-

Posts

167 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Derry, New Hampshire, USA

-

Interests

RC scale ships, plastic models ( ships and aircraft, mostly)

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I just found this thread, and am enjoying working my way through it. I have a question for you: Do the plans that come in the Occre kit have enough info to scratch build a hull? I would like to build an RC model of Endurance in 1/48 scale, and can’t find hull lines…. -Bill

- 183 replies

-

- Endurance

- Shackleton

-

(and 1 more)

Tagged with:

-

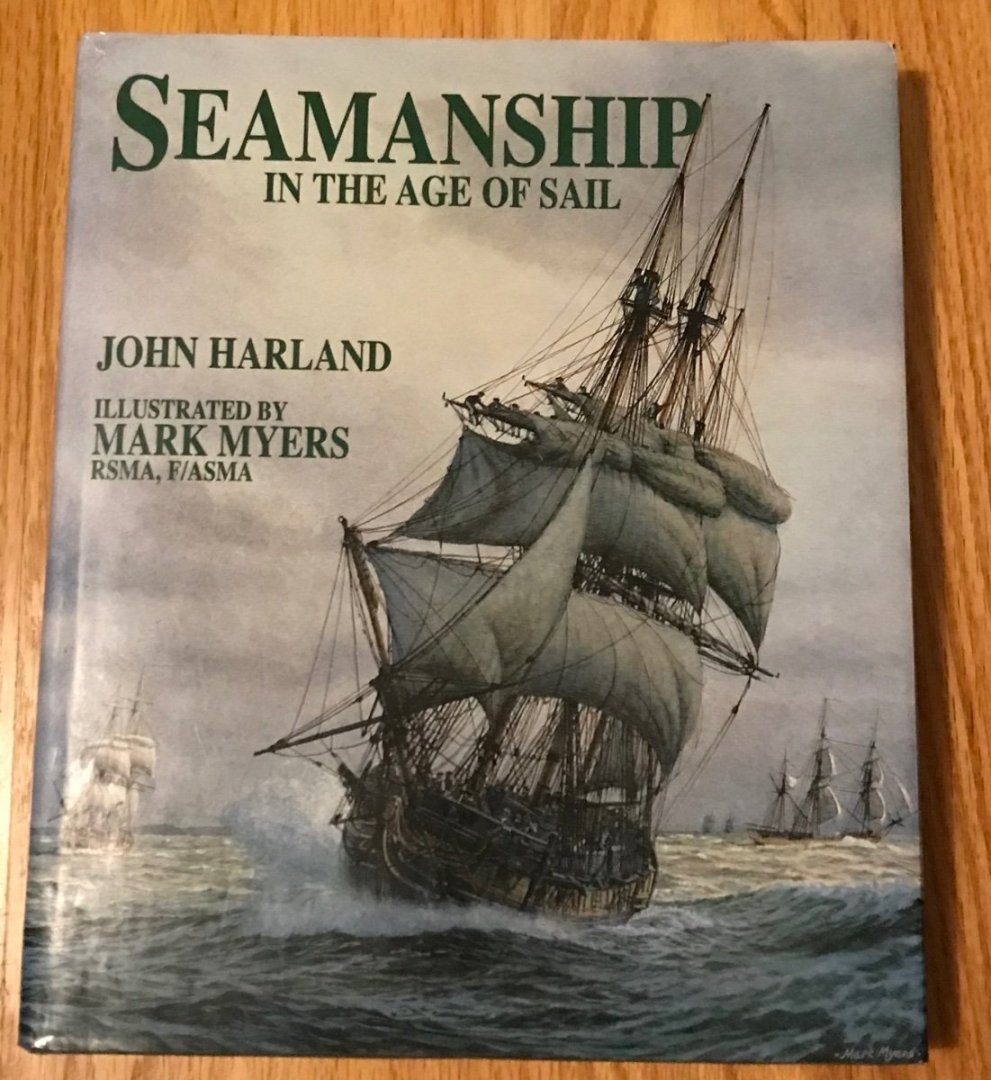

This is the 2000 reprint of the book. The entire book, including the dust jacket, is in very good conditions. No handwriting in or on the book. The going rate for this book seems to be in the $40-$60 range— I’m selling it for $30, plus shipping from New Hampshire. (I’ll do what I can to keep the shipping cost down.) Prefer paypal, but a USPO Money Order is OK too…. I’ll look for PMs here, and reply with my contact info… -Bill New Hampshire (This just my second time selling something here- I sold a trio of books here a few years ago with no problems.)

-

What plastic ship kits have you done?

