-

Posts

1,075 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drobinson02199

-

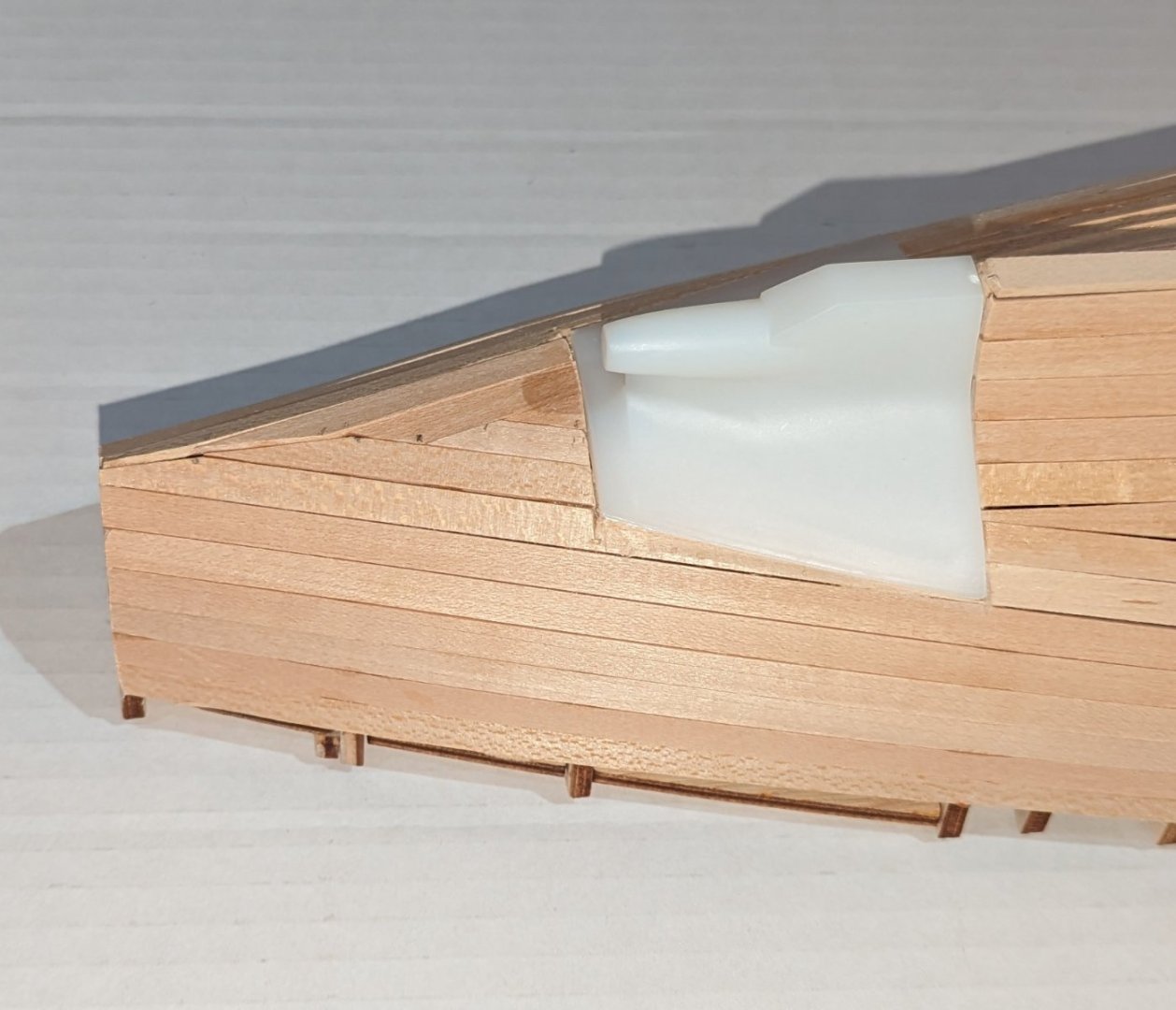

First planking done. These are pictures of the rough, unsanded hull. There is a plastic piece that fits into the hull as shown. Regards, David

-

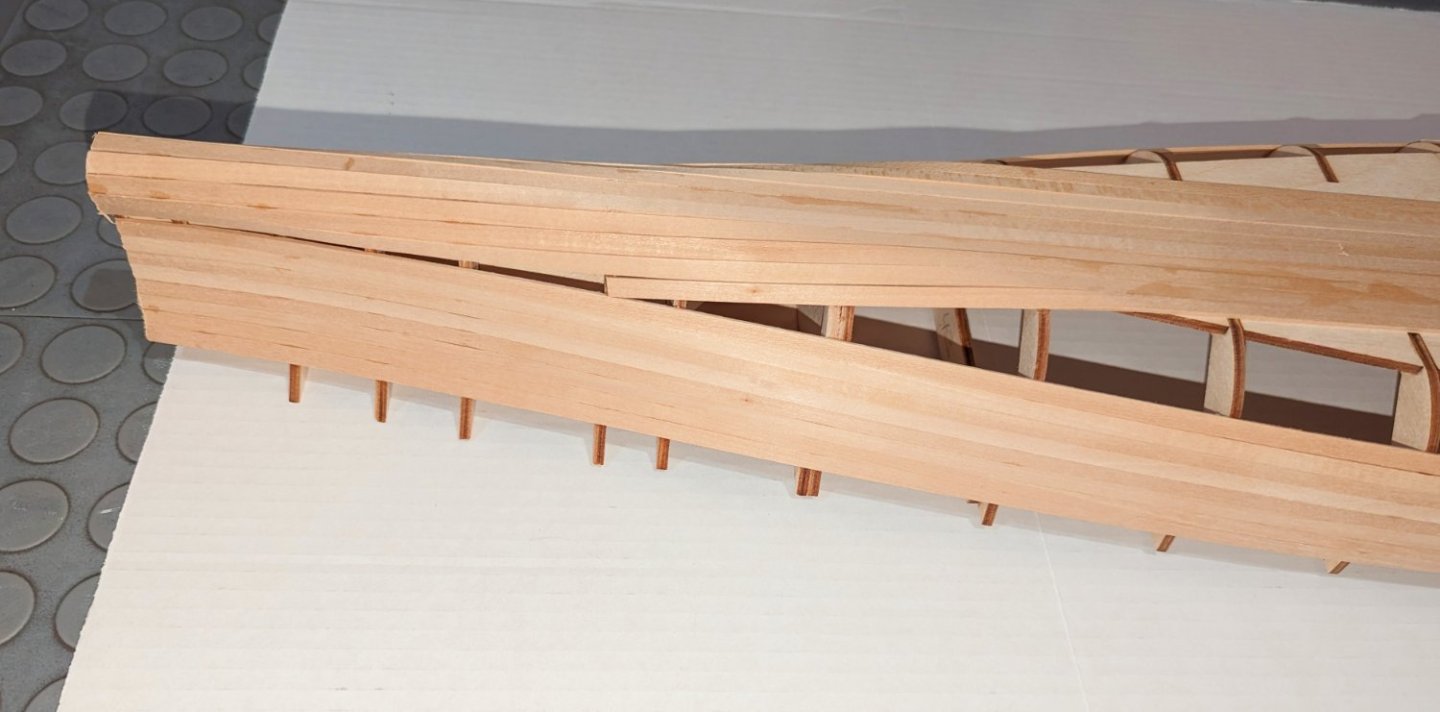

Planking progressing. I'm now at the point where I need to start shaping planks and using stealers. The planking wraps around the hull at the bow and stern, and I've used my steamer to help smooth that. This hull shape so far has not had much if any twisting of planks. The last picture has sort of an optical illusion, so I added an arrowhead. The face it's pointing to is vertical and faces aft toward the stern. But if you look for a bit it will "flip." Regards, David

