-

Posts

1,362 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you so much Greg. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

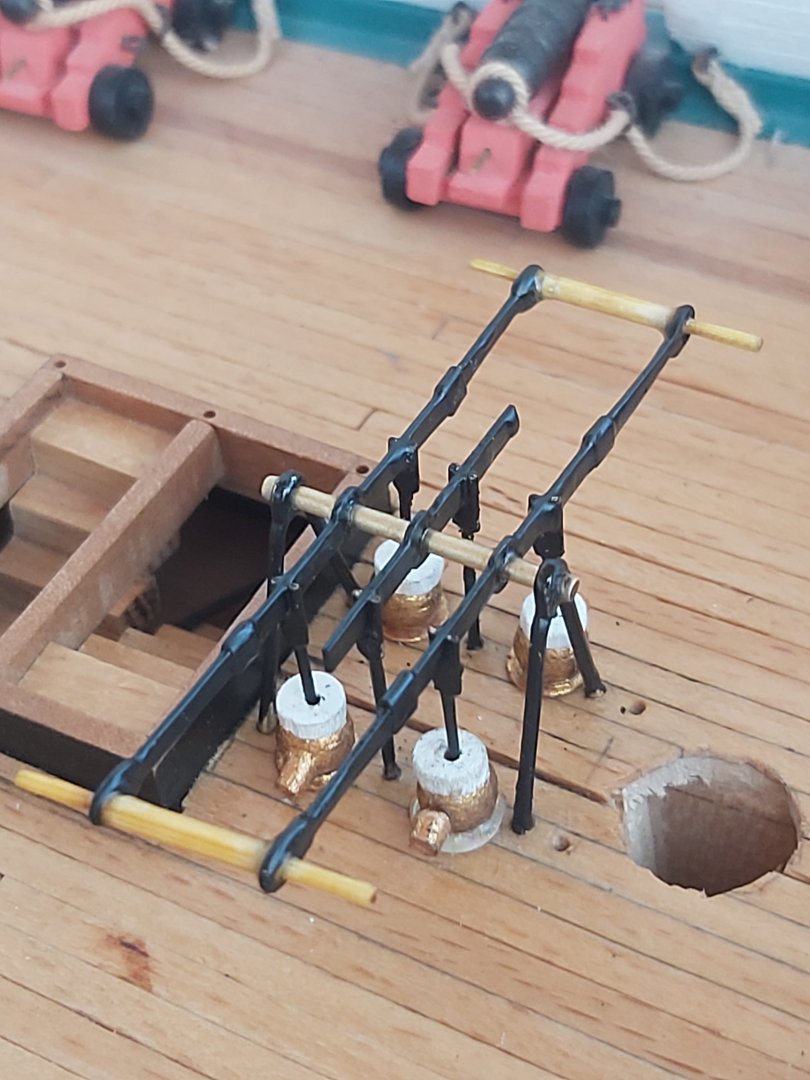

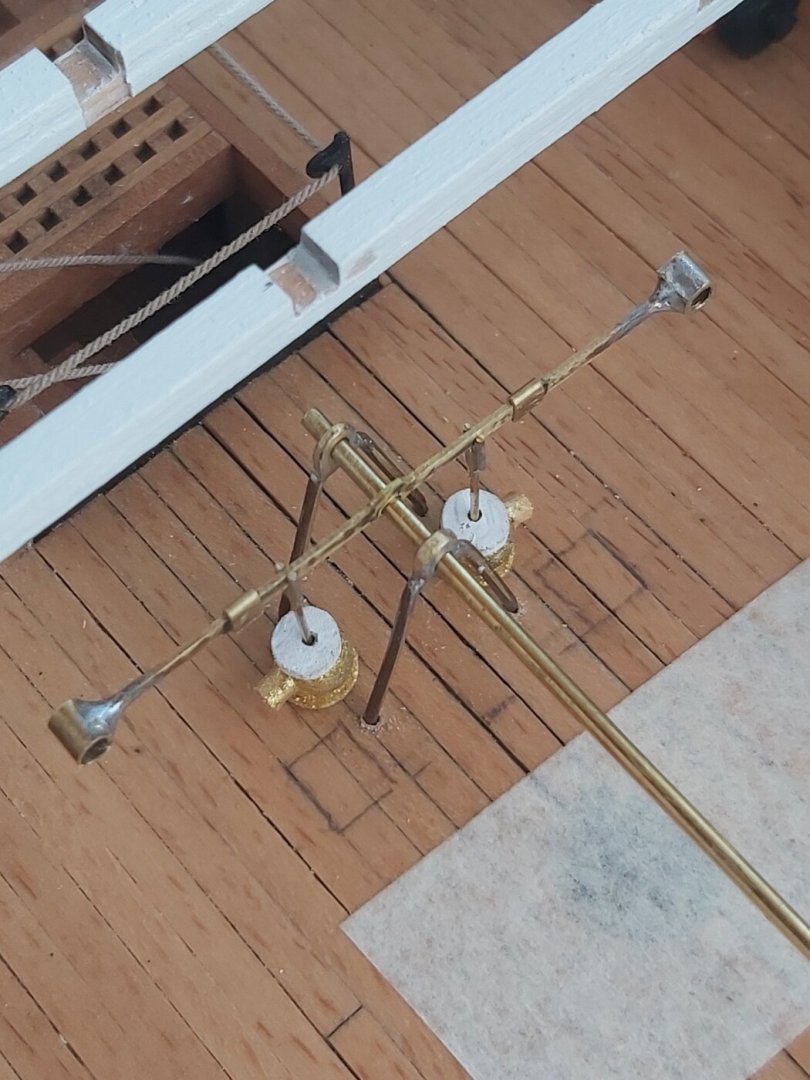

I had to think for a long time about how I could put the pieces together. This was a real challenge,for me especially on this scale. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