Rcboater Bill replied to Broadsides's topic in Plastic model kits

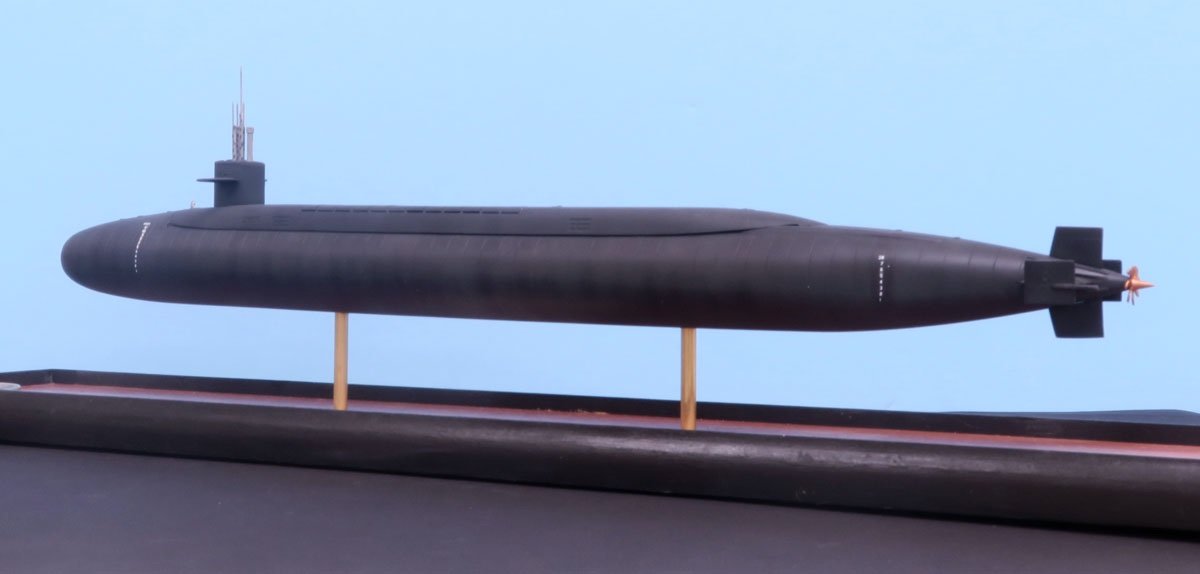

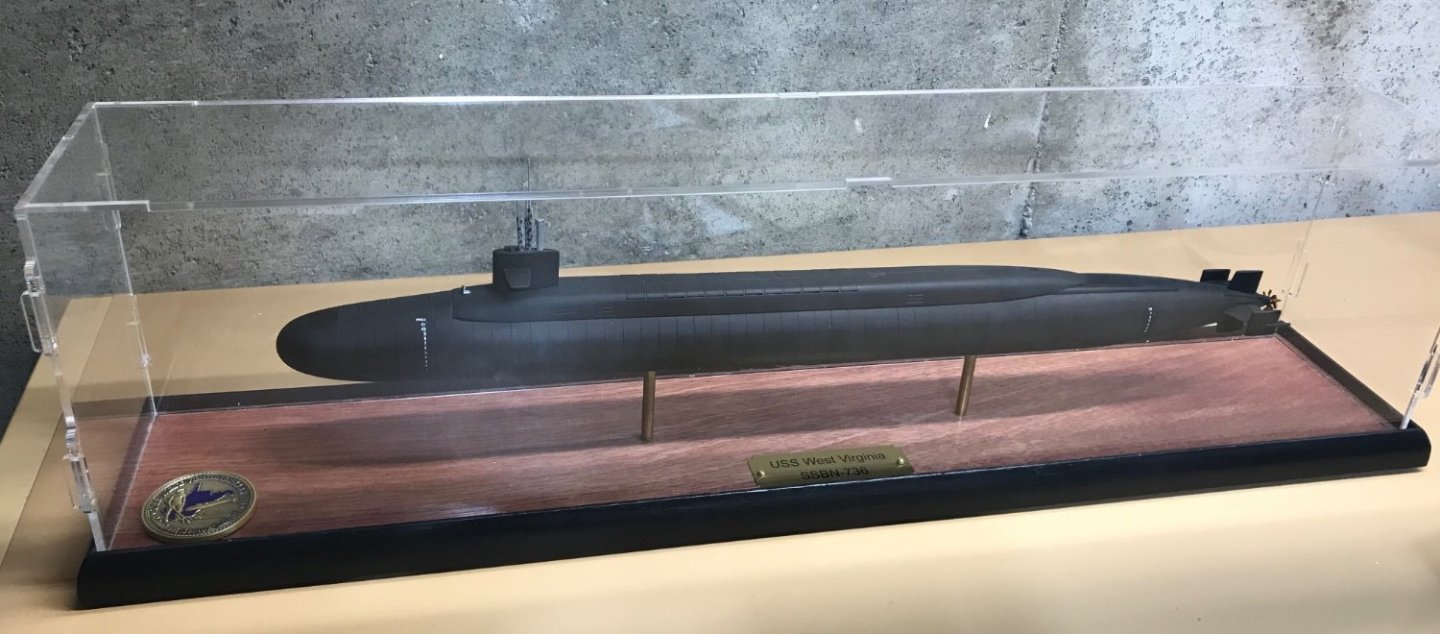

Another model built for a friend- this time a former crew member on the USS West Virginia (SSBN -736). Built from the Dragon 1/350 USS Florida kit- which is a modified Ohio class, but the kit still has all the original Ohio parts in the box. I made a custom wood base, and added a West Virginia Challenge Coin with the ship’s motto and a simple brass nameplate. I topped it off with an acrylic cover. The 1/350 scale model is about 19” long, and the base is 24”. Ohio class subs are huge!!! I am very happywith how it turned out, an my friend loves it! -

Thanks! There are sites online that sell modern hats with whatever ship name you may desire-- but finding an original Duane hat may be a challenge. Maybe try one fo the USCG veterans groups on Facebook?

