MikeR

Members-

Posts

149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MikeR

-

Hi Rick I purchased a 4 oz.bottle of Liver of Sulphur Extended Life Gel from "The Contenti Company". I mix 1/4 teaspoon of liver of sulfur with 3 oz of hot water. After I clean the copper with acetone I dip the piece in the solution or use a paint brush. It does not rub off very easily. It works great on copper and not well on brass. Mike R

-

Nick What are you using to cut them out? If you are using a scroll saw you can stack two layers of wood, I use double sided tape to join the layers and rubber cement the pattern to them. Cut it out and you will have two identical pieces. Mike R

-

Thukydides The R.A. Library is the Royal Artillery Library. The information I used was from "The History of English Sea Ordnance" by Adrian B. Caruana and on page 185 it states that between 1782 and 1783 the design changed from trunnions to a carronade loop also called "joint" Which did away with the quoin and handspike for elevation the alternative was using a screw for elevation. Druxey That is the same book I used for information. The carronade that I made was a 24-pdr cast by Carron in 1779 Length 32 inches.

-

Here is my attempt to make a made up foremast, I glued up two 1" dogwood boards and turned the 1 1/2" mast. I then cut a 3/4" piece off the mast. To this I used rubber cement to glue a pattern of the mast pieces i wanted to cut out. On my scroll saw I used a 2/0 blade (.0087 X .0236) to cut the pieces of the made mast. With this size blade I can cut sharp 90 deg. angles. I then cut these pieces to different lengths and glued them up and attached it to the mast. The top copper band hides the seam. I also added the mast bands, front fish, and rope woolding. Mike R

-

Carronades by Adrian B. Caruana "The History of English Sea Ordnance" The main reason for carronades mounted on the outboard principle is doubtless that throughout the American War and for most of the Revolutionary War the normal emplacement for carronades was on the forecastle, gangways or quarterdeck, where they were mounted en barbette in ports with no lids. Anonymous drawings probably dating from the 1790's of a joint carronade mounted on the outboard principle, with all its fittings (R.A. Library) I will be using cherry, dogwood, ebony, and ipe. For the carronade I will turn it from 1" brass stock on my wood lathe, but first I turned one out of wood for practice.

-

My very first scratch build wooden model was the Iron Horse Locomotive and Wagon. I built this in the 1990's. The plans for this were advertized in the back of several magazines. For the locomotive and cars I used walnut, dogwood, padauk, and purple heart. For the trestle bridge I used redwood, maple and walnut. This was G scale or about 1 : 24. Mike R

-

I had a lot of fun building this model. This model will be displayed with one of my half complete models when it is done, the HMS Pallas, which is in the back ground of the next few pictures. Mike R

- 11 replies

-

- Pallas

- 12-pdr gun

-

(and 1 more)

Tagged with:

-

Allan I am from western PA. so our summer temperatures were not to bad and our last few winters have been mild. Thanks, now I know how to measure barrel length. I have been thinking of another little project, a carronade, but I have not decided on a sliding carriage or one with wheels. Mike

- 11 replies

-

- Pallas

- 12-pdr gun

-

(and 1 more)

Tagged with:

-

Allan You asked if all the Armstrong pattern castings have a chase astragal and fillets between the muzzle astragal and the second reinforce ring and a button ring or were some cast without these? I don't Know. I found this pattern for the barrel on line and I scaled it down from 8 1/2 ft. to 7 1/2 ft. which is the length of the guns on the Pallas. I will be getting back to my Flying Fish soon. Summer time is a slow time for modeling, I will be working outside in the yard and garden. Mike R

- 11 replies

-

- Pallas

- 12-pdr gun

-

(and 1 more)

Tagged with:

-

Jared I used the same wire (.010") to pass through the eye bolts. I think it looks pretty close to scale. But my scale is 3/16 to1 not 1/8 to 1 Mike R

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Jared This is how I made the backstays for my Flying Fish. I used .010 wire which cut in about 1" lengths and bent the wire in half. For the holes in the yard I used a .6mm drill bit. Mike R

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

- 11 replies

-

- Pallas

- 12-pdr gun

-

(and 1 more)

Tagged with:

-

Hamilton It looks like you are doing a great job on the Bluenose, it is one of my favorite models. The three blocks you have fixed on the foremast I think are upside down. The hole for the rope should be on the top of the block closer to the mast so that the rope passes over the sheave. Mike

