-

Posts

27 -

Joined

-

Last visited

-

Work station clutter

Corey replied to Senior ole salt's topic in Modeling tools and Workshop Equipment

I find when I'm about to take photos for my build log, which I try to do frequently, I tend to tidy my work space up a bit. I wouldn't want to give my fellow modelers the wrong impression and let them see just what a total slob I really am. Before, and believe me it has been much worse! After -

Corey reacted to a post in a topic:

The Kit-Basher's Guide To The Galaxy

Corey reacted to a post in a topic:

The Kit-Basher's Guide To The Galaxy

-

Corey reacted to a post in a topic:

HMS Victory by Seventynet - Caldercraft - Scale 1: 72 - first build

Corey reacted to a post in a topic:

HMS Victory by Seventynet - Caldercraft - Scale 1: 72 - first build

-

Wow Ian, I'm very impressed. First of all because of the model you chose for your first build and secondly for the beautiful work you're doing! All I can say is WOW! Corey

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Wow Brian, truly a work of art and a piece to be proud of. As I go through some of these build logs I can only hope that some day... Corey

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Hey Mark, Thanks for the tip. Yes, I'm using PVA glue and I'll try using alcohol the next time I screw up. I learn something new every time I'm on the site. I just discovered yesterday, while reading a build log, that I should be sanding the laser char off of each part. My model kit directions are in Russian so I'm missing all of those fine details and essentially assembling this model by the seat of my pants. I wish more people would chime in with suggestions and thoughts. I could sure use the help. Thanks again, Corey

-

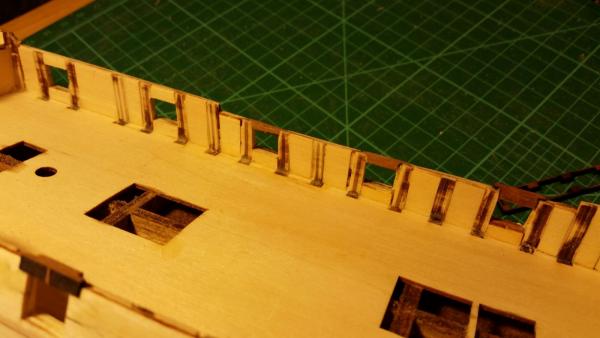

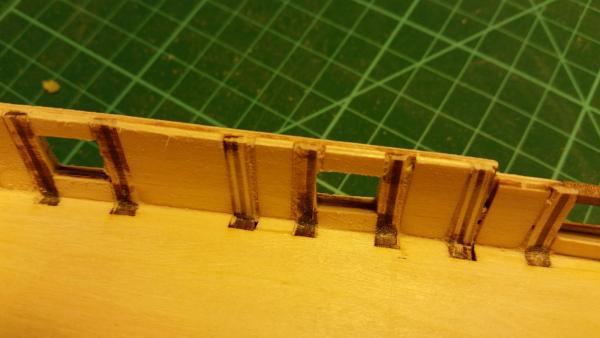

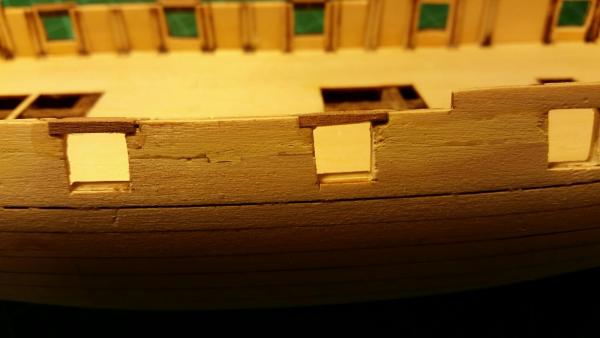

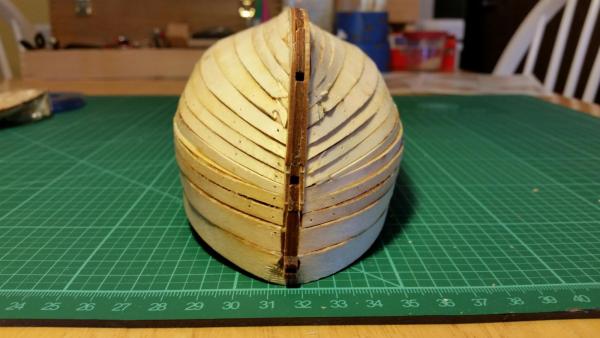

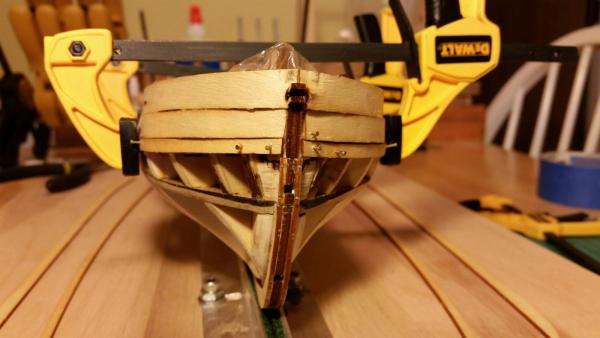

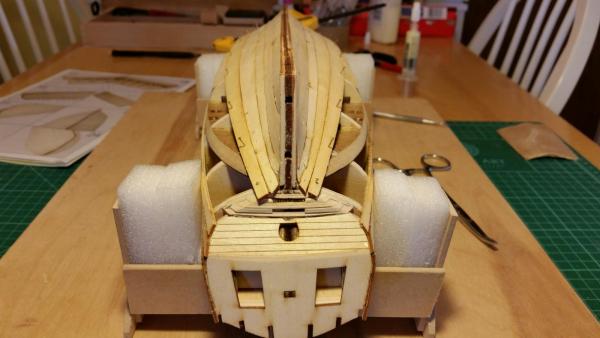

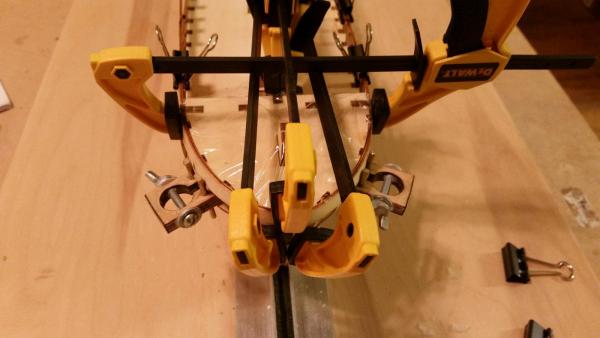

So far so good. I was on a work stretch so I haven't made a whole lot of progress on the model. I finished the stern portion, put in the sub-deck and started the base planking on the bulwarks. I don't have a plank bender and the planks that go on the bulwarks are plywood. I decided to steam the plywood planks which may not have been the best option because the outer layer tended to separate and wrinkle on the inside radius of the bend. Strategically placed clamps prevented this from becoming a major issue. Initially I formed the planks into the basic shape of the hull using clamps, allowed the planks to dry then glued and clamped them to the hull. I found it was easier to clamp the steamed planks directly to the hull to form them then glue them on when dry. Stern section complete Sub-deck added Preparing the keel for planking Forming the plywood planks Planks glued on and clamped Not too shabby at the bow

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.