-

Posts

1,353 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

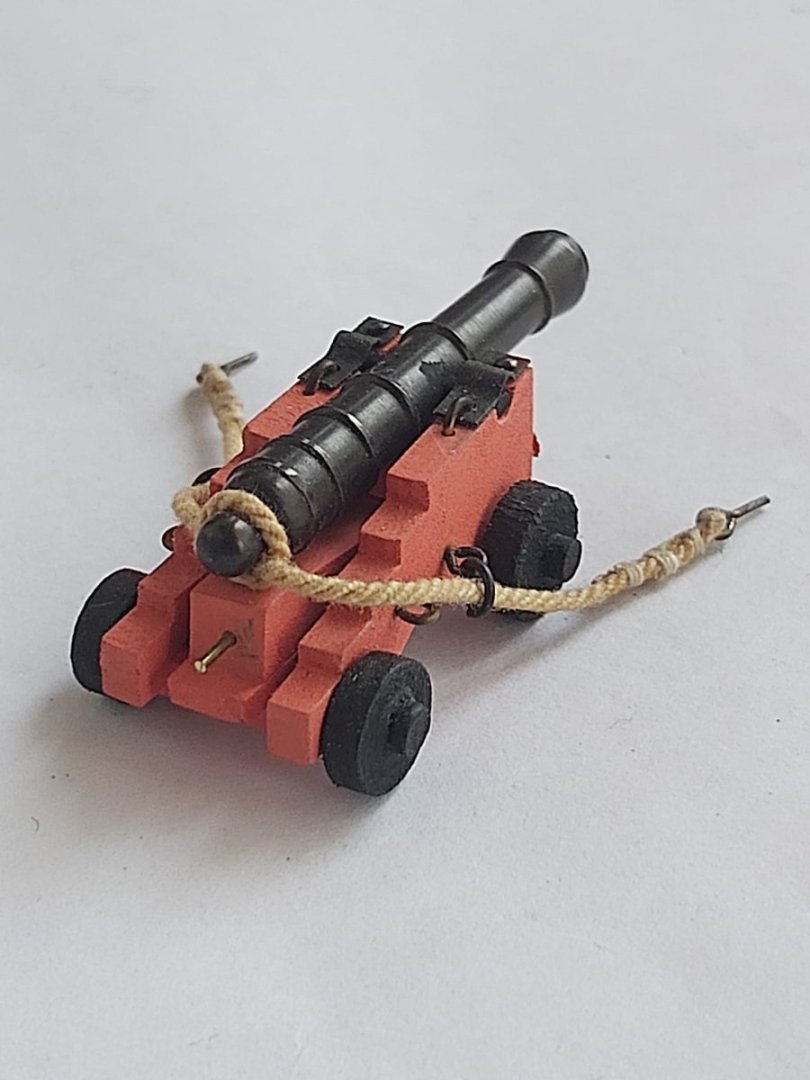

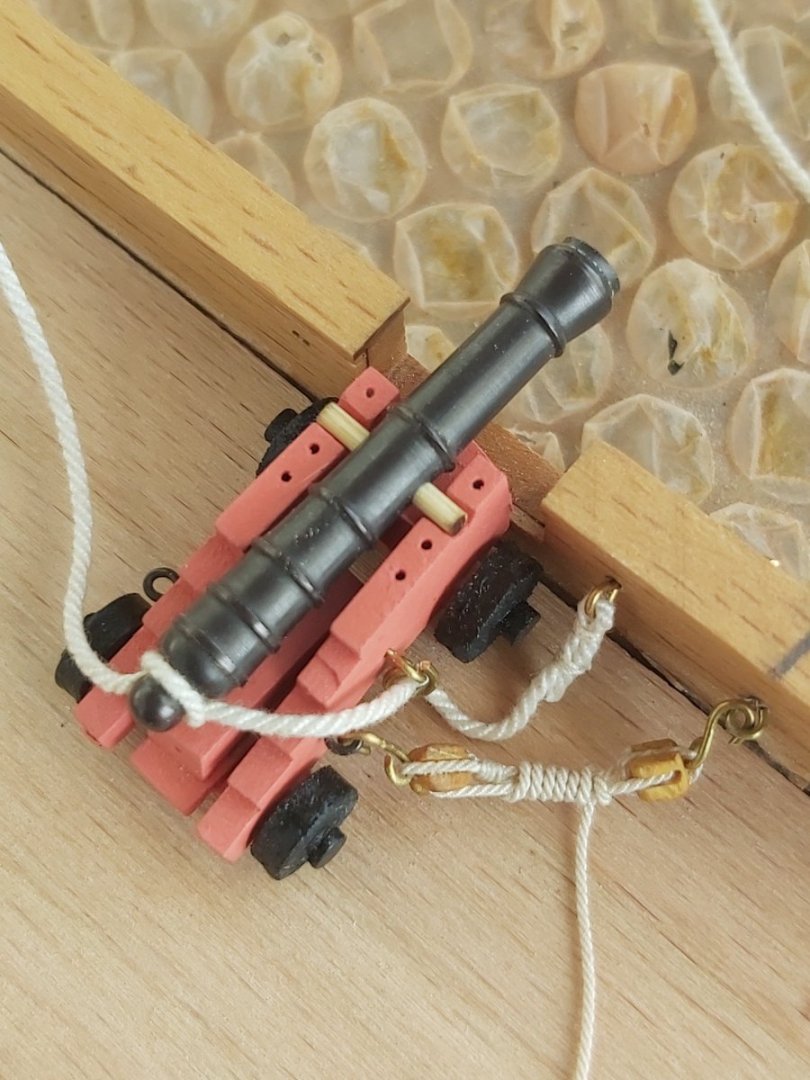

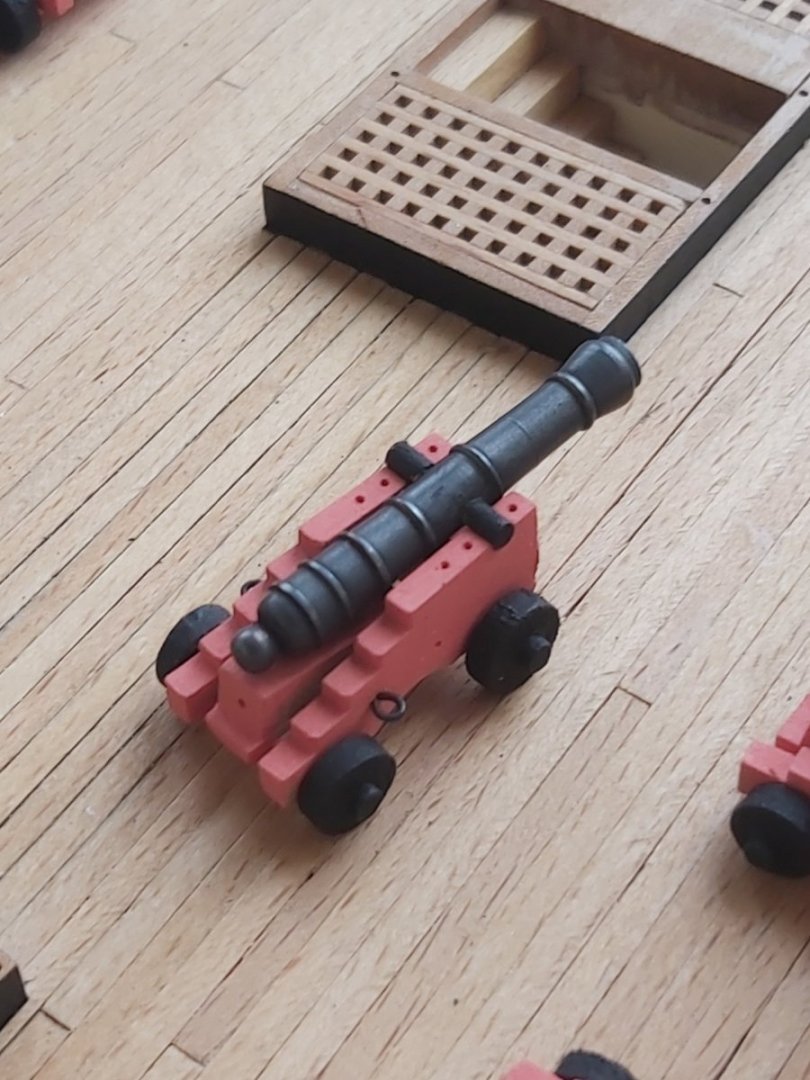

This is how the cannons on the gun deck will be seen in the end. Gun tackles will be added after the spar deck beam support knees are installed because gun tackle hooks will be attached to the eye bolts on the knees. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you for your interest Geoff. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USF Essex by mtbediz - FINISHED - 1:50

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1801 - 1850

Thank you so much. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Jon. It means a lot to me that this is coming from you. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

