-

Posts

159 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by LJP

-

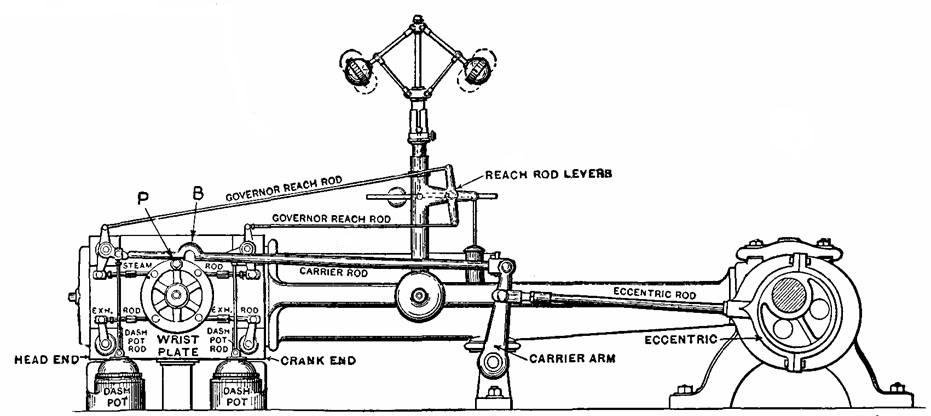

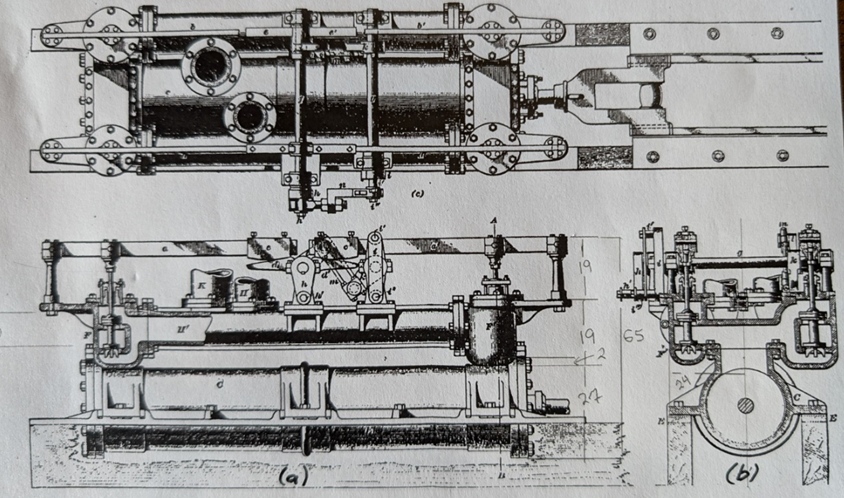

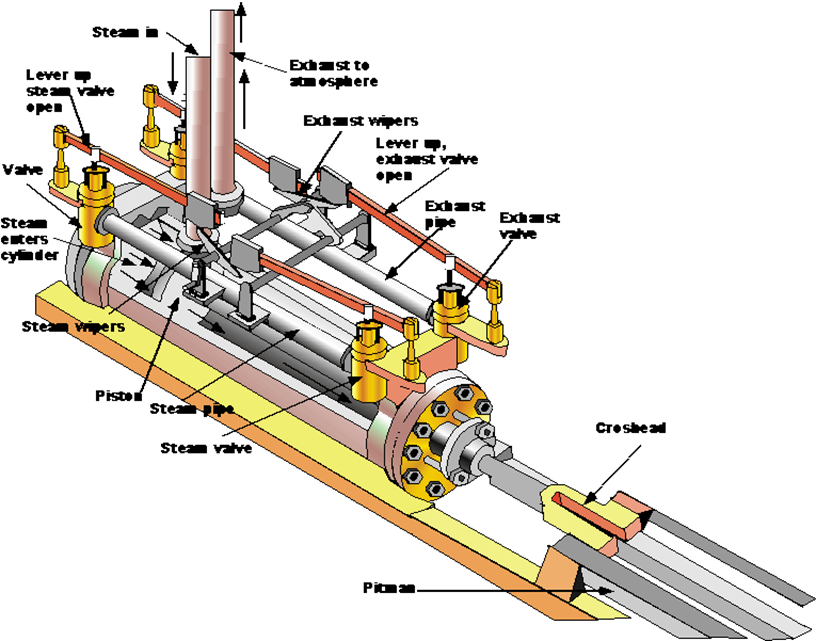

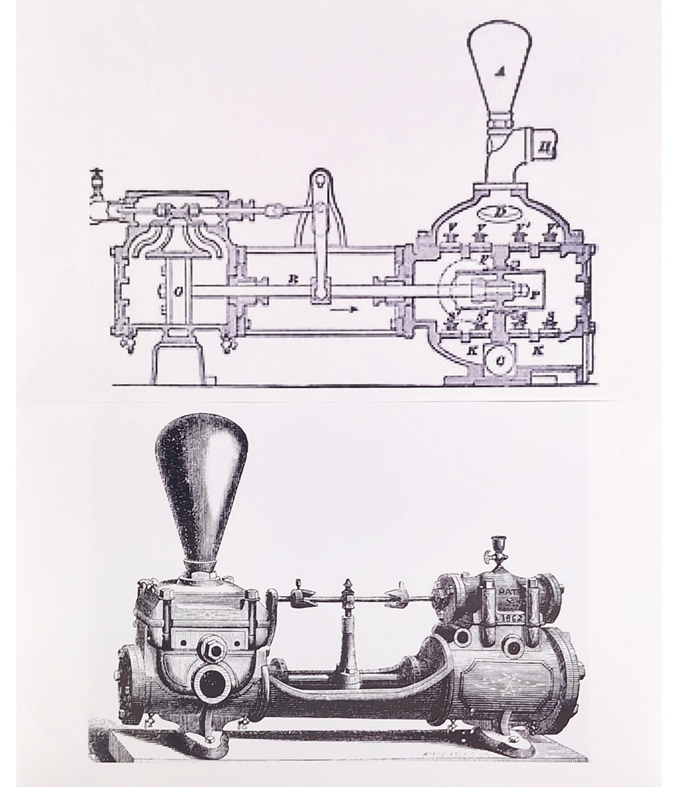

Keith, Thanks for your comments! Much easier at 1:64 versus your Lula scale. wefalck, Love your idea on boiler plating using aluminum and a ponce wheel. I will use on my next boat. That will really improve the skin on the boiler. You are correct on the boiler end. These were bolts and not rivets. I cheated on using what looked like rivets instead of trying to recreate bolts. The upper were bolted across the length of the boiler, while the lower were attached to the internal chimney. Not certain if that is the correct term but there was an internal open area and "chimney" at the back of a Scotch marine boiler. I used a generic Western steamboat poppet engine on JHC. These seemed simpler than the Corliss, even though the later Thistle my have had a Corliss. Again, Corliss may have been a generic name rathe than the manufacturer or the patent. Some Corliss' were really different from the Western engines. Two views of a type of Corliss is below. Thanks all. LJP