-

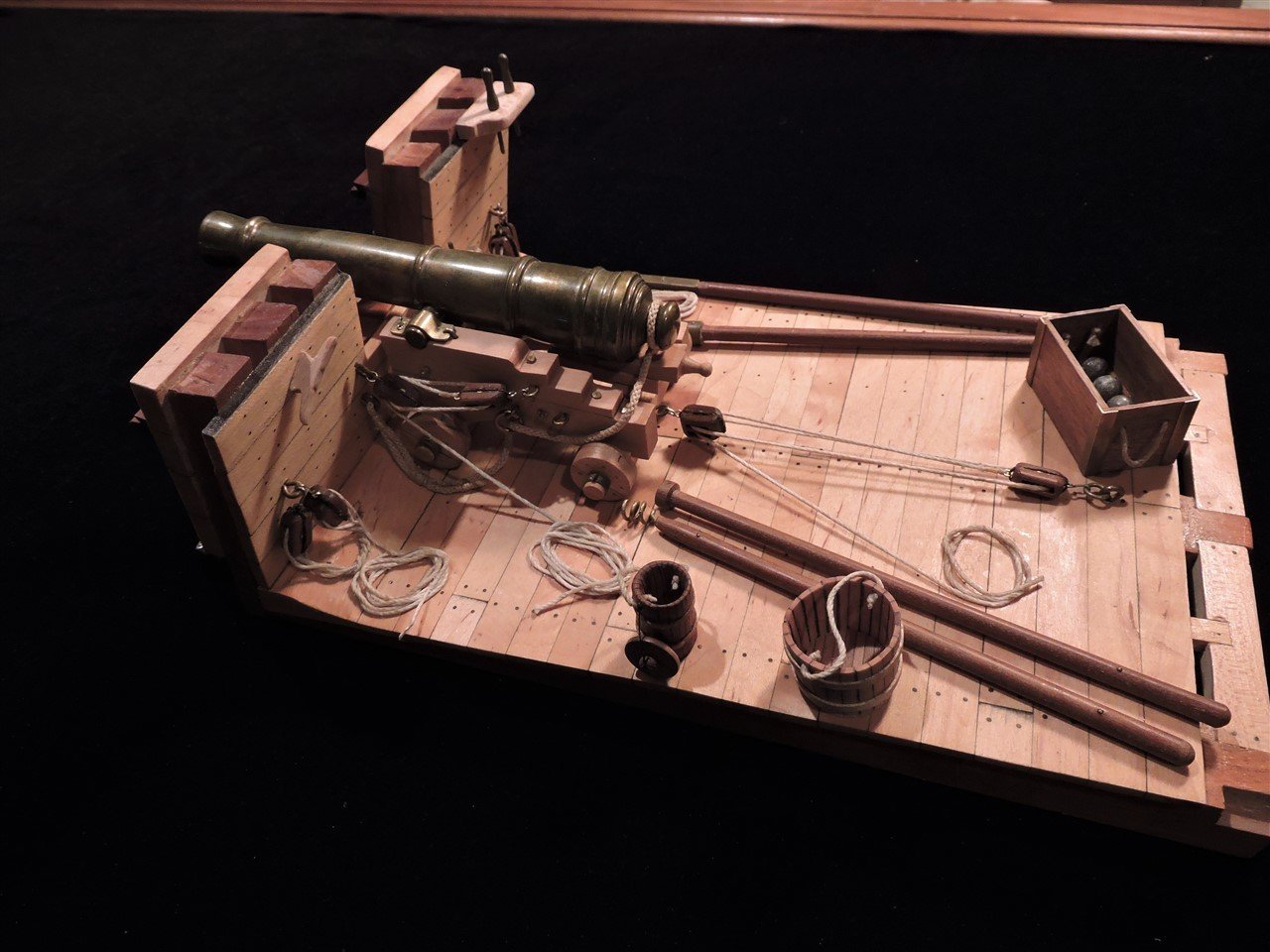

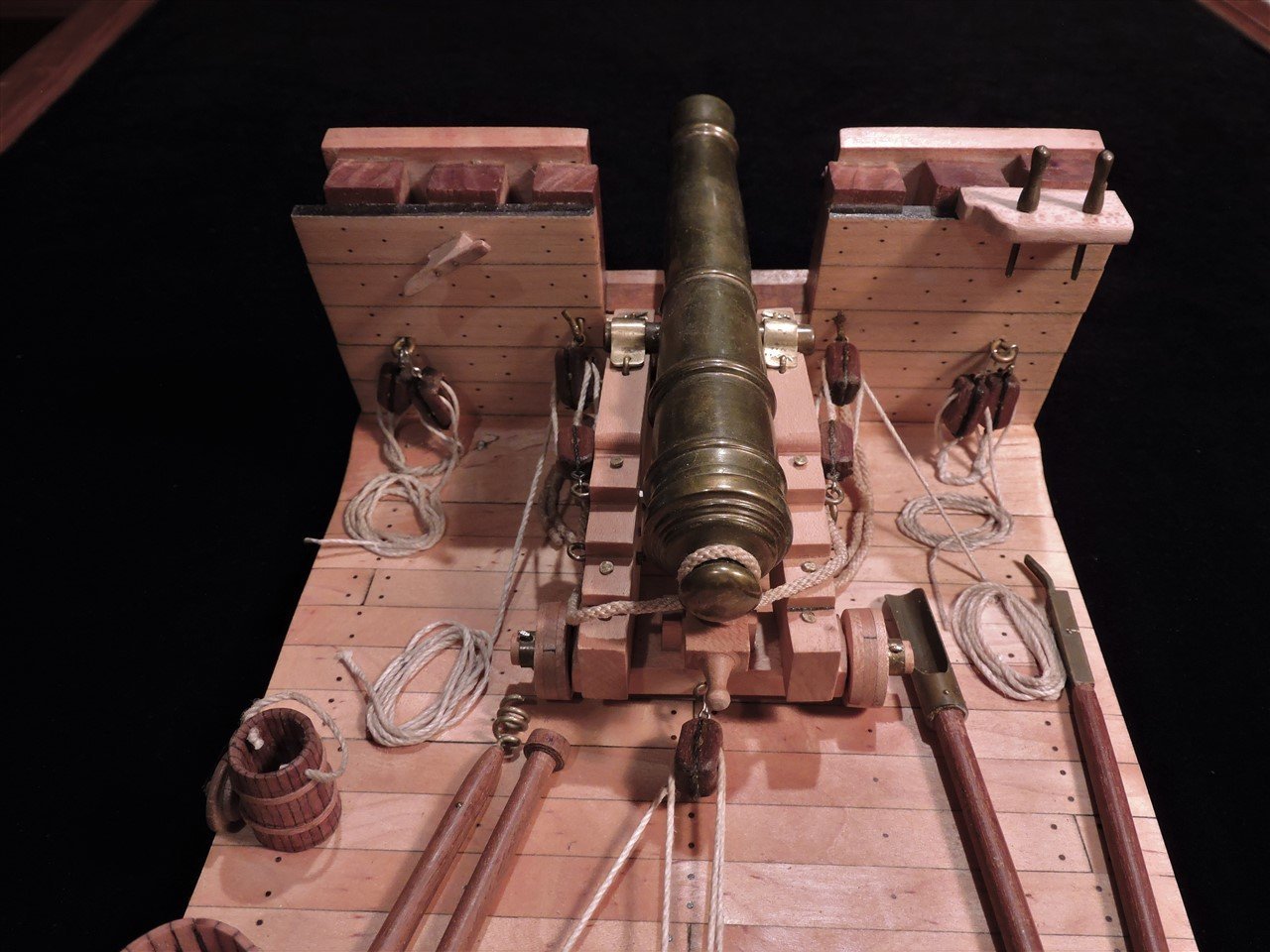

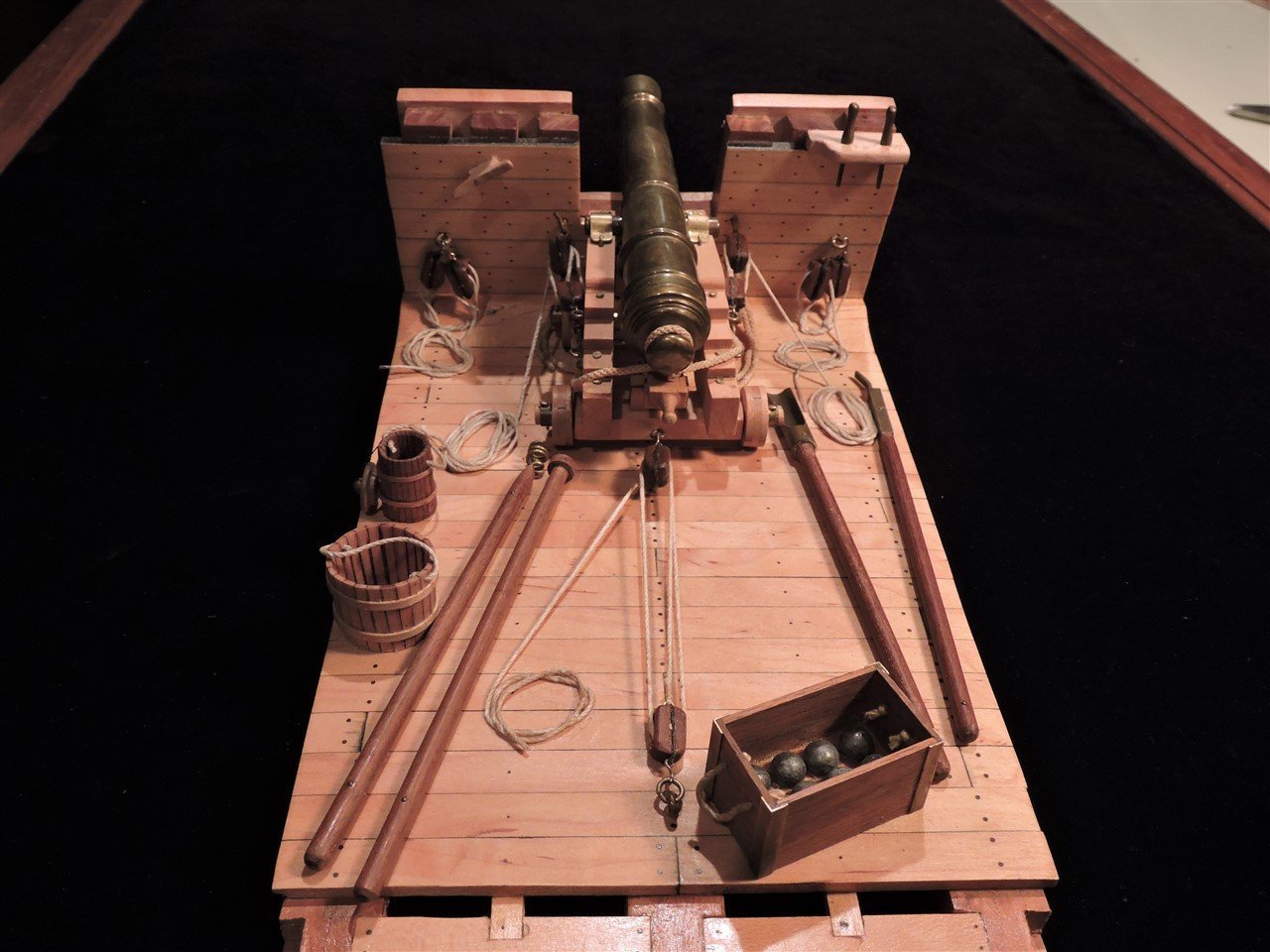

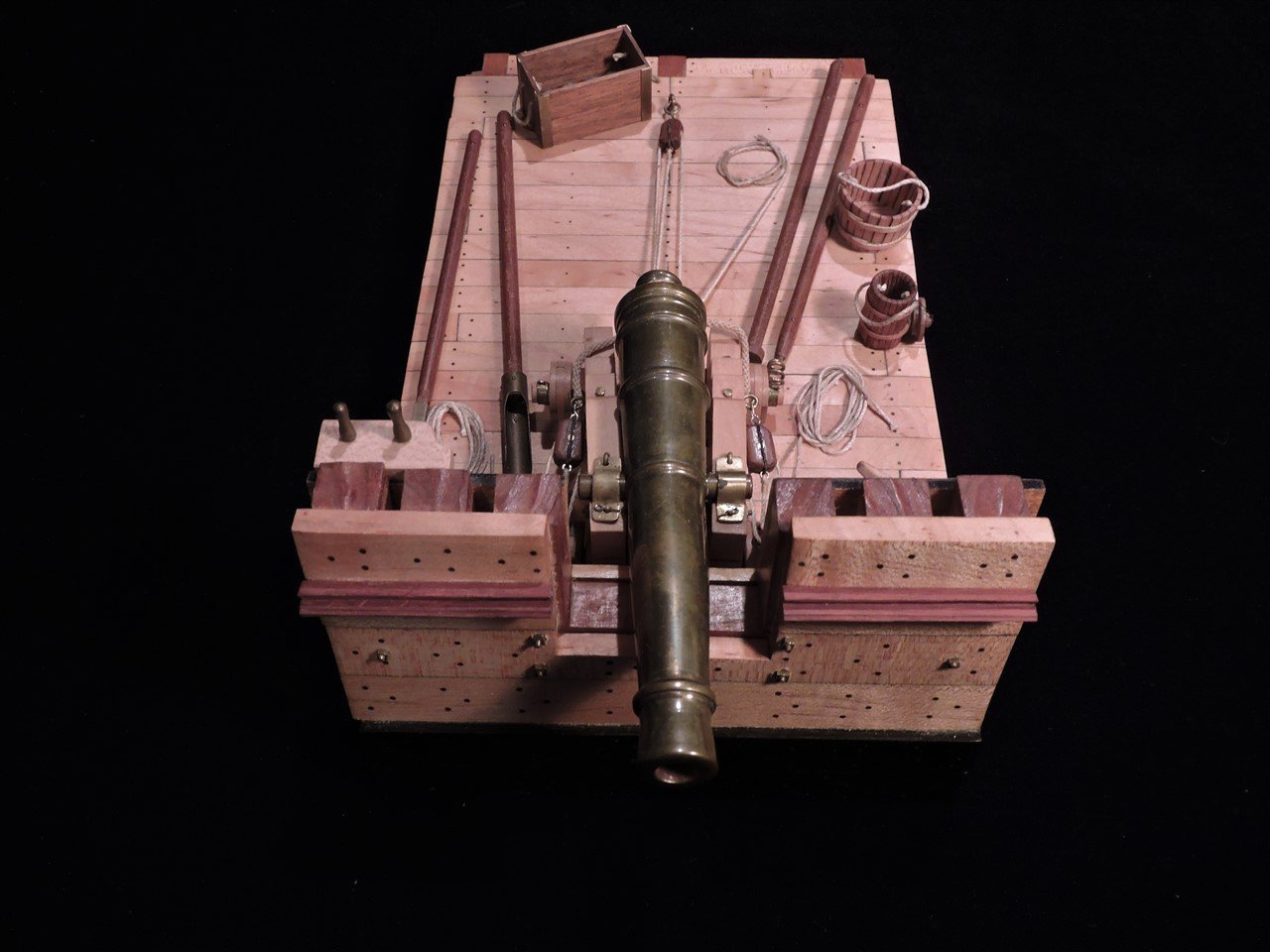

Chris It is not quite finished. I still have to make a couple of buckets, some block and tackles, and cut a couple of notches in the floor beams. Mike R

- 11 replies

-

- Pallas

- 12-pdr gun

-

(and 1 more)

Tagged with:

-

I took some time off from working on my model of the Flying Fish and built this model of a 12 pound cannon. This was something that I have been wanting to build for a long time. I used cherry for the frames and beams, dogwood for the planking and deck, ebony for the wales, and pink ivory wood for the molding. I made the blocks and gun tools out of ipe. The gun was turned on my wood lathe