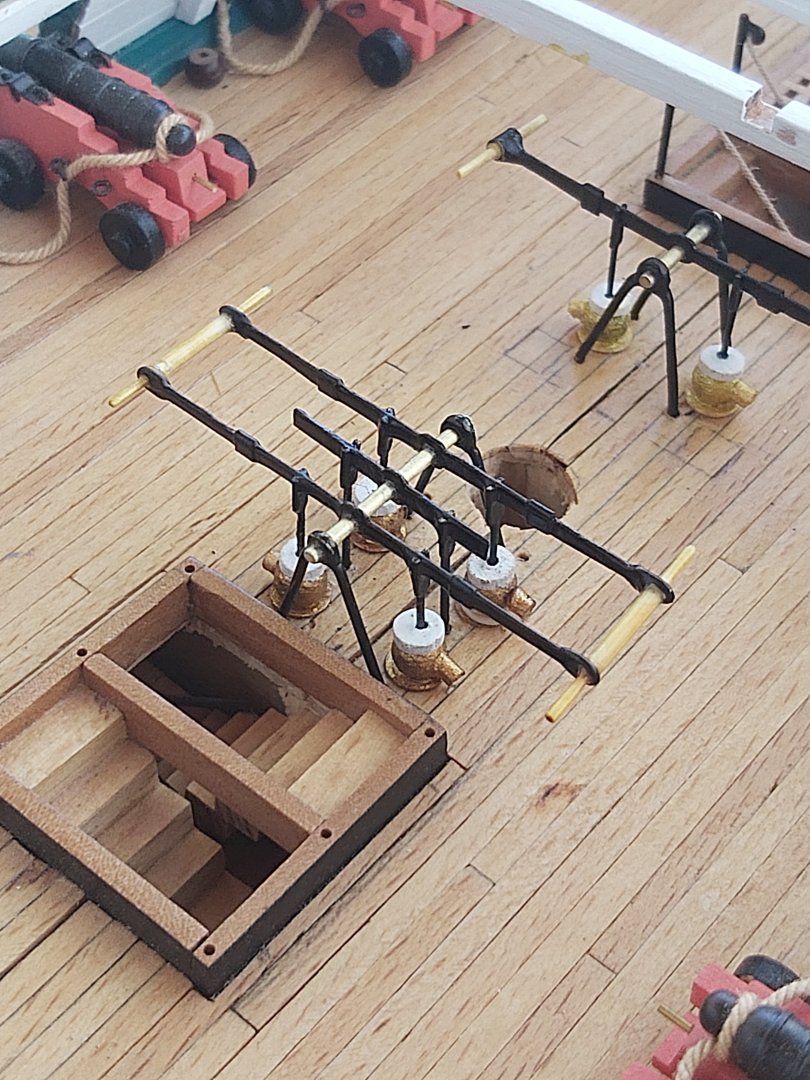

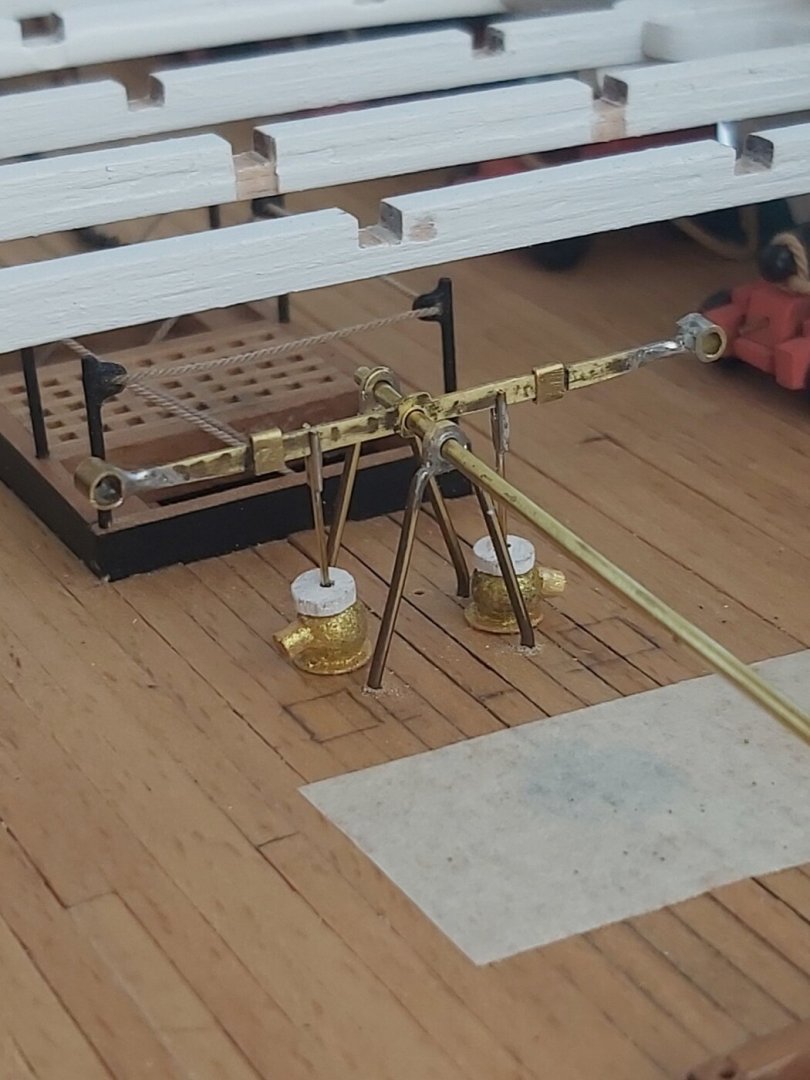

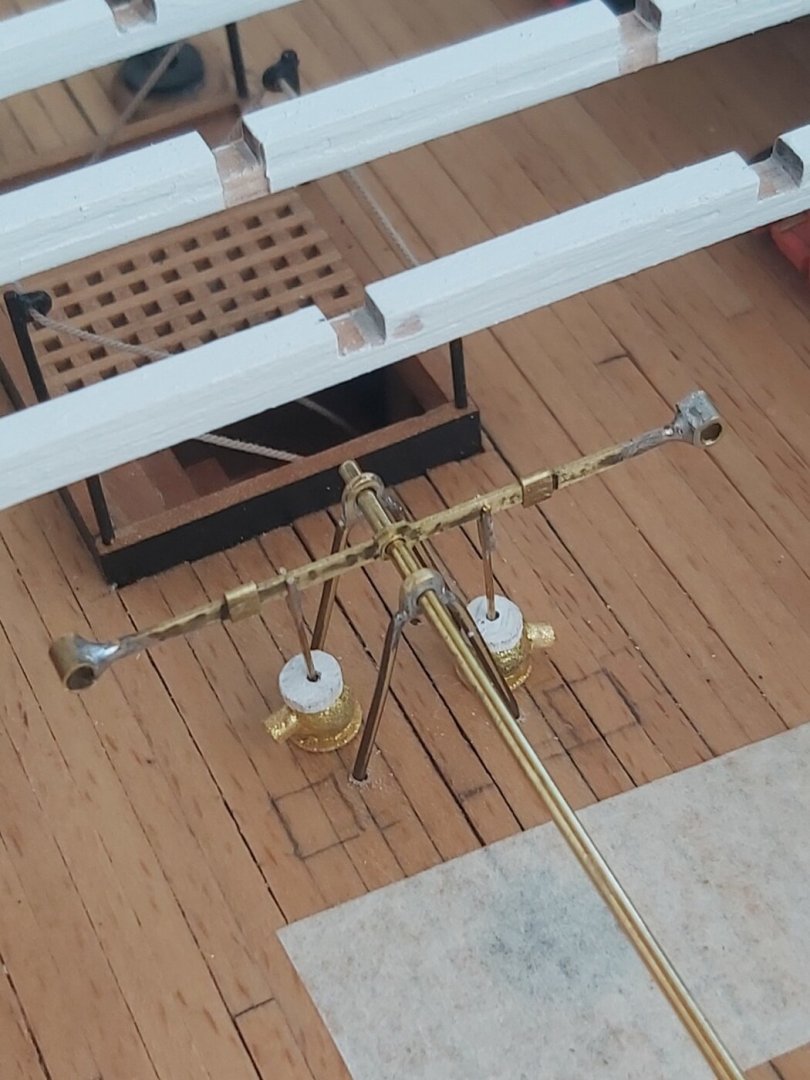

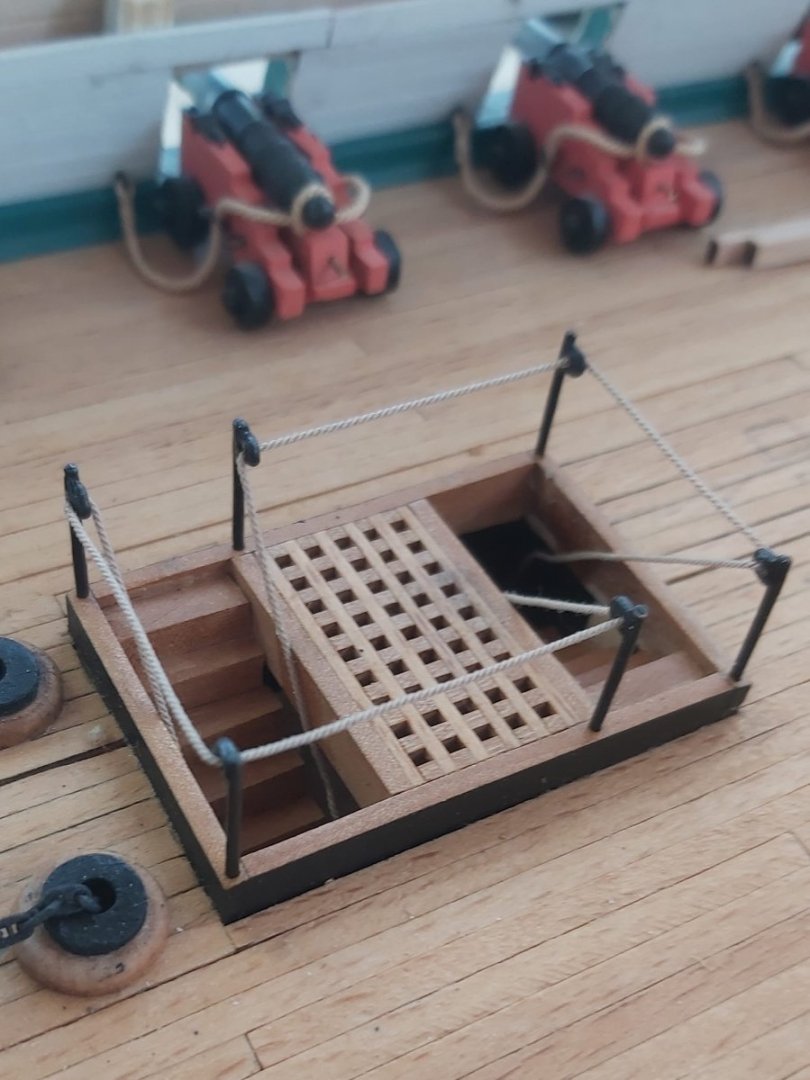

Quad pump completed.This has been the equipment I have had the most difficulty in manufacturing and assembling so far. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

