Mr Pleasant

Members-

Posts

57 -

Joined

-

Last visited

Profile Information

-

Location

Narangba, QLD, Australia

Recent Profile Visitors

-

Mr Pleasant reacted to a post in a topic:

HMS Bellona by Frecap - Corel - 1:100

Mr Pleasant reacted to a post in a topic:

HMS Bellona by Frecap - Corel - 1:100

-

Mr Pleasant reacted to a post in a topic:

HMS Sphinx 1775 by Ronald-V - Vanguard Models - 1:64

Mr Pleasant reacted to a post in a topic:

HMS Sphinx 1775 by Ronald-V - Vanguard Models - 1:64

-

Mr Pleasant reacted to a post in a topic:

3D Printing Cannons in Resin

Mr Pleasant reacted to a post in a topic:

3D Printing Cannons in Resin

-

Mr Pleasant reacted to a post in a topic:

3D Printing Cannons in Resin

Mr Pleasant reacted to a post in a topic:

3D Printing Cannons in Resin

-

jpalmer1970 reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

jpalmer1970 reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

Ronald-V reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

Ronald-V reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

Thukydides reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

Thukydides reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

GrandpaPhil reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

GrandpaPhil reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

yvesvidal reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

yvesvidal reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

ccoyle reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

ccoyle reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

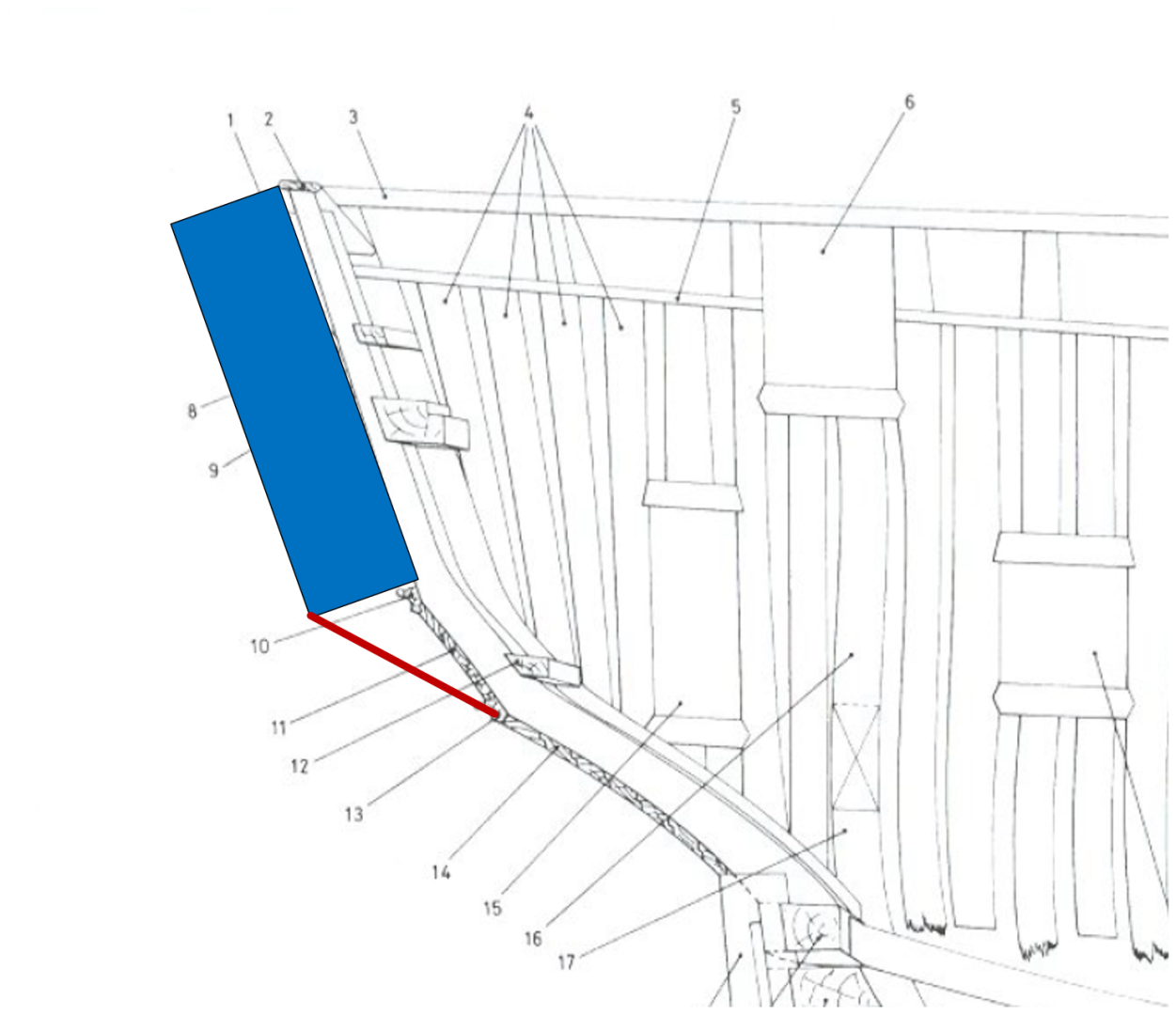

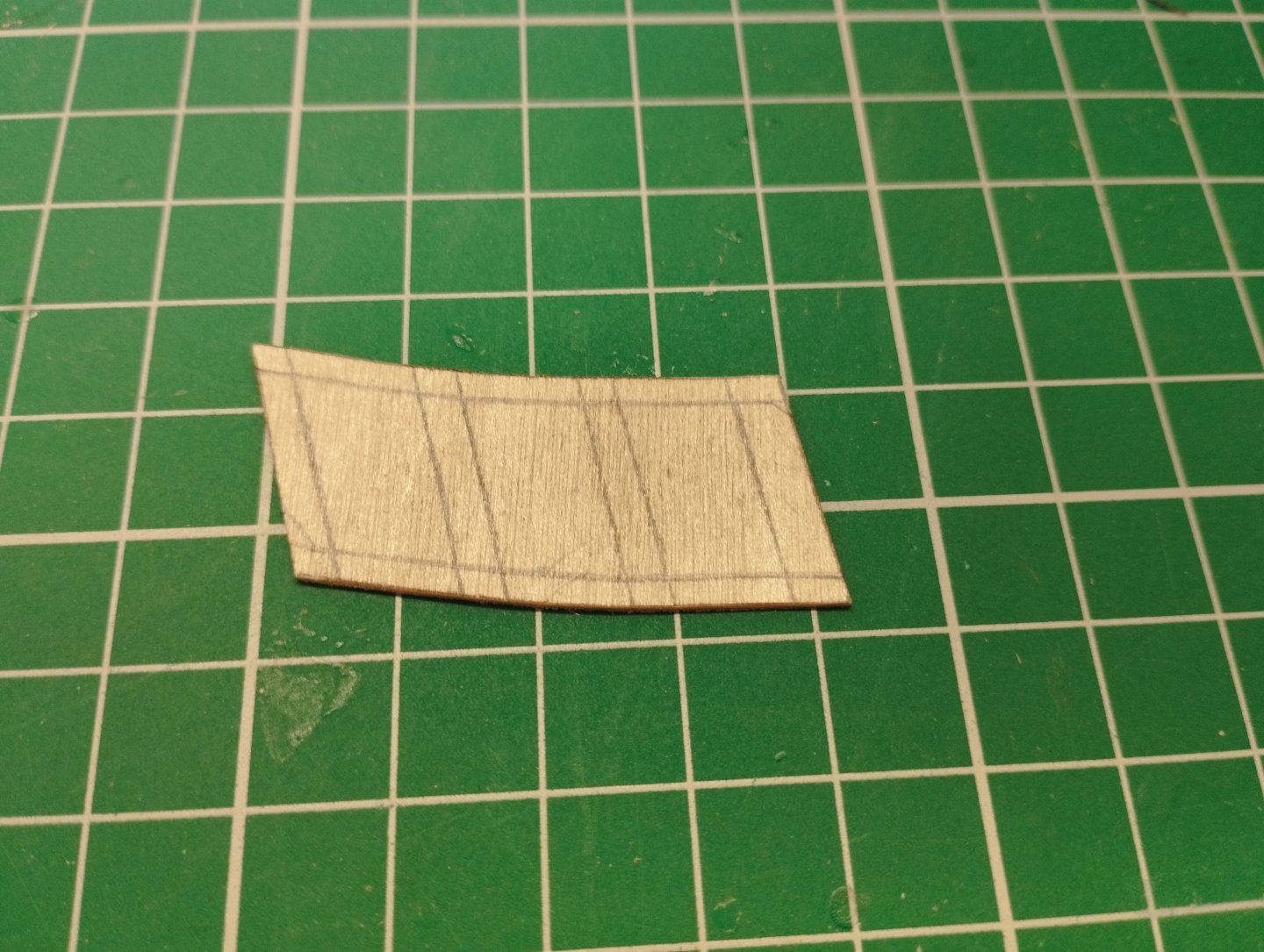

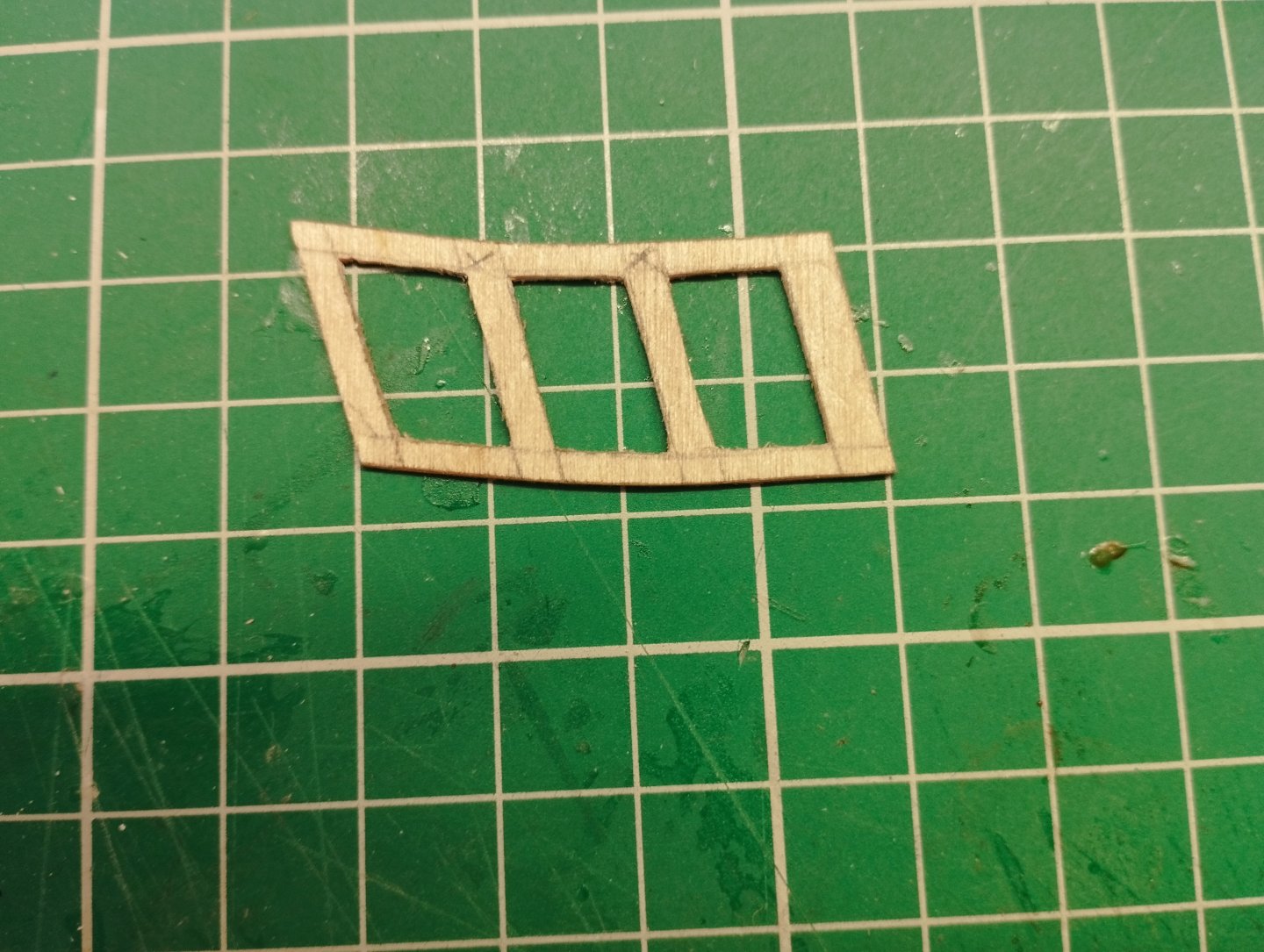

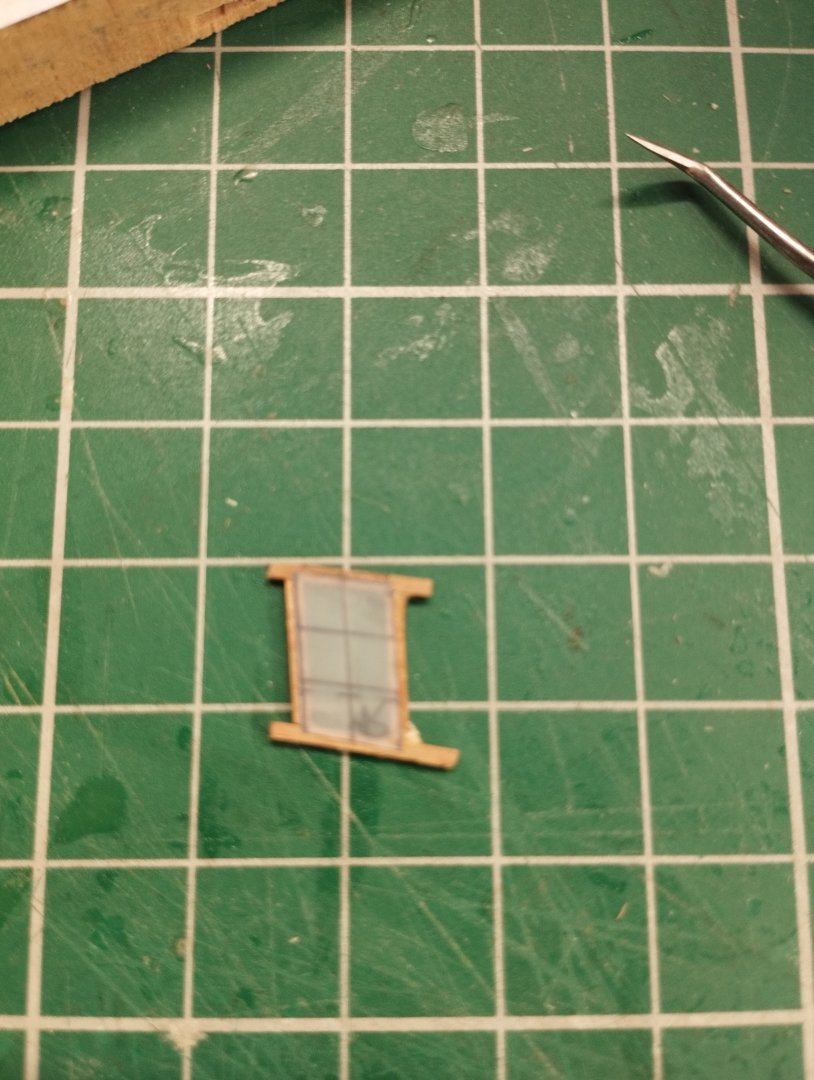

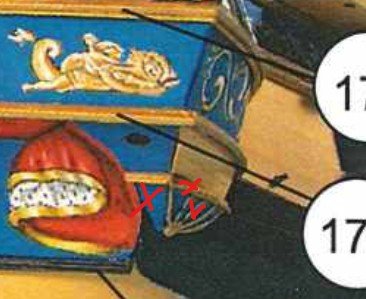

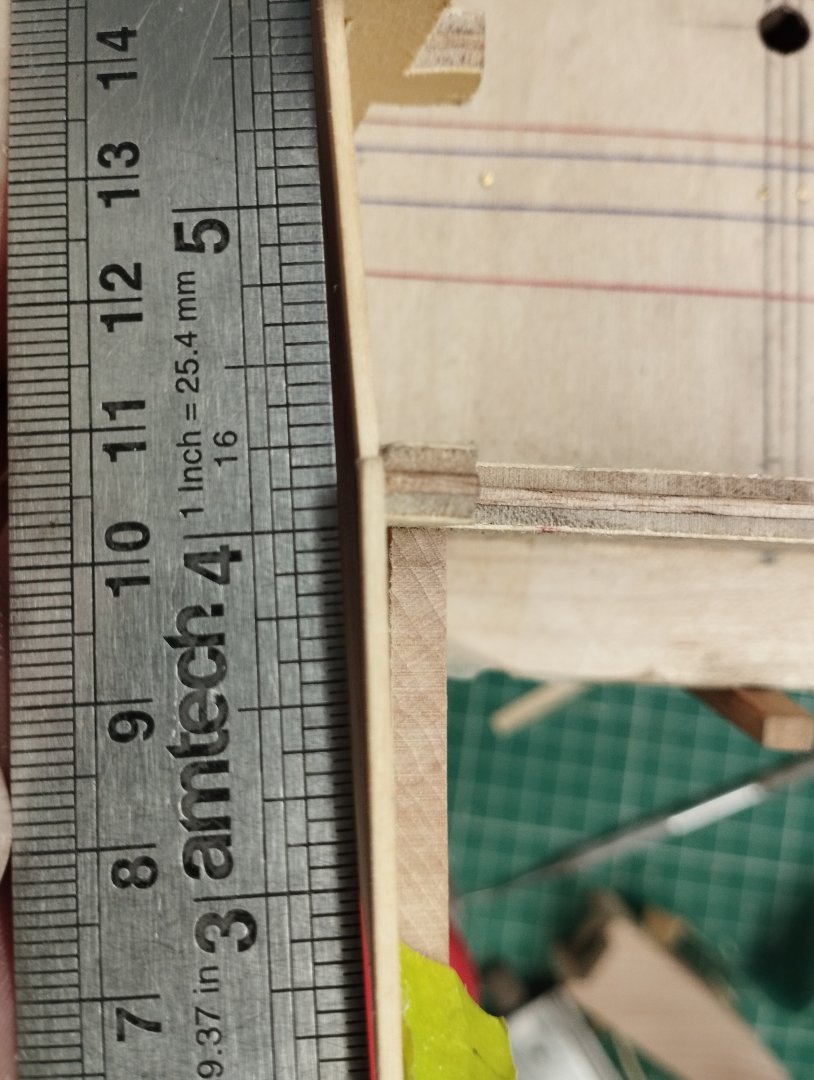

Hi All Work has been continuing on the stern area. The paper model gives the below and this is the look I'll be aiming for with some slight differences in colour scheme First things first was to determine the template to make. I'm slightly wider than the paper version due to the width in planking, I'd purposefully not made allowance on the bulkheads for the thickness of the double planking compared the requirements if this was been made out of paper and also referring to post #9 we can see the back has flared out a little (picture with ruler). I wanted to keep the shape at the edges so I cut two templates from those provided and slipped one behind the other to get the width whilst keep the height and edges correct. Once this was done it was a matter of arranging the windows to cater for the increase in width Windows were then drilled out and a the fascia made and holes created for the stern chase ports. Its worth noting at this point that the piece