-

Posts

1,019 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

While waiting for the railings to arrive, I did the nice plaque that comes with the kit. The brass is prepared the usual way -- paint then sand to leave the etched lettering visible. It mounts on a nice walnut block that comes with the kit. Regards, David

-

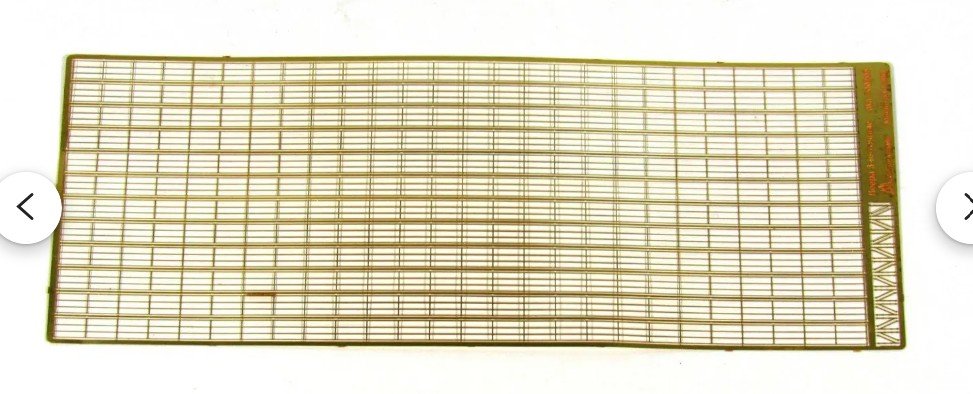

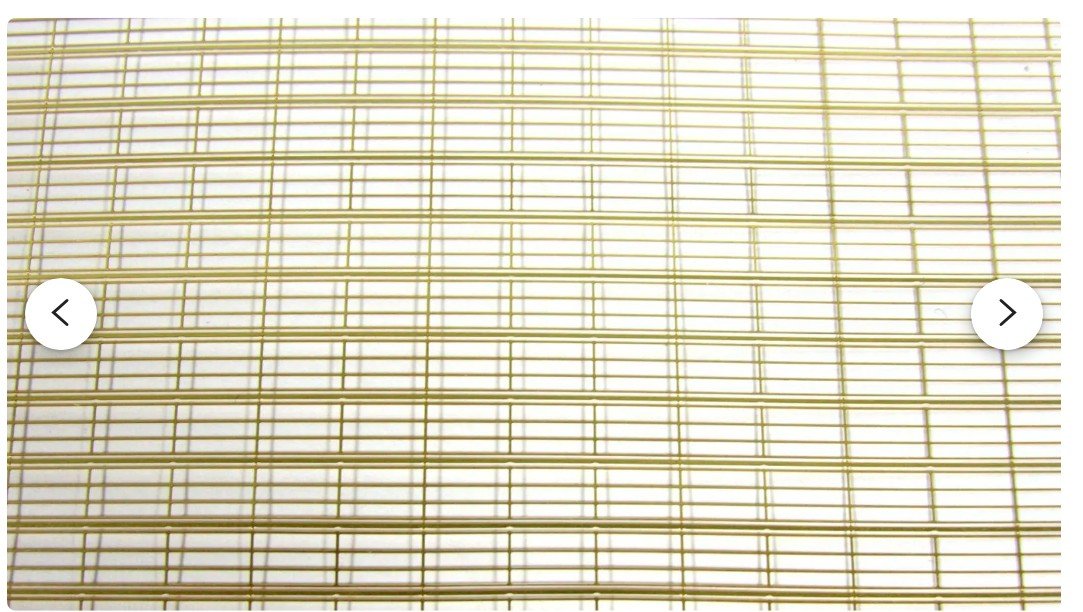

So I did some searching on Google and came across a number of photo-etched railings that go in as pre-assembled sections. These are a perfect match in scale and number of horizontal railings, so I have ordered them and they should go in fairly quickly on the starboard side. Right now, I don't intend to rip out the port side and put these in, as I think they will be a close match and only one side is the display side anyway. I'll pick that side after I see how these look. They will likely be delivered while I'm away for a couple of weeks, so late February installation. Regards, David