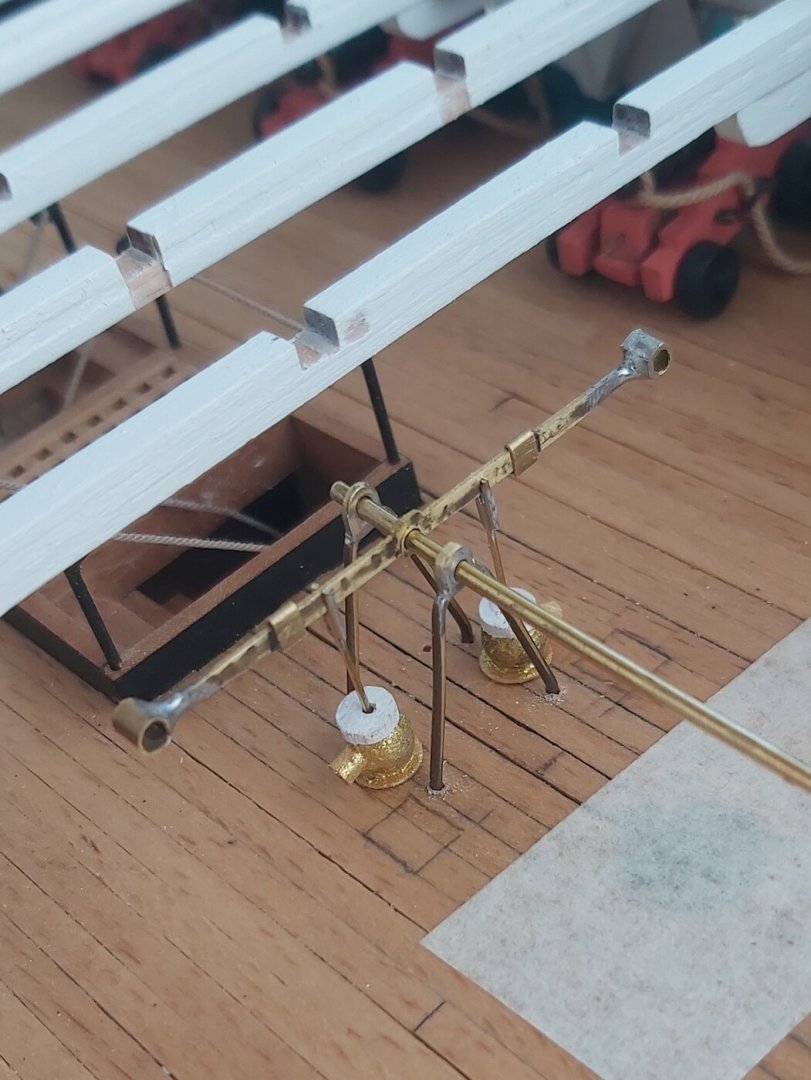

Thank you Greg. Normally, I do not paint the brass material, I just blacken it with chemicals, but since I use solder here, I have to paint it because the solder does not blacken with the chemical. I don't blacken the brass before painting, I just paint it with acrylic paint and apply matte spray varnish after the paint dries. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you so much my friend. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I have assembled the gun deck bilge pump parts in place for testing. The brass parts will be painted black. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Half of the spar deck beams are completed. I can only complete one beam and its connected knees per day. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