was made with 2 x 1.5mm ply resulting in a 3mm piece and the facia made with 1.5 mm ply....more on this later Widows were then created with 1mm x 1mm cherry for the outer frames and 1mm x 0.5mm for the inner. The small arches in the window frames were made with the aid of a 2.5 mm drill bit in a soldering iron, wetting the wood and using the heat to bend into shape and then cut to size So far so good....until coming to fit it on the ship!!!. With making the piece 3mm thick it didn't lend itself to fitting in with the planking on the upper counter. I've tried to show the issue below using Diana from AoTS as a background with the blue rectangle representing the 3mm stern piece and the two options I considered Option 1 on the left would have left the stern piece proud of the planking Option 2 on the right would require a single piece fitting to marry the planking and stern piece together as shown by the red line. Neither option was ideal but option 2 was closer to reality...despite knowing I wouldn't be happy I tried it in any case. I tried hard to convince my self that with a bit of filling, sanding and painting that I could live with it and also acknowledging the angle of this piece would make it difficult to see the name of the ship, but who looks at the back of the ship I kept telling myself. After days of inner turmoil in trying to persuade myself that everything would be good and I that I could live with it, I elected to remove it an start again. This time I stuck to a single piece of 1.5 mm ply and went through the processes above and that allowed the planking and stern piece to come together nicely. I don't have a straight after photo but this is how it came together Next was to make the columns between the windows To make the pedestal and associated top piece I scraped a channel in a 1.5 x 1.2 mm strip and made a jig to cut consistent angles. Once this was complete i drilled a hole slightly into the angled side resulting in this...bit small i admit, I probably should have zoomed in a bit more Once painted they were glued in position and masking tape used to determine the height and angle of the column. The tape was forced to make a crease with a pencil and this gave me the template to stick onto a piece of stock to cut/sand to the correct angle. I then milled groves to try and simulate a column To finish off the stern chase ports i reduced a dowel to the correct diameter and created a tube using the milling machine and the dividing head to turn the dowel as I moved the bit. The lettering for the ships name was simply printed onto paper and painted....I may revisit this a later date. After a fair amount painting, repainting, masking and repainting I'm finally at a point that I'm fairly happy with but there is still a way to go to complete this area Thanks for dropping by Mark