-

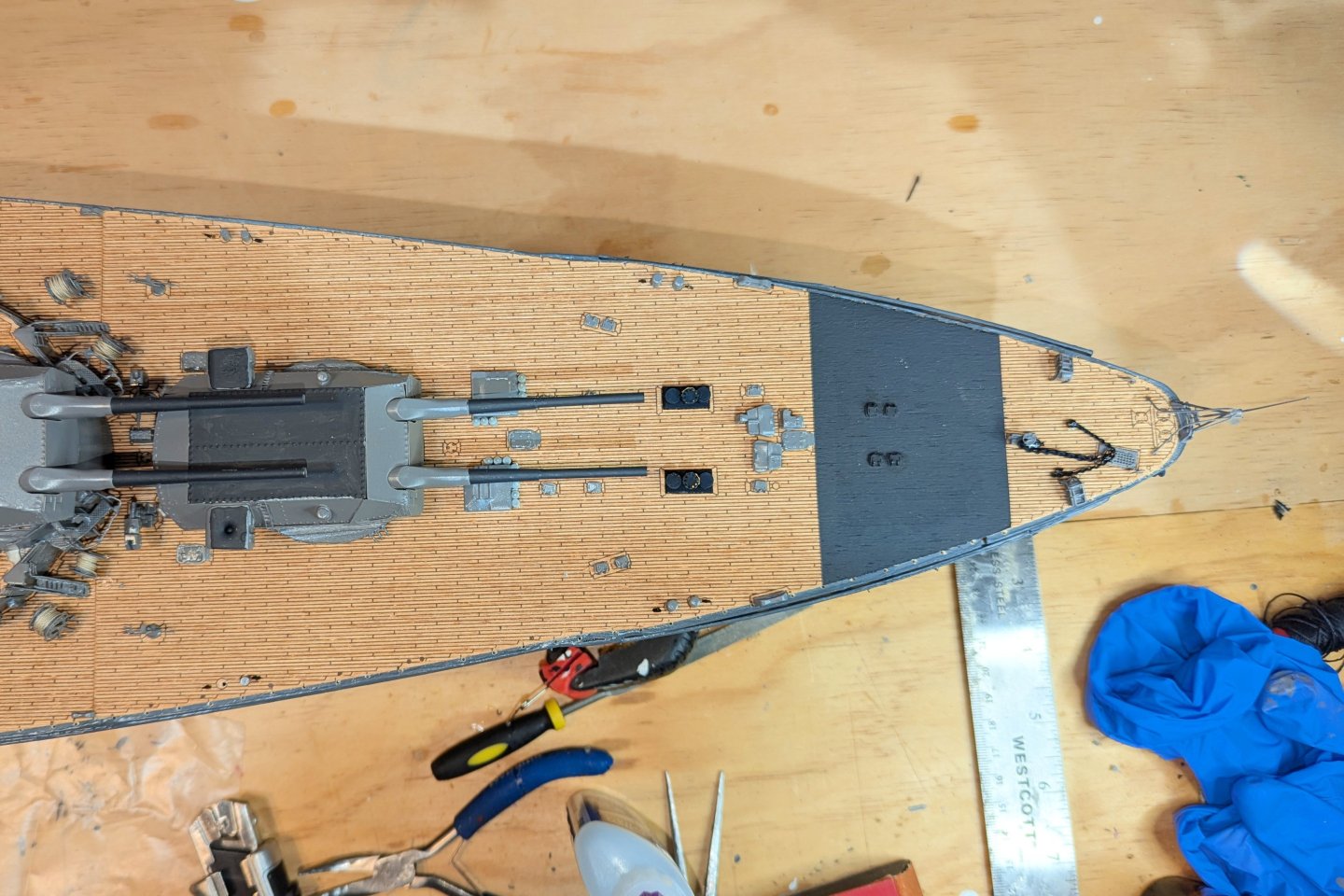

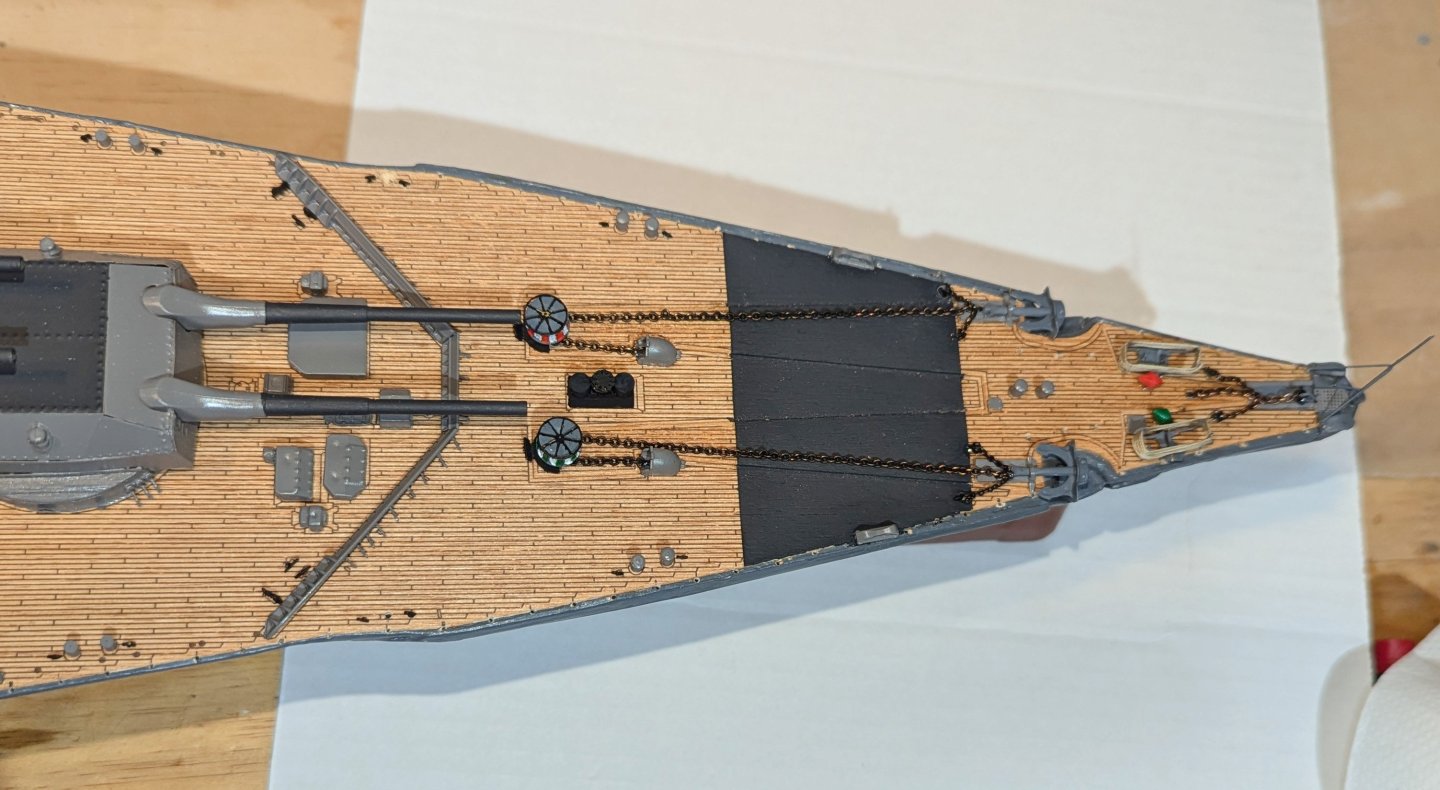

This morning I finally pushed through the first HALF of the railings. Looking at my logs above, I started this side on August 17, so about 5 months elapsed. I have a lot to say about how the manual says to build these, problems with that, and how I'd do it now if I had it to do over again (and why I can't adopt a revised approach for the starboard side). The problem comes from painting the stanchions ahead of time, and if you are building this ship and haven't done that yet -- DON'T. The difficulty comes from the paint clogging the holes, and how devilishly hard it is to clear them enough to thread the railing wires. So the approach I used was: 1) Paint the stanchions before removing them. 2) Use a fine drill bit (manually) to clear the holes. Often takes 2-3 tries and is hard. 3) Thread the wires thorough the stanchion. If they don't fit, enlarge the problem hole again. Sometimes do this repeated enlargement for 2 out of 3 holes on the stanchion. 4) Mount the stanchion. 5) Rinse and repeat. As I noted above, the manual says to mount all of the stanchions after clearing the holes, and then thread the wires. But that just wouldn't have worked for me, because I'd have run into holes I thought I had cleared but that needed another poke -- which can't be done after they are mounted. This has led to a rate of installation of about 4-5 per hour, and I have to confess that I can't stand to do more than an hour per day, and frankly haven't done work as frequently as I normally do because it's such a tedious task -- MUCH worse than say coppering the bottom of HMS Victory, all 2,500 plates, which was kind of fun. I wish I hadn't painted all of the stanchions, because if I had it to do over again, I would leave them unpainted, which should result in holes that will accept the threads, then thread and mount, and then when they are all done, paint them with a fine brush. That would have gone much faster. Finally, when you look at the pictures below, you'll see a lot of specks on the forward black section of the deck. I noticed those in the picture and just blew them off -- so no need to repaint. Now on to the starboard side. The snow will have melted by the time I get that done. Regards, David

-

Just about halfway through the first side on the railings. I can do about 7-10 of these per hour, so it's slow going. Regards, David