-

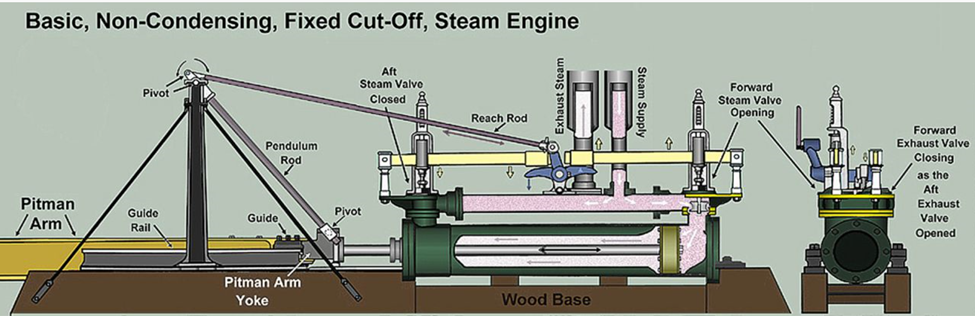

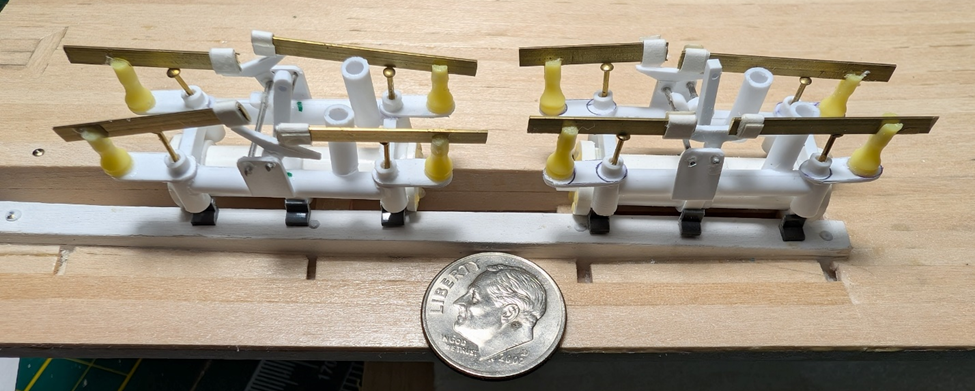

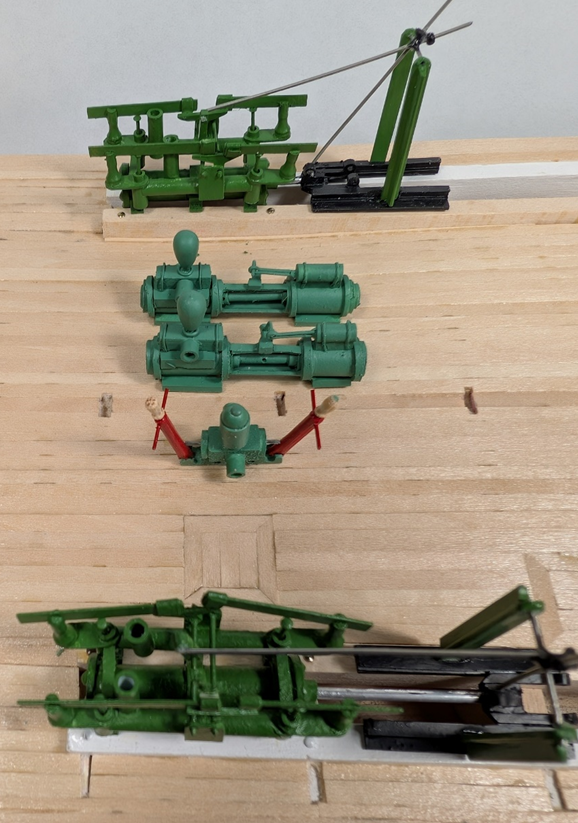

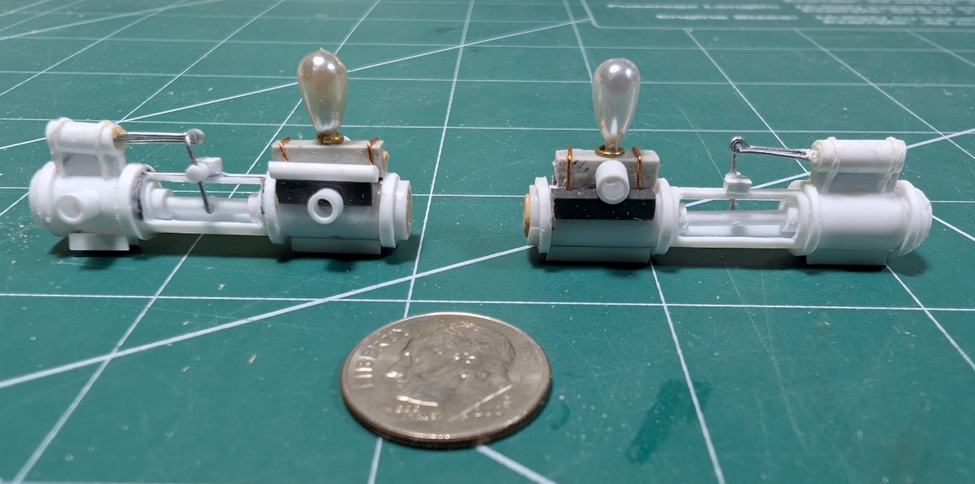

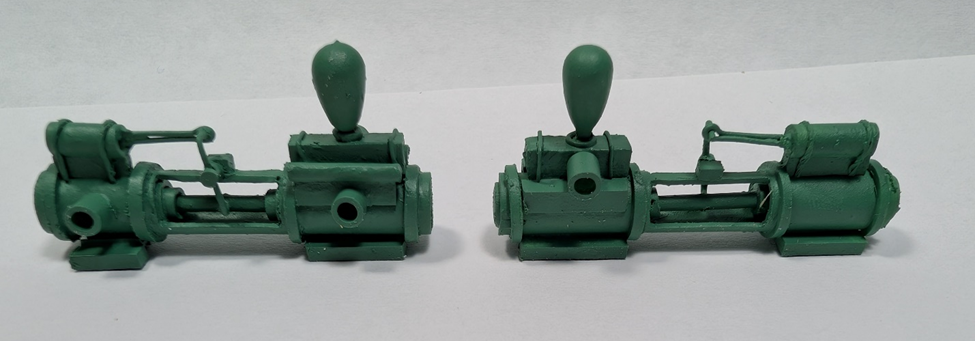

There are two differing sources for the J. H. Crawford engines. 1. Local 1894 newspaper accounts list the engines as being constructed by J. A. Barnes of Oshkosh. The cylinders were recorded as 13 by 50. 2. The Milwaukee Public Library, Great Lakes Marine Collection, listed the registered engines as Corliss condensing engines, with the cylinders noted as 20 by 42. Corliss was a local manufacturer located south of Milwaukee and close to Kenosha. The boat was listed on the sheet under Thistle and not J. H. Crawford. J. H. Crawford was never federally registered - as it was supposed to have been. The subsequent Thistle was registered finally in 1900. In fact, most Fox Wisconsin Waterway boats ignored registration until caught and threatened by the federal government. That being said, neither dimensions are really that different at 1:64 scale. Likewise, Corliss made poppet valve engines along with a myriad of other types. It is possible but unlikely that JHC/Thistle would have had its engines changed out in the 1899 hull extension and name change. As with the feed pumps, there are many, many examples of engines. Alan L. Bates’ The Western Rivers Engine Room Cyclopedium had numerous types and photos if you want a more in-depth discussion. I chose to use this Bates photo for my build, although I have seen this photo in several 1890s books and on internet feeds. Another useful engine graphic is both labeled and provides a quartering perspective. Source: Western Isles Photos/Graphics Note the following photo used a pendulum attached to the pitman to run the valves, unlike many other boats that used an eccentric attached to the sternwheel itself. Some boats actually used both the pendulum and the eccentric. Source: Steamboats.com JHC did have a pendulum based upon the cropped and enhanced photo below. I left the model’s engines with solely a pendulum for the steam cut-off control. I also used a simplified rocker assembly. Heavily cropped and enhanced. Note the pendulum. Source: University of Wisconsin LaCrosse Murphy Collection Dime time with the finished but unpainted engines. The left engine is fully extended while the right is exactly at mid cylinder. The final painted products. I needed to add the pendulum and slide for clarity. The entire unit will be removed from the model until later assembly. Makes life much easier. And this is sorta what it will look like with the feed and manual water pumps are added. But still lots of detail to be added. I need to make the sternwheel now. I will use the same process an I did on Thistle. The process, along with upcoming family duties may require some time before completion.