-

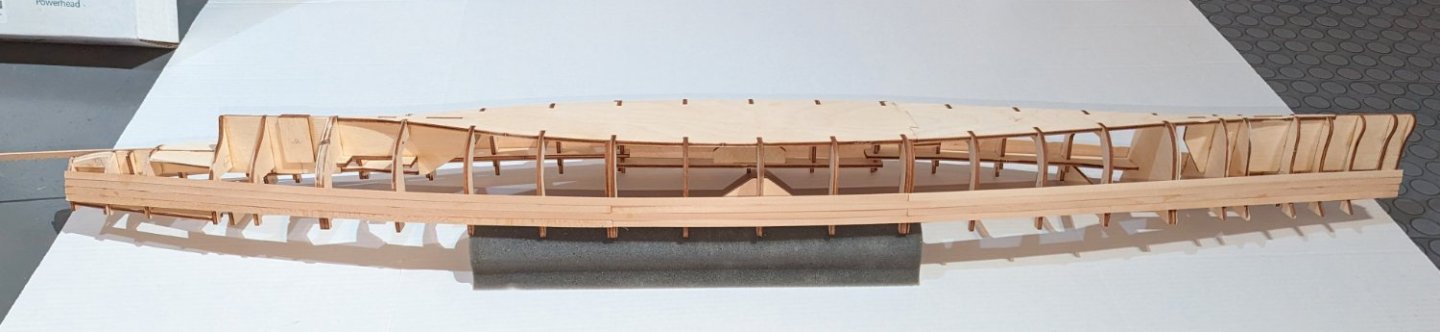

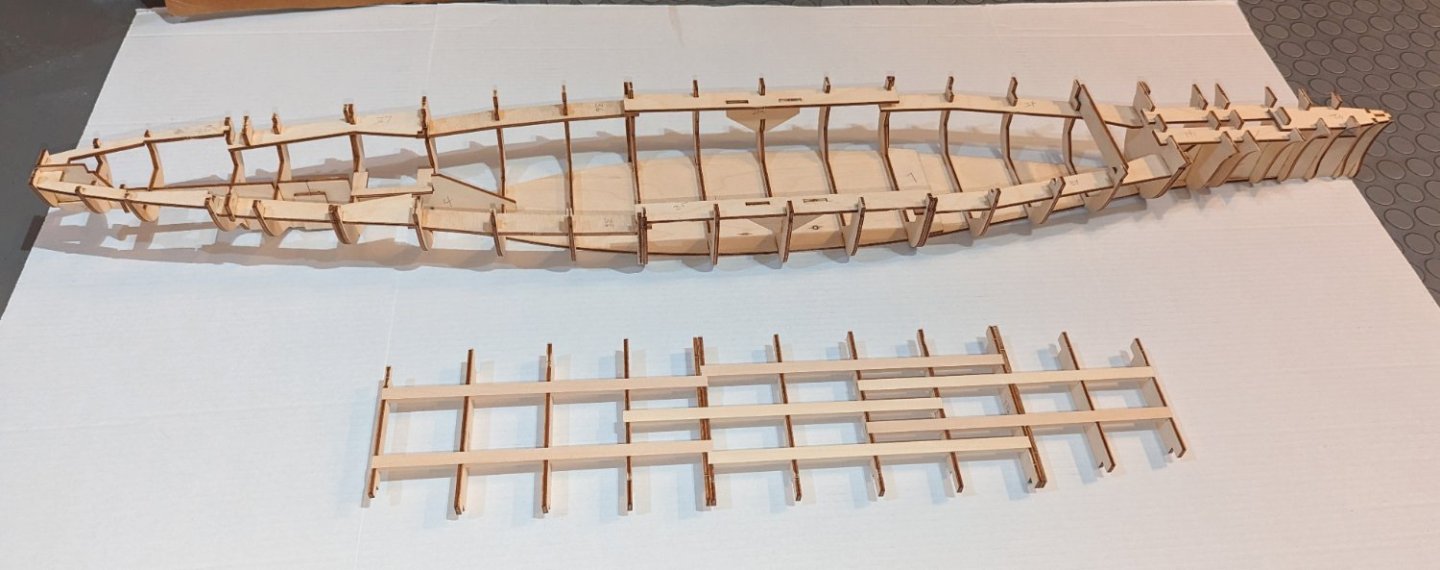

The deck is built to be removable, in anticipation of R/C requirements. Since this will be a static model, at some point it will be glued down. Regards, David

