates. Got some thicker brass to use hoping it will be more durable. If i can drill through it that is.

-

Will be watching closely. I have this kit in the closet and hope to get to it sometime in the next year or two. Great work so far as always.

- 75 replies

-

- constitution

- mamoli

-

(and 2 more)

Tagged with:

-

Thanks all. I've already sanded them out and started drilling holes. I didn't like the pattern either. I had some sloppiness in the template I made for making them. I did a poor job of getting my holes dead center on my layout lines. What I did this time, I drilled a hole in one sheet of brass, then centered that hole over the bottom sheet of brass with the marks on it. centered the hole on the cross mark, clamped in position, and used the top sheet as basically a drill bit holder to keep the bit from walking and removing an inaccurate punch process. Looking back at some pics I took last year of the Constellation down in Baltimore, I'm going to try to mimic it as much as possible. I already started some tests with drilling and toothpicks, and didn't mind the process as much as I thought I would. The white wood toothpicks I have seem a hair dark for my tastes once the poly soaks in. I have some bamboo ones coming that I will compare on a mockup to make my final decision. In the mean time i'll keep drilling holes. This is my goal. and as for stripehunter, you guessed it. Andy

-

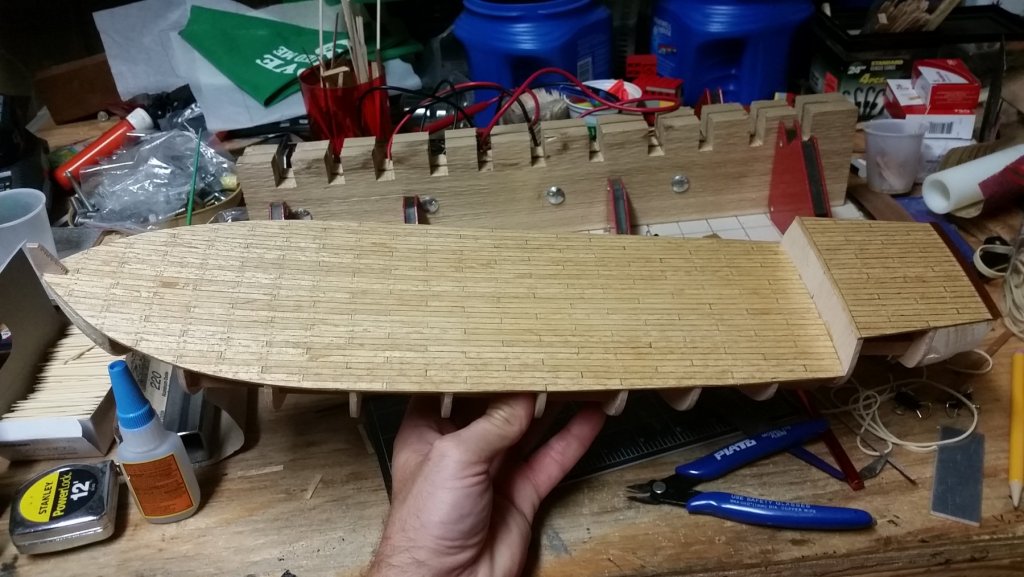

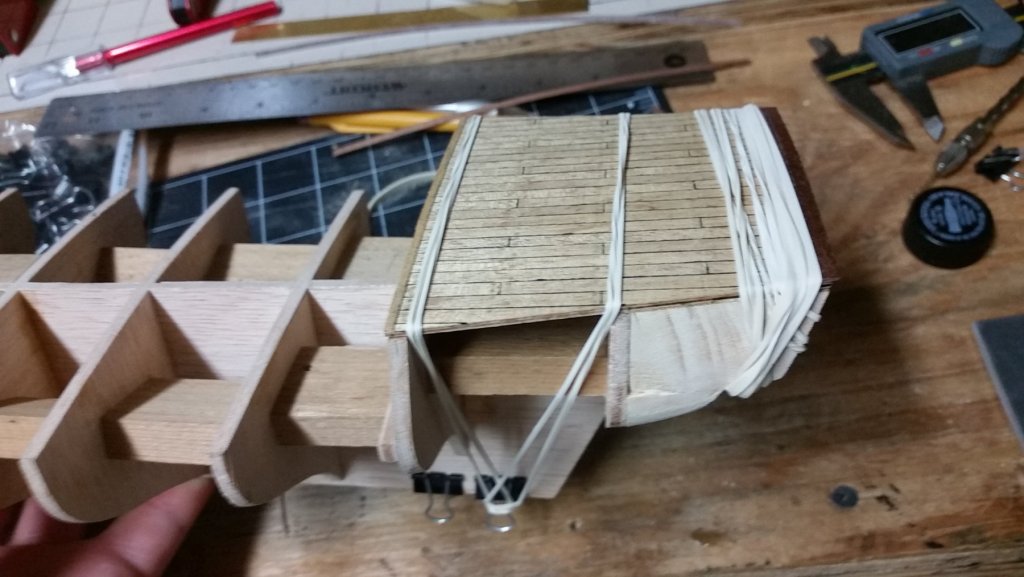

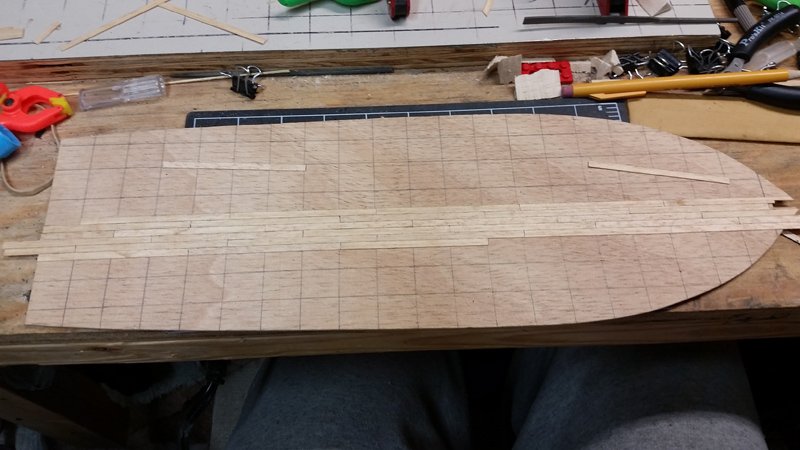

Life has kept me from doing much work for some time. Ive been working on my deck planking. I have some more log photos to post as time permits. In the meantime though im looking for opinions on my simulated trenails. Im thinking i dont like the results so much. Not as subtle as id hoped. Im seriously contemplating sanding them out and trying something else. Thoughts please?