-

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

-

KARAVOKIRIS reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

KARAVOKIRIS reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

jpalmer1970 reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

jpalmer1970 reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

ccoyle reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

ccoyle reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

Thukydides reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

Thukydides reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

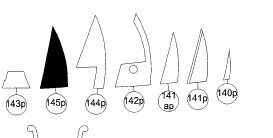

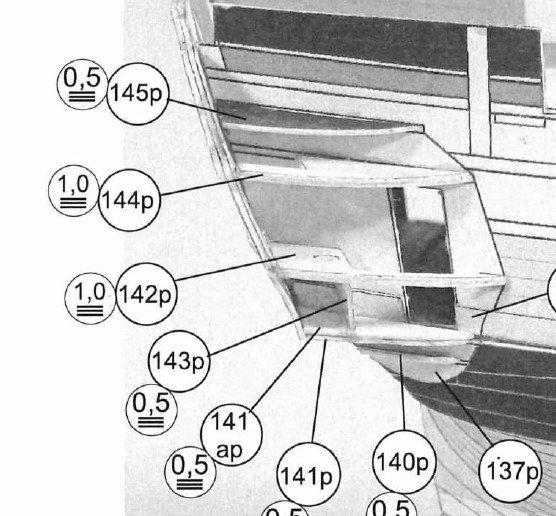

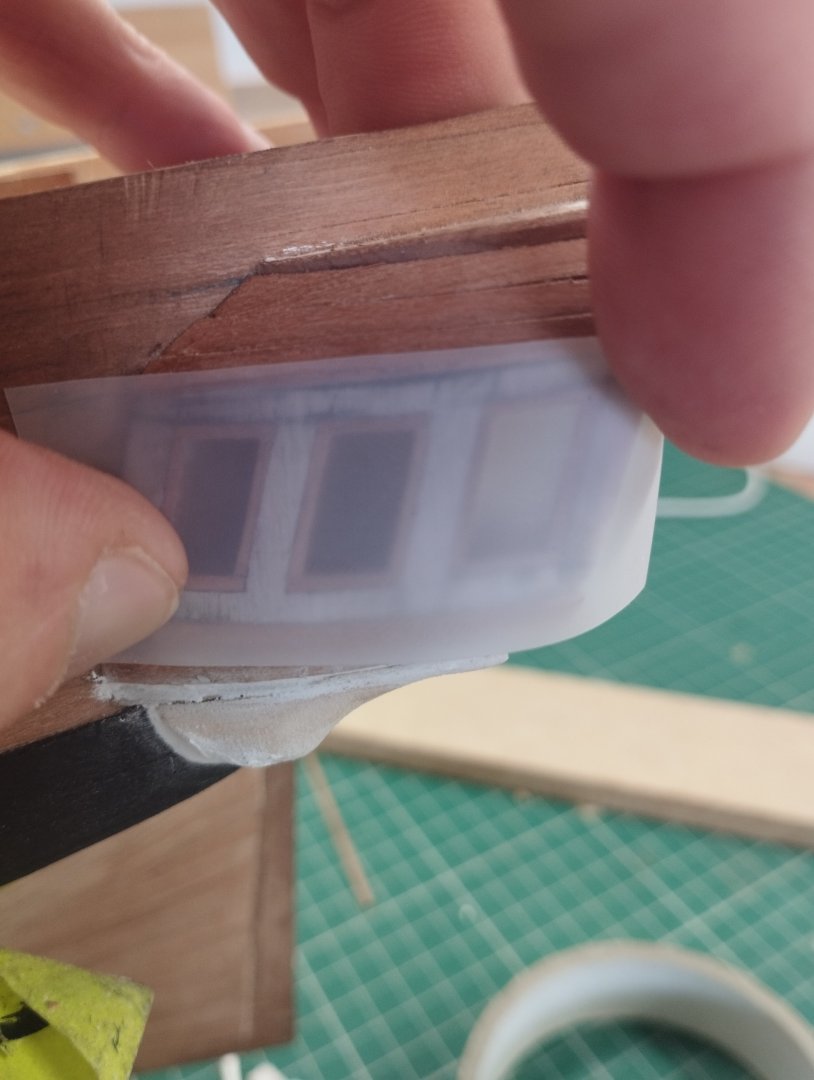

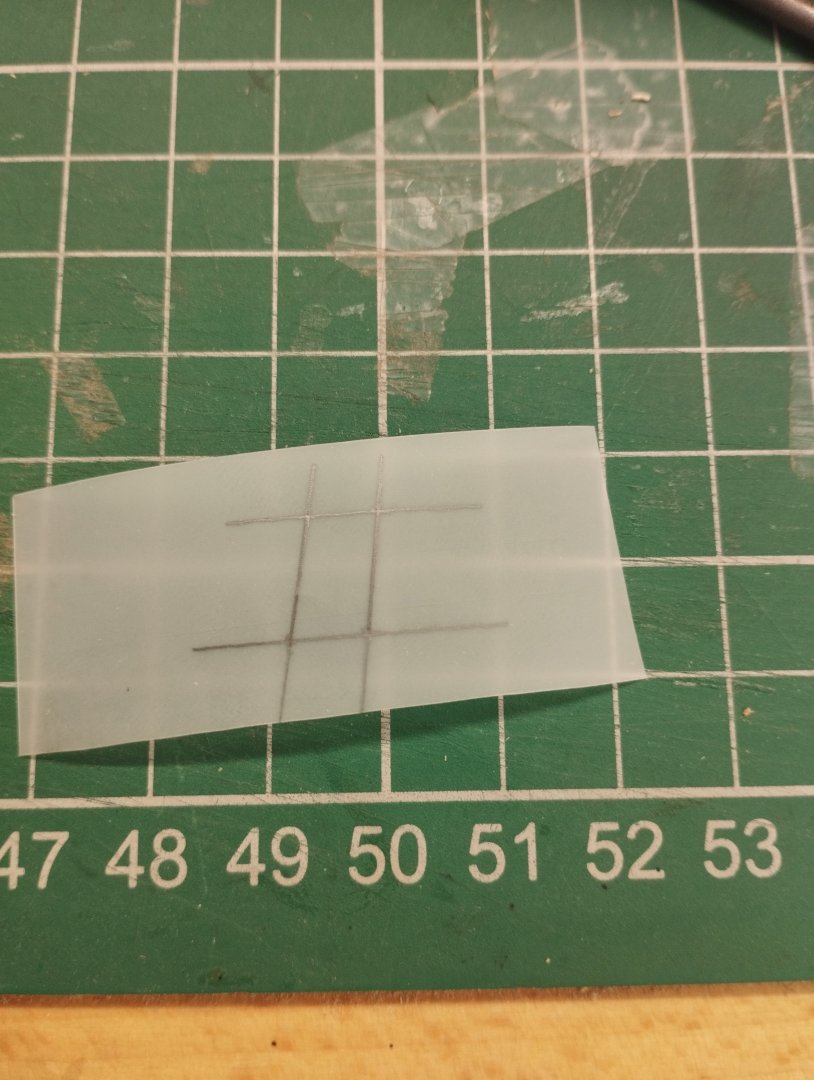

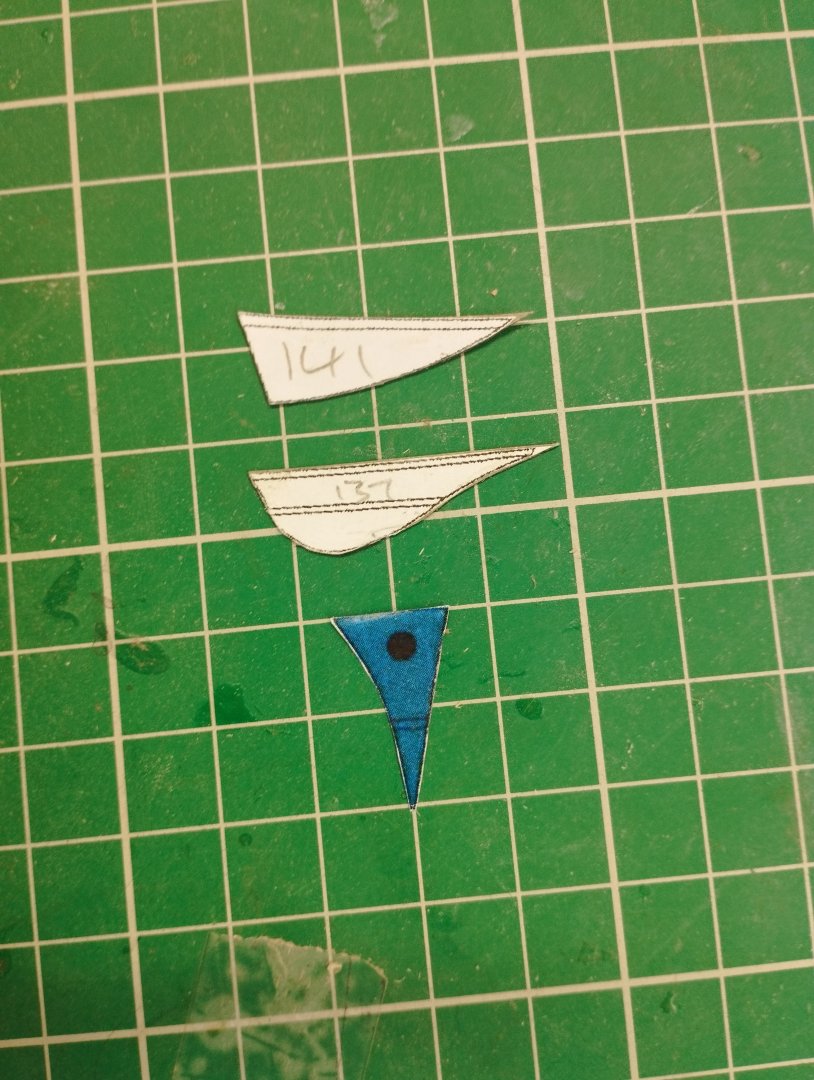

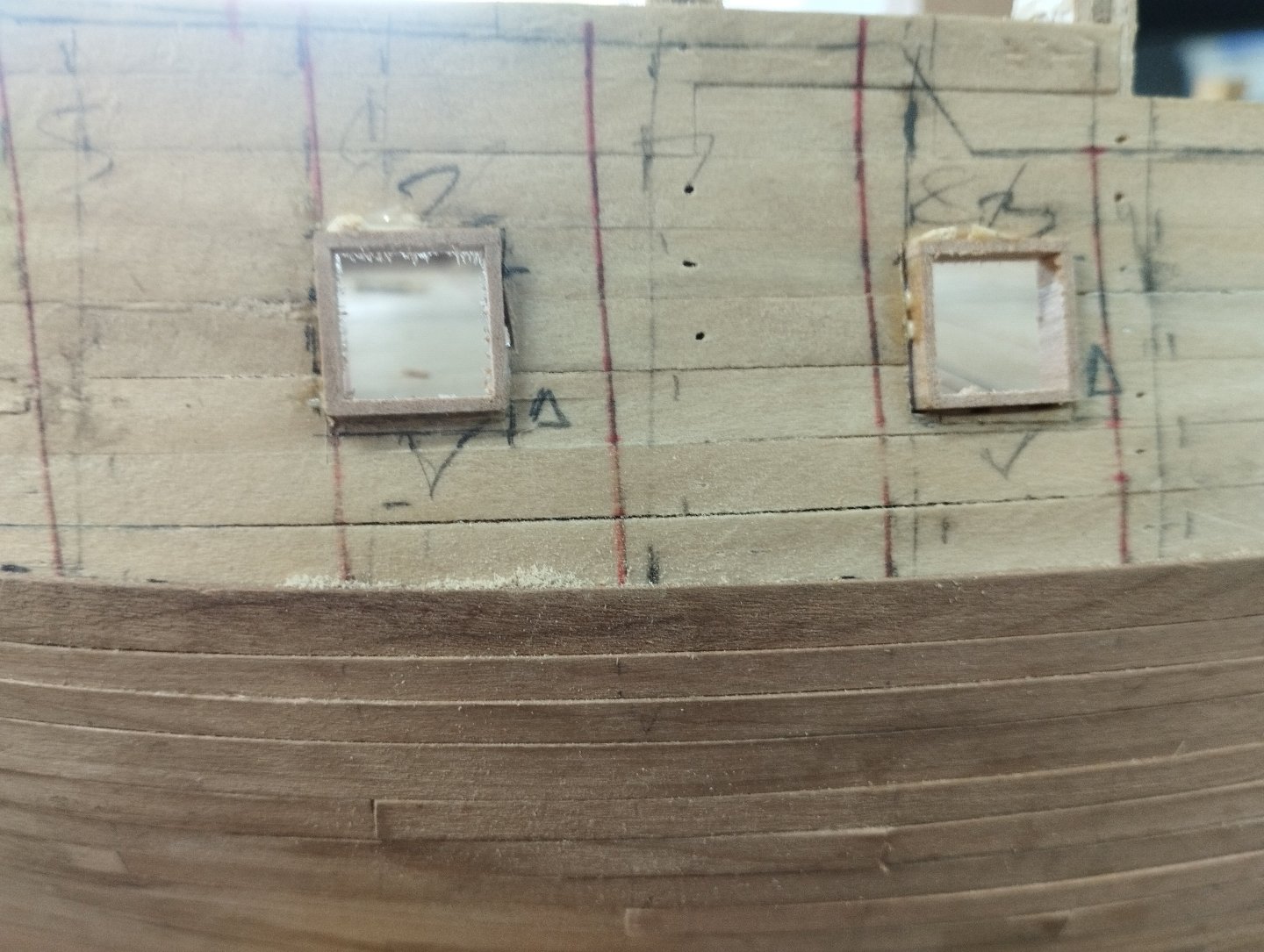

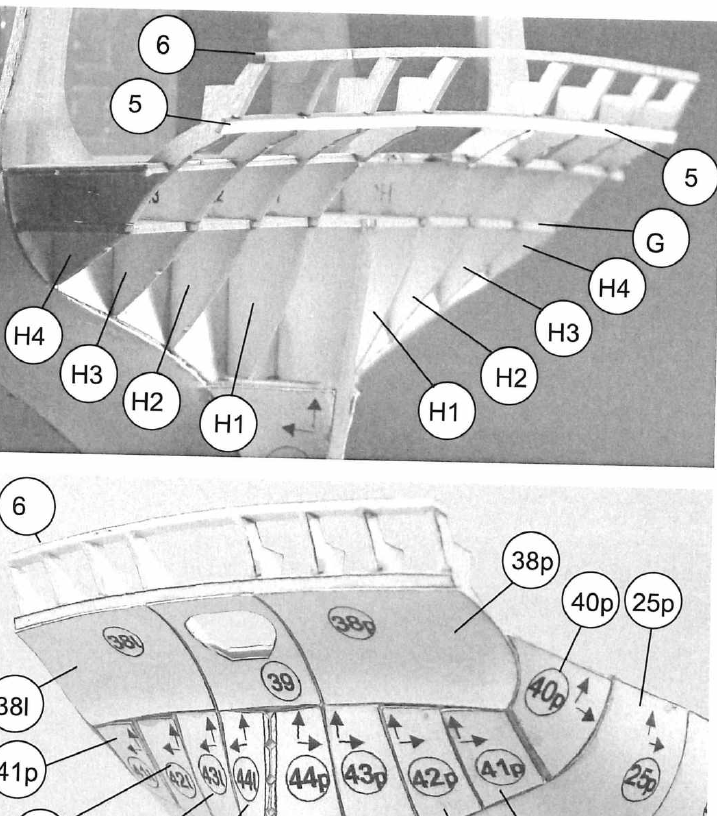

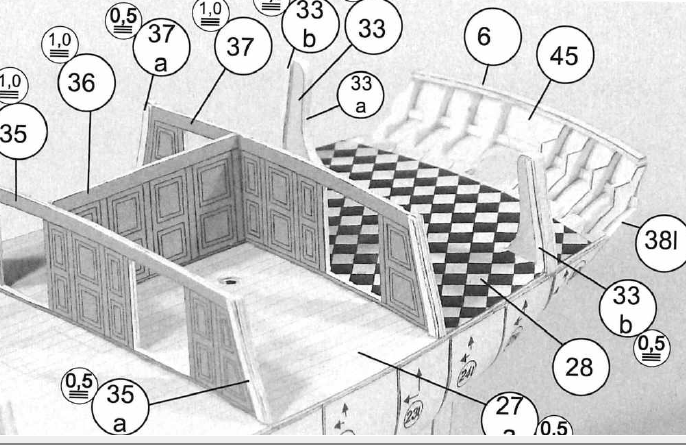

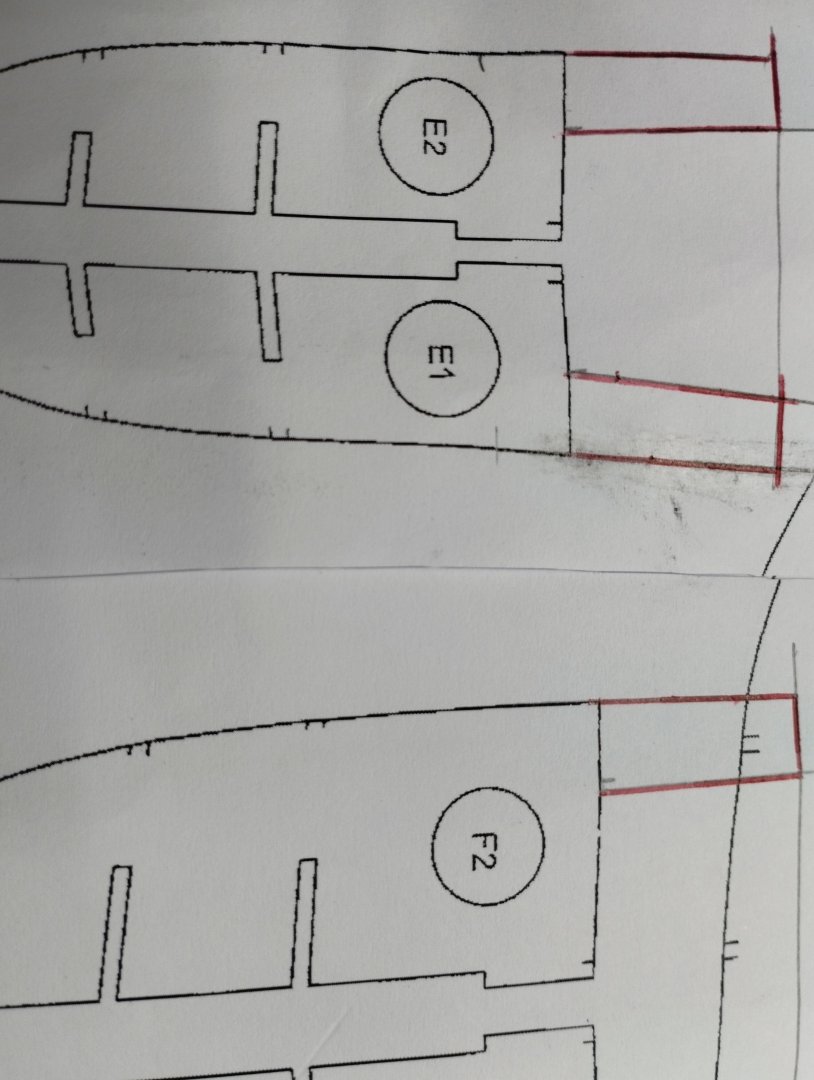

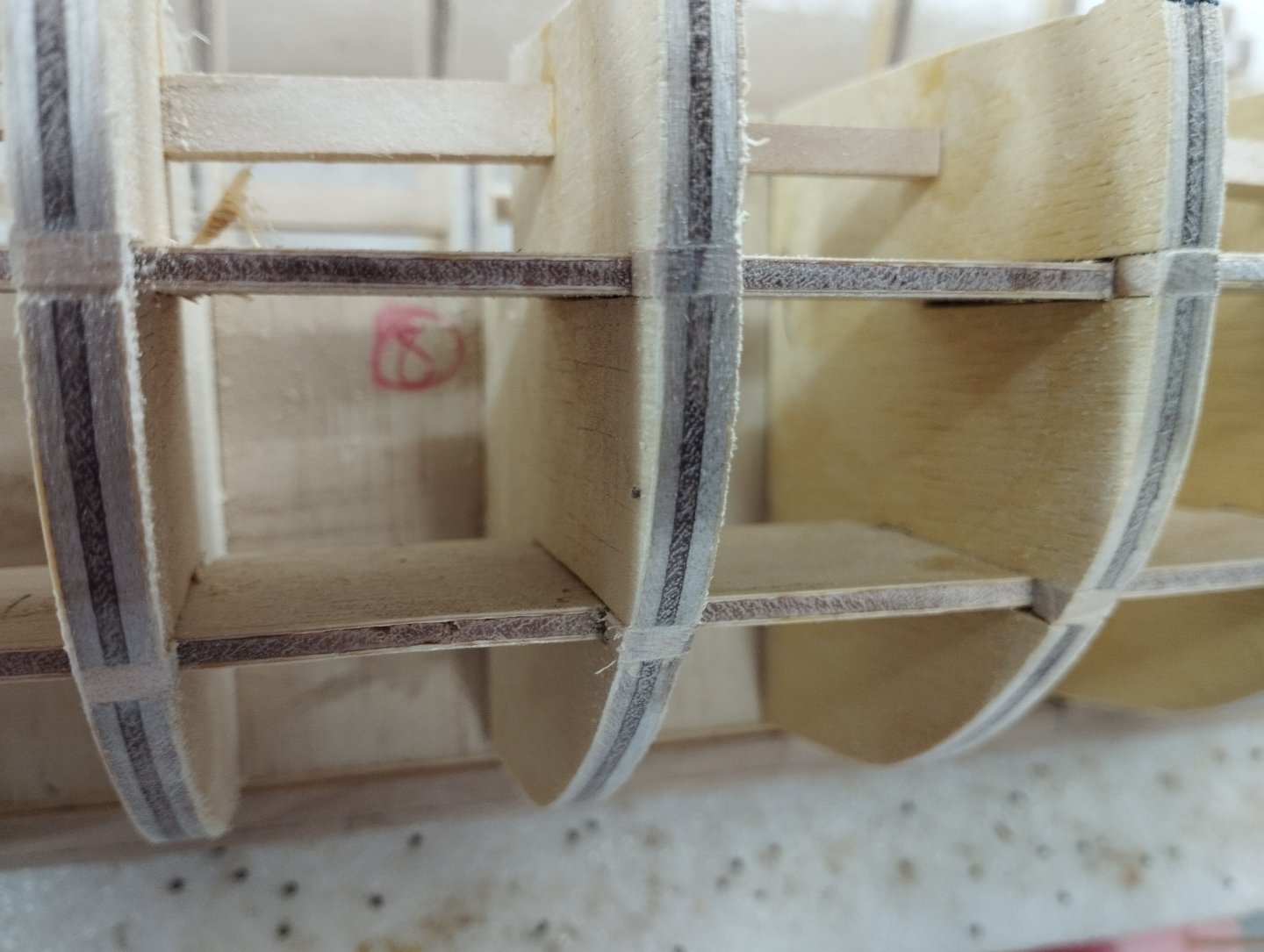

Hi All Must be time for an update. I've been working on the stern and quarter galleries and was hoping to combine these into one post but but time available will mean I split these into two. I'll concentrate on the quarter galleries in this one and show where I'm up to...generally I like to complete a section before posting but this is an update on where I'm at and is more of a work in progress than a finished piece of work. In all my models to date I've not had to deal with constructing quarter galleries so this was venturing into new territory. Using the parts depicted in the paper model for the formers (left photo) and the side template of the ship (middle) for placement and a pictorial view (right) on what it should look like The formers were made of 1.5mm cherry, simplified as I'm not showing any internals and glued to the side of the hull. Having no scale plans available it's critical to maintain reference points along the hull so that correct positioning of the hull template is maintained Next came the forming of the window frames using 1.5mm ply and the paper model parts as a guide I then used 1mm x 2mm cherry for the external window frames. Some planking was also completed at this stage aided by filler blocks between the formers Modelling the internal frames was more tricky and I'm sure there are far better ways of achieving a better result. Using see through film I marked the corners of the widows and drew the shape of the frame and cut this out double checking that the shape was a good fit Using this template I glued 1mm x 1mm cherry so that roughly half was overhanging the template, apologies the photo below is not the best but hopefully you get the idea Once the glue is dry it's then a matter of sanding the "external" wood back to the template and fine tuning to fit the window opening. I then used 1mm x 0.5mm cherry to make the individual widow frames (and I can't find any photos of this)....but if you imagine from the photo above that the lines marked are the actual pieces of wood then I first glued the vertical piece and then the individual cross pieces. This was all painted white and backed with black card an clear craft glue used to simulate glass (white glue would give the same result). Because I used 1mm x 2mm for the external frames this gave depth that allowed the internal frames to be set back a little to give some definition The rails were made from 1.2 x 1.5mm