-

When underway, you always use the ratlines on the windward side to go aloft- when ship is sailing into the wind, and heeling over, the ratlines become less steep, and the futtocks are closer to vertical, making them easier to climb… (Former Eagle sailor)

-

Rcboater Bill changed their profile photo

-

I’m always glad to see another USCG subject as a new kit! But at the same time, I am also a little disappointed that we’ll have yet another USCG subject in a one-off scale that is different from the common scales you find modern boat and aircraft models in. Personally, I would be much more likely to buy the kit if it was in 1/72 scale, so I could display it with my collection of other USCG helicopters and other similarly-sized boats. (PT boats, landing craft, RNLI lifeboats, Swift boats, Vospers, etc.) This is only my opinion, and you folks certainly know your potential market better than I do. No matter what the scale, I hope you sell a zillion of them, which leads to the release of more USCG subjects. “More USCG subjects as model kits” is always better than “ less”!

-

Do you mean “Matchbox 1/72 Flower Class Corvette”? ( I never heard of Minicraft also releasing the kit.). When Matchbox got out of the plastic model business, Revell bought all the molds. The kit has been released by Revell a couple of times since, as “HMCS Snowberry”. There is LOTS of info online about the kits….

-

Attn: ALL LINDBERG Model fans! (Test your knowledge?)

Rcboater Bill replied to BoSmith_12's topic in Plastic model kits

That model is clearly the Revell 1/305 scale USCGC Taney. (Not a Lindberg kit!). It was originally released as USCGC Campbell, a sistership. Built as kitted, it is a model of the Campbell in her Korean War-era fit. (The seven ships of the class went through a lot of changes over their 45-50 years of service!) I built that kit as the USCGC Duane, as she appeared ca. 1981, for an old friend and classmate who served on her. I documented my build here: FWIW, The Destroyer Escort kit looks like Revell 1/240 scale USS Buckley class. -

That’s actually what I was trying to do when I got the error. It seems the software won’t let you include a string that looks like a URL unless it ends in .jpg ( or one of the other supported image formats.). A string ending in .mp3 is rejected. I was hoping there was a trick that I just wasn’t aware of- hence my original question.

-

That is very true- I see it in a number of modeling forums- especially older ones. Fifteen-plus years ago, many forums required you to use an external hosting site for photos. For example, there are now lots of useless threads out there, ones that now have no photos, thanks to the whole Photobucket debacle. But if the site didn’t allow/support native hosting of images back then, you can hardly blame people for using 3rd party hosting for images. (And the gallery still supports using them to this day!)

-

Sorry, I’m not following this line of reasoning at all…. how does a video of an RC model underway make it not a “Completed Model”? (But an action shot photo of the same model in the water is OK??) Plus, your response isn’t answering my question at all. Pretend for a moment I took a video that slowly pans around a completed static model, showing it from all angles. As I said in my original question, I know the gallery only accepts certain types of files. (Images only). I understand why - videos can really eat up storage space. That’s why I asked if there is a way to use an external link….

-

I know that the Gallery is only for photos, and limits the types of files that can be uploaded. Is there a way to link to an external site for a video? I have a short video (30 -60 seconds long) of my model underway. It is hosted on my (publicly viewable) Smugmug page. I tried to add a link in the description of the album, but it won’t let me- I get an error “There is no image at that URL”.

-

Lindberg ship kits are old, old molds- from the 1960s, primarily. A lot of their sailing ship kits are old molds acquired from long-gone companies, such as Inpact and Pyro. The are basically equivalent to old Airfix kits from the same era. Revell (USA) sailing ship kits are just as old in many cases, but usually with some more detail and parts than equivalent Lindberg kits. In an age of simpler, affordable kits aimed at younger modelers, Revell also offered the bigger, much more involved kits like the big USS Constitution and Cutty Sark. But as the late renowned ship modeler Dr. John Tilley posted on Fine Scale Modeler in the early 2000s, Revell hadn’t done a new sailing ship kit since the early 70s, and had been out of the sailing ship business for longer than they were ever in it…. (and Lindberg is even worse off.) If you are interested in reading quick reviews of the old Revell and Lindberg ship kits, “Rajen’s list” is still a valuable resource. ( You will quickly get a sense of how terribly inaccurate many of the Lindberg kits were!) It was in its heydey in the late ‘90s and early 2000s, but “Modeler Joe” has picked up the torch and updated it somewhat. http://www.modelerjoe.net/shipmodellist.html It may sound like I’m dumping on Lindberg, but as a boy 50 years ago, I built a bunch of them and enjoyed them. Some of the old Pryo molds they acquired still aren’t bad- the Steam Paddle Revenue Cutter Harriet Lane and the Lightship Nantucket, for example, are still decent kits- simplified detail, but the general shapes are correct and a decent foundation for whatever scratch building or other improvements you. may wish to add.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.