-

Keith, Unbelievable detail at so small a scale! I know how difficult these engines are to build. Way to go! LJP

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

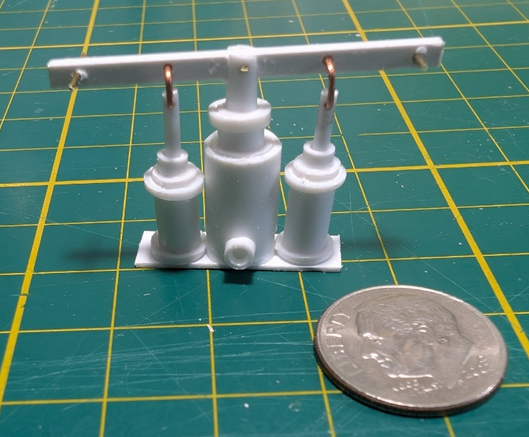

There are numerous examples of feed pumps out there. I did not use Moyie’s pumps as they are completely different and much more modern than many of the period single pumps. While I used photos of several different pumps for the period, the two following are the ones I most relied upon. My build used rocker arms (top photo) versus the older slide model on the bottom litho. The dime is back! The finished but unpainted main and auxiliary pumps are below. I have included a photo of each side to show the detail. The air chambers are cut down corsage pins. The rest is numerous pieces of Evergreen plastic, wire, and thread. The finished products, again showing both sides. And “saved” with paint. Now onto the engine assembly. This means I will need to build the engines, slides, pitman arms and the paddle wheel – along with the cylinder timbers and sternwheel bracing. This will take time and will be several individual projects. I want to build each of the individual components and then place them where they should be in the final build. That way it will be easier to install during final assembly. Once completed, I can then build the crew quarters and layout the engine room before re-installing the engine assembly.

-

Keith, Great job! But your "Valuable lessons learned should I have the opportunity to make another sternwheeler. " should read WHEN I make the next sternwheeler... LJP

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

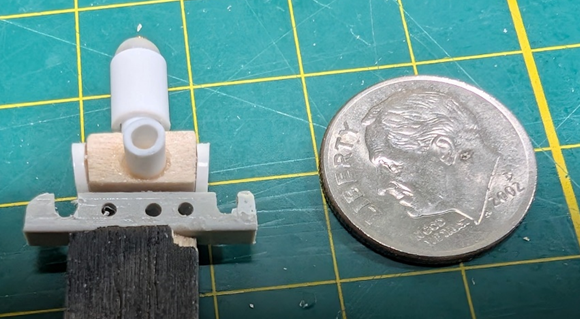

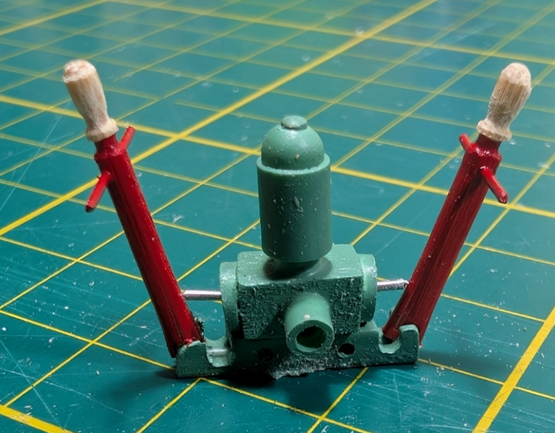

My major source for images of some of the machinery and the engine room is the S. S. Moyie (1898). Moyie is now a museum boat in Kaslo, British Columbia. It had an incredibly long life and ran Lake Kootenay until 1957. It has numerous YouTube videos, both of the ship as a museum, but also when it was still in operation. Several years ago, the museum website (which also has a Facebook account) had an interactive video (since discontinued, unfortunately) that afforded an true in-depth look at the boat. I have gotten screen shots from several of the videos. Moyie had two manual pumps that I replicated. In the engine room was a manual fire pump while in the boiler room was a manual feed pump. These are two photos of the fire pump. This is the build without the handles. Note a new dime – wore the other one out. The diameter of the dime equates to 3’ 8” in scale. I lightly glue small parts to scrap balsa to make it easier to airbrush or paint. That is what you see at the base of the part. Finished product, with arms. Ready to be placed in the engine room. I do not have a great photo of the manual feed pump but it still provides enough detail for a build. Another dime time before painting. And the finished product. This will be placed on the main deck in front of the boiler pit, just like Moyie. Next, onto the steam main and auxiliary feed pumps.