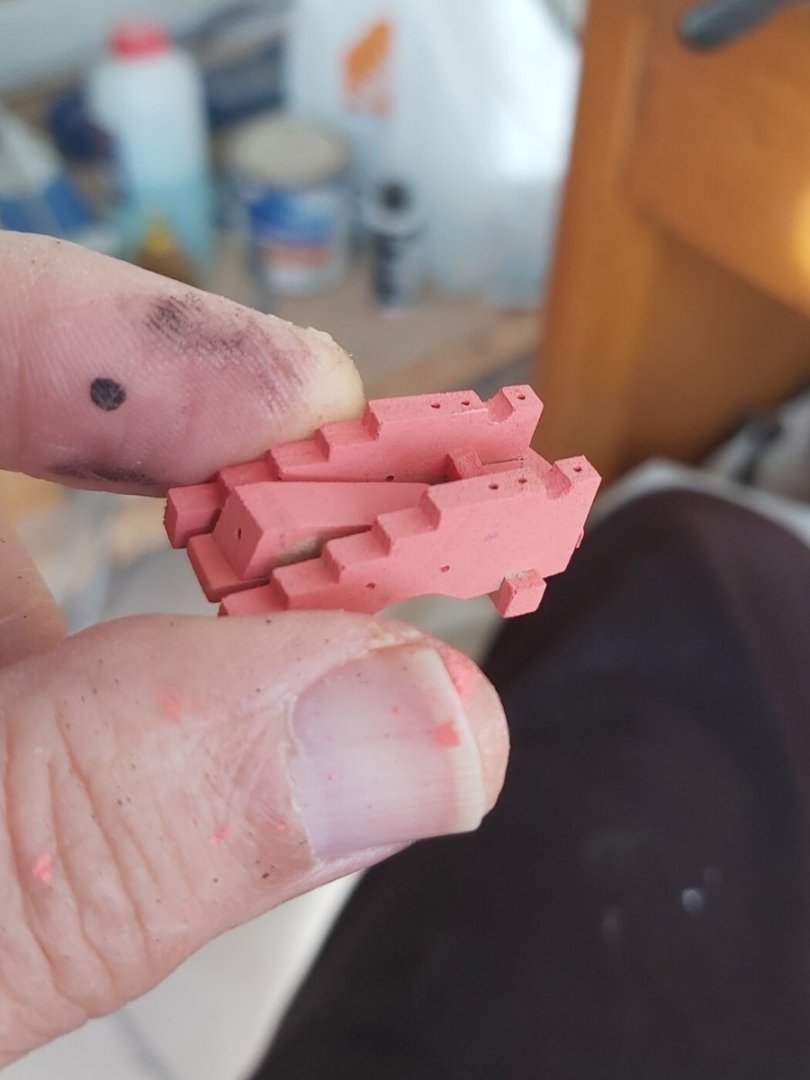

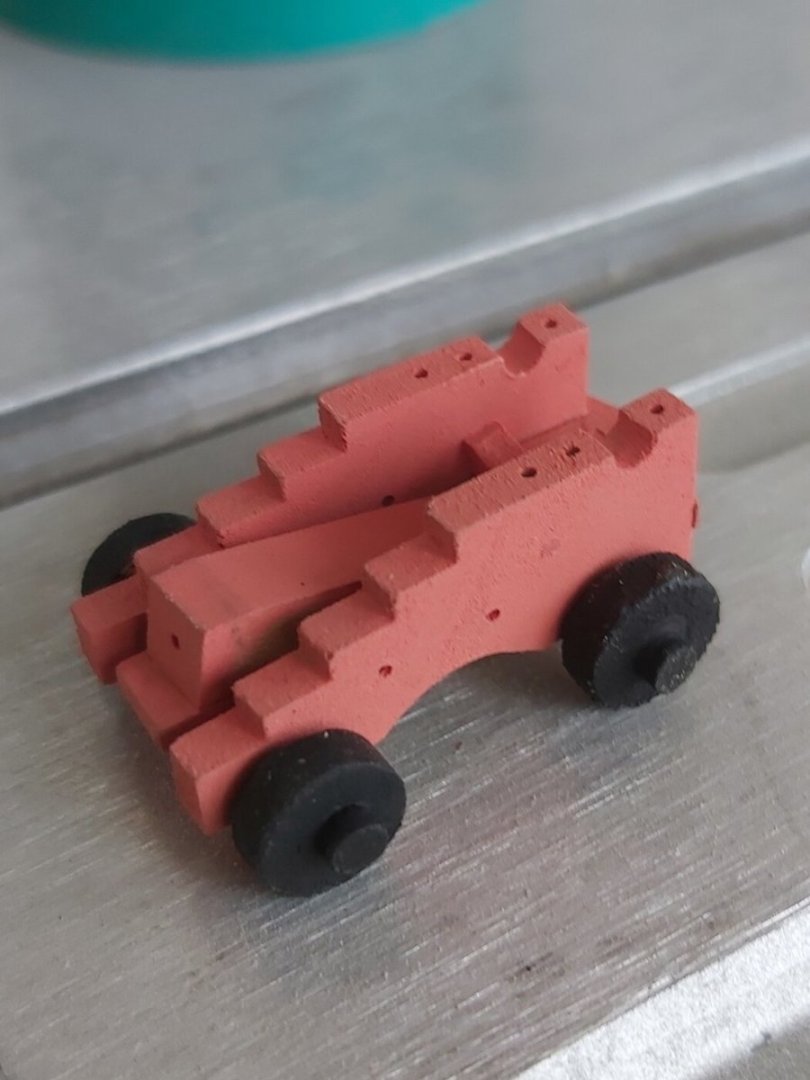

I have started painting of the gun carriages. I mixed red and yellow paints 50-50. Some friends may find the color of the carriages wrong (pinkish), but I tried to capture the color in the photos taken on the real ship. I think the paint on the carriages on the real ship has also faded over time or the photos taken may not reflect the real color. Despite everything, since these cannons will be under the spar deck anyway, the color will not stand out too much. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