-

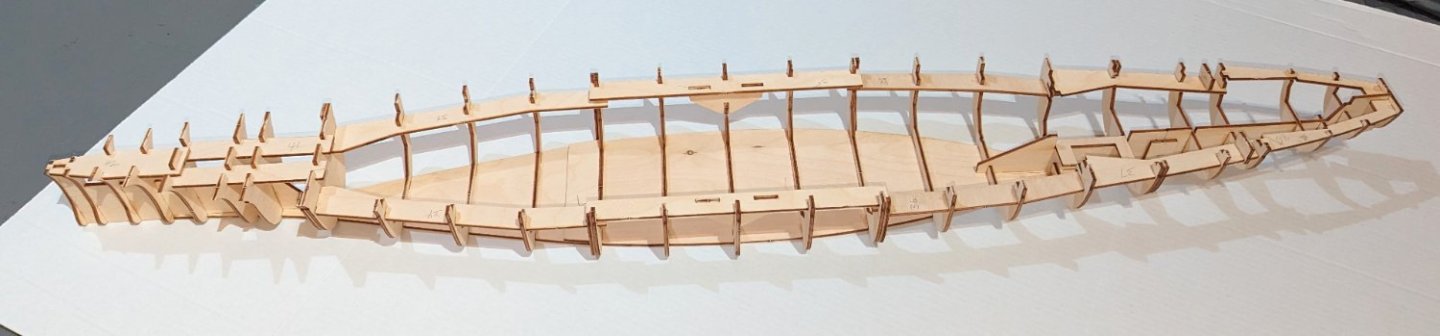

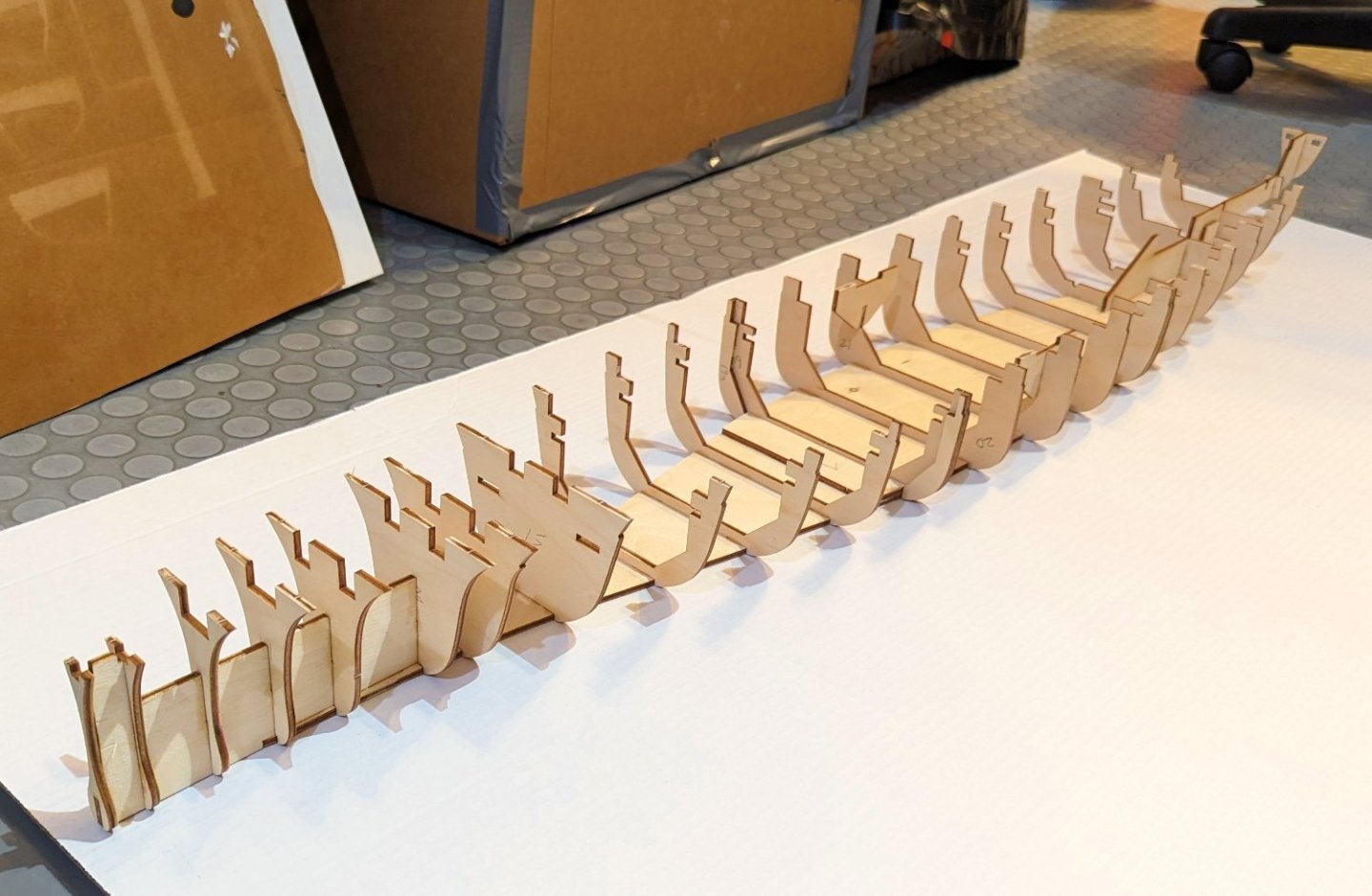

Here's the hull with a bunch of horizontal reinforcing structures added. This eases my mind, because those frame ribs are really "twangy" and not very strong on their own, and a stray elbow would have broken one. Regards, David