starting with 1" brass bar stock. The Venus class of 36-gun frigates were designed by Thomas Slade, in 1756, the Surveyor of the Navy and former Master Shipwright at Deptford Dockyard. Alongside their smaller cousin, the 32-gun Southampton class, the Venus-class represented an experiment in ship design; fast, medium-sized vessels capable of overhauling smaller craft and singlehandedly engaging enemy cruisers or privateers.[1] As a further innovation, Slade borrowed from contemporary French ship design by removing the lower deck gun ports and locating the ship's cannons solely on the upper deck. This permitted the carrying of heavier ordinance without the substantial increase in hull size which would otherwise have been required in order to keep the lower gun ports consistently above the waterline.[2] The lower deck was instead used for additional stores, enabling Venus-class frigates to remain at sea for longer periods without resupply.[3] Armament Pallas' principal armament was 26 iron-cast twelve-pound cannons, located along her upper deck. The guns were constructed with shorter barrels as traditional twelve-pound cannons were too long to fit within the frigate's narrow beam.[4] Each cannon weighed 28.5 long cwt (3,200 lb or 1,400 kg)[5] with a gun barrel length of 7 feet 6 inches (2.29 m) compared with their 8 feet 6 inches (2.59 m) equivalent in larger Royal Navy vessels.[4] The twelve-pound cannons were supported by ten six-pounder guns, eight on the quarterdeck and two on the forecastle, each weighing 16.5 long cwt (1,800 lb or 800 kg) with a barrel length of 6 feet (1.8 m).[2] Taken together, the twelve-pound and six-pound cannons provided a broadside weight of 189 pounds (86 kg).[6] She was also equipped with twelve 1⁄2-pound swivel guns for anti-personnel use.[5] These swivel guns were mounted in fixed positions on the quarterdeck and forecastle.[4]

- 11 replies

-

- Pallas

- 12-pdr gun

-

(and 1 more)

Tagged with:

-

Allan Several years ago 90% of the dogwood trees in my area died off. I cut down several trees in my yard and I have been using the wood for my models. It is a hardwood that cuts and sands and keeps sharp angles very nicely. It turns great in a lathe also. The color of the barrel is off do to the lighting. The bluenose deck above is the color of the dogwood. MikeR

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.