-

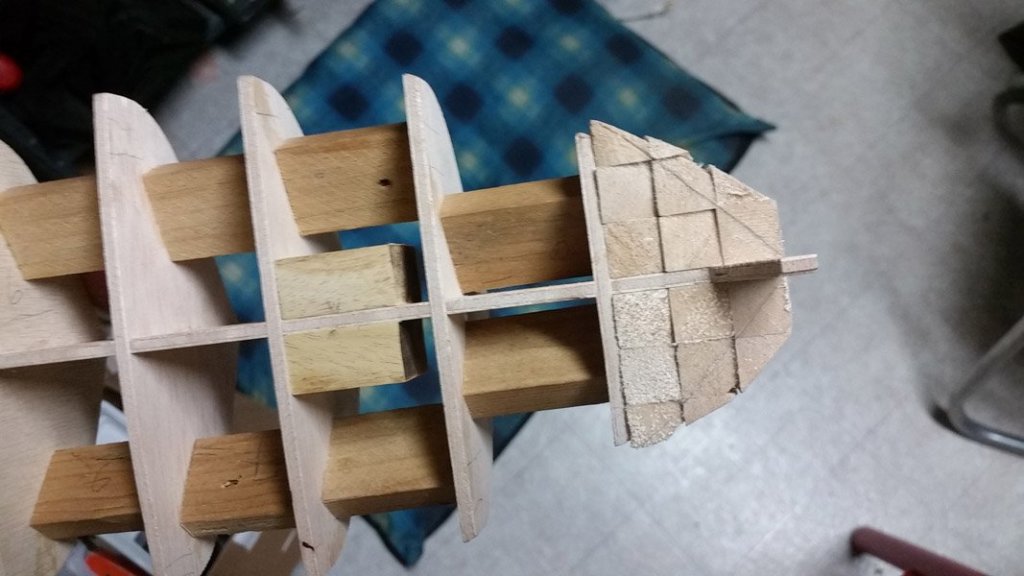

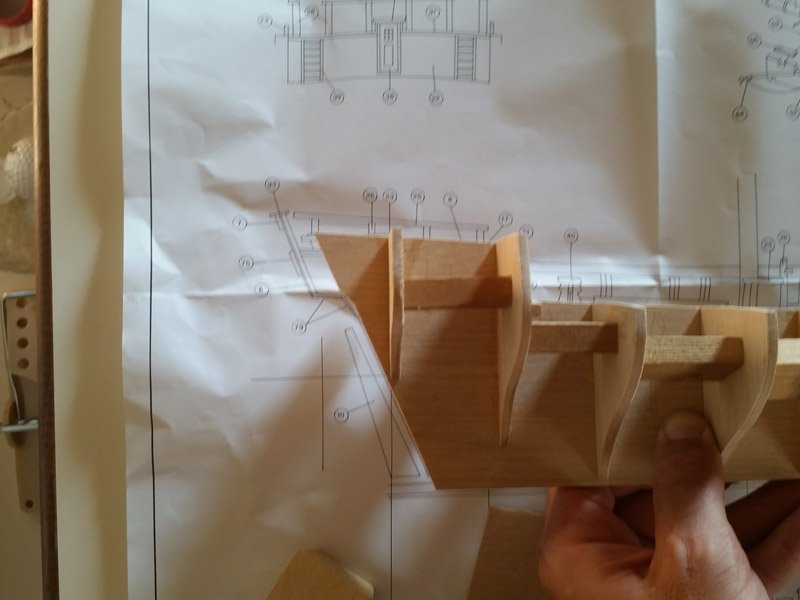

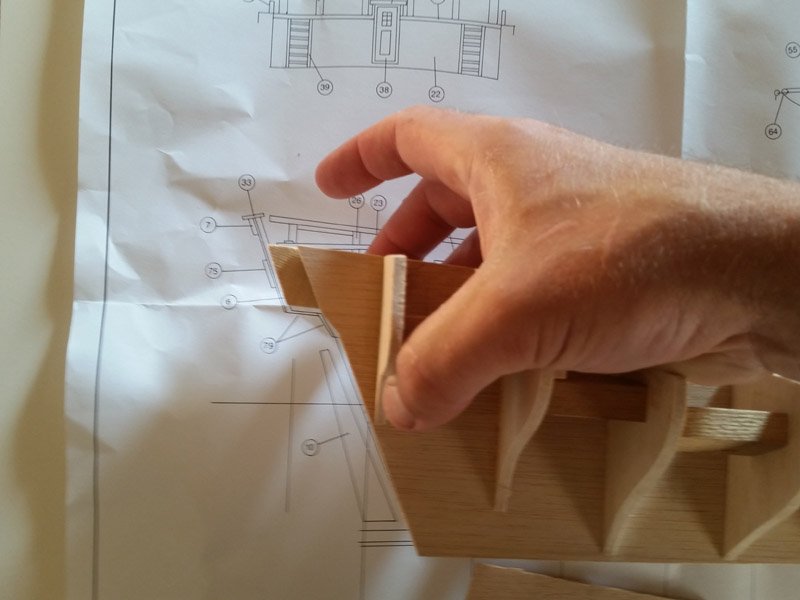

encountered my first oddity with the kit when starting to work on my bow and stern fillers. The upper deck extends way beyond the back of the keelson, as do the filler blocks provided. I compared all to the scale drawing, and it looks like the stern filler blocks are the desired dimension to use. The plywood keelson is cut out way too short in the stern. Once I made that decision, I started shaping and gluing bow and stern filler blocks. Still have much work to go on that.