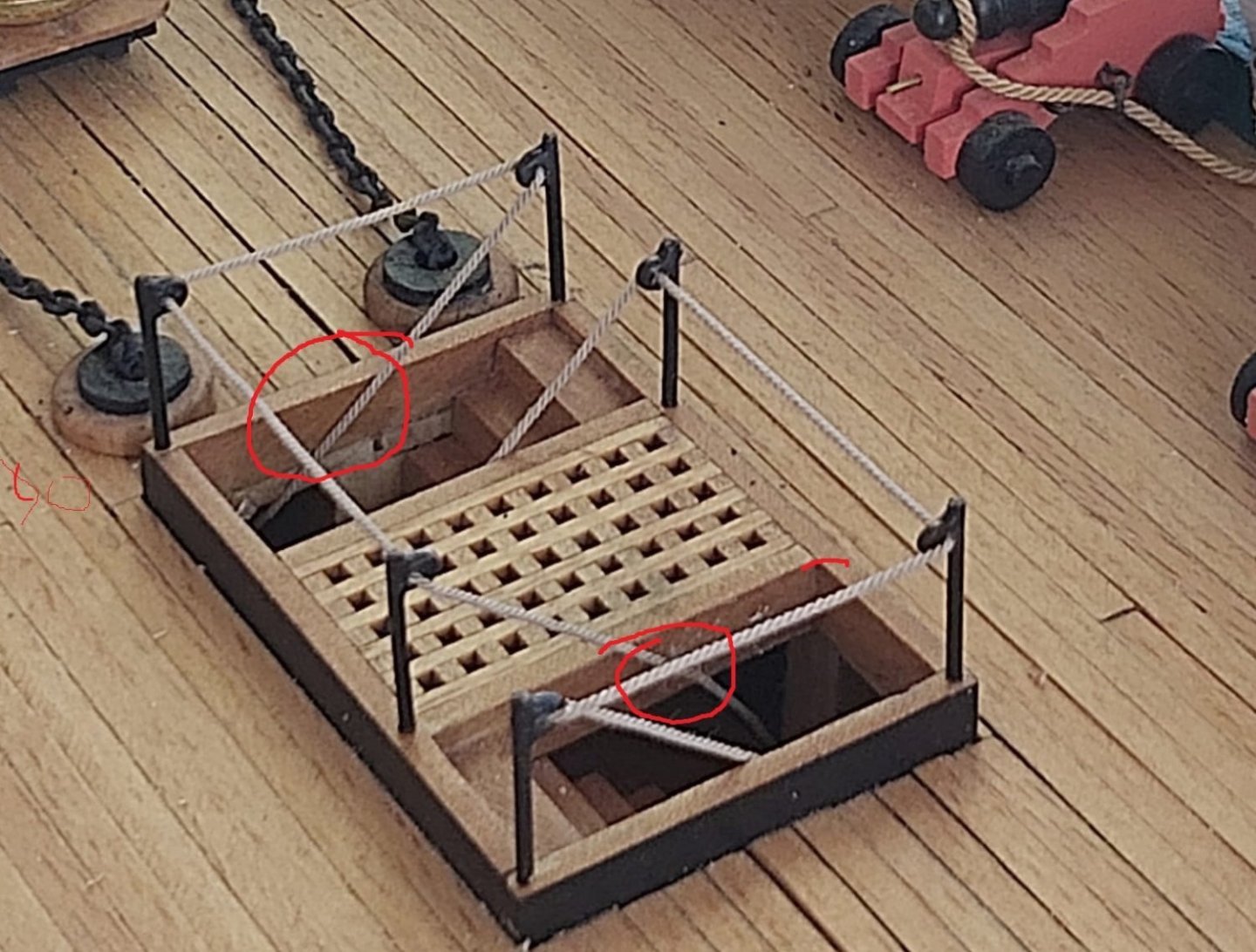

I glued the ropes with CA to the frame, where I marked with a red circle in the picture. While gluing, I stretch the rope with a pair of tweezers that I extend below. So it looks like it's tied somewhere below. The end of the rope is not tied to anything, I found such a solution. -