-

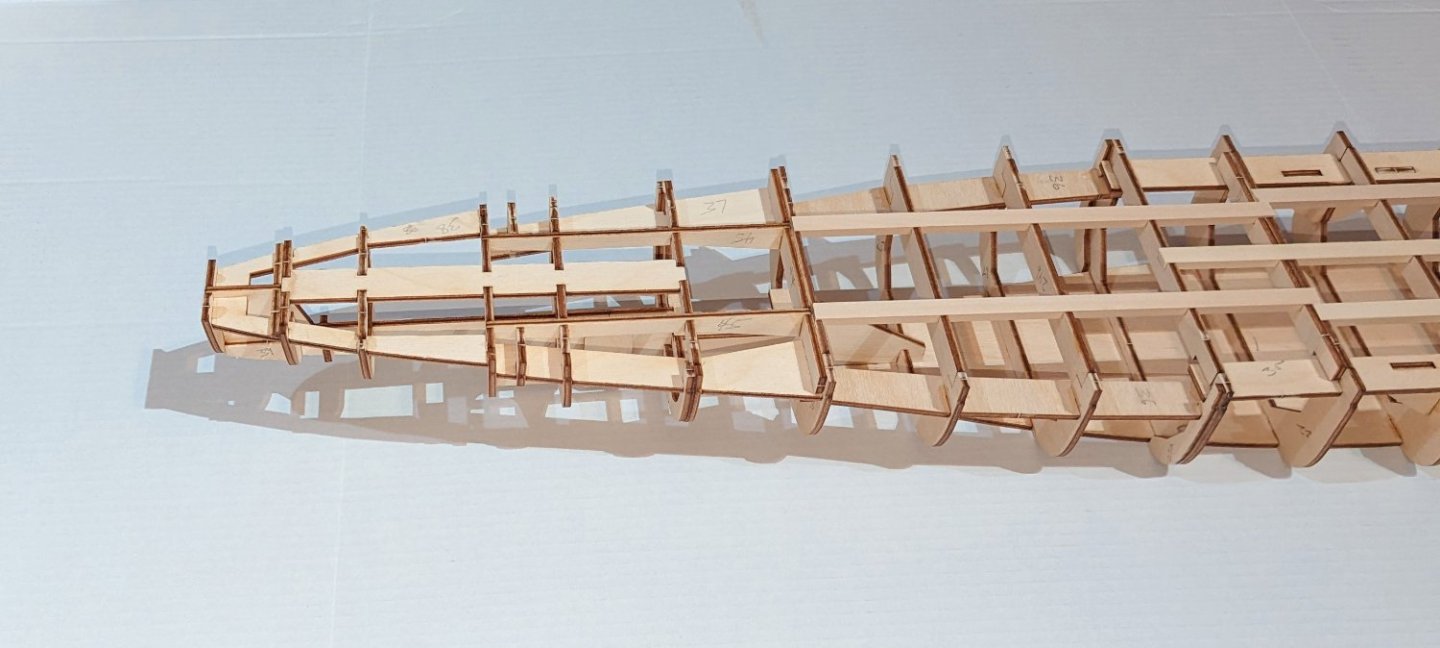

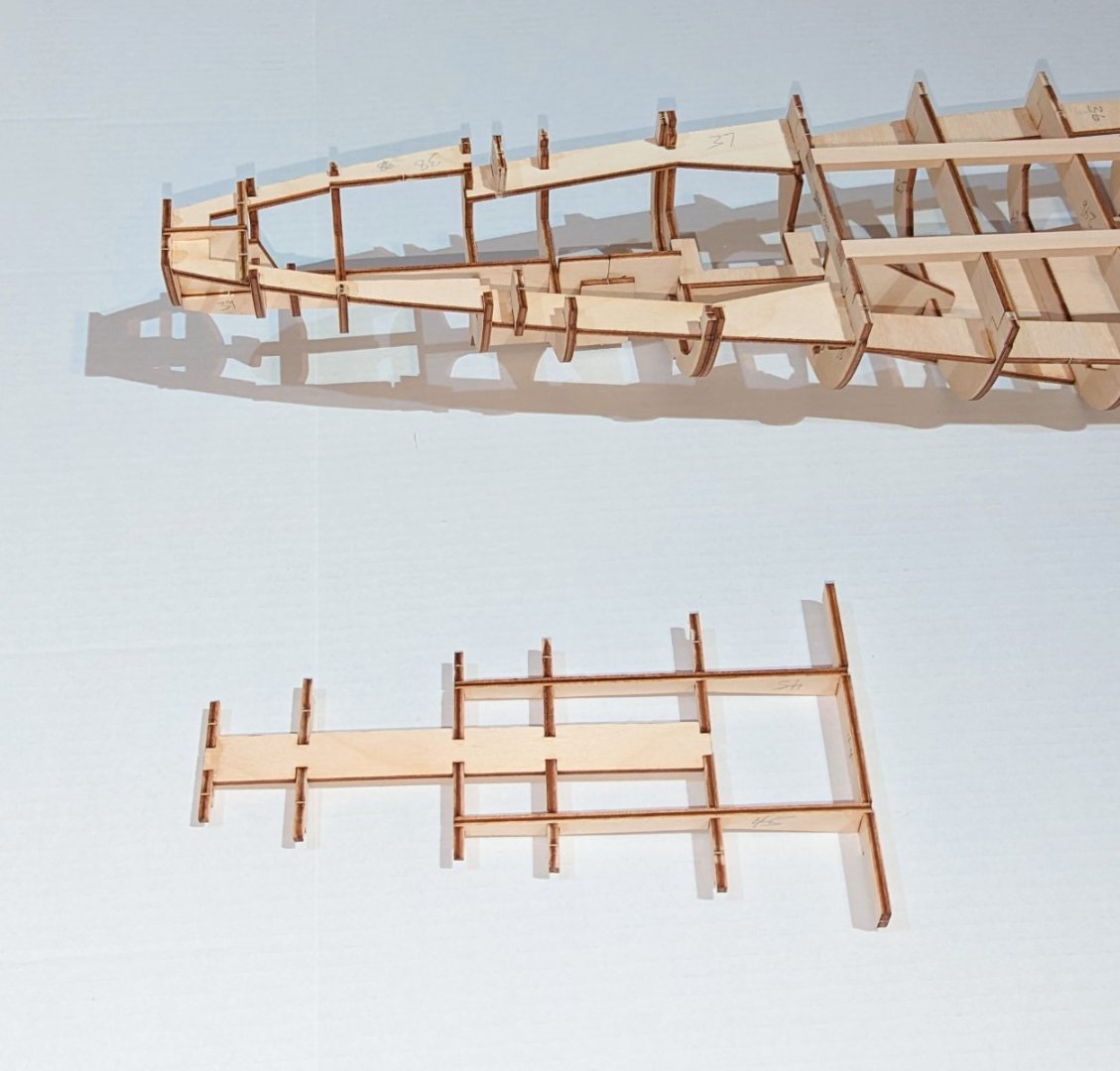

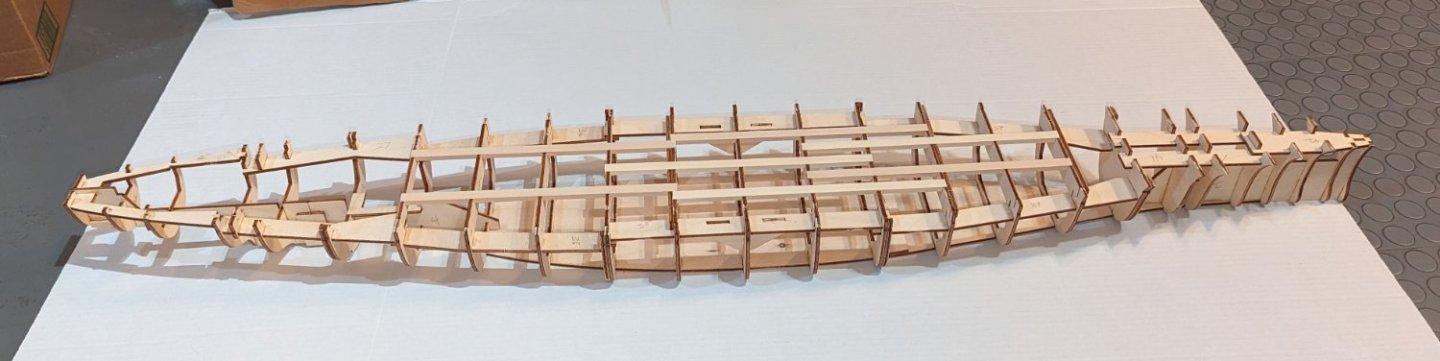

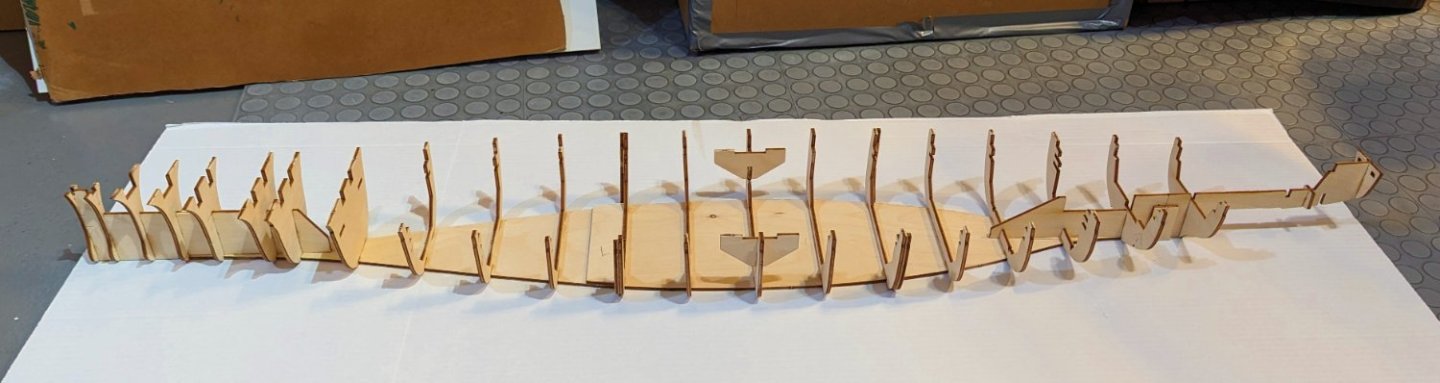

Here's the first part of the keel and frame structure. This will be the longest model in my collection -- what you see here weighs in at 48" long. Hats off to Amati for the plywood laser cutting. Very few connection points to cut, and they are tiny and easily cut. The frames fit into slots with no sanding required -- in fact, there is enough play in them that I used a square while gluing to keep them aligned. Manual called for wood glue, which would have taken forever given drying time. I used BSI medium gel, which is my go-to glue for everything. Regards, David

-

Thomas -- I got it from Ages of Sail, which is where I buy many of my European kits. I think they are the Amati distributor for the US. Regards, David

-

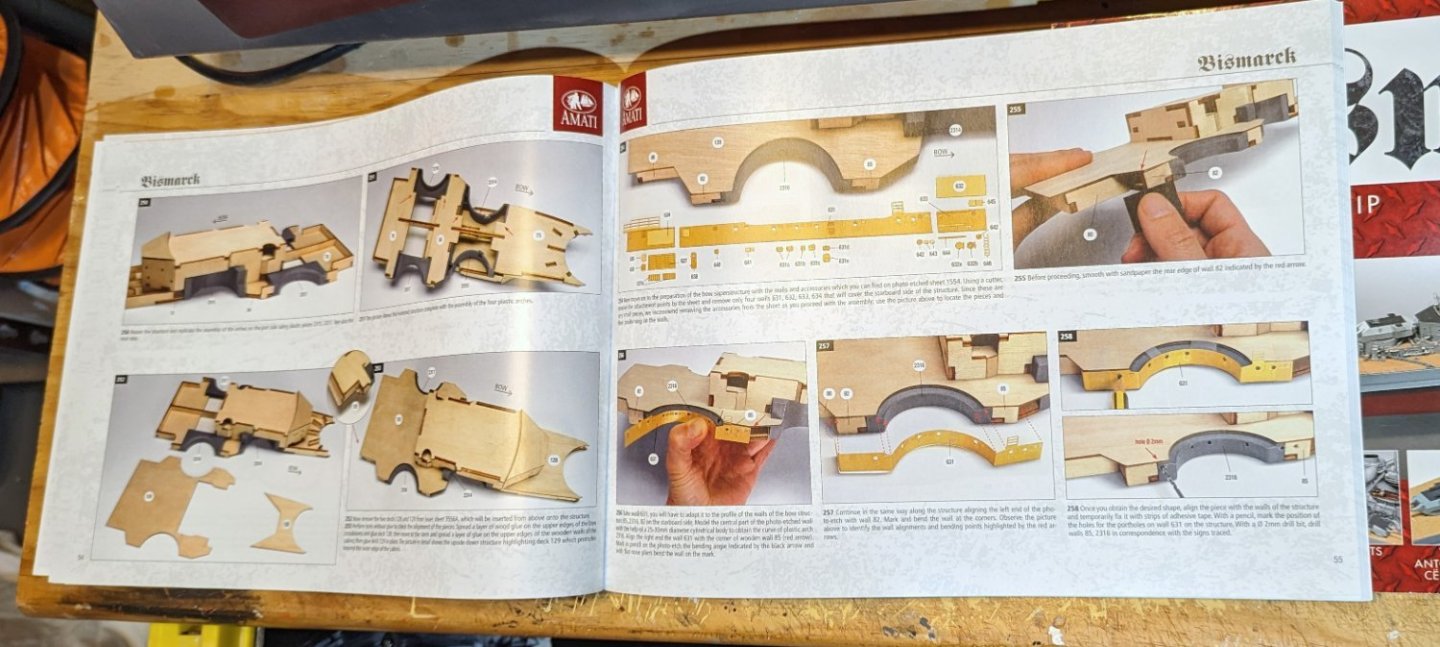

Time to tackle the Bismarck. I'll start with a version of the traditional "what's in the box?" You can see the finished model on the box as well as two very detailed instruction books with color pictures. Example of detail page shown. The hull and deck are wood, but much of the superstructure is built from plastic parts -- I've shown a sample of how they are packaged (in individual clear plastic envelopes). There probably isn't another material that would be feasible. The box says that there are "2,266 photoetched parts" -- so this will take a while. I don't know if that count includes the plastic parts and it's just sloppy box legend drafting, but there are a lot of plastic parts. The usual things are in the kit: wood strip, photo-etched brass, and laser-cut sheets. Those, interestingly, appear to be made of plywood (I haven't pulled any out of the box yet). That's a shift from other Amati models in the Victory series that I have built that used MDF for the hull and frames. This will also be the longest model I have built at 132 cm. Regards, David

-

Thanks, Bob. I've really enjoyed your "USCG Insider" comments. Next one up, when I get motivated, will be the Amati Bismarck. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Completed! Last step was to build the little Naiad boat that goes into the rear launch well. Some pics here of that. A full set of completion photos is in the Completed Kit Built Gallery. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Lots more done. Finished the railings on the main deck and cabin deck. Applied all of the decals, which really spiffs up the ship Applied black striping at the waterline. Now what remains is the little Zodiac boat that fits into the rear well -- and that will be it. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