-

Another reason to use the approach I've described above to string the railings vs. mounting all the stanchions first (as recommended in the manual). I'm finding that even after I poke the paint out of the holes and think I've enlarged them, I occasionally have to go back in with my very small miniature drill bit (manually) and clean them out to get them to accept the thread. This would be impossible if the stanchions were mounted first, because the adjacent stanchions would block getting the drill bit lined up. Regards, David

-

More work on the railings. The reason these take so long is that you have to poke the paint out of tiny little holes using a tiny little drill bit, then thread them (like threading a needle), then mount. Regards, David

-

I'm now working on the railings, and it's going to be a long, delicate process. First picture is of the metal railings, which are installed at points on the deck. Second one shows the start of the cable railings. The instruction manual says to install all of the stanchions and then thread the wire, but the holes are just fiendishly small. So my approach, as shown here, is to string the wires as I go, which means I can thread them off the ship where I can manipulate the stanchion to see the holes, and then install the threaded stanchions. Working well so far, with a LONG way to go. Regards, David

-

Here's the rest of the deck detail at the bow. The rope racks next to the red and green buoys are actually fabricated from wire -- I somehow lost the photo-etched ones. I can't figure out how -- if I knew I could probably find them. So I just built these two. Regards, David

-

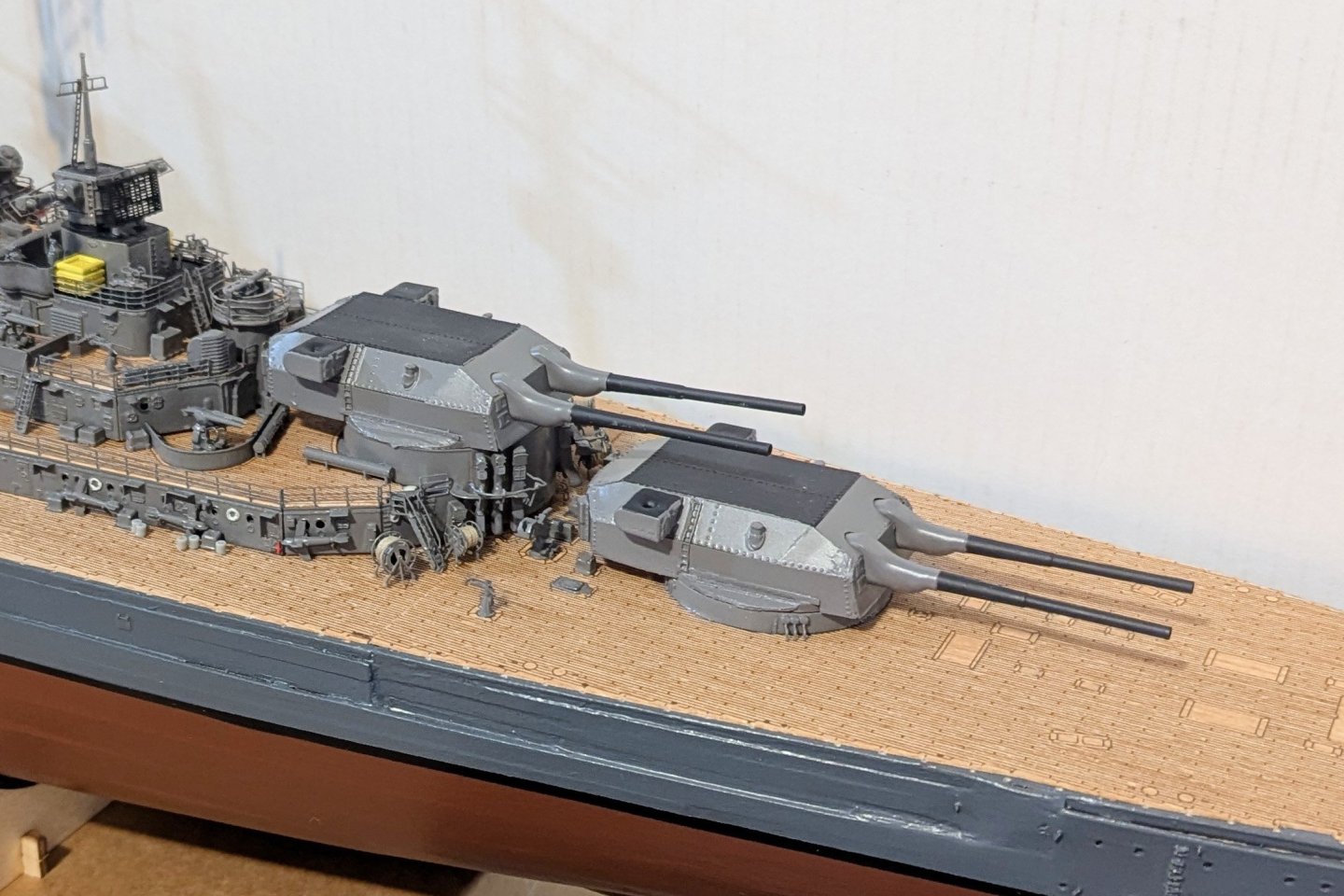

The 15 inch gun turrets are now painted, and the guns mounted on the ship -- again, not yet glued but they will be at the end. Here's a picture of the whole ship up to this point. Not yet finished, but the big guns really make it look like a battleship. Regards, David

-

Now the medium guns are painted and mounted. The instructions say to leave them free to rotate on a dowel, and for now I have done that in case they have to be moved later to account for some construction, but before I'm done I will glue them down. Can't imagine having a loose piece on the model. Regards, David