-

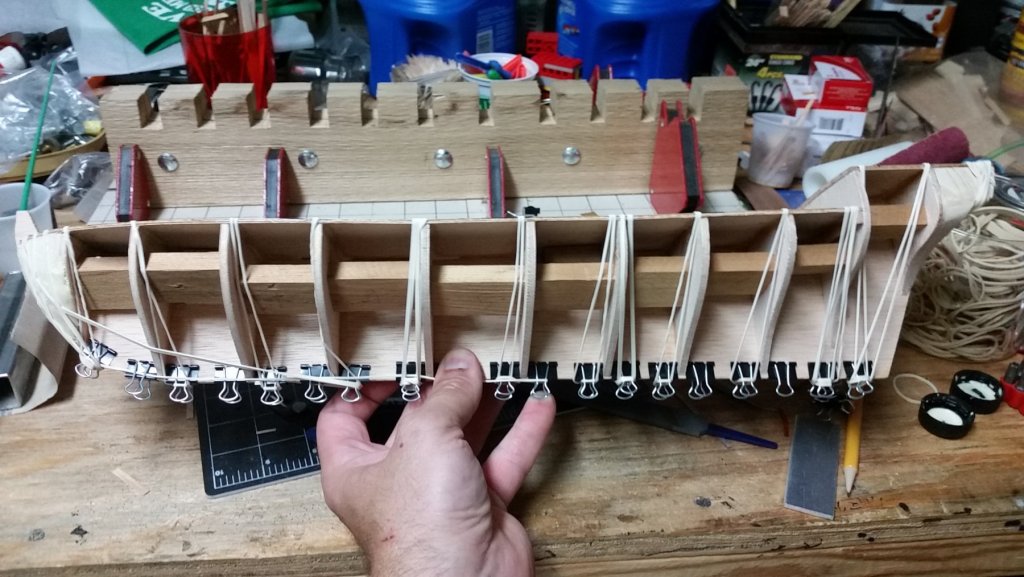

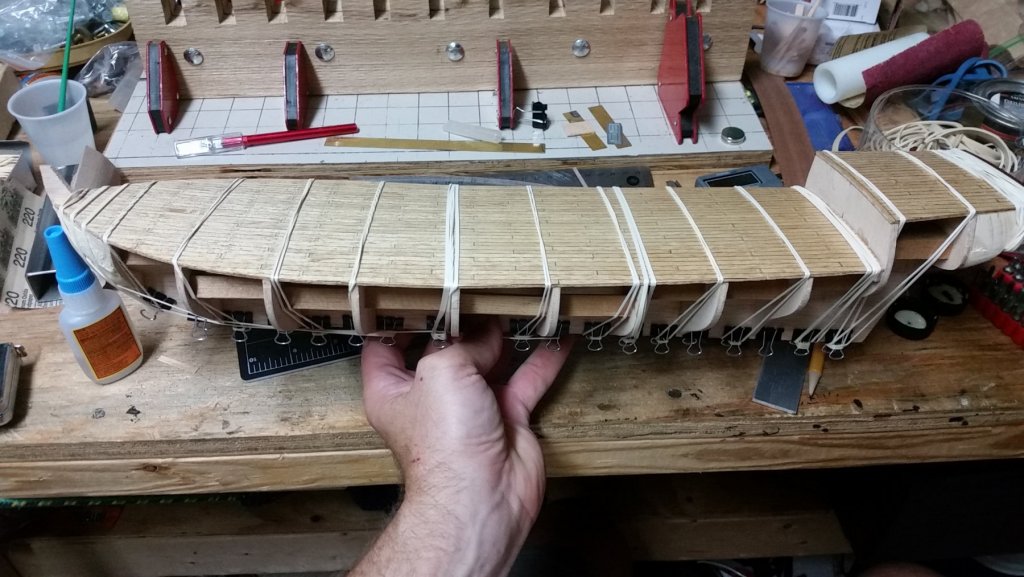

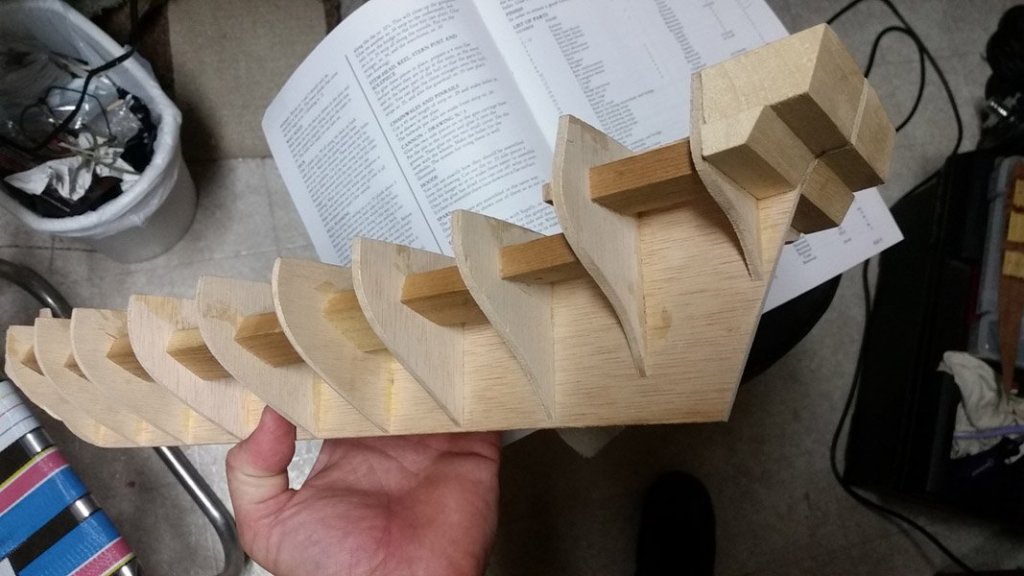

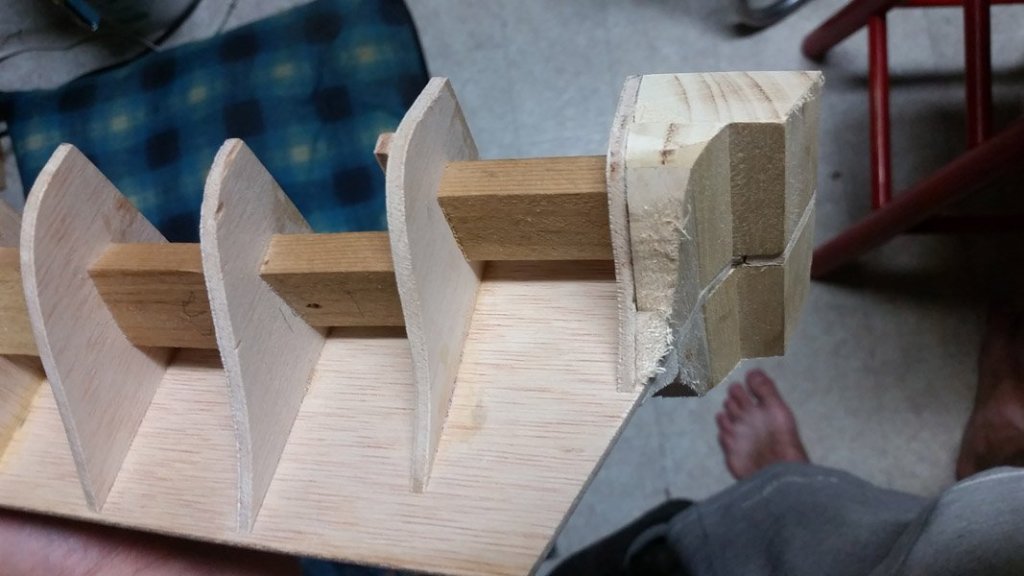

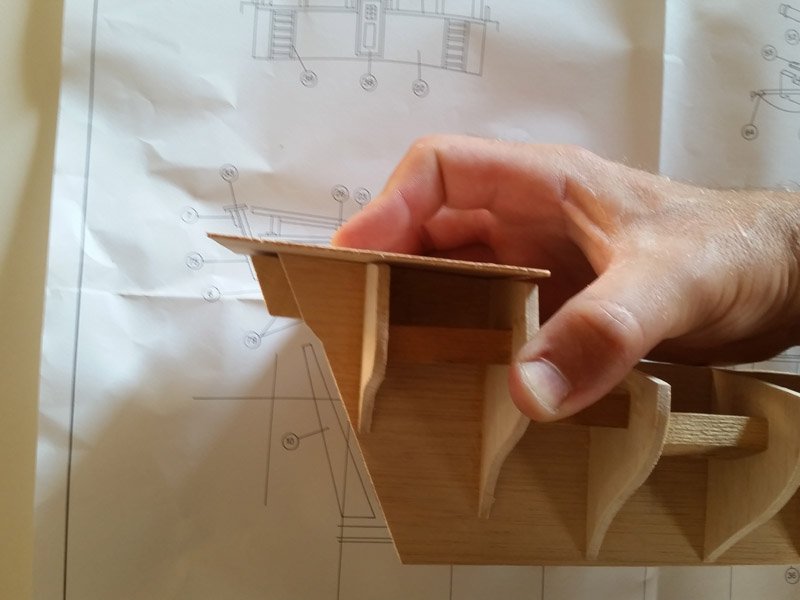

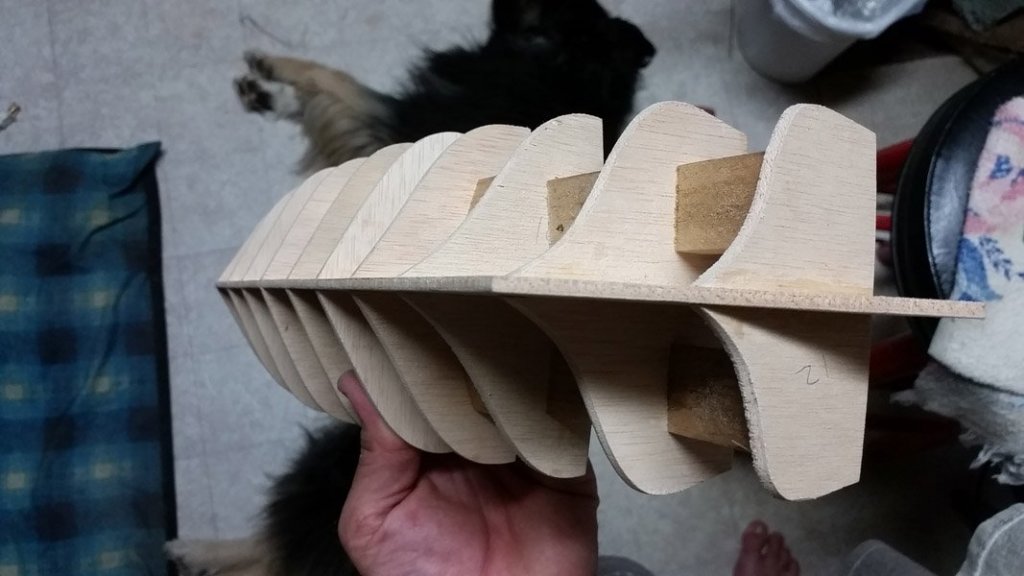

Somewhere along the way my frame picked up a slight warp in it. Modified one of my clamps to allow the bulkheads to pass through, steamed the keelson and clamped up with a shim to straighten. This got most of the warp out, but still had a hair. So I decided to put back in the clamp, and cut/fit strengthening blocks between each bulkhead. This locked everything dead on straight, and the frame is rock solid strong as well. Will definitely do this again. Took a lot of sanding to get the perfect fit on each block but well worth the effort. I'm planning on simulating trenails on the deck using a sort of a stamping technique with a pencil tip touched to a marker and rotated to make a small circle. I made a jig that should help me do this consistently. We'll see how it goes. I like the look, not sure how the logistics will work out though. test plank is wider than the deck planks will be so proportions look a bit off.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.