Great job on the metal, Greg. Looks like brass material, have you ever thought of blackening it? It looks more realistic.

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

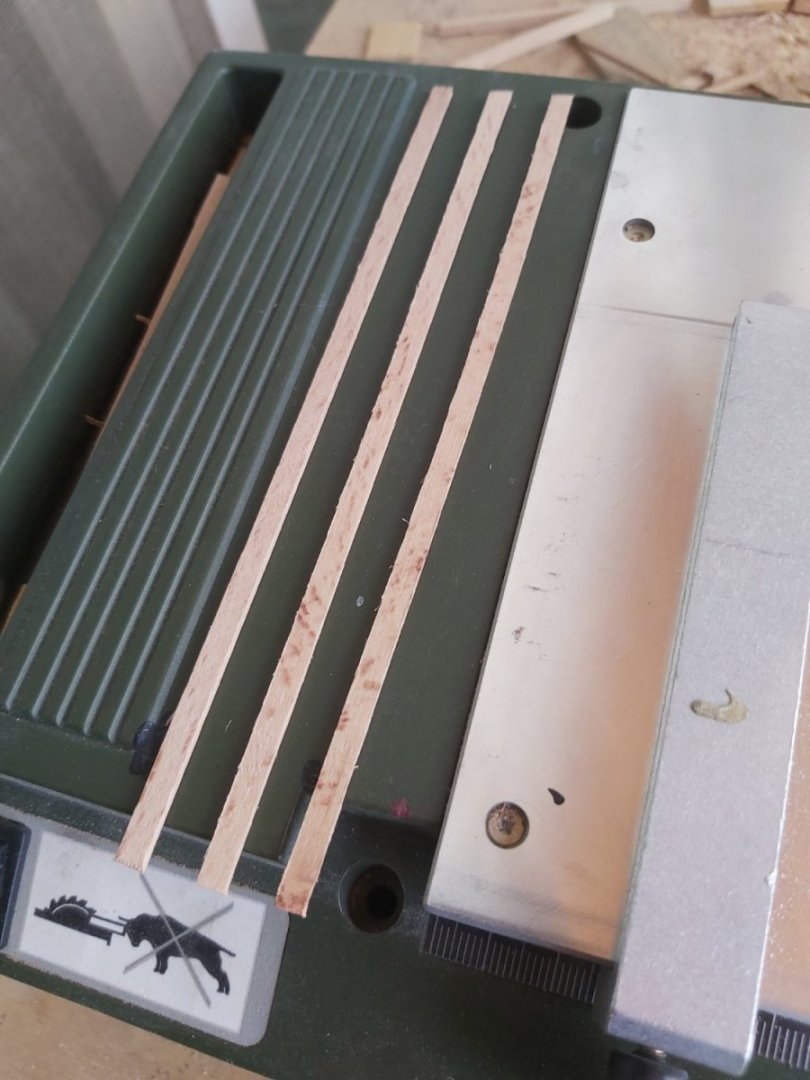

Thank you Greg. My table saw is a Proxxon KS230. It's Proxxon's simplest saw and does a good job within its capabilities. I've been using it for six years. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