-

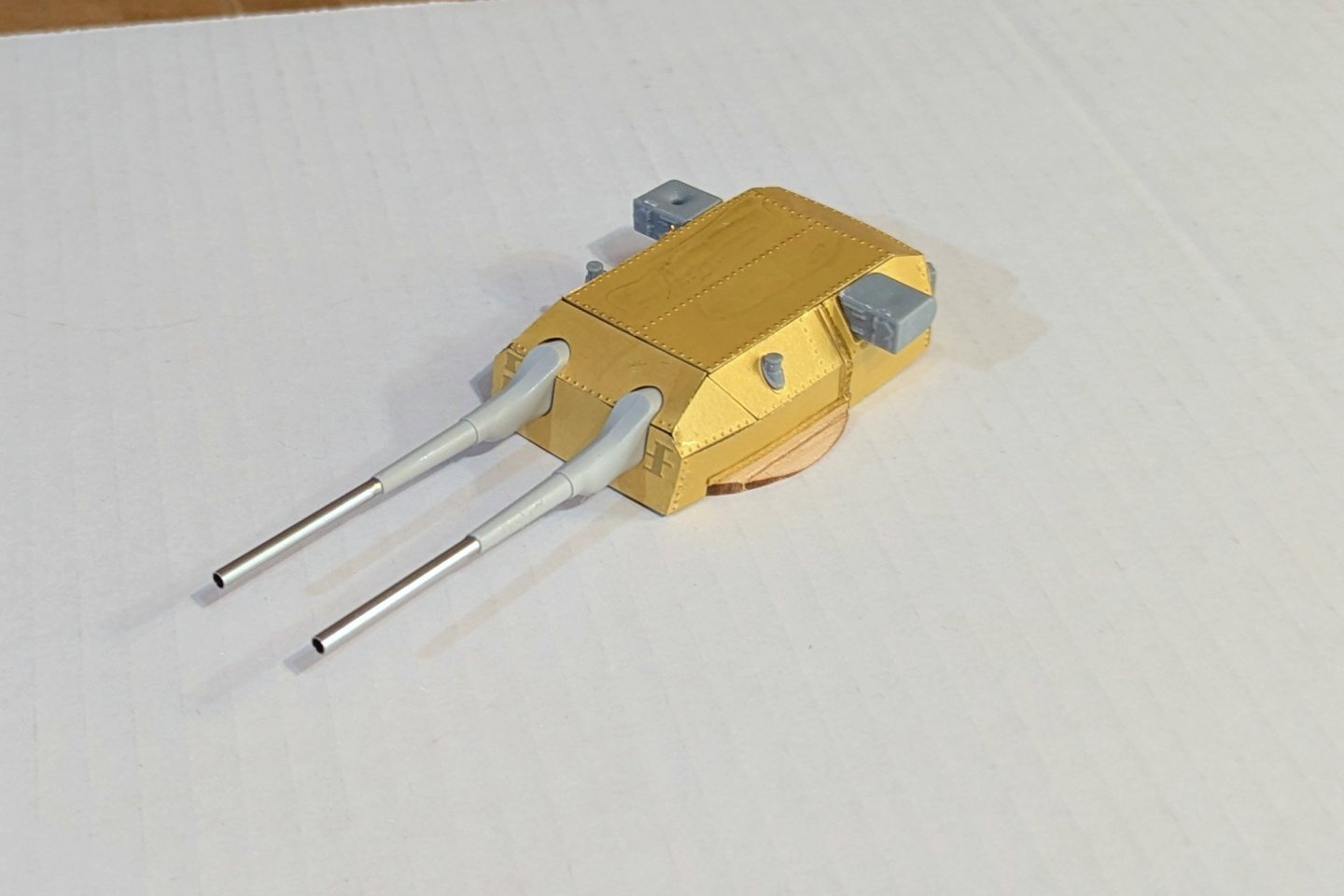

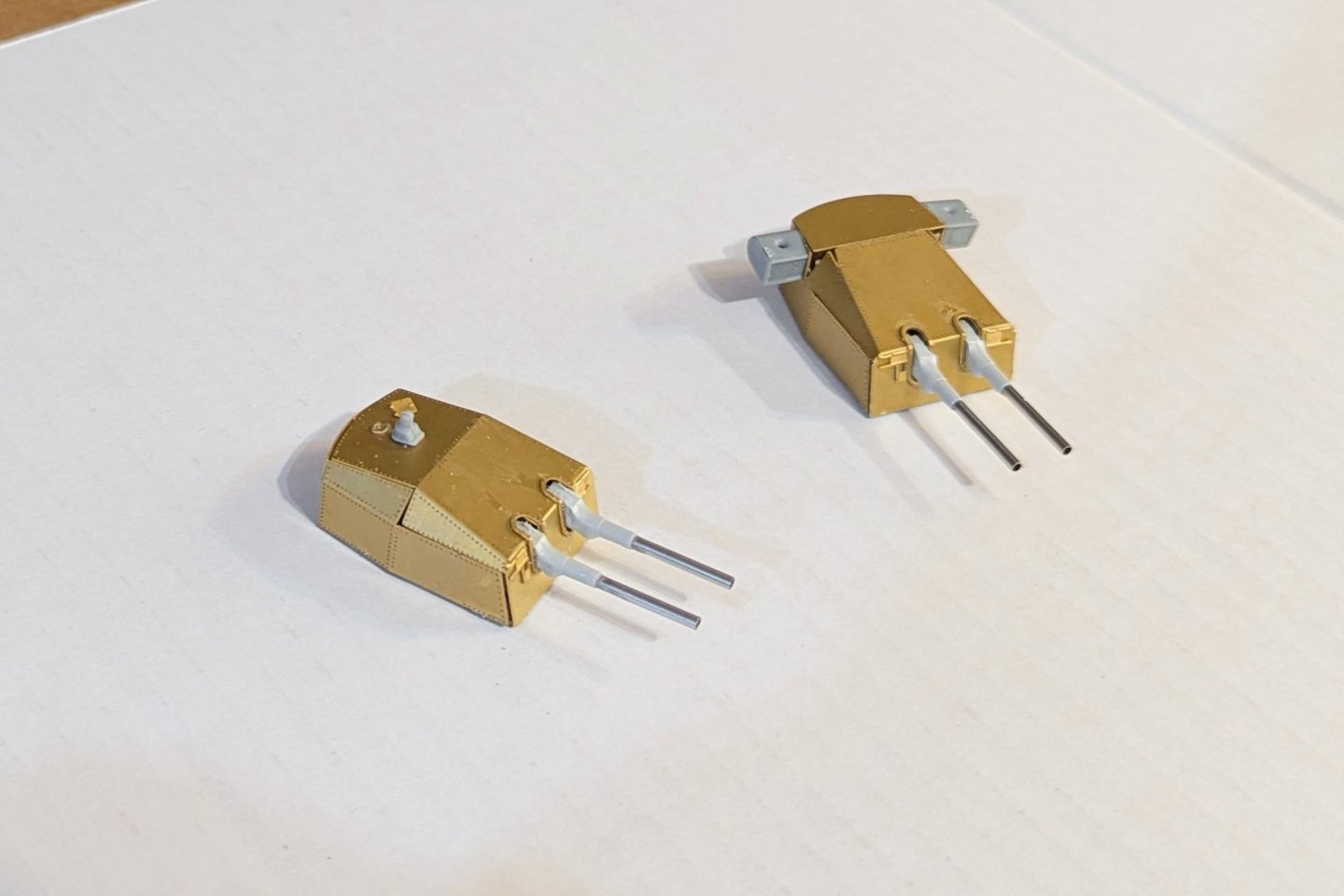

Midsize guns before painting. There are four of the type on the left, and two of the type on the right. Regards, David