-

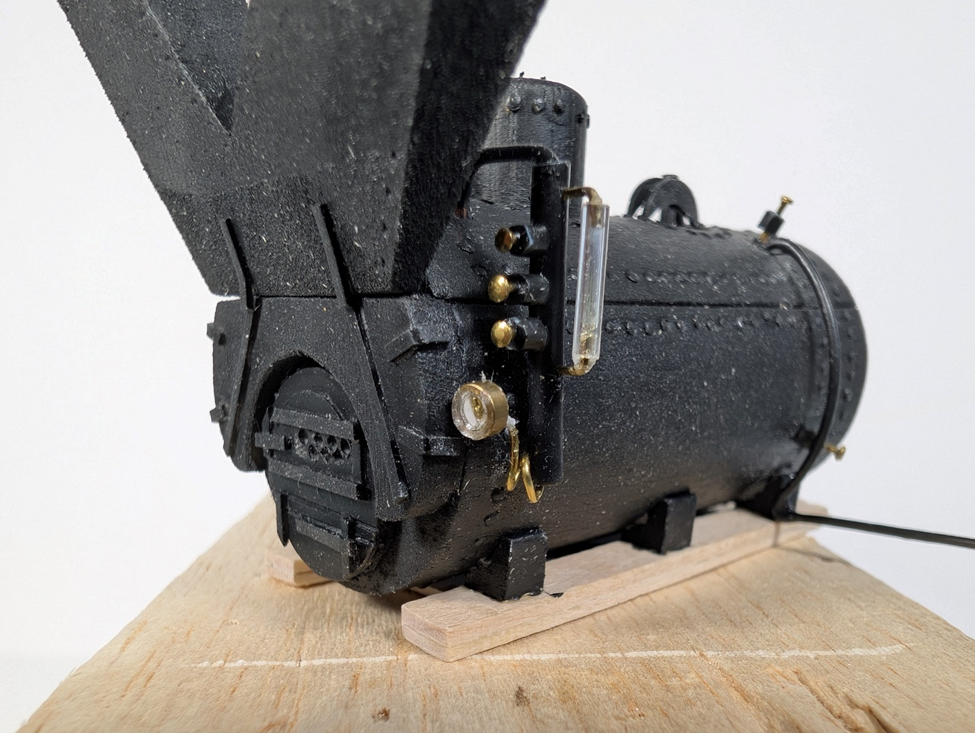

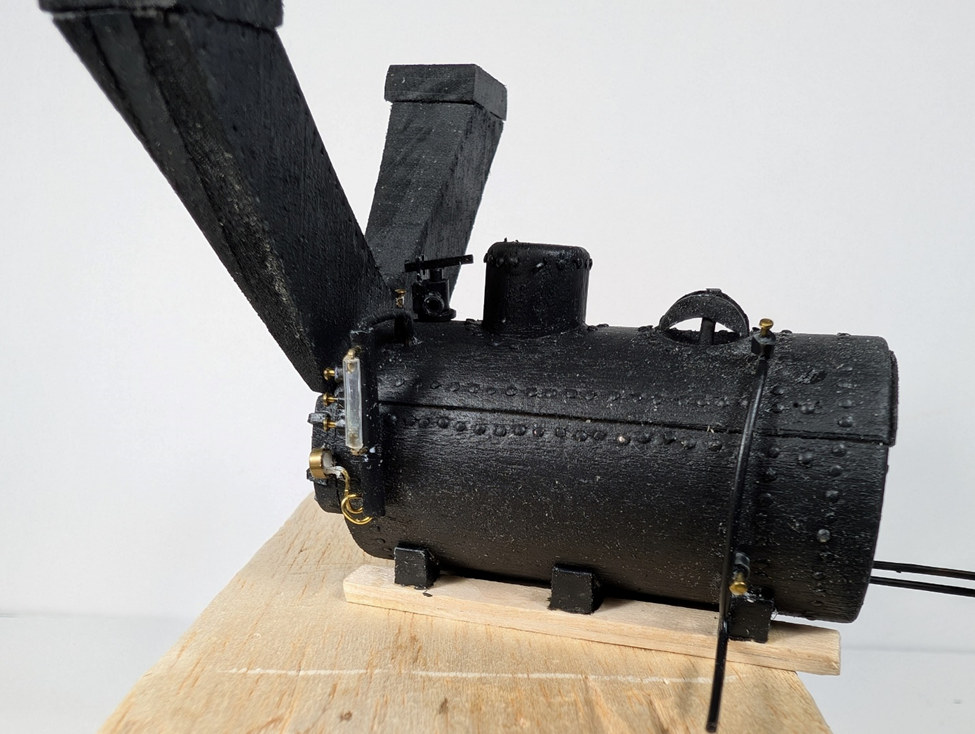

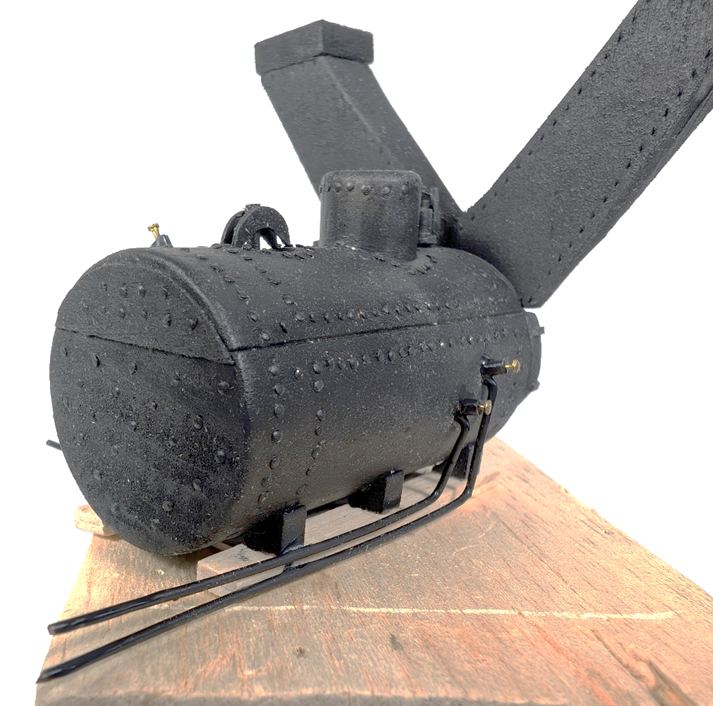

Hi John, Here is the finished boiler assembly. And John’s comment in Keith Black’s Lula build on painting saving the day is right on the money. Here is my final painted ( a/k/a “saved”) boiler assembly. The actual boiler colour is a dark black. I enhanced some of the photos to show the detail as dark black obscures the detail.. This one is slightly enhanced. The gauges are on the right. The curved pipe on the rear of the boiler is the blow out pipe. The breechings are overly large due to photo perspective and have been cut off. Side view, unenhanced. The safety valve and man hole cover are prominent. There is another view of the gauges and blow-outs. Quartering rear view. This has been enhanced to show detail. This view shows the main and auxiliary water feeds. And here is how it looks in the hull. It has not been glued in yet as I do not want to damage it as I am working on other things. The black squares in the foreground are coal hatches. Now onto the other machinery: engines, feed pumps, hand pumps & such. Still tiny stuff, probable re-dos and much more self-discussions. These are each little mini-projects so I will do a few at a time. I will start with the hand pumps.