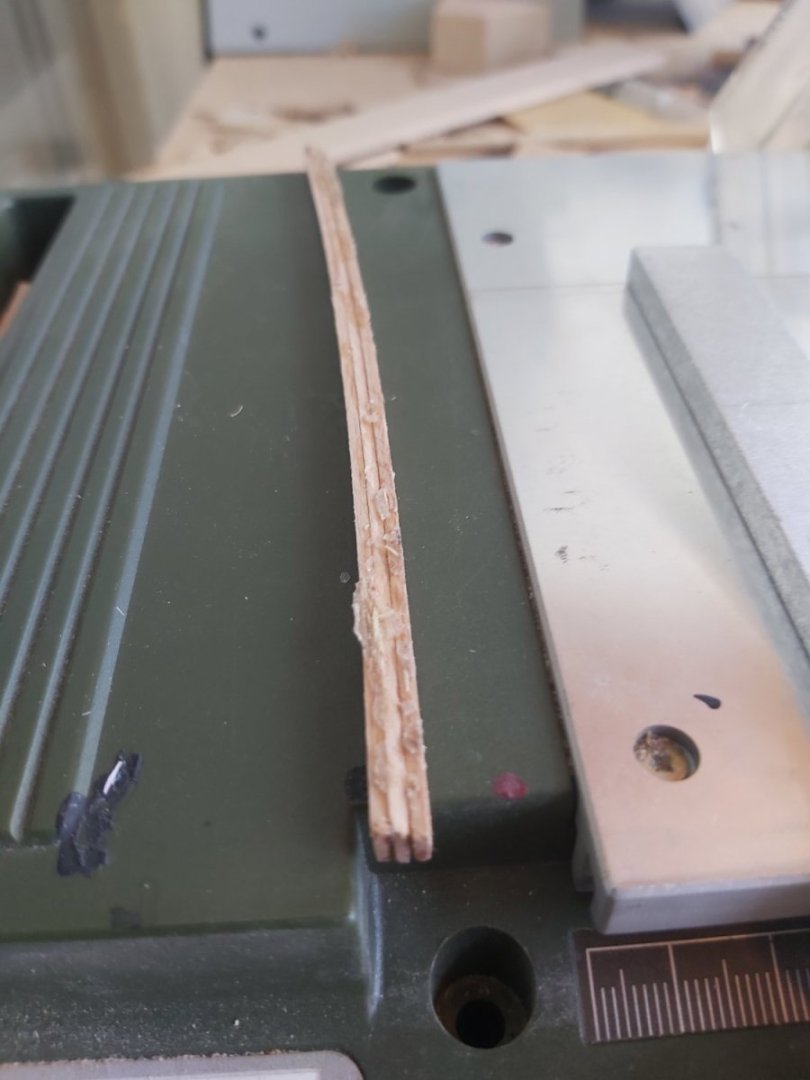

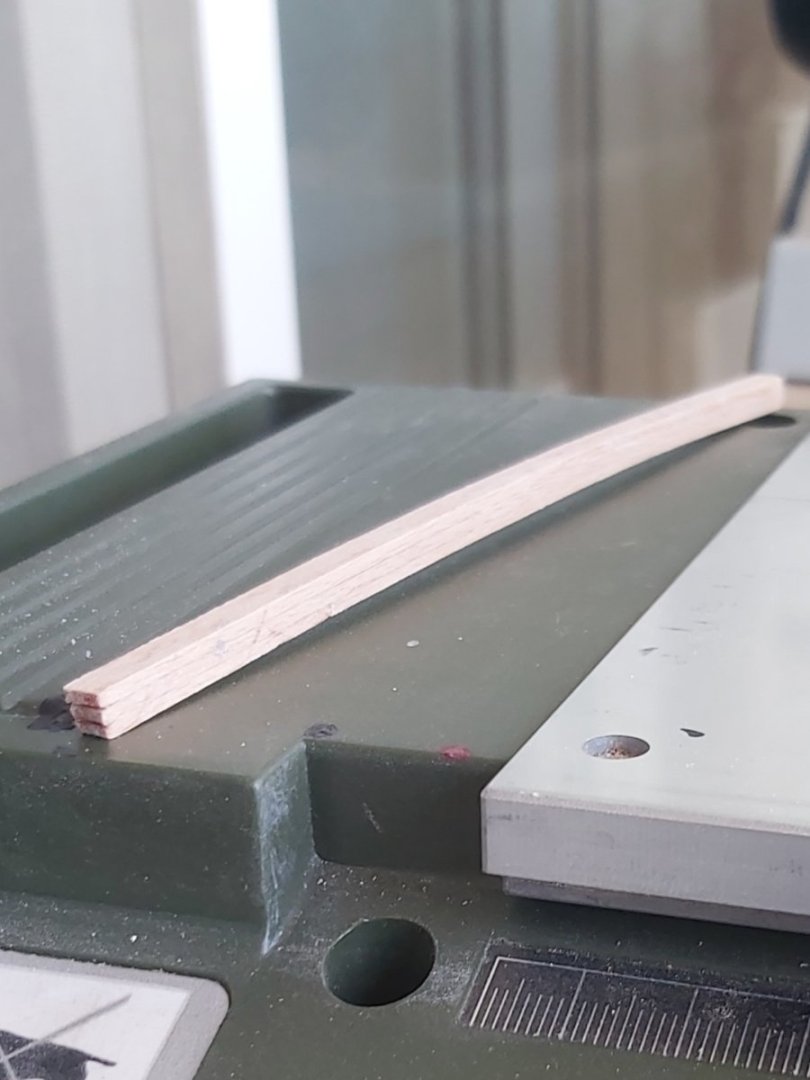

I would like to show how I made the main beams for those who are wondering how I did it. Since I have difficulty obtaining smooth beams by cutting and sanding wood, I use another method. I cut 3 pieces of the same size strip from 1,5x5 mm stock, apply glue between them, clamp them to the mold I prepared before, wait for it to dry, and remove it from the mold. Thus, I obtain standard curved beams. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thanks for the info John. As far as I understand what I made is a Grog Tub -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Greg. I really don't know what was in the barrel. There was probably a liquid inside, such as water or alcohol. I added it because it was on the deck of today's ship. Jon is really knowledgeable on Conny. Maybe he can make a contribution. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I don't know when this ship was launched, but my guess is that she is at least 200 years old and is still alive and well. She deserves her name. She's an ''Iron