cherry and a simple scraper was made from a razor blade The making of the "bottom" of the galleries (not sure what this rounded part is called) which you can see in the right hand photo above required the use of 3 templates to get the required (or close to) shape and fortunately although not the intended purpose there is enough provided in the paper model to fashion this piece. Part 141 below is a former piece of the galleries Part 137 is the shape againt the hull and the blue piece is the shape that ties into the planking These were glued to a block of Jelutong and sanded top a shape (or at least what I thought was to shape) and glued to the hull and over the wales. If you look at a couple of photos above where I'm describing the marking of the external window frames this originally was quite chunky and required quite an amount of shaping to get a better look. It's far from perfect but I'm quite happy with the result and will look a lot better once painted. I'll leave it here for now and will follow up with a post on the stern area soon Thanks for dropping by Mark

-

Mr Pleasant reacted to a post in a topic:

Casks - hollow with separate head (lid)

Mr Pleasant reacted to a post in a topic:

Casks - hollow with separate head (lid)

-

To help keep things stable I put a pin in the yard and drill a corresponding hole in the mast. Where the two meet I file them a little flat and then use a bit of epoxy to glue the two together. It's saved me numerous times as I've inadvertently knocked the yards when doing the rigging

-

Mr Pleasant reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

Mr Pleasant reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

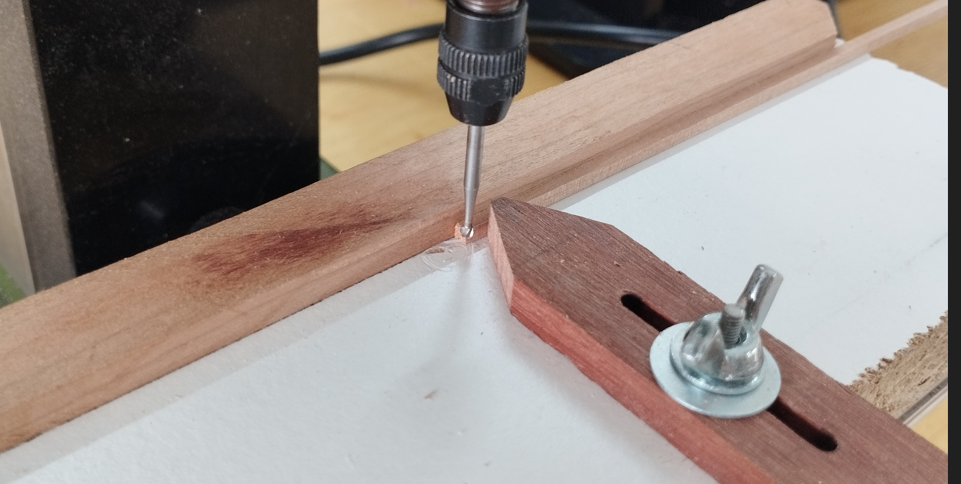

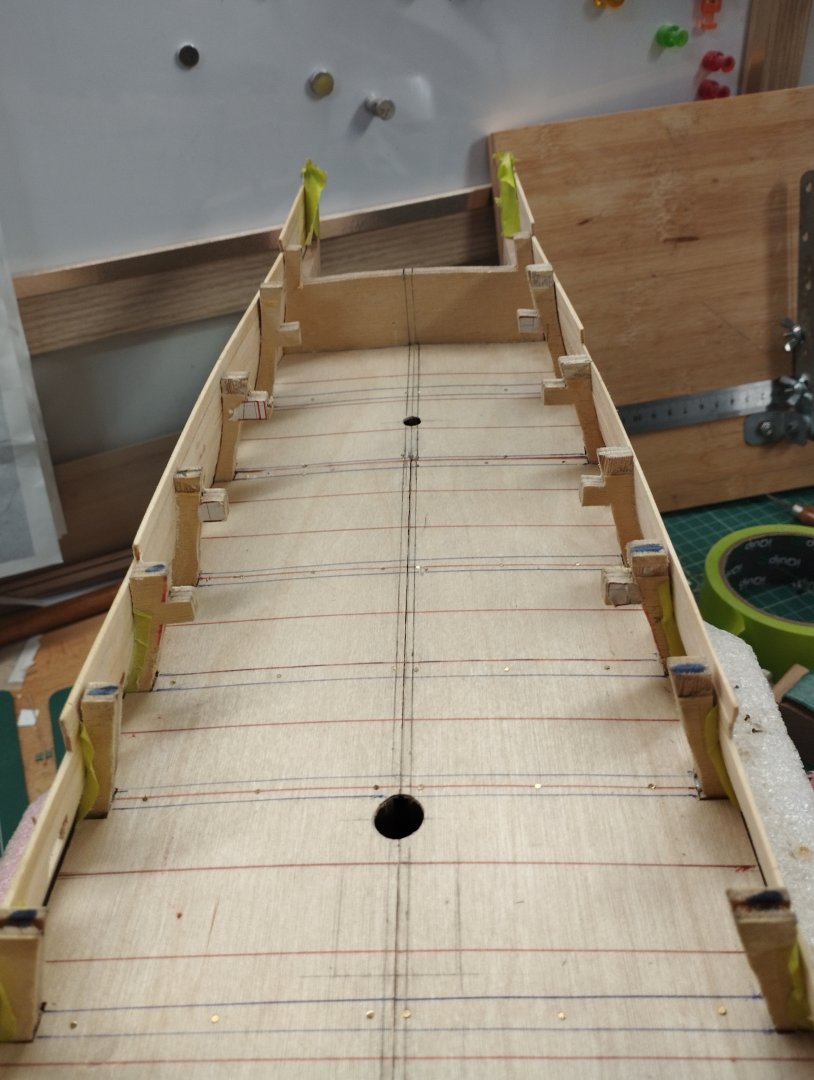

Hi All Quick up date to show planking of the main deck. Although the plans don't provide for a waterway I've modeled a basic version of those shown in Peter Goodwins reference book on the construction and fitting of a Sailing Man of War. Using a 2mm x 2mm length of cherry I ran this past a ball nose mill bit to provide the required profile. This took several passes to achieve the correct profile as I needed 1mm at the top and bottom of the concave shape The table fixed to the milling machine is simply a piece of melamine board with a fence glued to run the stock against. I also added a version of an adjustable "feather board" to help keep the stock tight against the fence as it passes the mill bit. The waterway was added to the false deck. I've removed the temporary bulkhead extensions discussed in post#1 and added additional internal planking to thicken the bulwarks. First was an additional 1mm of cherry that I had left over from the external planking and the final planking is 1mm of Tasmanian Myrtle and this will be left natural and not painted. Total thickness of the bulwarks is now 4.5mm I've cheated slightly in that the waterway is only fitted to part of the deck where it will be visible, I've not ran it the full length of the ship. I've used poplar for the planking. King plank and margin planks are 1mm x 6mm the rest of the planking is 1mm x 4mm. To represent the caulking I use a medium hardness charcoal pencil. A 4 butt shift pattern has been used The waterway is flush with the deck planking having allowed the 1mm and I've just got to add the spirketting which will be 1mm to fit against the top of the waterway Thanks for dropping by Mark