-

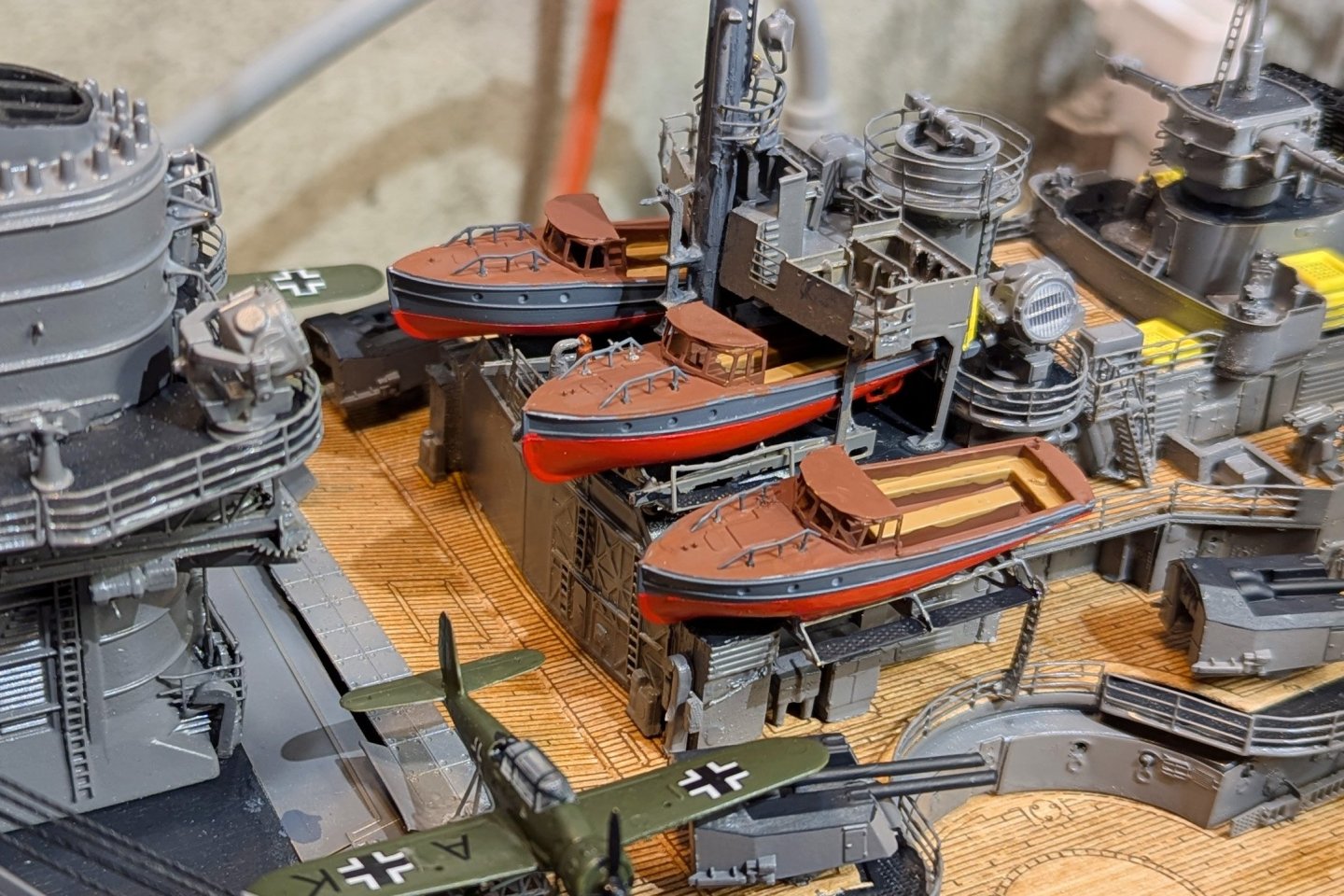

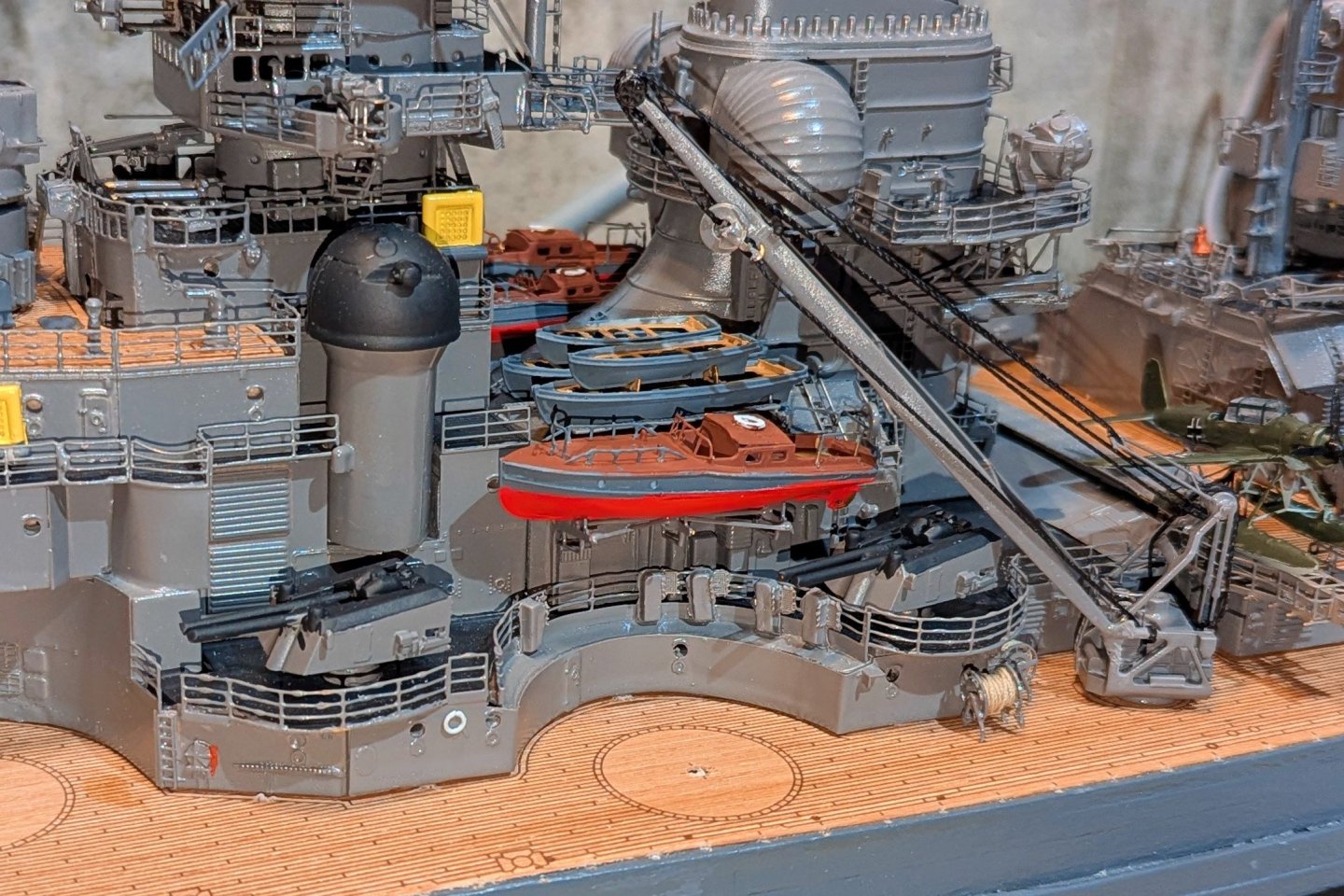

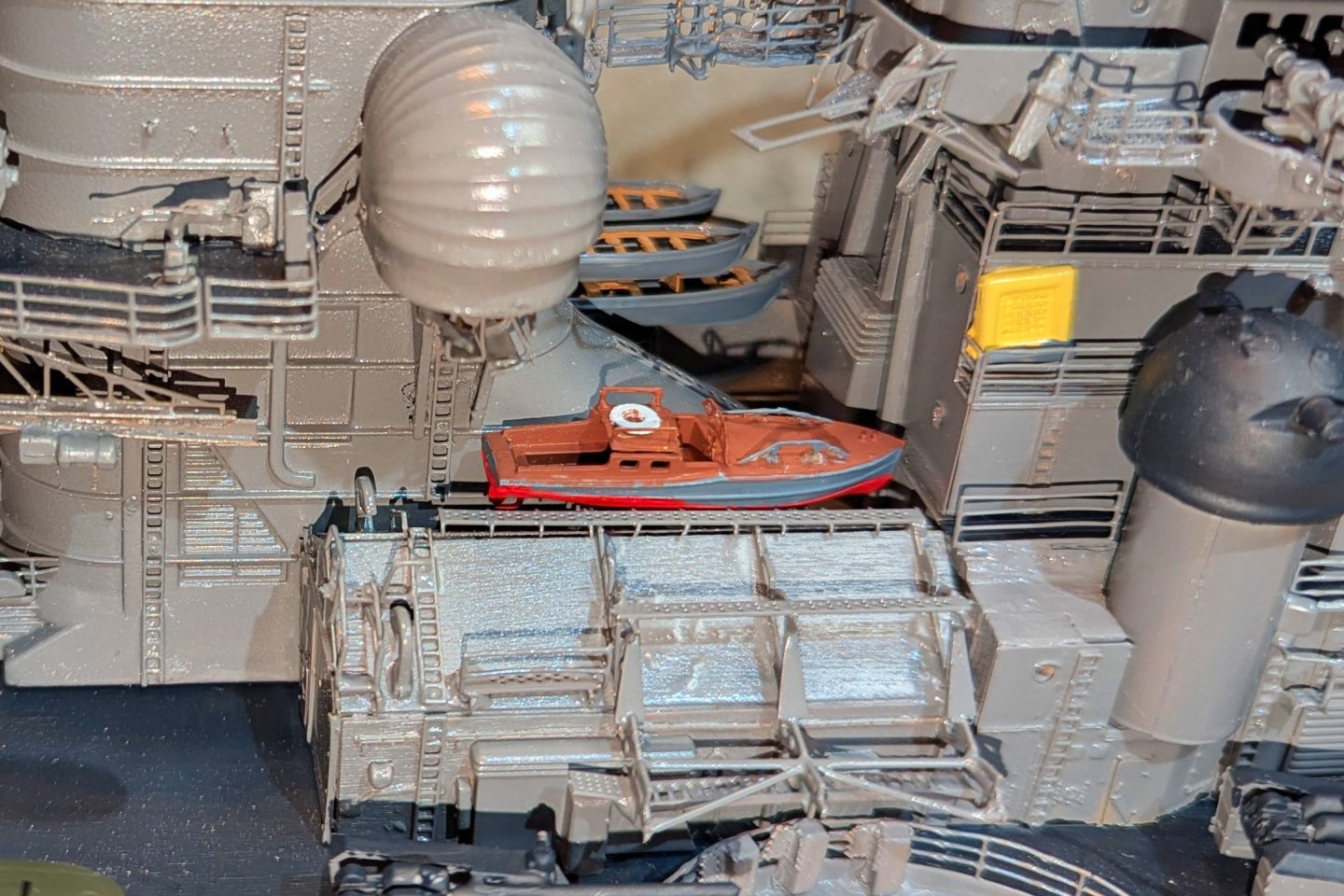

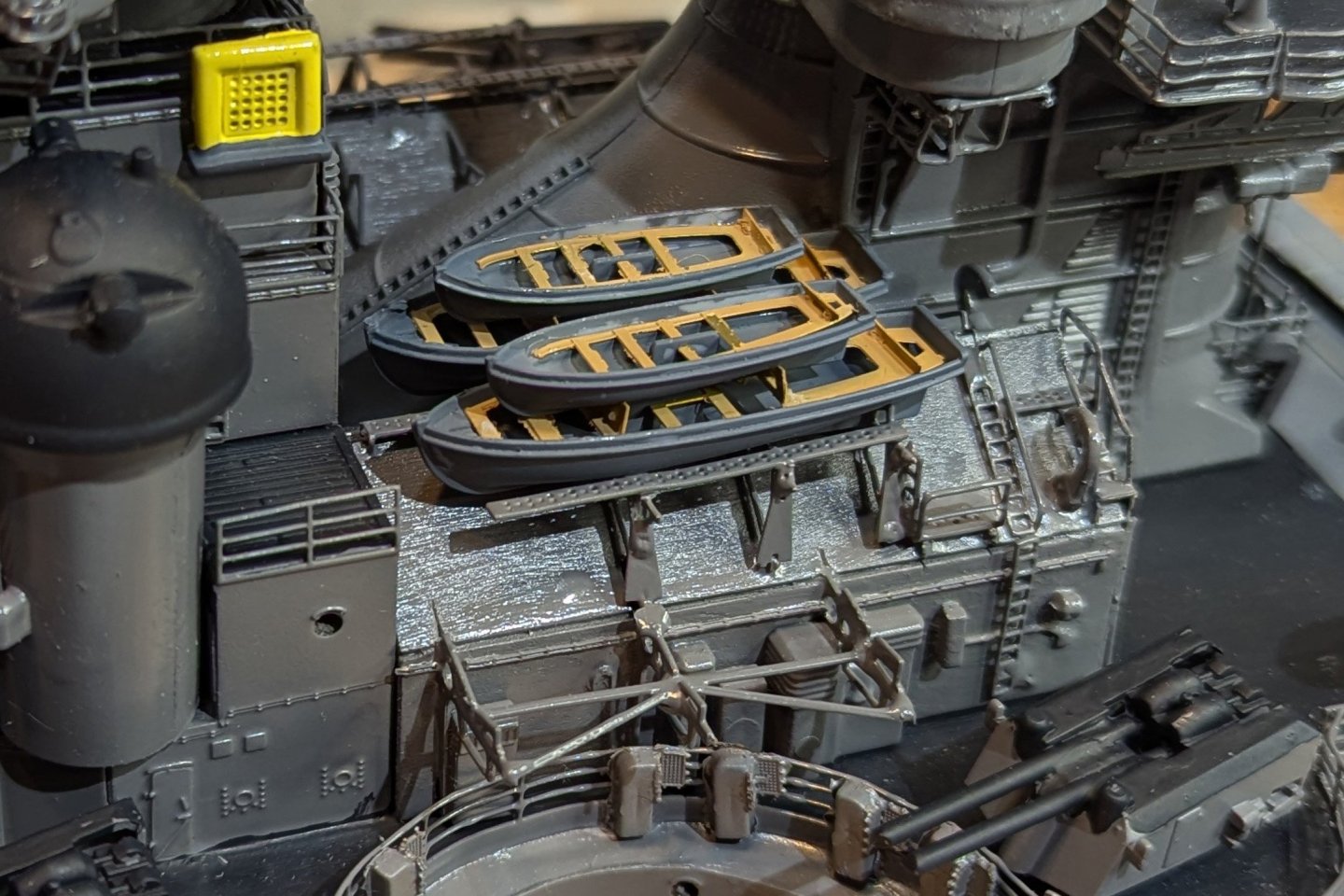

Last set of boats, called "Connection Boats" in the instructions. I have no idea what that means, but they look nice. Regards, David