-

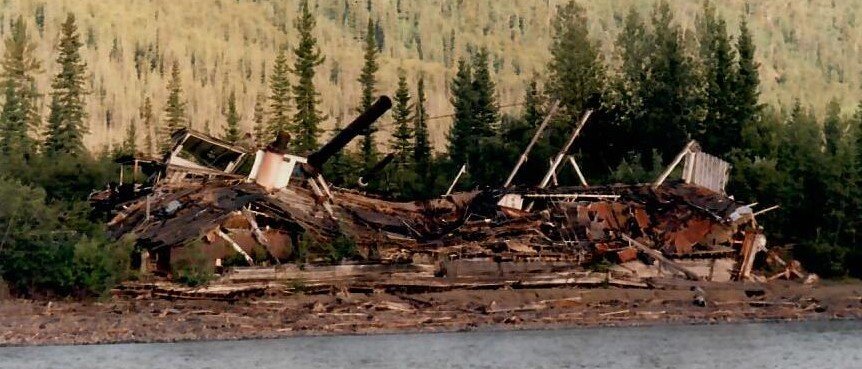

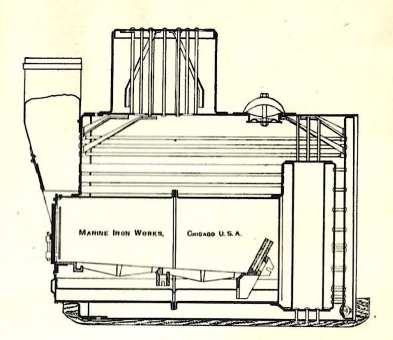

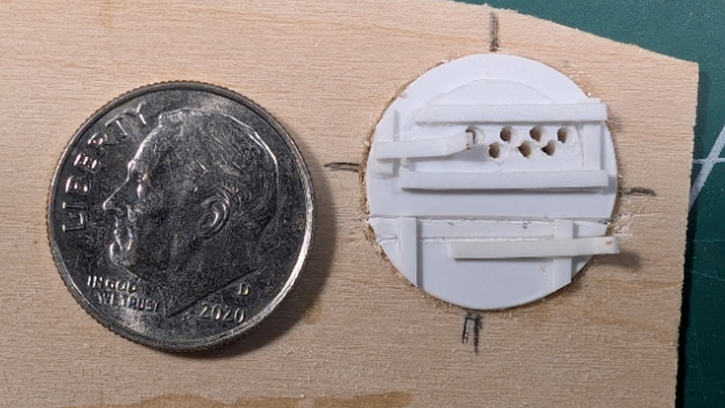

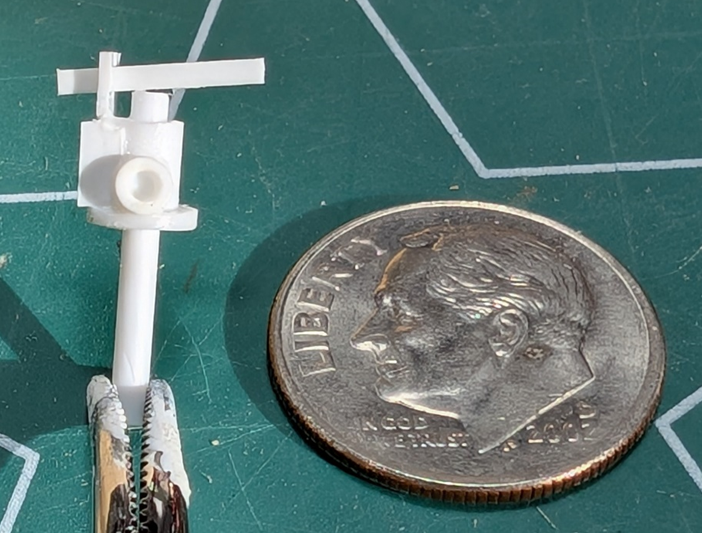

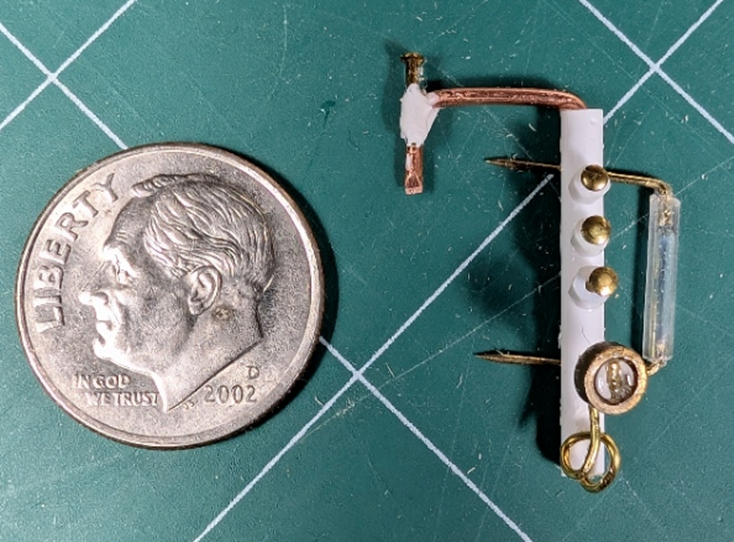

I got to working on some of the tiny boiler assembly detail. The door to the firebox was a challenge. I used plastic for the top layer and detail while there is a wood backing. The dime gives some sense of size. Another tiny addition was the safety valve. I used a safety valve litho from the International Library of Technology book from the 1890s. This was one of the books for engineers. It contains way more information (and mathematical formulas) then I ever want to attack. The part used six different type and size Evergreen plastics. Same dime, different boiler part. An unusual construct on my boiler is the layout for the glass, stop cocks and water gauge. Marine Iron Works has a print from a photo (which means it actually was built) where all of the items were on a separate pipe apart for the boiler. I simply had to use this layout. As noted on Keith’s YouTube schematic, gauges &c. were often attached to the boiler itself. Source: Marine Iron Works of Chicago USA. This is what I ended up with. This is a temporary layout that still needs to be painted, trimmed and then secured. I had to rearrange the components because of the dual stack breeching. This was a horrible build with redos and many conversations with myself. For the glass, I used a section of straight hobby bead . The gauge was a brass part from my possible box (everything possible is found in there). The pins will be trimmed after painting. Yup, same dime put to use again. An issue I could not completely resolve was the breeching layout for dual stacks on the bolier. There were lots of single stack examples for a single Scotch Marine boiler, and numerous examples of multiple Western Marine boilers on dual stacks – but no dual stacks on a single boiler. I used a poor quality photo of the 1922 burnt Valley Queen (Ryan built ex- Leander Choate) from the Oskosh Public Museum for my layout. The breeching will seem huge in relation to the boiler. This may be due in part to the boiler being situated in a boiler pit within the hull as opposed to on the main deck. No dime, no photo. The final boiler will also include the upper & lower blow-outs and main and auxiliary water feeds. On to assembly and painting. This should not take too long.