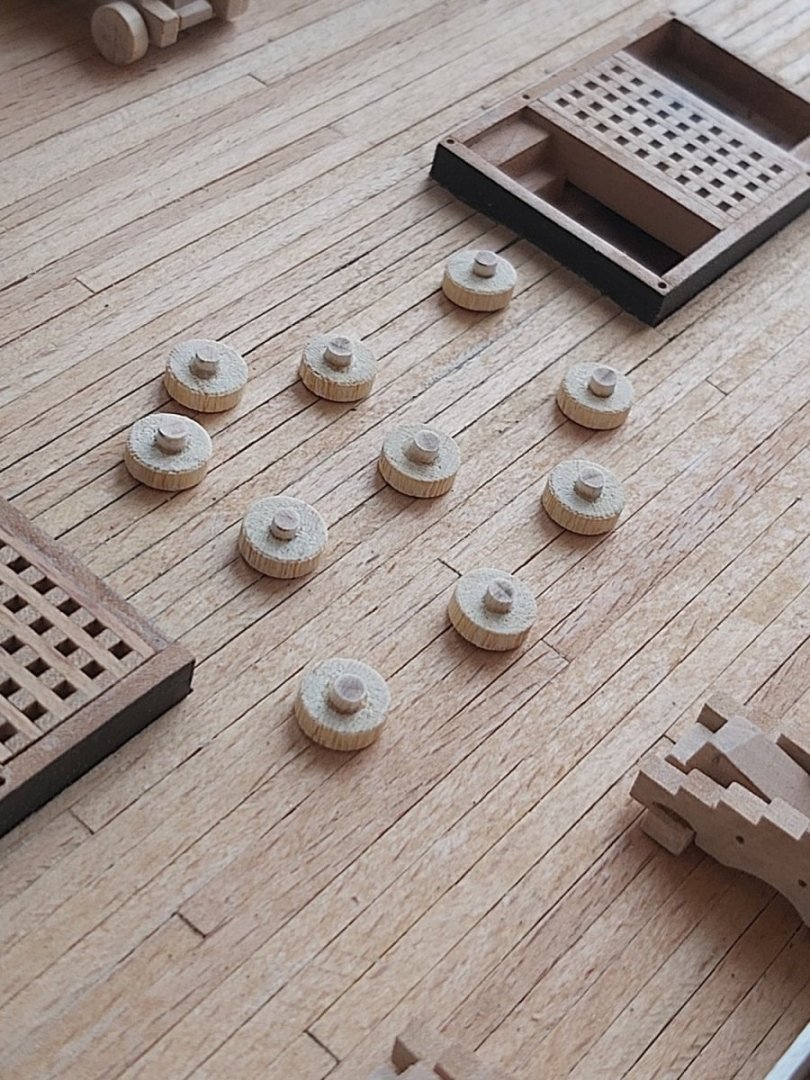

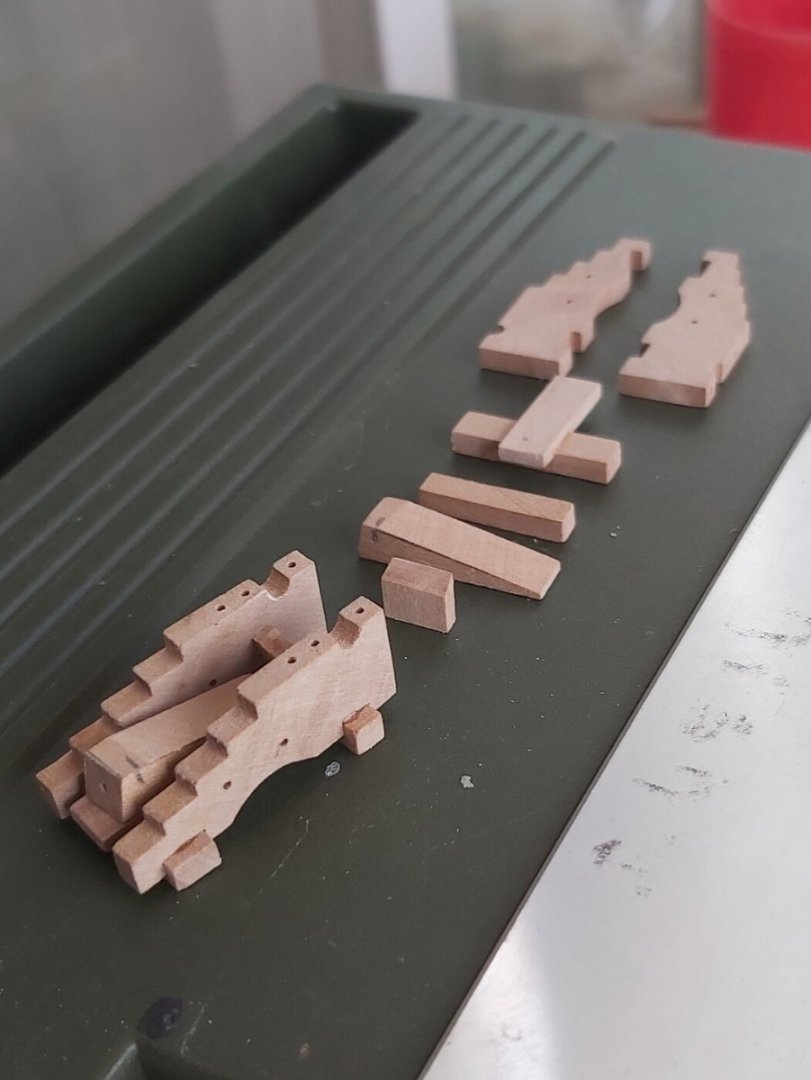

Thank you Greg. First, I cut the wheels from a dowel to the appropriate thickness with a table saw, then from a smaller dowel, I cut the pieces representing the axle extensions and glued them to the center of the wheels with CA. I glue these wheels I prepared to the carriage axles. Lazy job -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hello Phil, thank you for sharing your technique. Good technique and nice result. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks Greg. The micro mill is a tool that every modeler should have. Thanks to it, I can do many tasks faster and more accurately. I am using Proxxon MF70. An excellent machine, I recommend it. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks for the useful information Jon. I actually don't know the length of the original guns either. I just wanted the tip of the guns to be a little further out from the gun ports. Happy new year. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