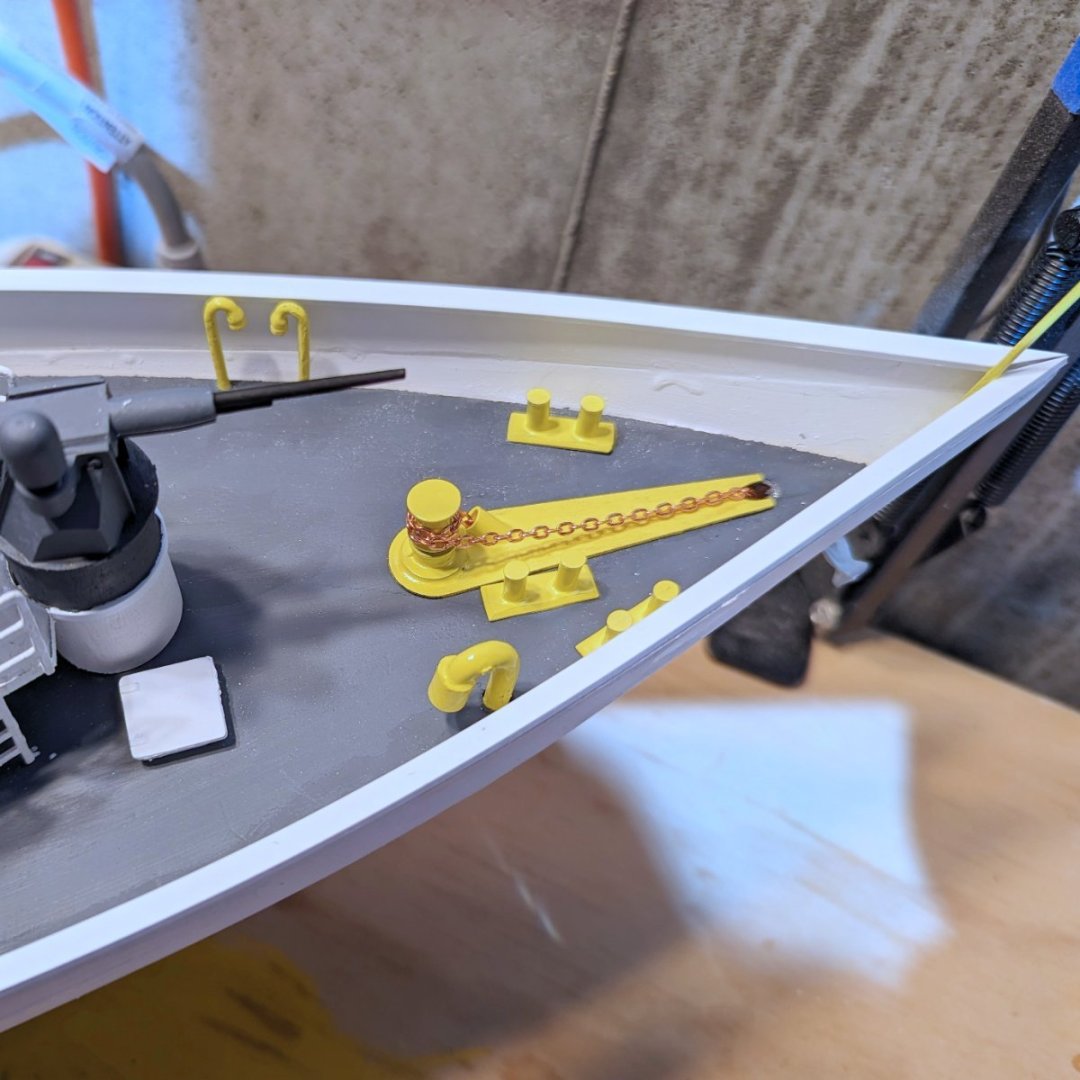

More deck fittings. The instruction manual says to build the rear railing fixed onto the stern, and then paint it. But my only yellow is spray paint, which I want to match to, so I reverse engineered it to make it removable. See first two pictures. Then painted yellow. Other deck fittings on stern and bow shown below. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

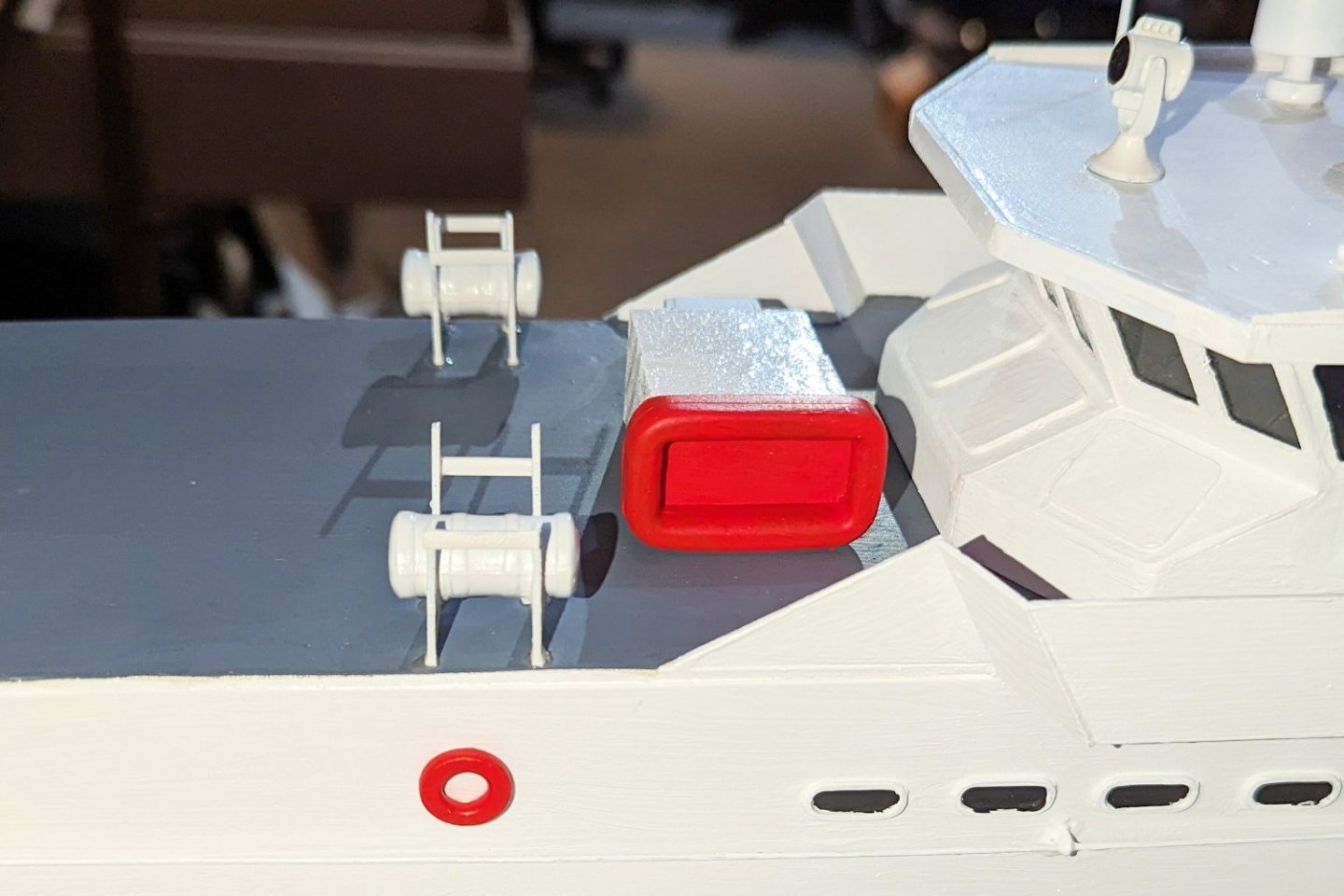

Lots of deck fittings added: Air vents Whip antennas Radar domes, radio antenna, searchlights Inflatable life rafts; rigid life raft Ammo lockers Flag Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Thanks, Bob. That's really interesting stuff. Once I have the model completed and have completion pics, I might give them a call. As a USCG alum, are you thinking about building this one at some point in the future? Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