-

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

-

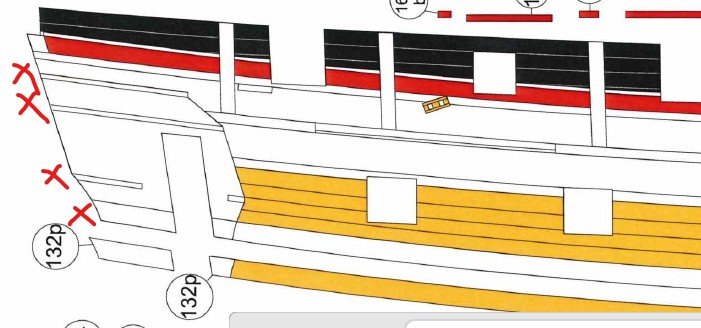

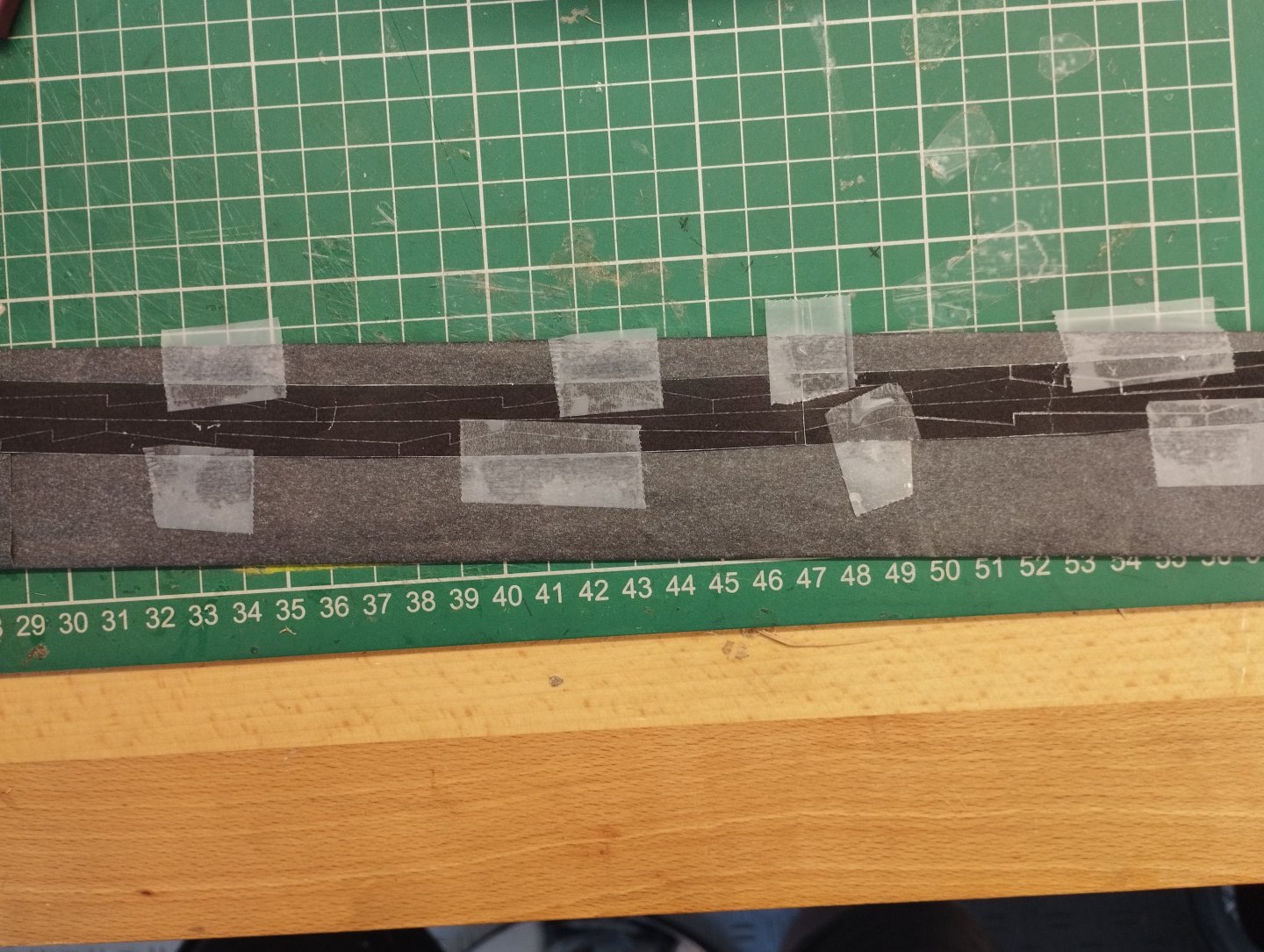

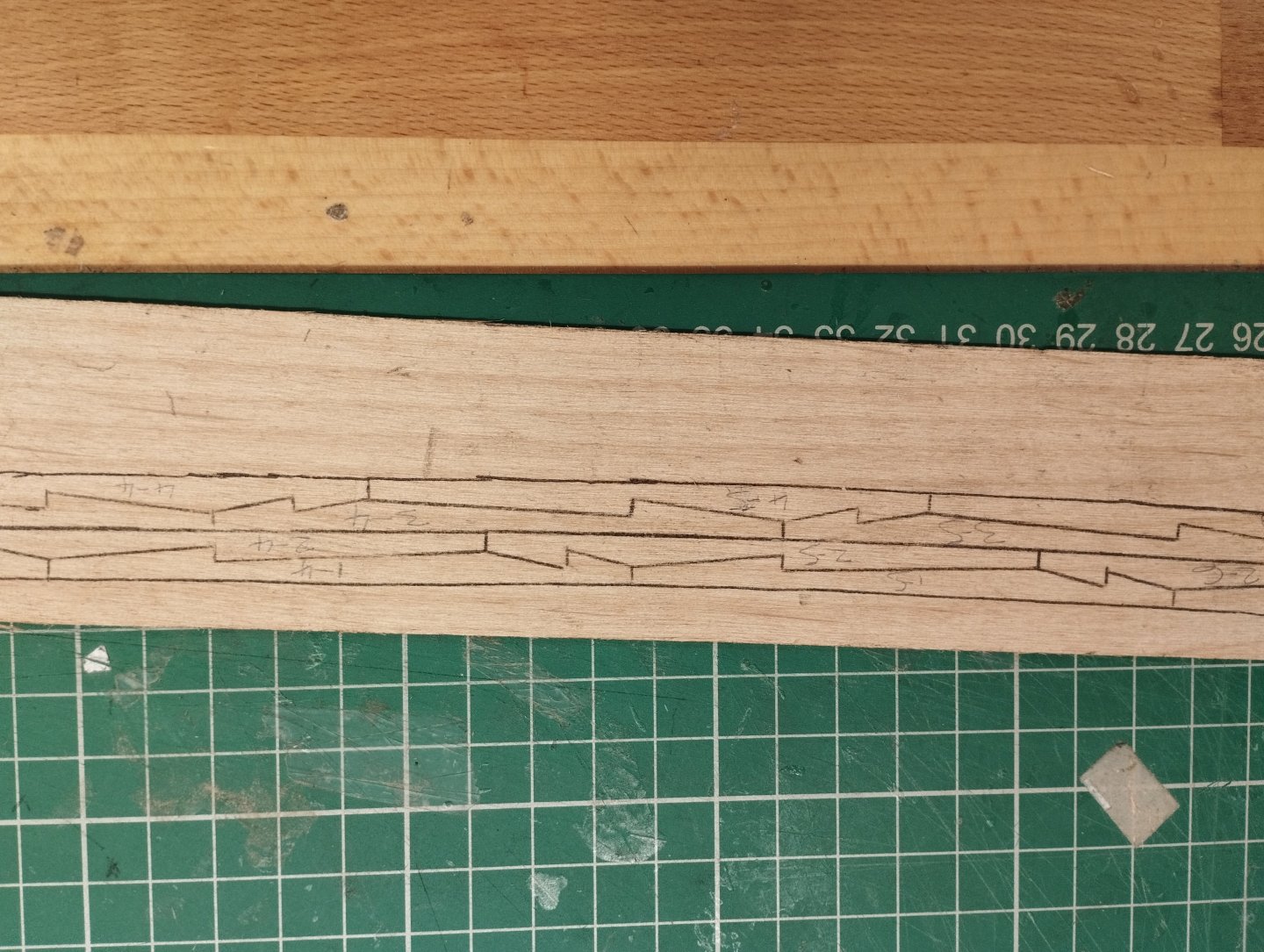

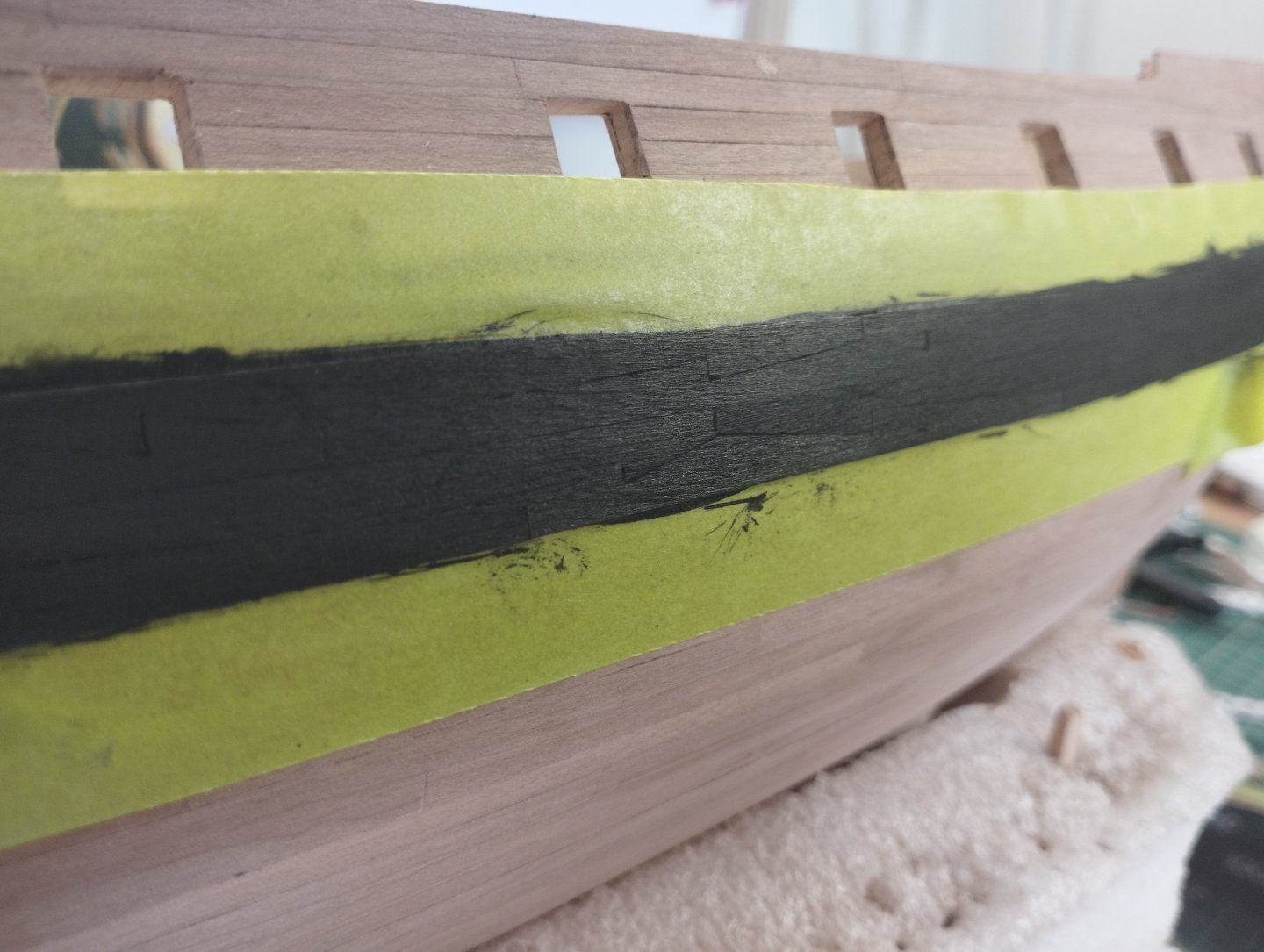

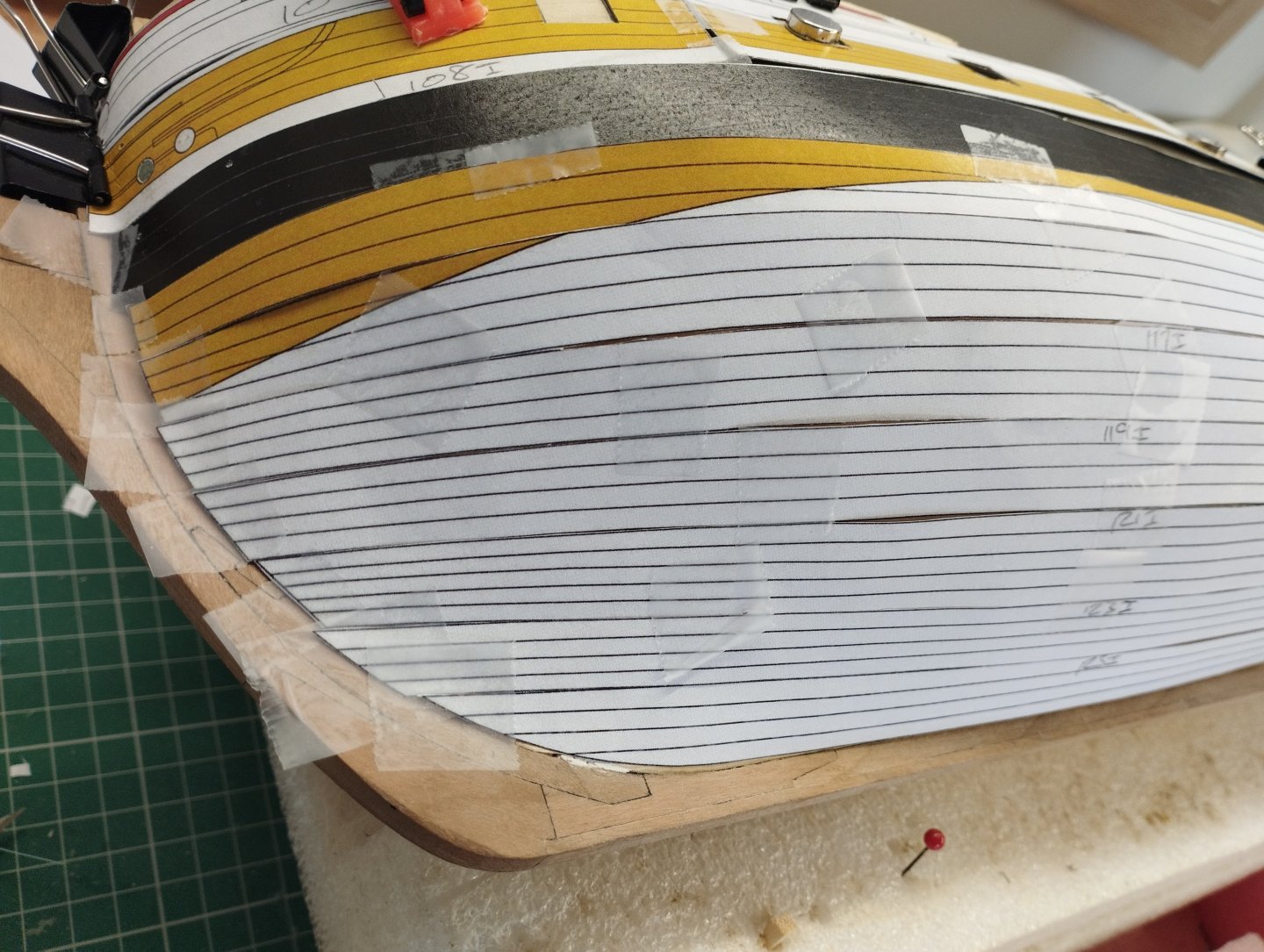

Hi All Thanks for the likes. Wales are now complete. The paper model simply has a paper template glued to a sufficiently thickness of card and stuck appropriately on the model. The template shows a hook and butt planking and I've used this to provide the shape of the planks for the wales I taped the template to some carbon paper and this was then taped to some Alder milled to 1mm. I used Alder for no other purpose than I had some deep enough (50mm) from stock that allowed the template to fit. The lines were then drawn over with a 0.3 mm pencil to provide the cuts required. The planks were individually numbered and cut out with a knife, below shows the work in progress Once complete I masked off the hull and used black wood stain to finish. I didn't use paint as I wanted to keep as much definition of the planking as possible seeing as how I had put the effort in. Masking tape will stay in place for the time being as I work on the quarter galleries and there is a further row of planking required just above the wales which I'll complete later. Thanks for looking in Mark

-

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

Mr Pleasant reacted to a post in a topic:

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

-

Mr Pleasant reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

Mr Pleasant reacted to a post in a topic:

HMS Mercury 1779 by Mr Pleasant - 1:64 - based on Shipyard paper model

-

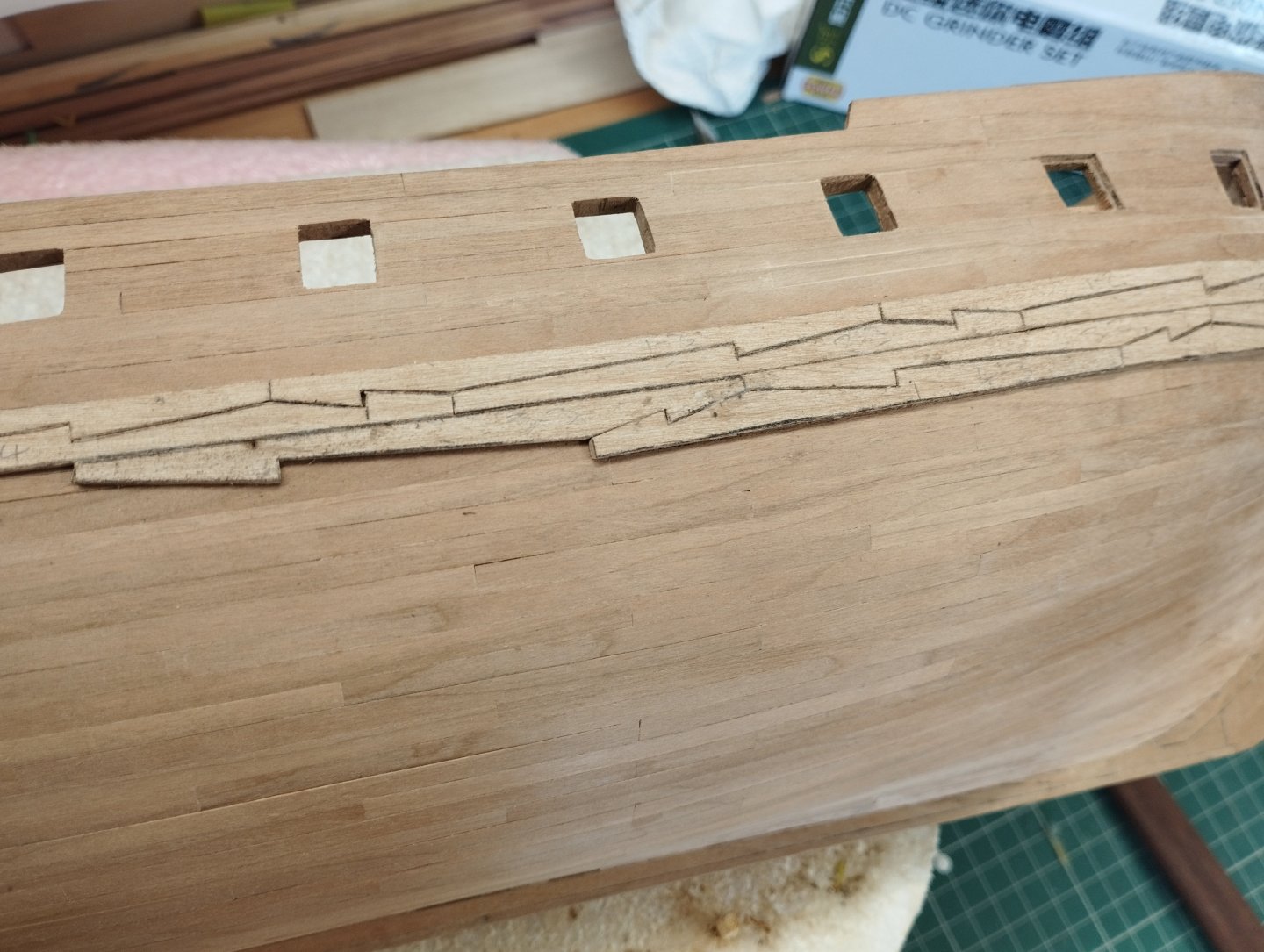

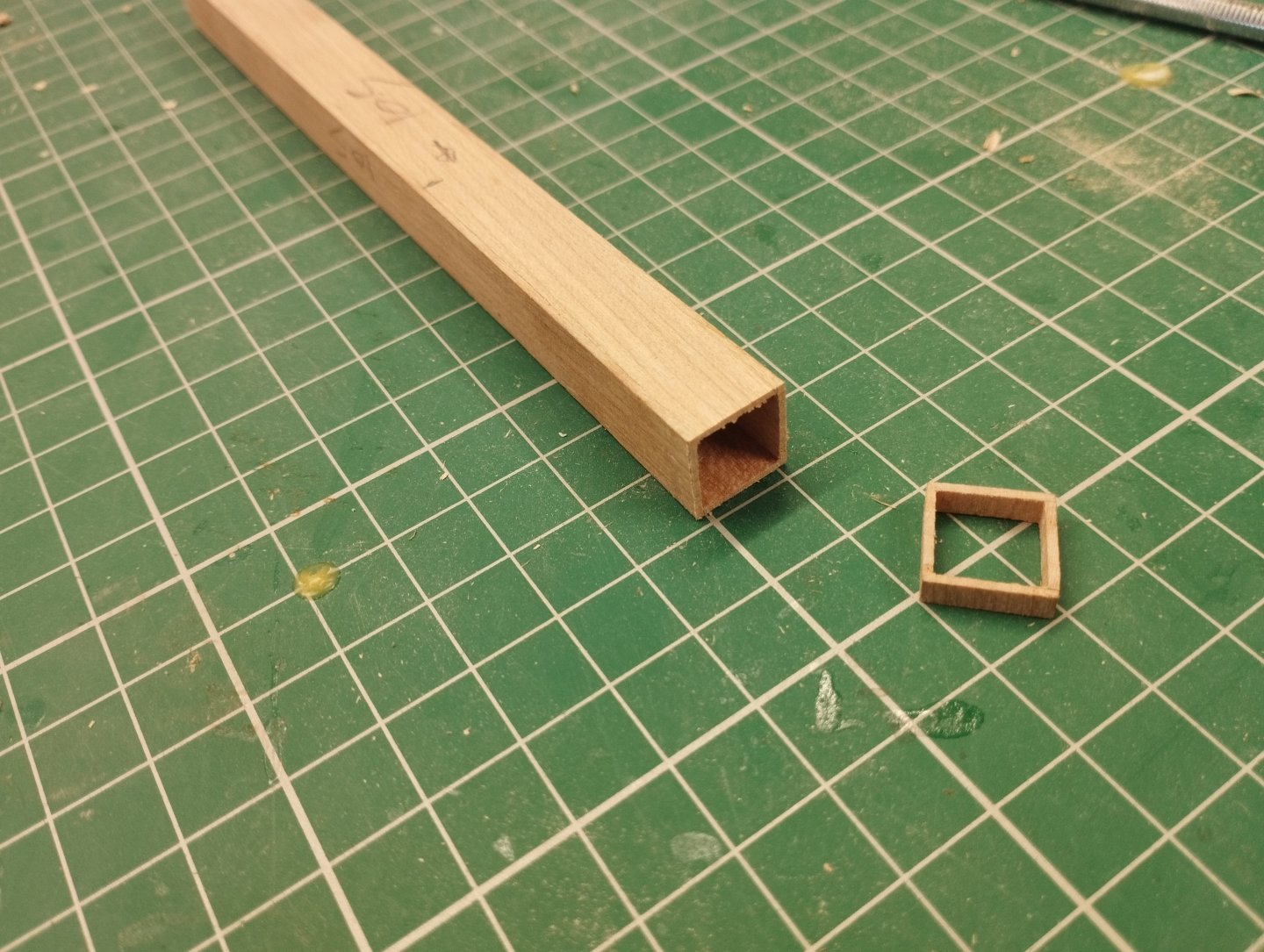

Hi All First things first....Happy New Year and hoping you all have a great 2025. Looking back at the date of my last post it's taken me 7 months to complete the second layer of planking - I envy those who can plank in a matter of weeks as it (obviously) to take me an age to do. This seems such a small update bearing in mind the effort Planking has been done with cherry at 4mm x 1mm and in 100mm lengths. I've used a 4 shift butt shift.....not sure if this is historically accurate but I like the pattern. I've a little work to do in finishing off and it needs a sand but the following photos show the progress Side view.....there are a few gaps 3-4 strakes below the gun ports but this was rough planking as they will be covered by the wales To ensure the ports were all the same size, I made a "tube" and sliced an appropriate length to go through all layers of planking (internal and external). First step was to create a former off the correct squareness and then used 1mm cherry to "plank" around the former Following shows the ports installed Just some more photos showing the planking Hopefully the next post won't be as long in the making Thanks for looking in Mark

-

Byrnes table saw - belt tensioning

Mr Pleasant replied to Mr Pleasant's topic in Modeling tools and Workshop Equipment

Hi Mark Thanks for this, I'll do this next time I have the saw out for use. Mark -

Hi All Is there a way to tension the belt? I was ripping some planks today at it sounded as if the belt was rattling against the belt guard. I removed the guard but there was no apparent way to apply more tension to the belt apart from lifting the motor on its hinge point. As a result I've chocked some wood under the motor and this has solved the problem. Anyone know a better way? Thanks Mark

-

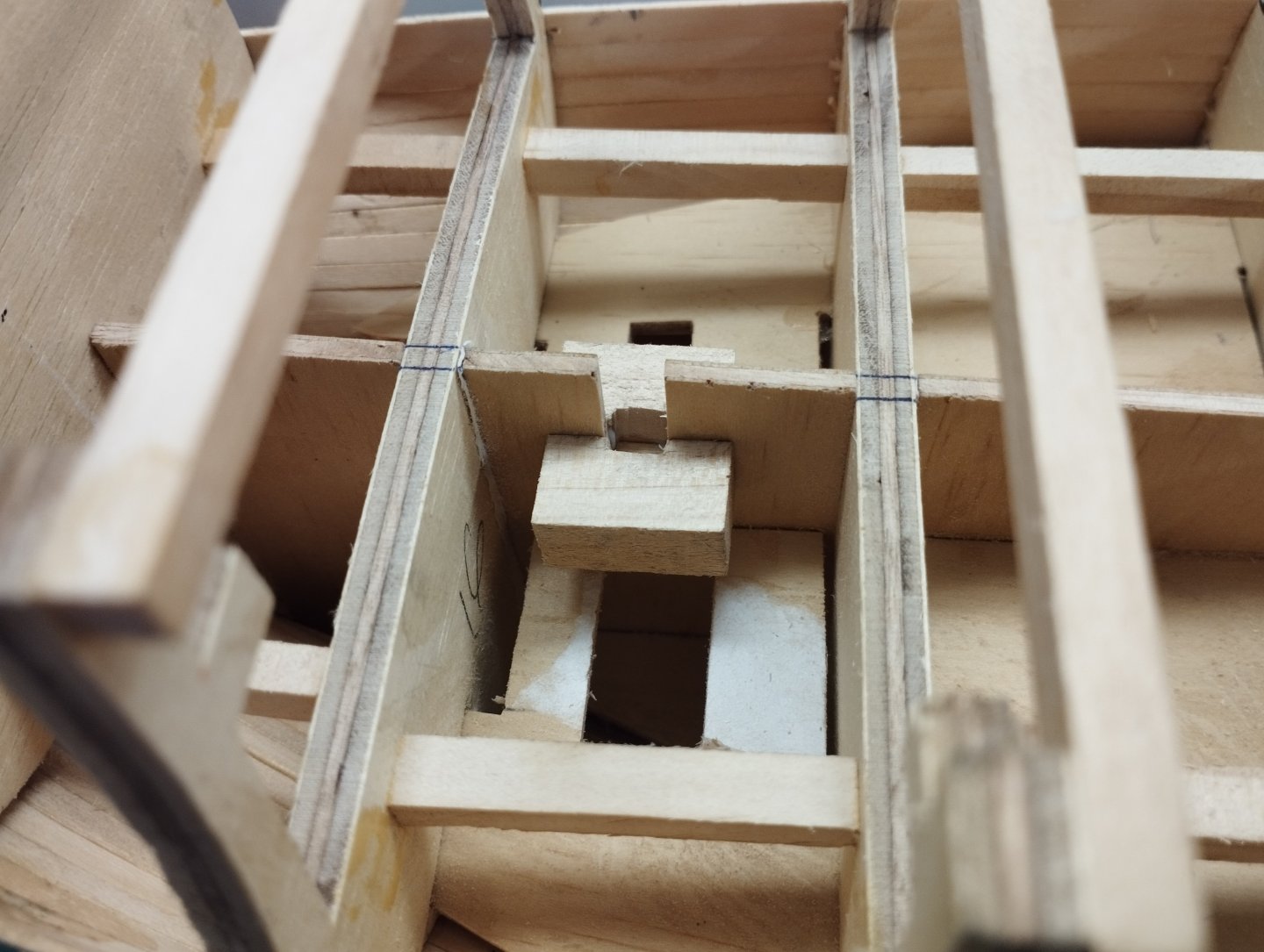

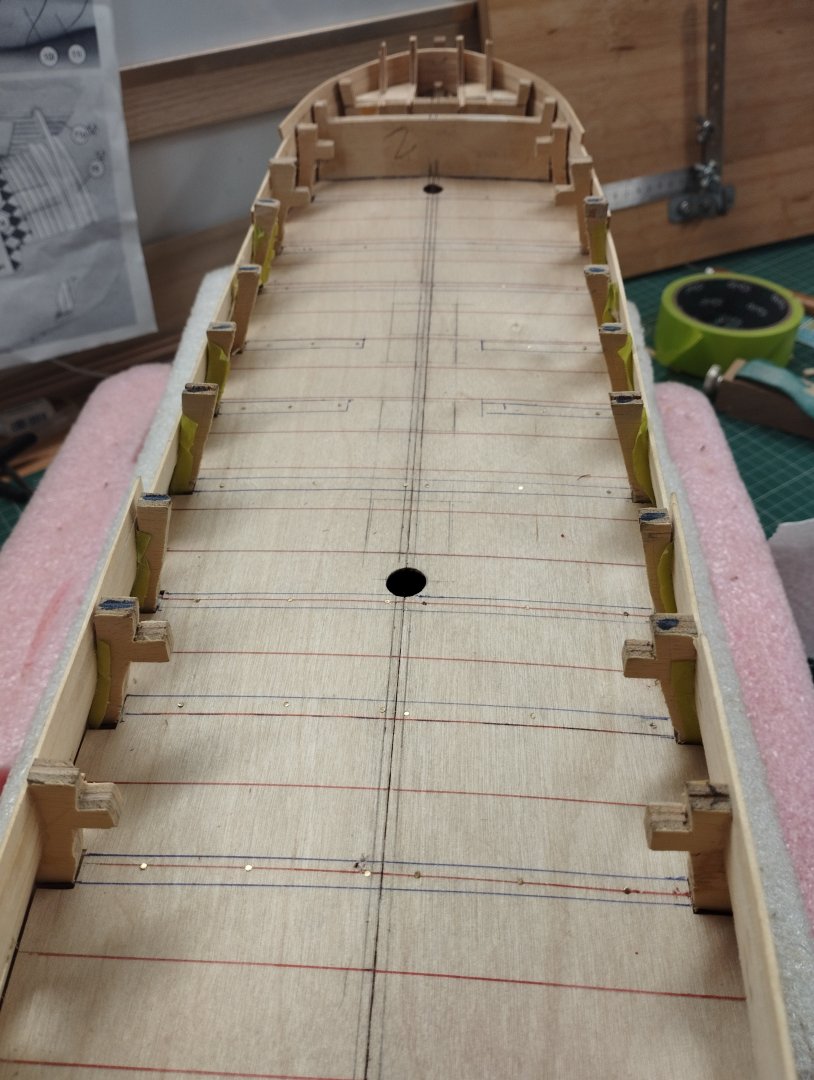

Hi All Thanks for the likes....time for a quick update. First layer of planking is now complete, below shows a bit of the progress, rough finish and after sanding. I placed tape around some of the bulkheads where I didn't want the planks to adhere to as these bulkhead extensions are to be cut away in future. I could have used templates to cut the bulwarks out of some ply but I've elected to plank instead. I also added some strengthening across the bulkhead extensions to protect and reduce the risk of them breaking them during planking. I used hoop pine for the planking and milled to 5mm x 1.5mm strips. Hoop pine has no discernable grain and bends quite easily....most importantly it stays straight after been cut into strips from a larger plank The planking turned out relatively ok, however, for transparency.....I did make a slight error. In the previous post I mentioned that I'd fair the mdf that I added as packing, which I did. What I didn't do was fair the "leg" above this and this has resulted in a run of concave planking for 5 or so planks. This will be hidden by the galleries but leaving like this will make it awkward to shape the formers of the galleries so I'll fill and sand this gap to get a straight run Fashioned a bit of a mast step glue well for all three masts as the 3mm spine would not give enough surface to glue onto. I know some people just rely on the rigging to keep the masts upright....but not me , more glue the better, no way am I relying on my rigging to keep anything straight As a quick check on how accurate I am at this stage to the paper model, I overlaid the paper planking templates onto the hull and all appears ok. Normally I would line off the hull for the second planking by working out the bands but as things look ok, I'll use the templates to give the bands and tweak as I go along (you can just make out the separate planking templates by the numbers I've written on them) . At the top you can just see the templates that could have been used to cut bulwarks out of ply And finally I added the false deck for the main deck. A joggle stick was used to shape the false deck and cut from 0.8mm ply. I had to install in separate pieces as I couldn't get it into place in single go. Holes cut (not vey well but sort of round) for the masts. I've marked the deck at every 20mm to help with the planking shift pattern Thanks for dropping in Mark

