-

Posts

236 -

Joined

-

Last visited

About Michiel

- Birthday 04/14/1978

Profile Information

-

Gender

Male

-

Location

Leuven, Belgium

-

Interests

besides modeling: playing classical music (Bassoon), Aikido, horse-riding, materials science, nano electronics, ...

-

prutser reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

prutser reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

Archi reacted to a post in a topic:

Prins Willem 1650 by Michiel - 1:50 - POB Zeeland ship from own plans

-

Baker reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

Baker reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

-

Baker reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

Baker reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

-

Ian_Grant reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

Ian_Grant reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

-

Michiel reacted to a post in a topic:

Wood Hull Screw Frigate USS Tennessee 1869 to 1886 by Keith Black - scale 1:120

Michiel reacted to a post in a topic:

Wood Hull Screw Frigate USS Tennessee 1869 to 1886 by Keith Black - scale 1:120

-

Michiel reacted to a post in a topic:

HMS Beagle by Michiel and Raphael - OcCre - 1:60

Michiel reacted to a post in a topic:

HMS Beagle by Michiel and Raphael - OcCre - 1:60

-

Mr Whippy reacted to a post in a topic:

HMS Beagle by Michiel and Raphael - OcCre - 1:60

Mr Whippy reacted to a post in a topic:

HMS Beagle by Michiel and Raphael - OcCre - 1:60

-

Cathead reacted to a post in a topic:

HMS Beagle by Michiel and Raphael - OcCre - 1:60

Cathead reacted to a post in a topic:

HMS Beagle by Michiel and Raphael - OcCre - 1:60

-

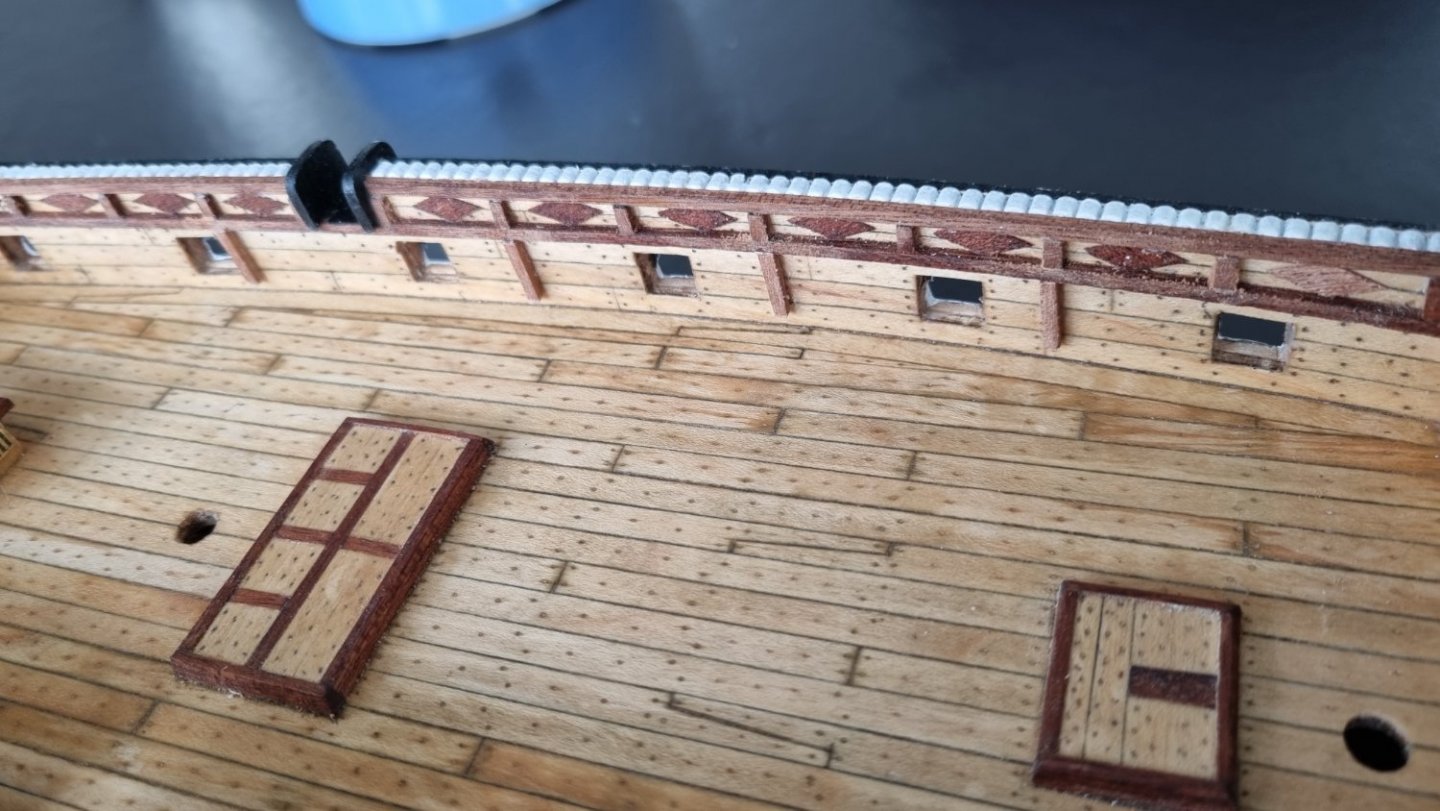

Cleaning done repairs started... put the window frames back in and the broken of deck parts, also the broken piece of deck is back in place next step is repairing broken masts:

- 6 replies

-

- Statenjacht

- Billing Boats

-

(and 1 more)

Tagged with:

-

Michiel reacted to a post in a topic:

1:60 H.M.S. Beagle - OcCre

Michiel reacted to a post in a topic:

1:60 H.M.S. Beagle - OcCre

-

Michiel reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Michiel reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Michiel reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

Michiel reacted to a post in a topic:

HMS Beagle by Patrick - OcCre - 1/60

-

Michiel reacted to a post in a topic:

HMS Diana by dunnock - FINISHED - Caldercraft - 1:64

Michiel reacted to a post in a topic:

HMS Diana by dunnock - FINISHED - Caldercraft - 1:64

-

Michiel reacted to a post in a topic:

HMS Flirt by Dfell - FINISHED - Vanguard Models - 1:64

Michiel reacted to a post in a topic:

HMS Flirt by Dfell - FINISHED - Vanguard Models - 1:64

-

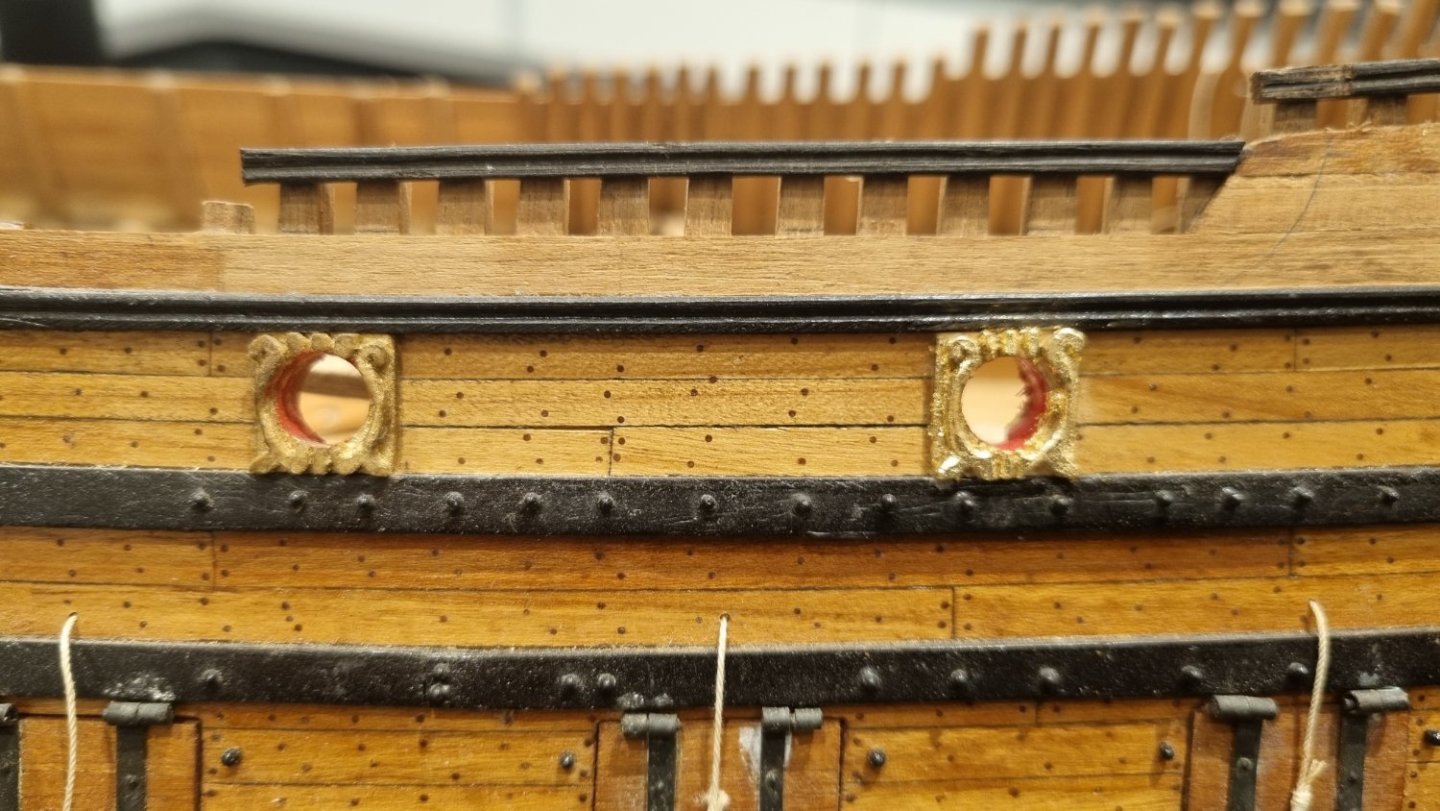

It's been a while... mostly because of the other projects. I started using gold leaf to redo the previously gold painted parts. I really like the effect. It is however hard to make pictures that realty do justice to the result. the left port is still in the original state the right one is in the new state.

-

Michiel reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

Michiel reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

-

so I carefully removed all the rigging, all the parts that came loses, and some very ugly previous repairs. Come to think of it those may have been done my an about 30 years less experienced me. After that I started cleaning. This really took several hours. The cotton swipes kept turning black. It sort of gave that feeling of those movies of professionals cleaning a discolored layer of varnish of an old painting. In the end, I think she is more or less clean and ready for the repair. fortunately it seems there is no structural damage. about 7 compound parts have come loose form the deck and sides. There are two part of the masts broken, and the anchors are broken and the broken of parts are missing. Also the decorative piece on port starboard side next to the stern is gone. The square pannel you can see in the picture below on the port side. I'll have to recarve that. I usually carve in a bit more detail so maybe the main challenge will be to stay in the style of this model.

- 6 replies

-

- Statenjacht

- Billing Boats

-

(and 1 more)

Tagged with:

-

Michiel reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

Michiel reacted to a post in a topic:

Statenjacht by Michiel - Billing Boats - 1:50 - RESTORATION - 1970 model

-

As you can imaging the chaos is complete. The following pictures are not for the faint hearted, but I promise it will become better from now on:

- 6 replies

-

- Statenjacht

- Billing Boats

-

(and 1 more)

Tagged with:

-

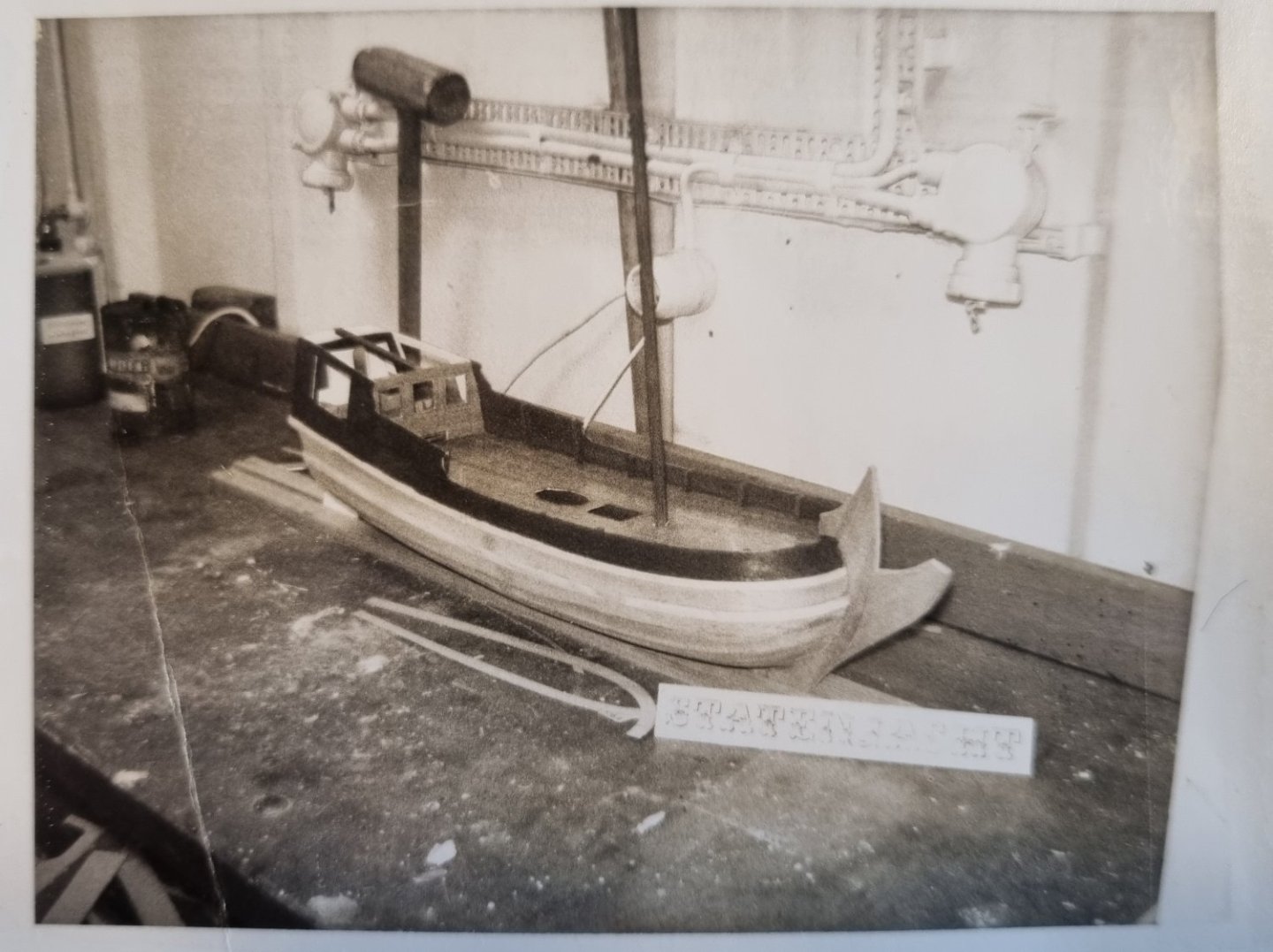

I recently came in possession of two models in certain states of, well, being. one is just in a early state of building, and has been in this state since as long as I can remember. At some point I'll start an other log when I come to finish this one. the other is also older then I am and used to hang in my parents home... until it came down. After the unfortunate event she ended up in the attic. After another unfortunate event about a month ago she is now in my workshop, and I hope to restore her to the state I remember. The original build took place around 1973 on board the ship my father was serving his apprenticeship on. With the two models also a pile of picture albums came in which found these two.

- 6 replies

-

- Statenjacht

- Billing Boats

-

(and 1 more)

Tagged with:

-

On my phone I have difficulties with adding text. Somehow this always adds lots of empty lines. So I now just dump pictures and skip the text. May add some later on a laptop. Anyhow, here's a few shots on the progress. assembled the main mast and a lot of small things on the deck. Also added some figures to make it more lively. That are Darwin and Fitzroy discussing the progress on the second picture... 😉

-

Michiel reacted to a post in a topic:

HMS Victory c.1765-1791 by Steve Anderson - FINISHED - 1:64 scale

Michiel reacted to a post in a topic:

HMS Victory c.1765-1791 by Steve Anderson - FINISHED - 1:64 scale

-

Hey Chimp, I agree, but then again what you get here for the price is actually quite a lot. I think the rope is not too bad. For my other build I also make my own, mainly to have it all to scale, and to have a orientation correct. In the other build I use pure cotton and a homemade device to turn the thread. There are pictures in the prins willem log if you like. I do agree it is quite fun. Here's a picture of the rope from my kit. so here I hooked up the digital microscope. the rope to the left is from the kit, the middle one from the picture above. The one to the right is my own. You can see the twist is wrong in the one from the kit. Indeed the one made from cotton is much cleaner than the kit one the sails are a bigger problem than the rope. I may replace those by something with a finer weave, like silk. my biggest complaint about the kit would be that many visible parts are made of plywood, which then needs to be painted. This I don't like at all. If I would suggest something to the supplier is to replace those two boards by solid wood.

-

Michiel started following HMS Beagle by Michiel and Raphael - OcCre - 1:60 , HMS Beagle by Dean77 - OcCre - 1:60 , HMS Beagle by Clementine - OcCre - 1:60 Scale and 2 others

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.65f6b76cfa11ead98867ae1c9a2d3f3d.jpg)