The scale of my model is 1:76. Actually, I needed slightly larger cannons, but this is the closest cannon I could find in Turkey. It was possible to buy larger sizes abroad, but since it would cost me a lot, I decided to use them. The length of the cannon is 43 mm. -

La Palme by Tobias - 1:36 - POF

mtbediz replied to Tobias's topic in - Build logs for subjects built 1501 - 1750

Very nice nailing Tobias. Happy new year. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Greg -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

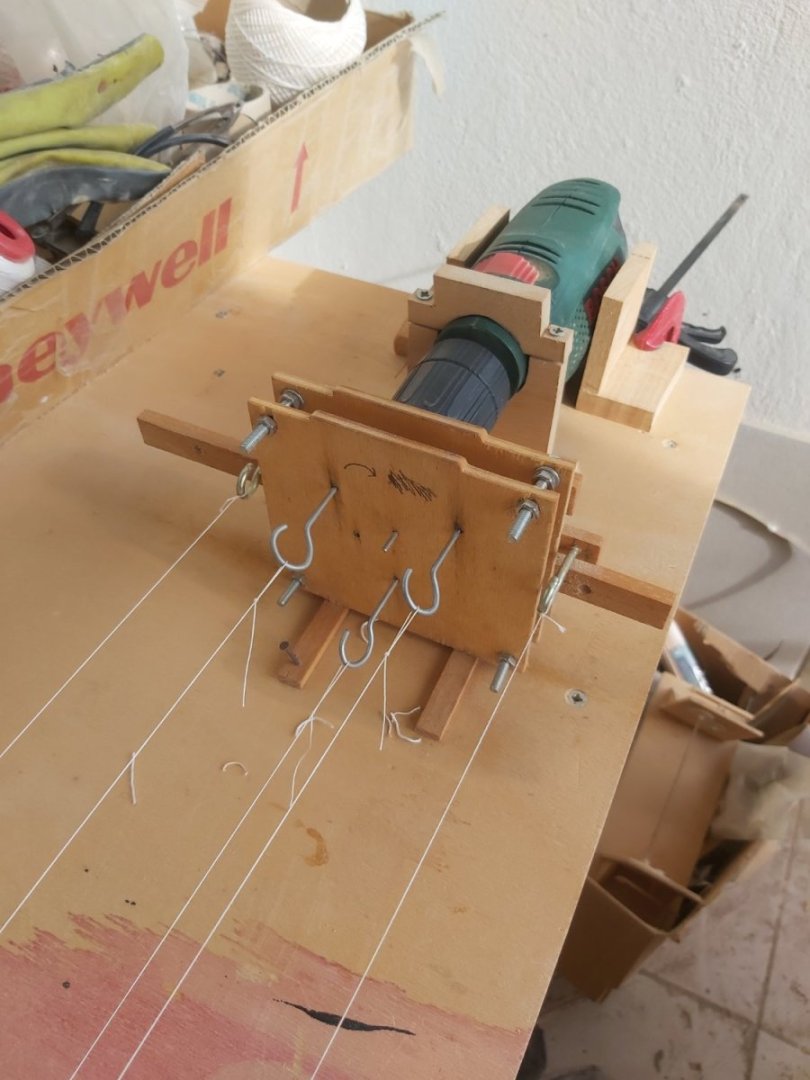

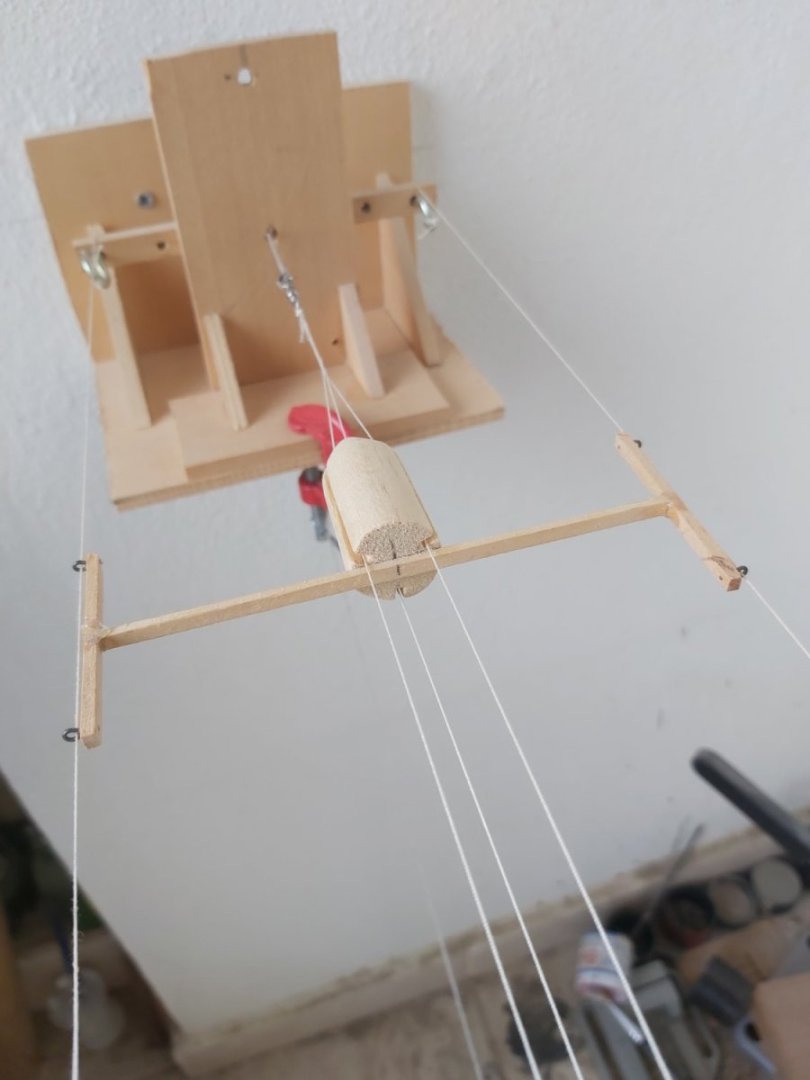

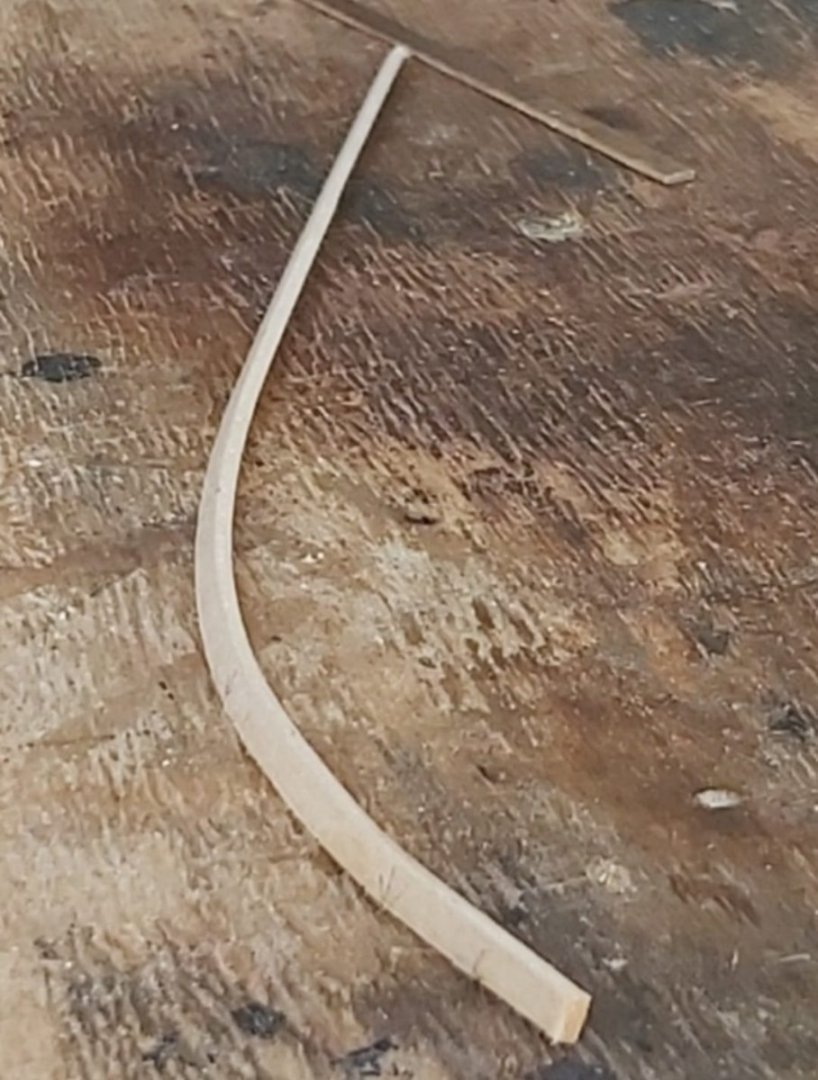

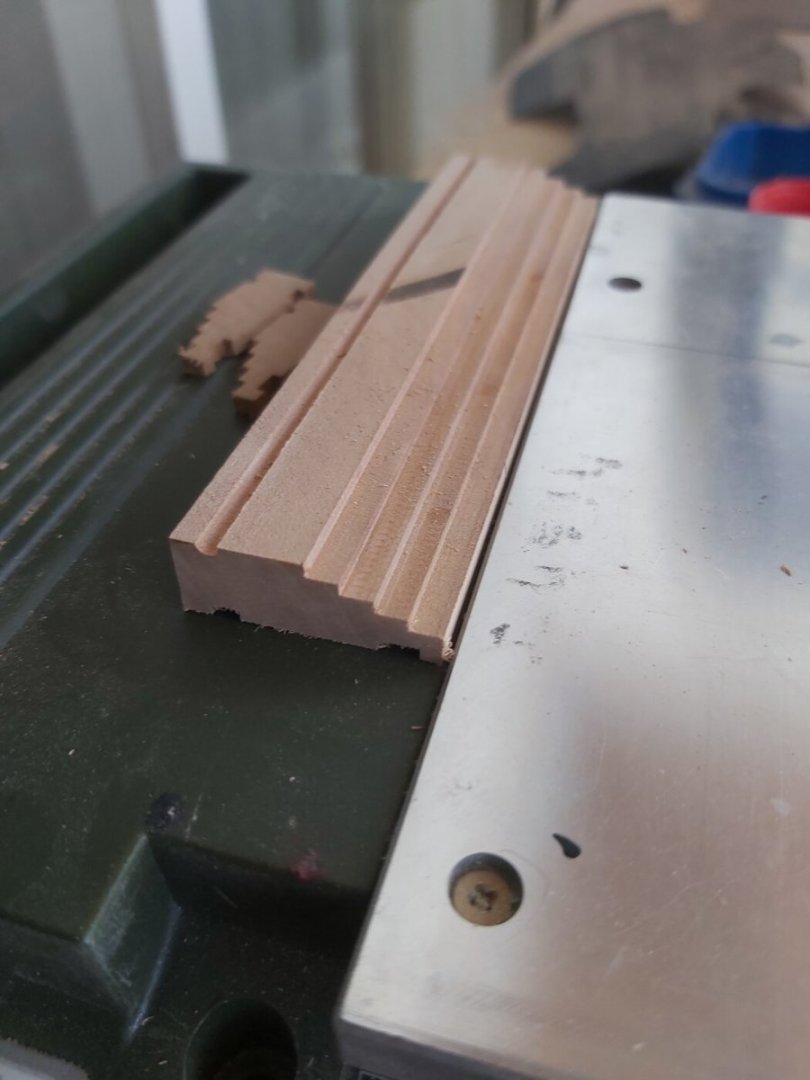

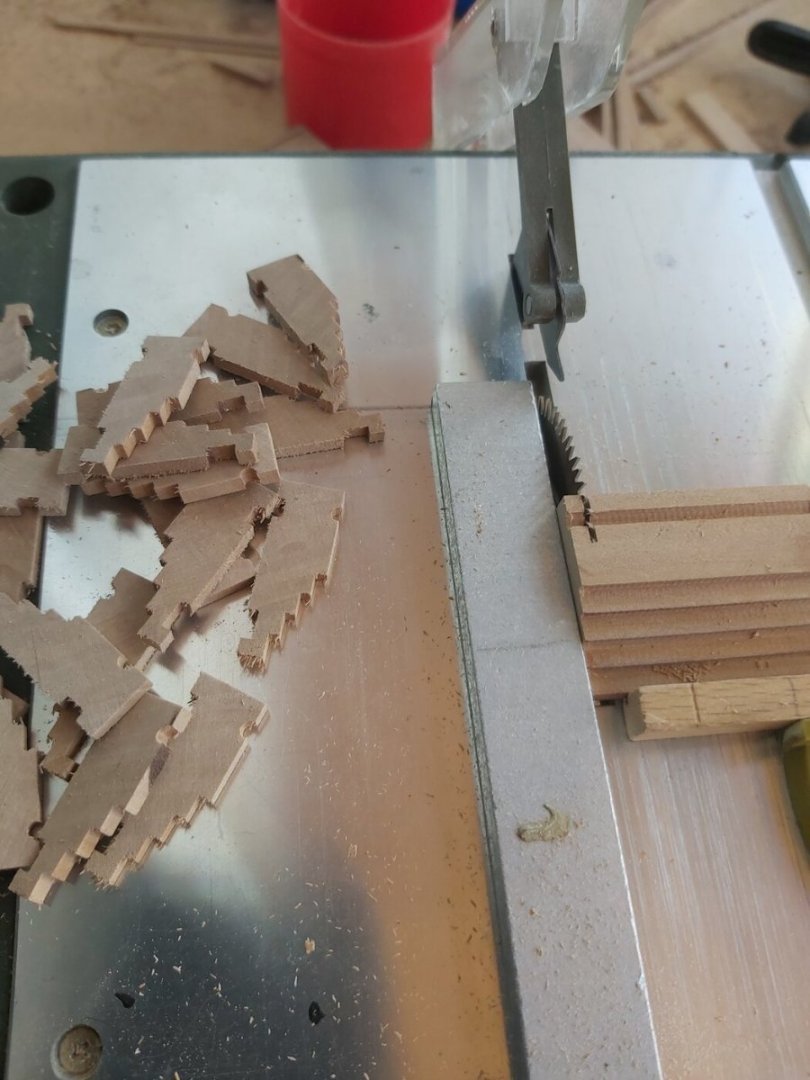

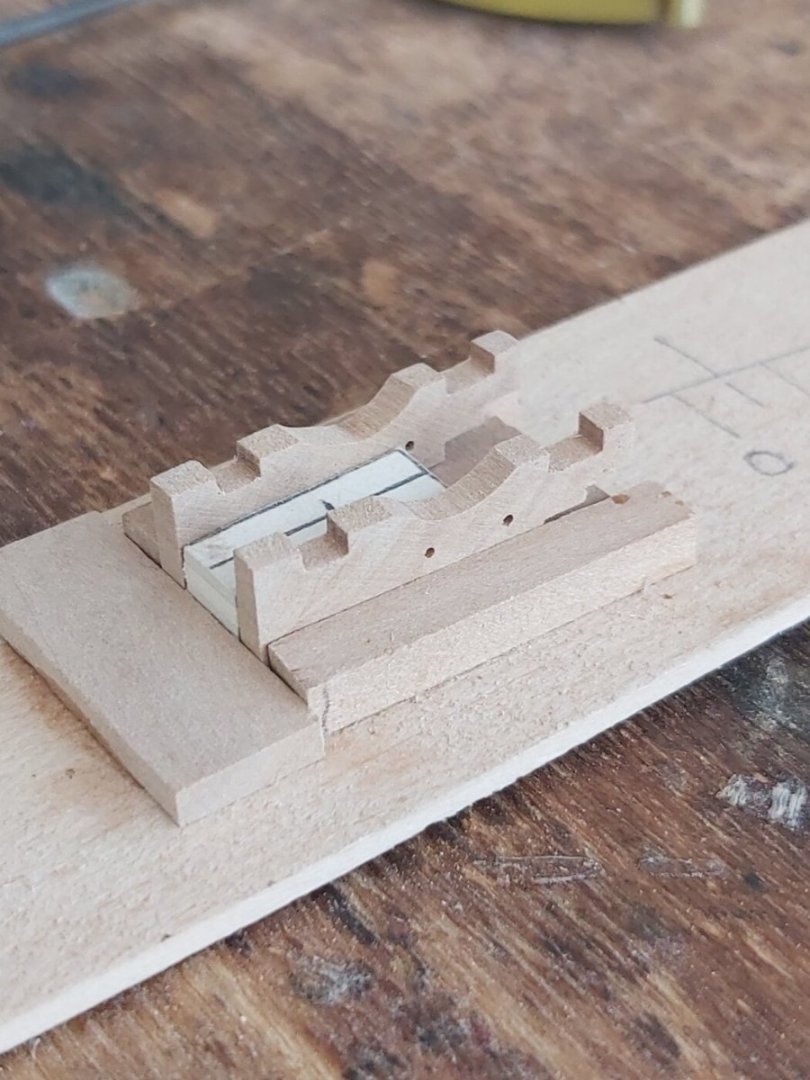

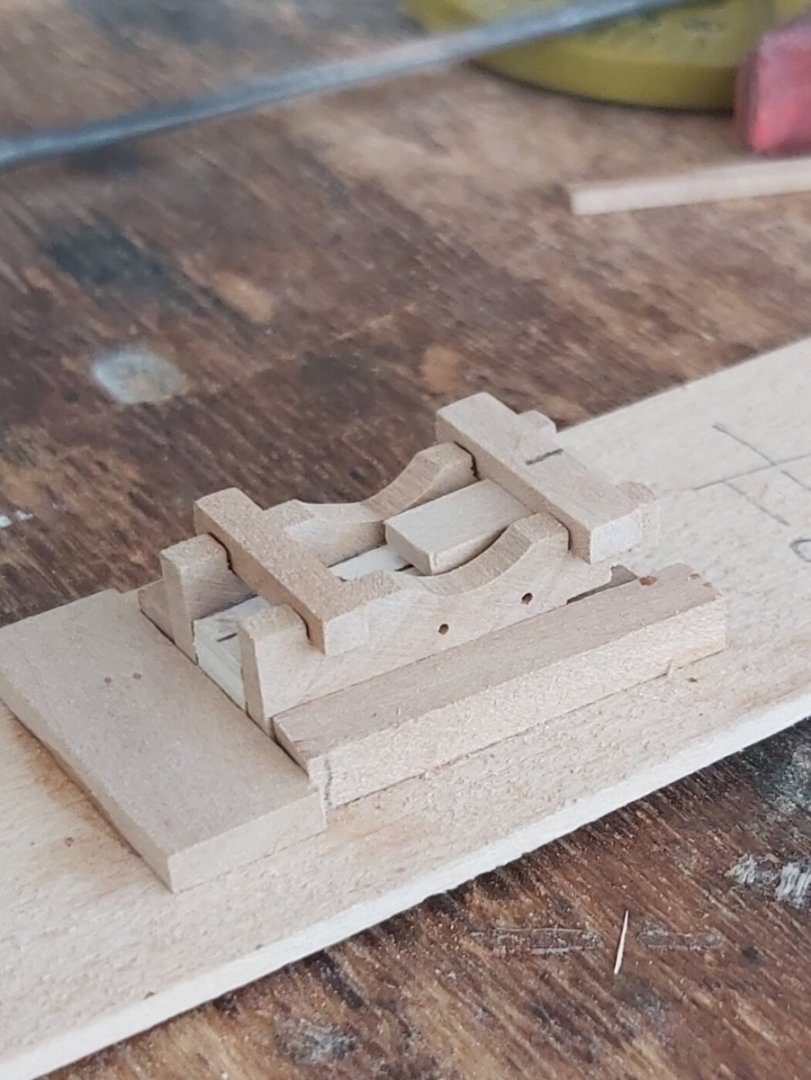

I have started the construction of gun deck cannon carriages. There will be 30 in total. I am making the cannon carriages from pear wood. First, I prepared a block that would form the side walls with a milling cutter, then I obtained the side walls by slicing the block with my table saw. After sanding and necessary drilling, I combined the front and rear wheel axles that I had prepared before with the side walls using the assembly jig I made. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

No problem. These types of discussions are instructive for everyone wherever they are held. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you very much Jon. I agree with Greg, these are great information and pictures and helped me a lot. Now I have to decide whether to add window sashes or not -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Dear friends I need a help in this stage. I would like to ask my friends who have knowledge. As far as I can see in the photographs, there are no frames in the stern windows of the ship today. Were there frames for glass in the windows in previous periods? If so, why did they remove these frames? Thanks. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I agree with you on the issue regarding the wife.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.