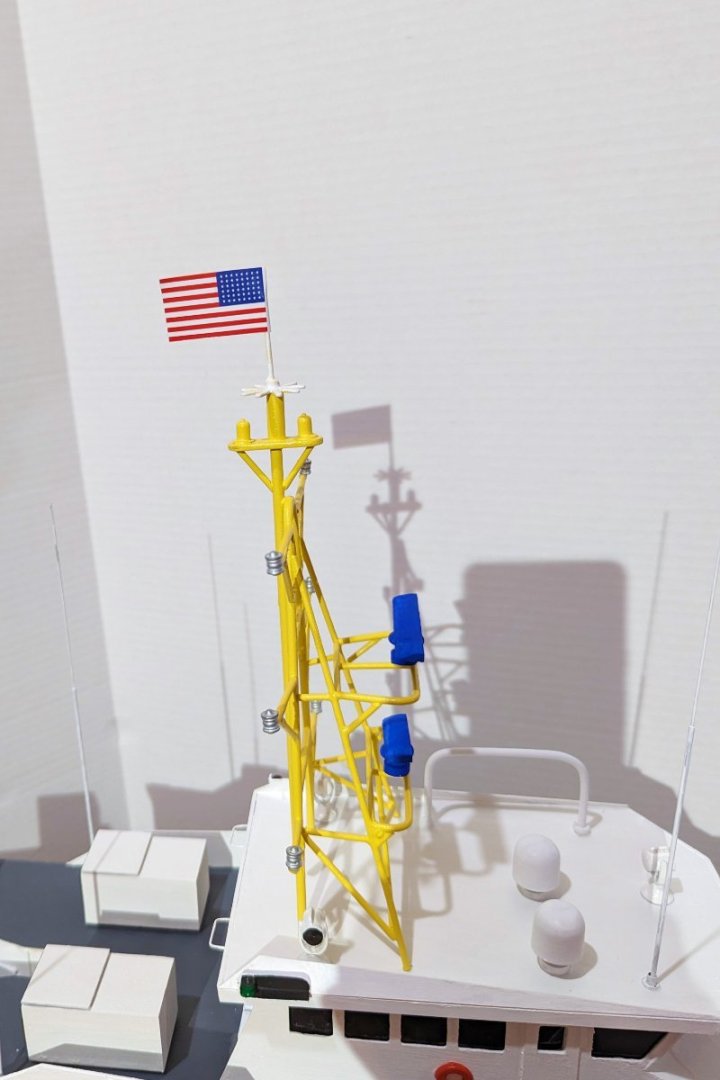

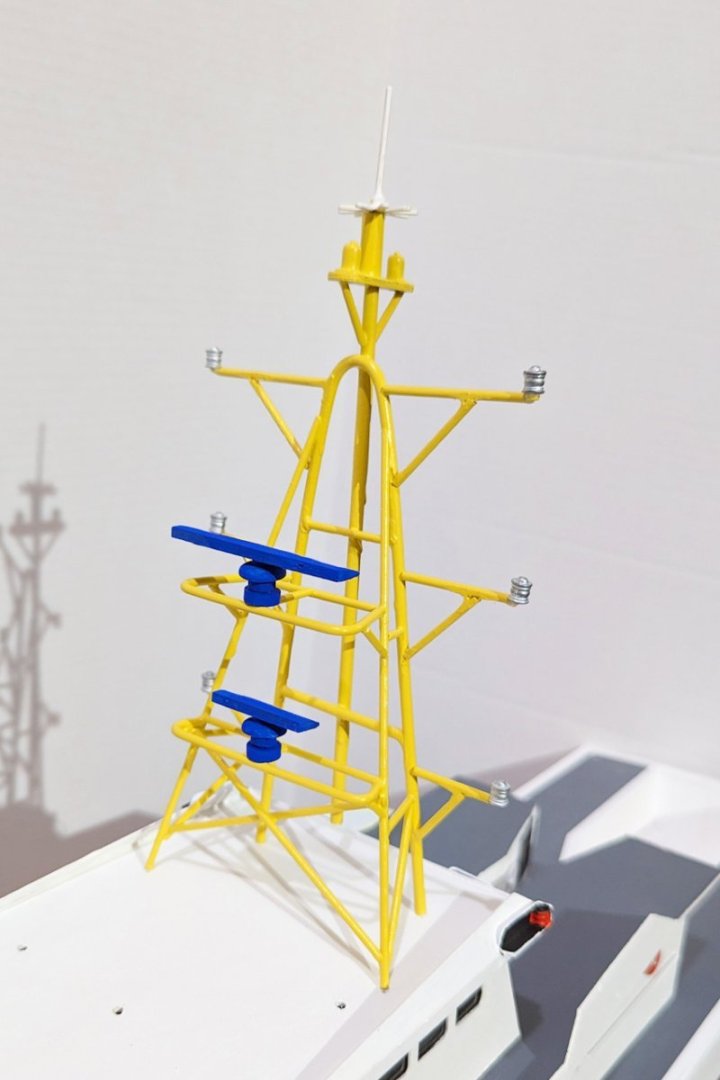

Finished the somewhat complex radar structure. As you can see, it's made up from a combination of styrene tubes and wood dowels. A few construction notes: It's just a bit oversized. That's due to a gap between the instructions and the diagrams. For those who might follow, the thing I didn't do was to resize the basic A-frame (before any bracing) to match the full size template. I cut it to the length specified in the instructions, and that's a bit too long. I then added braces, and only discovered that it was oversized as I got into the detail. Not a big deal. If you follow the instructions, the whole thing would be yellow. But the box art shows the white top, blue radars and silver (e.g. unlit white) sidelights. So I resequenced things to match the box art, which i smore interesting. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Thanks to Javelin, I got my head screwed on straight and have now fixed the running light positions. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Thanks, on second look you are absolutely correct. I'll have to repaint. I got my orientation completely screwed up, and I checked and double checked it -- but was just 180 out in my addled brain. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