-

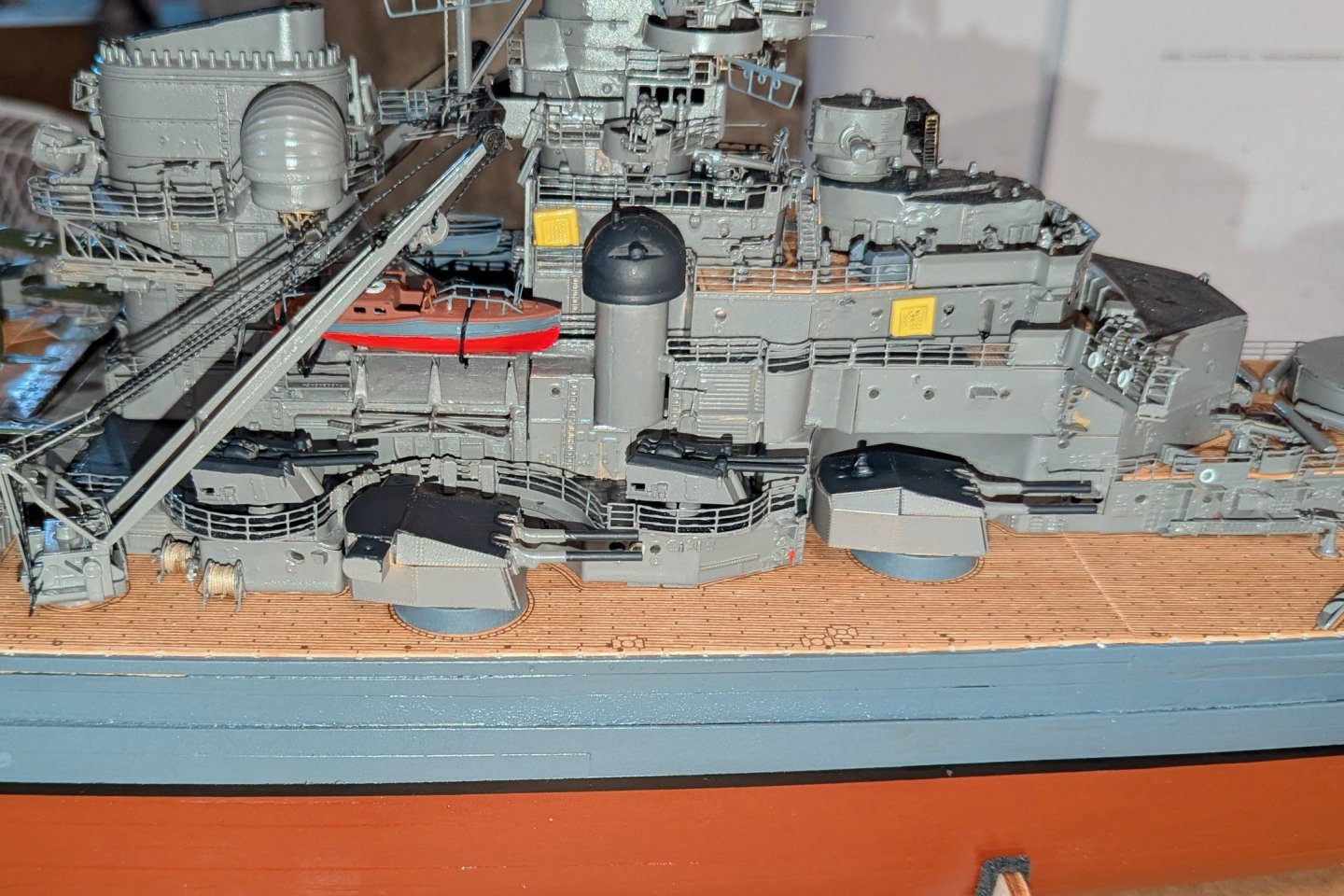

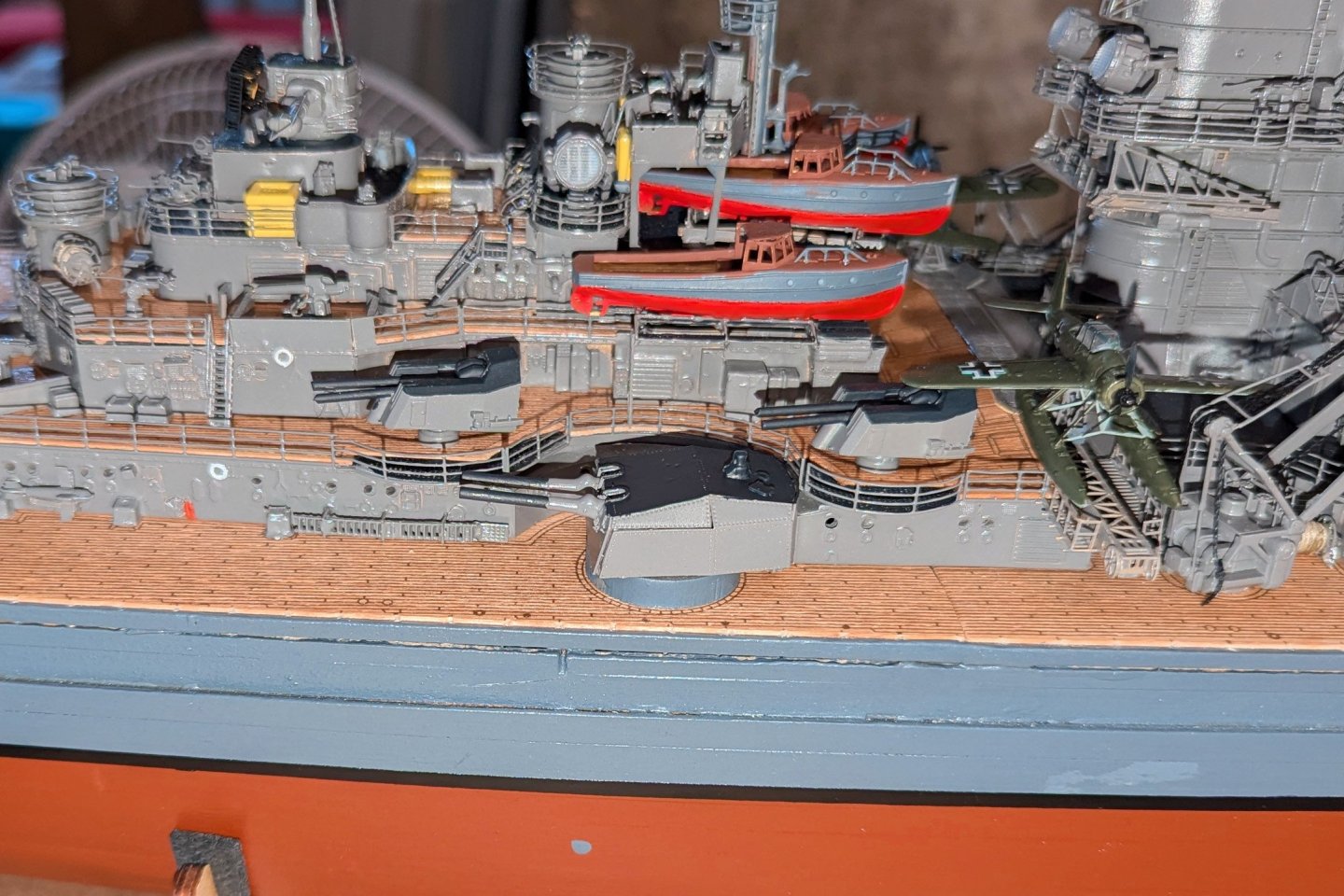

Officers Launch built and mounted. Cranes (previously built) also now mounted on both sides. Regards, David

-

Here's the first motor launch. Requires some careful hand-painting and small parts assembly. Regards, David

-

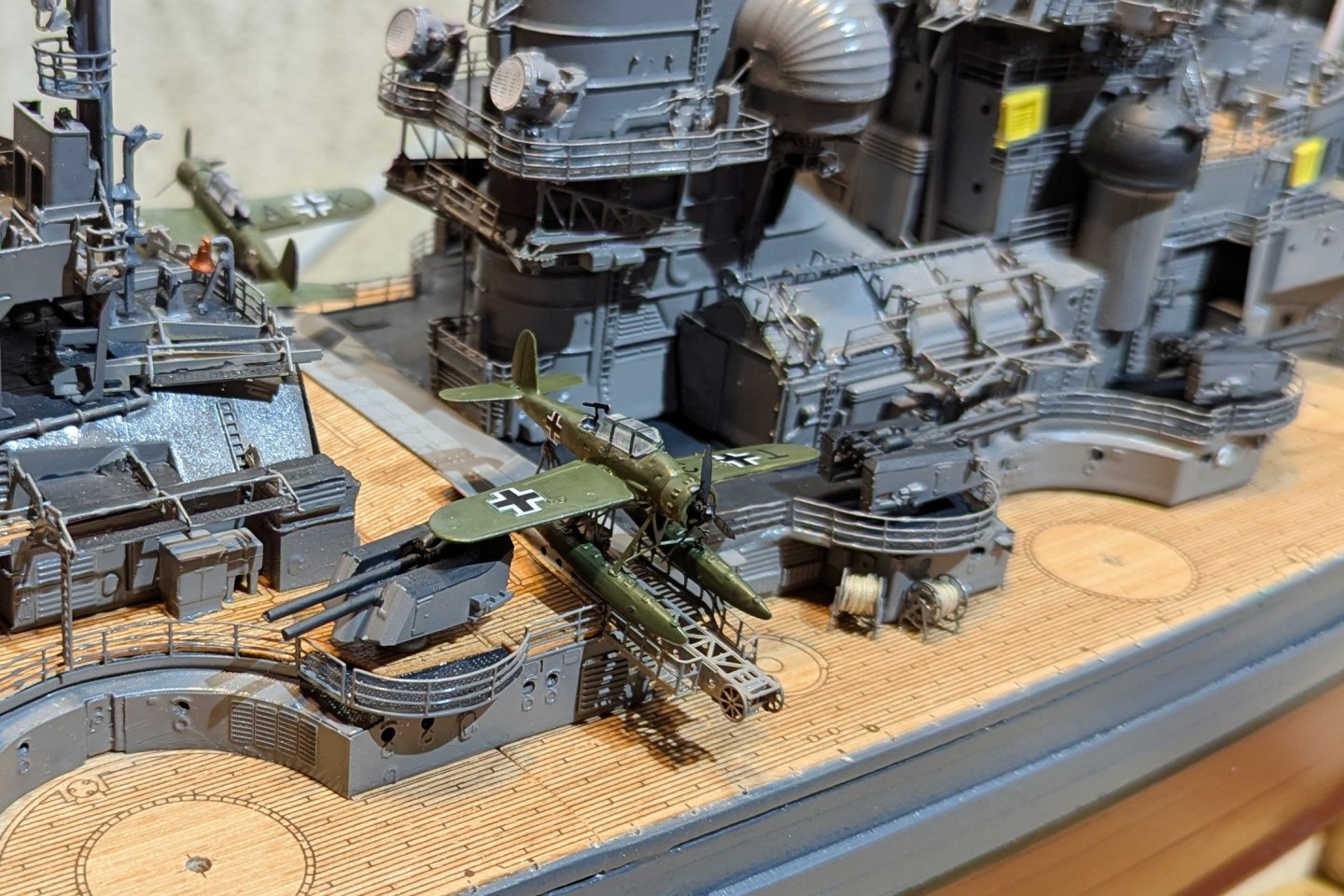

Built, painted and decorated these two little Arado floatplanes. I need to wait for some clear spray to arrive from Amazon today, to be sure the decals are secured, and then I can mount them on the catapults. I read up on the Arados. All German heavy ships were equipped with them. The Bismarck's never flew. In her last battle, they wanted to use an Arado to get some important documents off to land, but discovered that the catapults weren't working, so the planes went down with the ship. Regards, David

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.