-

Use a piece of thin card or paper say 10mm in width. Stand it on its edge and form it around the bow area along your red line and mark the start and finish points. This will give the length of the space that you need to fit the planks to. Divide this length by the number of plank runs required at midship bulkhead (or however you've determined the number of planking runs required) this will give you the width of the blanks at the bow. Mark

-

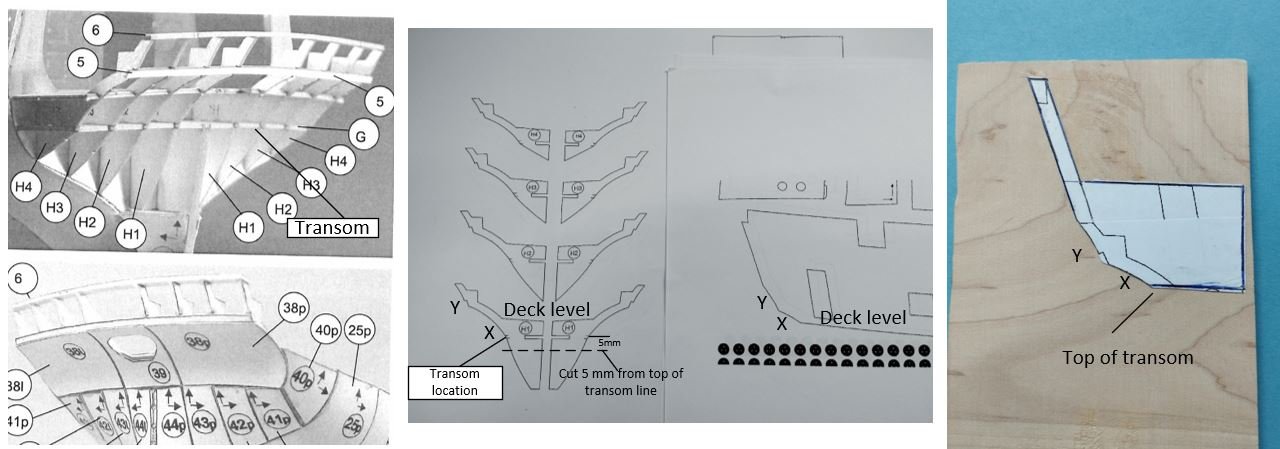

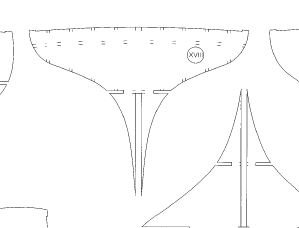

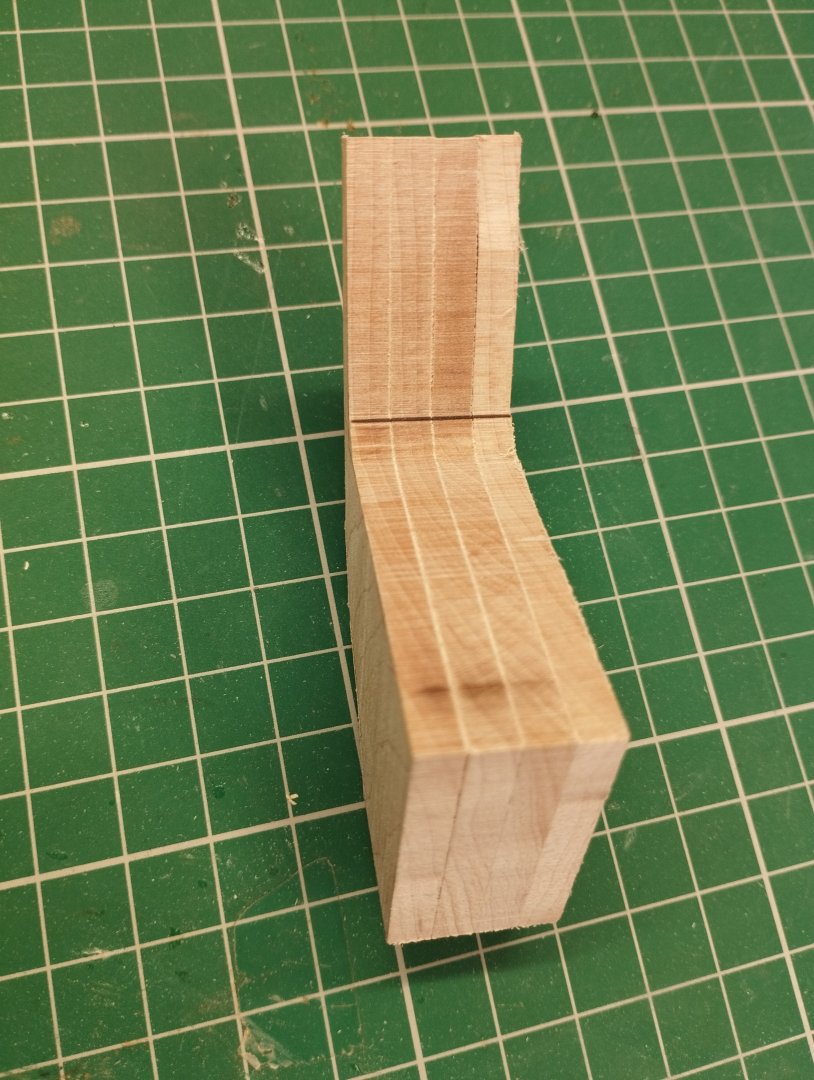

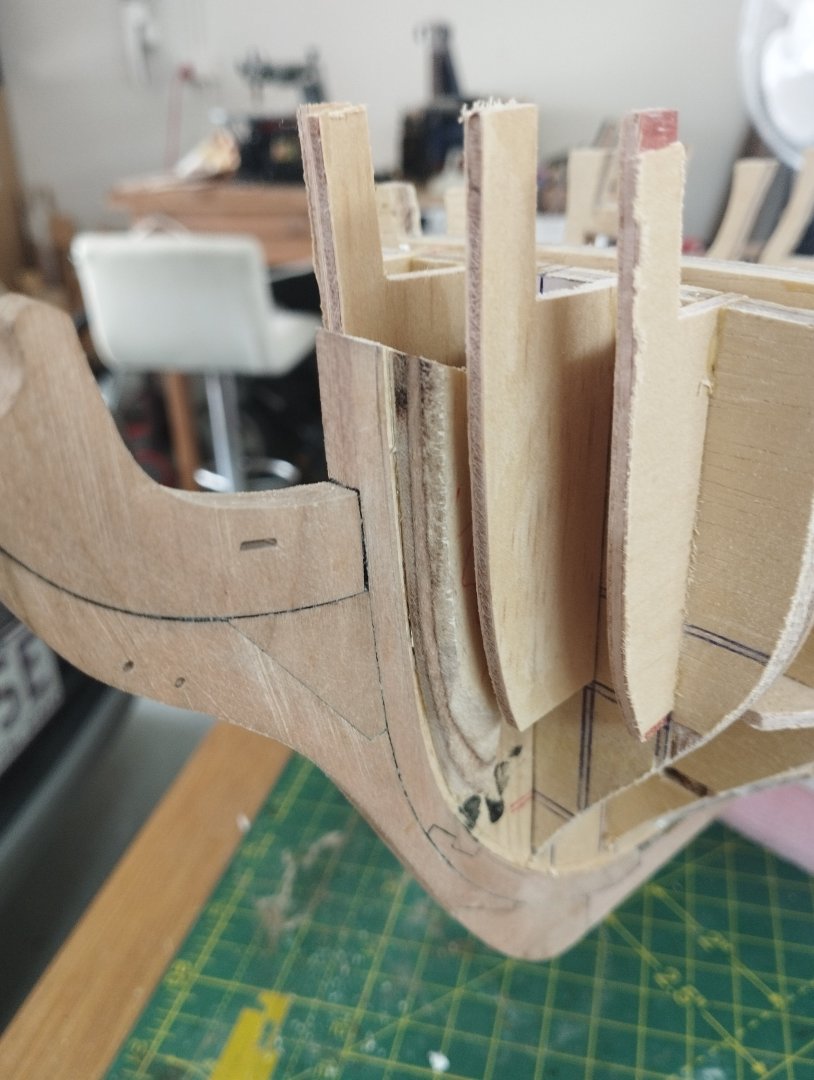

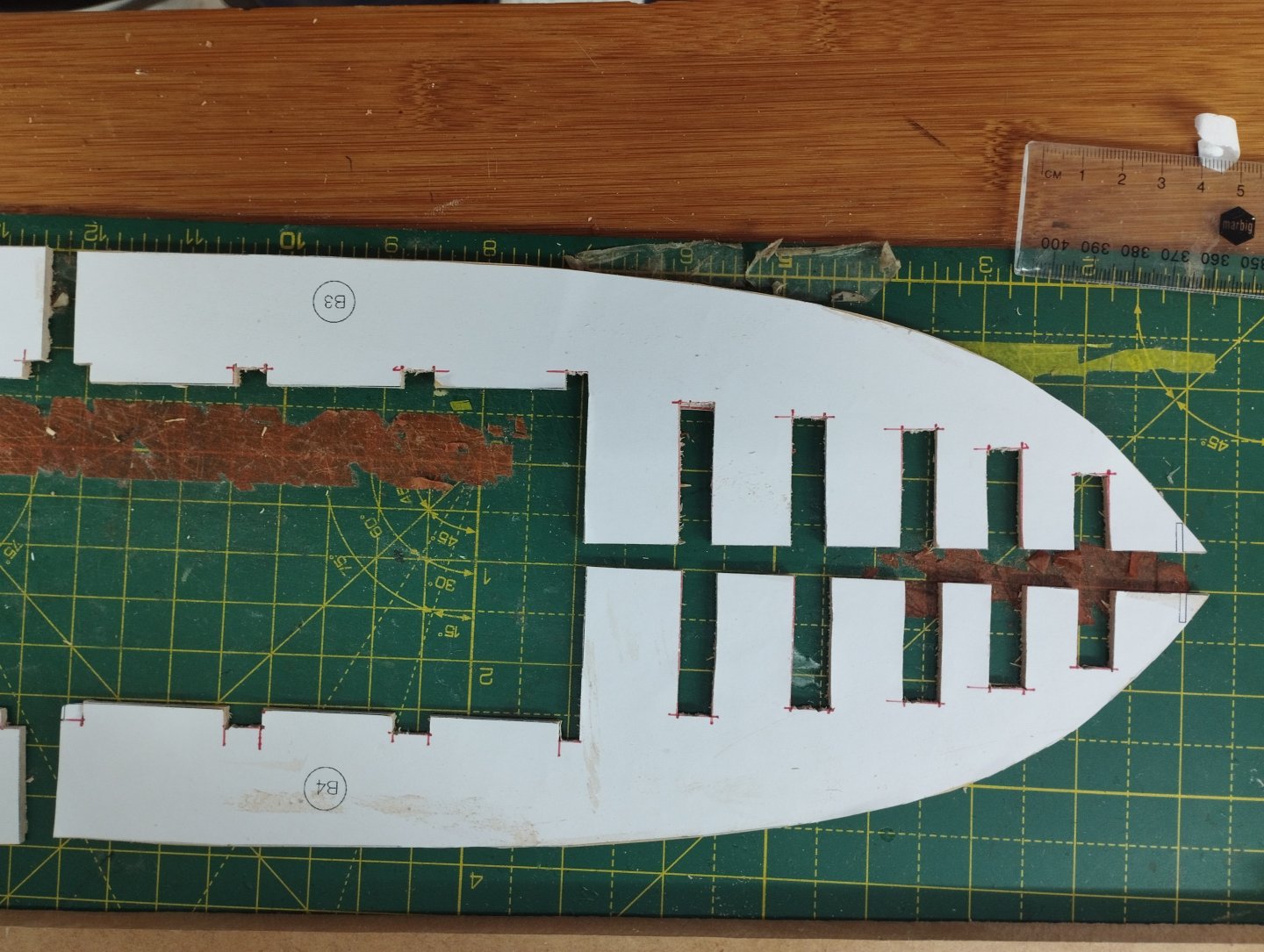

Hi All Thanks for the likes... Moving onto the stern area, this needed some manipulation to how the paper model is constructed. Hopefully my explanation of how I achieved this is not to confusing. Firstly for context this is how the paper model is done This formation allows for the modelling of the internals and for a moment my ambition threatened to overrule my ability, eventually, however reality prevailed and I decided against going this far. This means I have to change parts H1 to H4 (top left) to accommodate the fixing of the stern fascia. The paper model simply has this glued on top of part 6 (top left) and to the bulwarks and relies on the flexibility of the card to get some curvature. Although there are no corresponding parts to what I need to achieve, there is enough information provided for me to fashion the parts needed and this explained (hopefully) below Part G (above top left) is the transom and this was fashioned out of some hard maple 5mm thick by the template provide in plan view and the curvature determined by the markings on bulkhead 17 (horizontal markings). A chamfer was then created for the planking Next was extending parts H1-H4 to allow the forming and fitting of the stern fascia at a later date. To achieve this I used common features of two templates to give me the final shape Middle picture above....X, Y and the deck level are common on the formers H1-H4 and to the bulwark templates. These were glued one on top the other to produce a single template shown in the right. Blanks were then cut from hard maple using the template ...I'm only using H1 and H4 on both sides of the stern post and omitting H2 and H3 The only difference in the finished parts of H1 and H4 is the length that attaches to the transom to give the curvature of the stern fascia and this was cut to the correct size H1 and H4 templates were then used by subtracting 5mm for the transom to give me the shaping for the planking below the transom. Below shows these fitted and then filled with balsa and shaped Finally H4's are glued in place, with a bit of additional padding (3mm mdf) to help with the run of planking. This will be sanded for a fair line. I'm not installing the H1's at this stage as they will interfere with the planking Hope this all makes some sort of sense. Thanks for looking in Mark

-

Byrnes Saw for sale in the UK

Mr Pleasant replied to Some Idea's topic in Modeling tools and Workshop Equipment

It sold for £1020 which is roughly US$1300 and the thicknesser sold for £445. For comparison the saw was US$520 in July last year when I bought mine. -