Lady'' -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Greg, I know it's too early to ask because you're concentrating on your Bluenose right now, but while it's mentioned, let me ask anyway. Are you considering adding a gun deck to your Constitution? As far as I know the kit does not have this. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

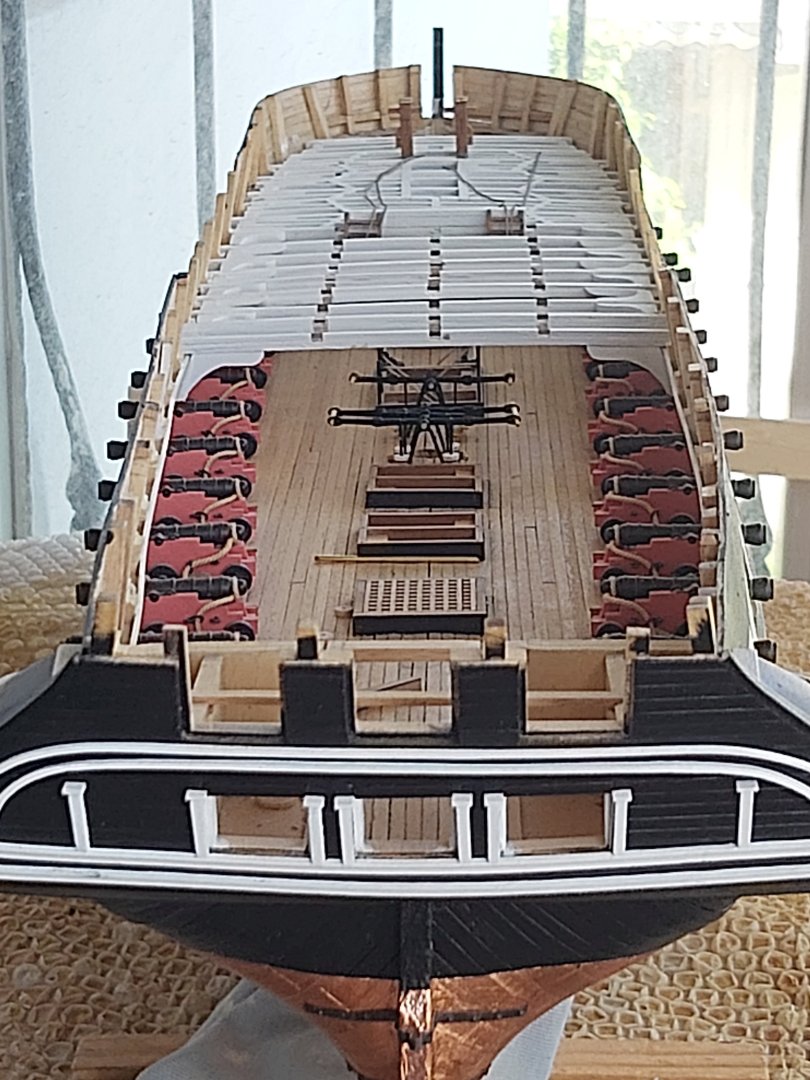

Yes Jon, you suggested this to me before. Even making the auxiliary beams thinner at the front of the ship didn't help make the gun deck as visible as I had hoped. So I decided not to put them in anymore. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I decided not to add the auxiliary beams along the gratings on the spar deck. I'll settle for just the main beams. Thus, the details on the gun deck will be more visible. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Since I was away from the shipyard for a while, there was no progress on the model. Let me share a few photos that I like. -

You are very good at metal work. Everything looks so nice Greg!

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.