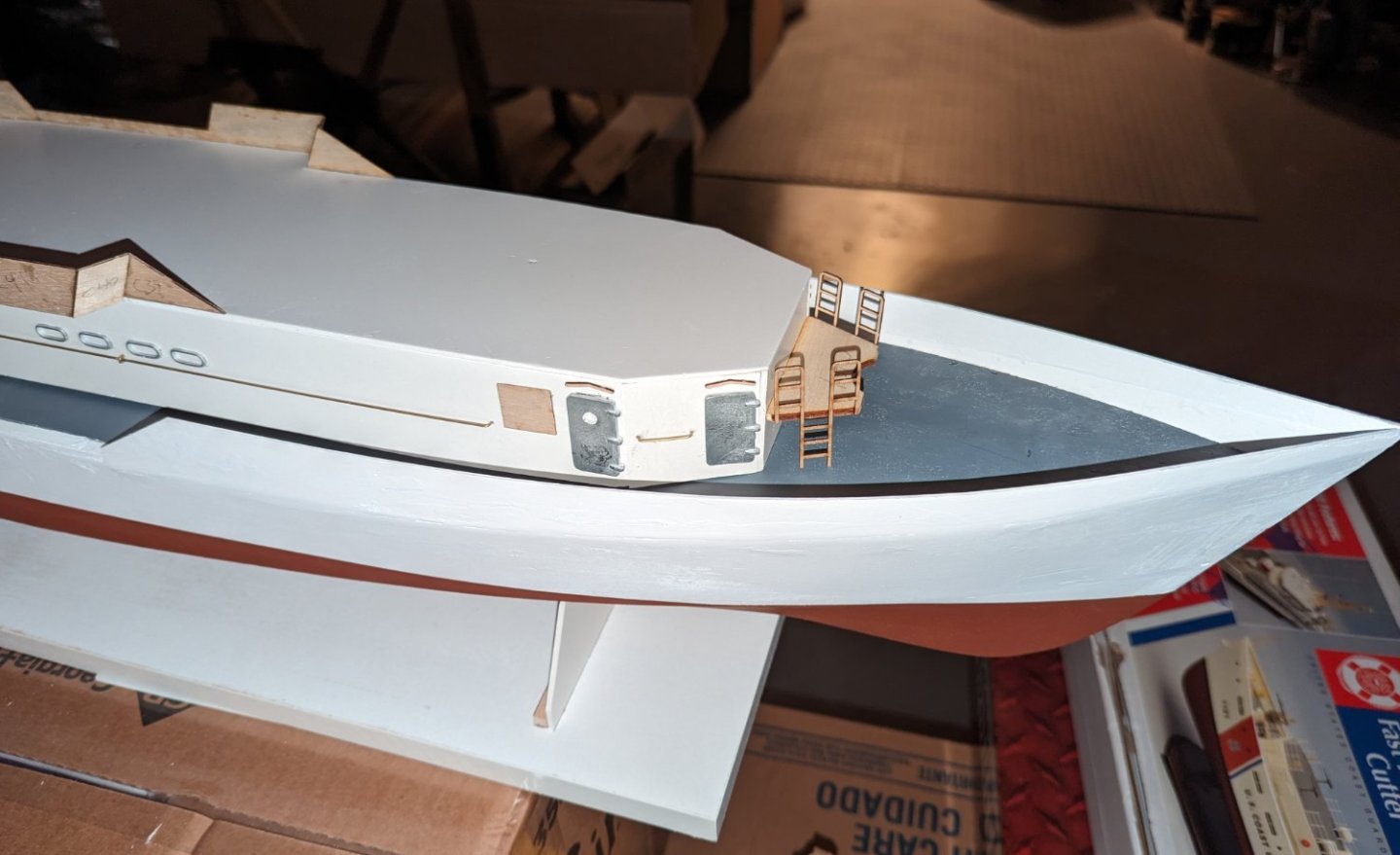

Pilot house roof installed (and glued on). Pilot house and cabin are still dry-fitted. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Now back from vacation and back to the model. Painted the cabin and mounted some accessories on the sides. Cabin in pictures is dry-fitted to the main hull at this point. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

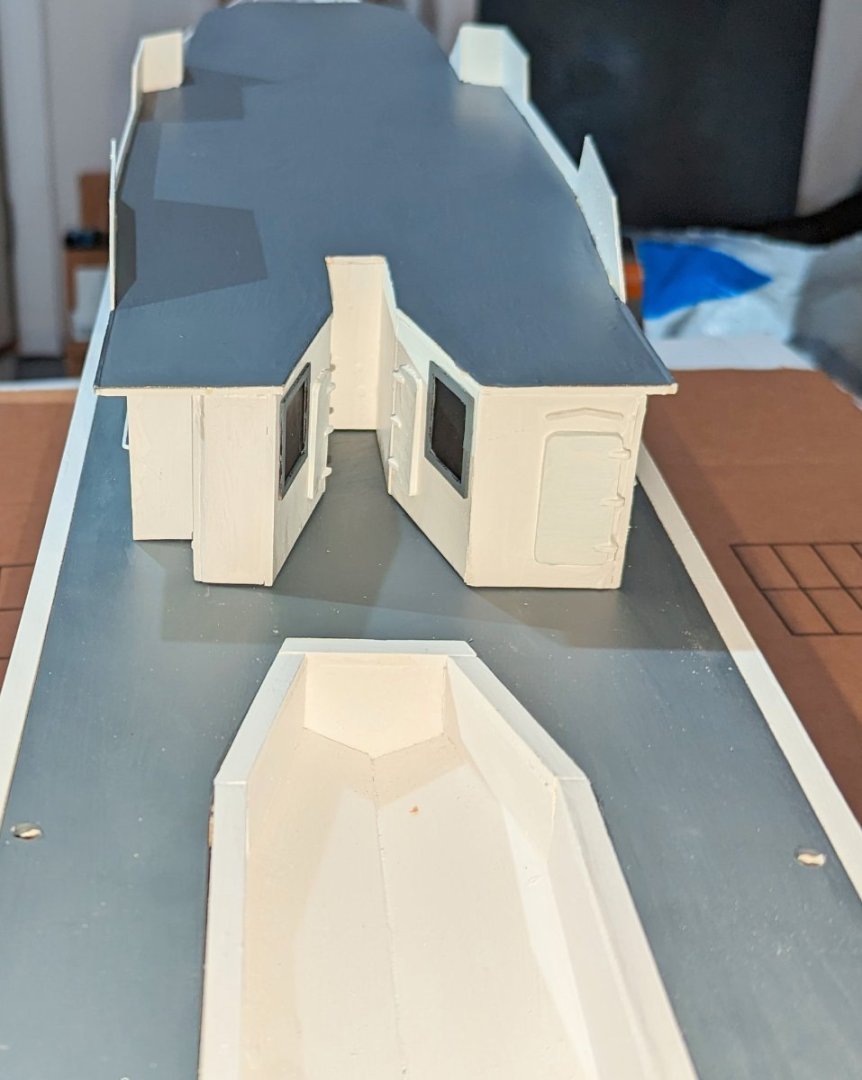

This will be my last post for a few weeks as I'm headed out for a vacation. I have added most of the details to the cabin. Everything you see will be painted white, and then black fill inside the portholes. I've placed the cabin where it will go on the boat. The main hull is sitting loose on the stand, which will be painted black when construction is done. The top cabin deck will be gray. The long side rails need a support bracket about halfway down. What's not mounted yet are: large vents, painted gray with black fill, and life rings, painted red (the manual wants orange, but I don't have any orange paint and red will do fine). I will tackle the painting when I get back in late September. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Cabin sides on and something called cabin shields mounted. Next step is to add some detail to the cabin sides. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

-

Here's the cabin framework. This is upside down, so the cabin roof and deck are lying on the work table. Next step is the cabin sides. Regards, David

- 46 replies

-

- Fast Response Cutter

- Dumas

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.