Hi All Thanks for the likes.... Just a quick post setting out the bow area for planking. This isn't the way I've done it in the past but seeing as how I'm experimenting in how I can use a paper model as the basis of a wooden version I've stuck with the way the paper model is done. From left to right shows the process First I extended the formers (red lines) above the deck level with sacrificial tabs to aid in the planking around the bow above the level of the deck Next shows them fitted and I've added some 6mm ply against the spine that follows the curve of the stem post and in line with the rabbet piece i fitted in post #1 Finally I've filled between the formers with Jelutong wood. This sands quite easy but takes nails better than balsa should I need to More functional than pretty Thanks for looking in Mark

-

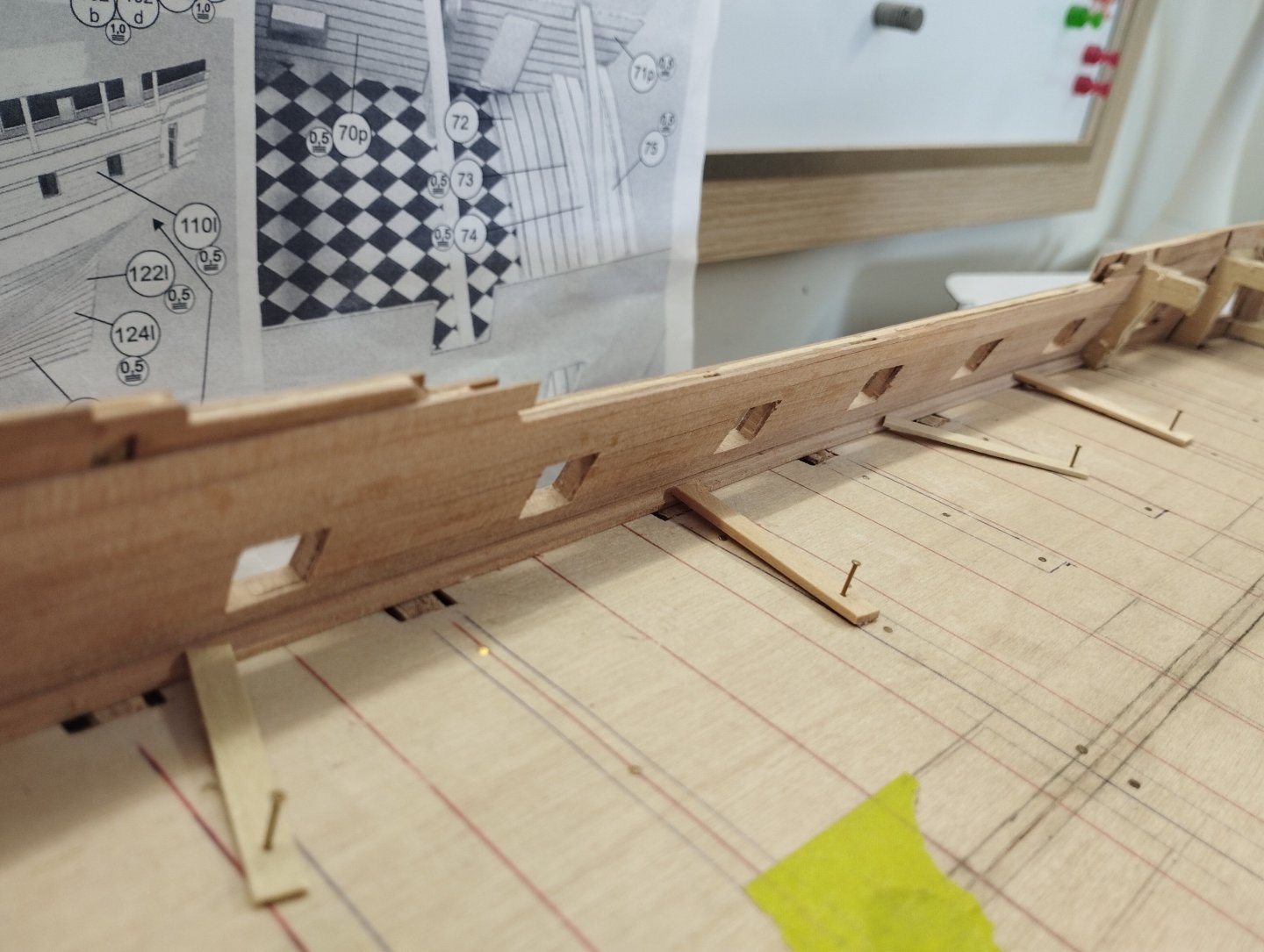

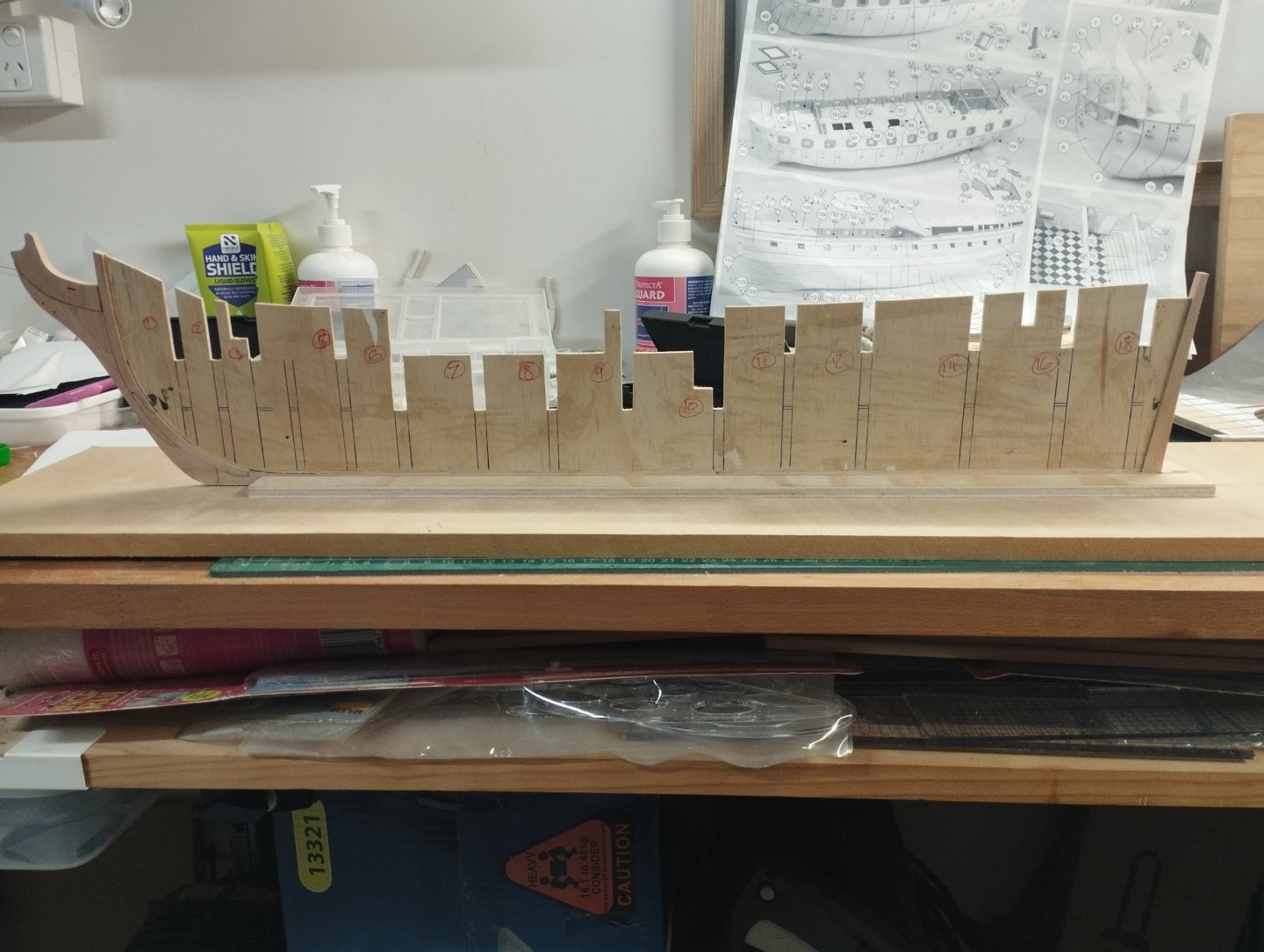

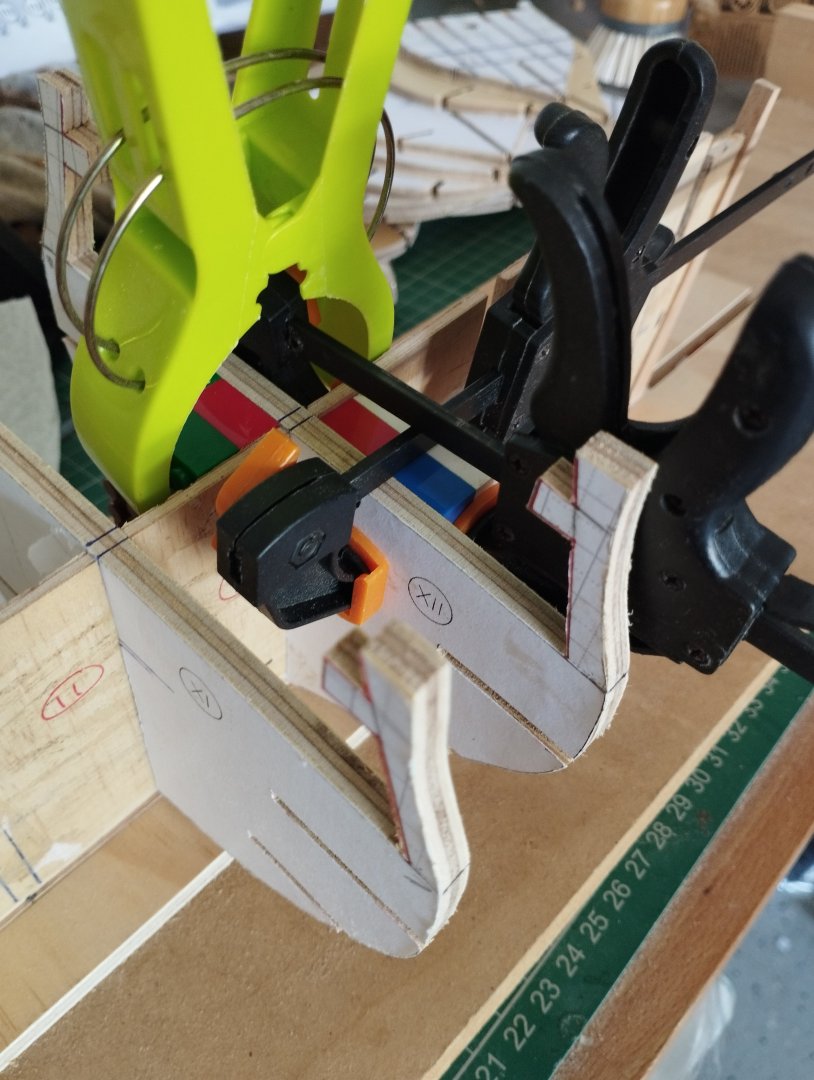

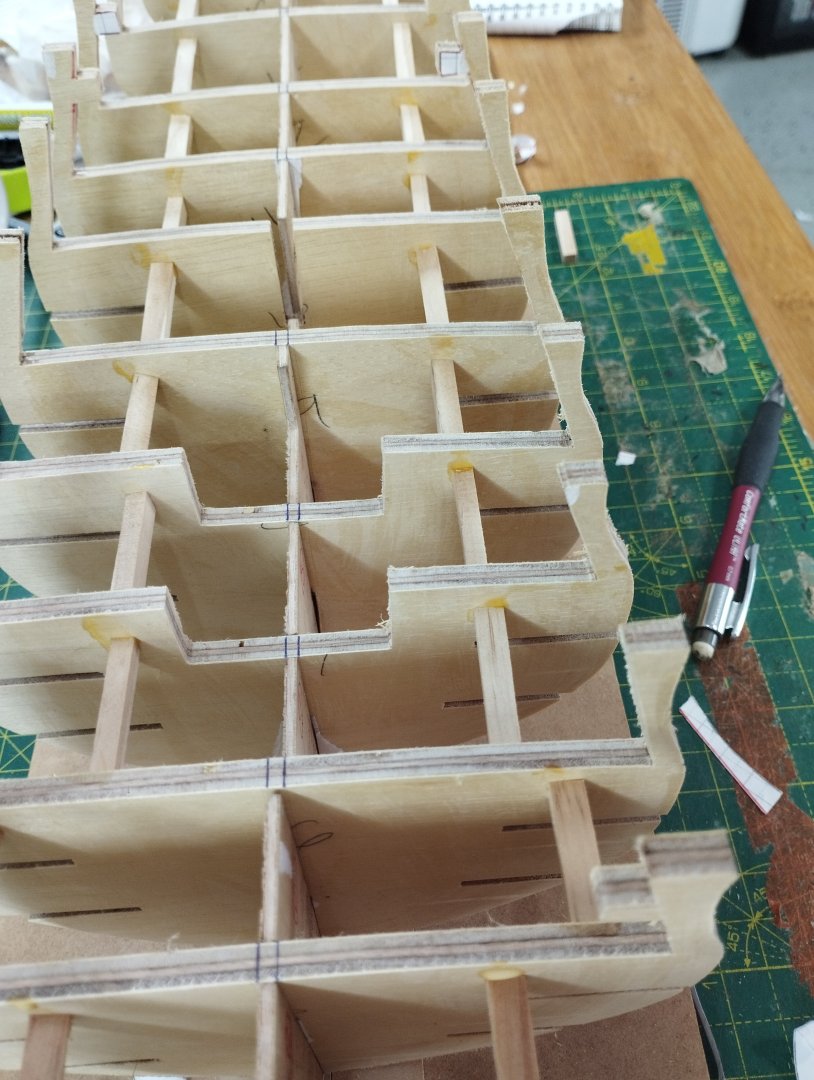

Hi All Thanks for the likes. Onto fitting the bulkheads A quick jig was made to keep the spine vertical whilst the bulkheads were fitted. Bulkheads kept square using Lego and clamps Once all bulkheads were fitted I added spacers to keep everything square, this is simply achieved by taking measurements of the gaps between the same bulkheads on either side of the spine and taking the average, two pieces of stock are then cut to that length and glued in place between the bulkheads The 3mm ply spine is still flimsy at this point so bracing pieces are required. These are cut from the templates provided and 3mm ply is used. I cut the bracing pieces roughly 5mm less wide than the templates so that the edge of the bracing pieces were clear of the bulkhead edges.. Following shows a couple of the bracing pieces cut and installed clear of the bulkhead edges Gaps in the bulkheads are plugged with some pine and sanded flush The frame is now rock solid and straight Thanks for dropping by Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.