-

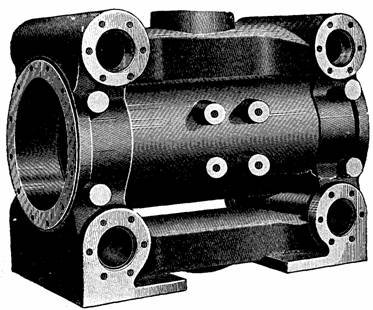

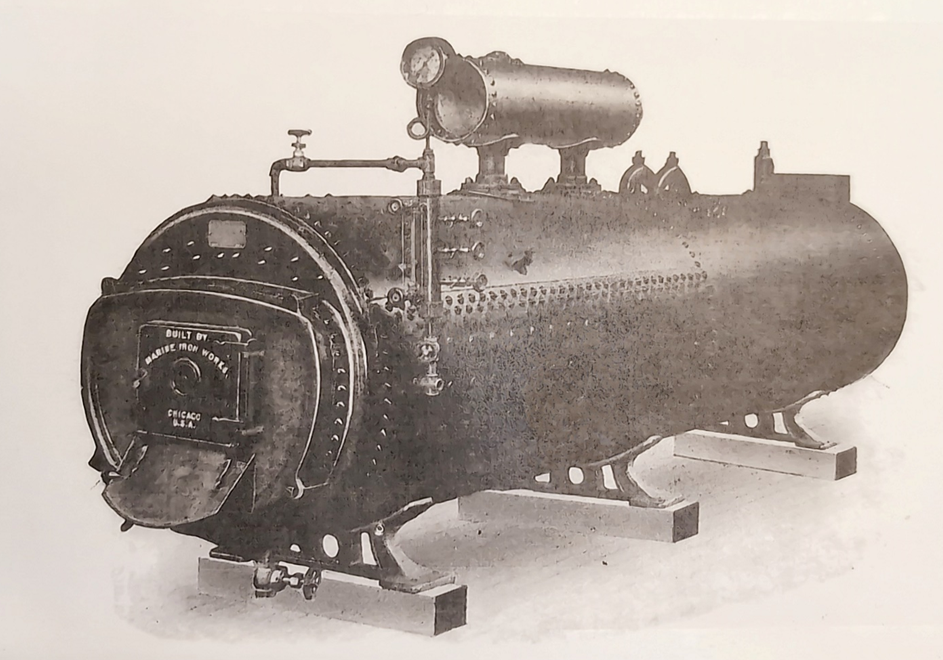

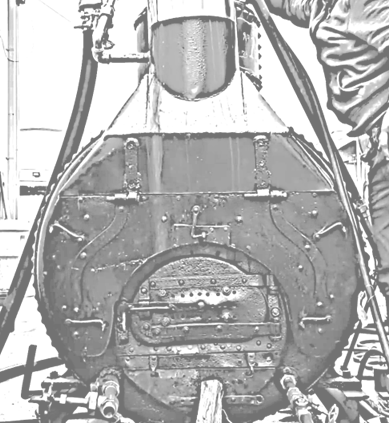

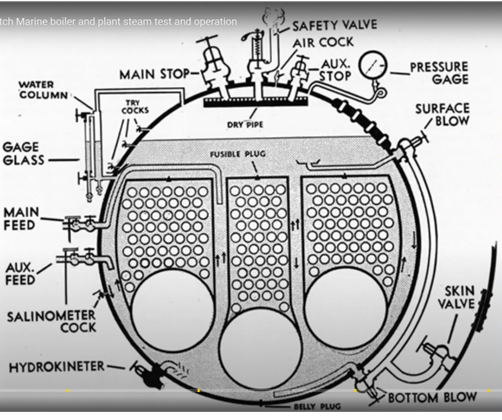

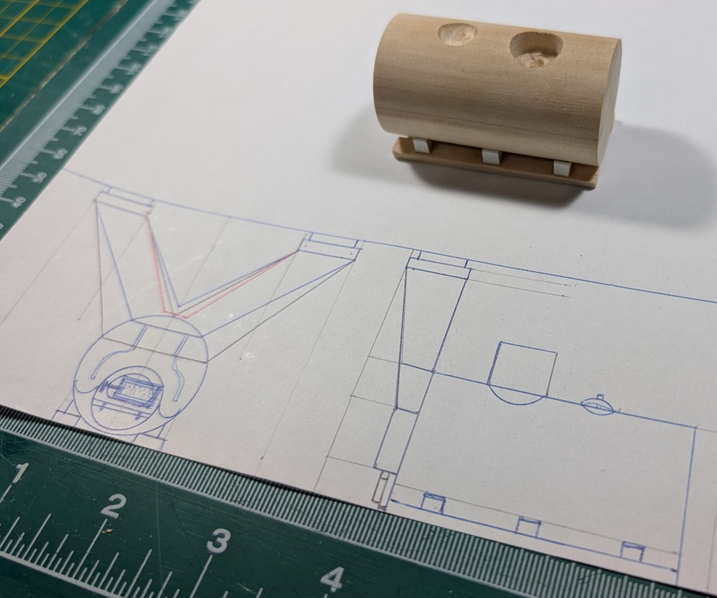

Building the boiler assembly turned into a project onto itself. The J H Crawford had a single Scotch Marine boiler that had been built by Burns of Fort Howard (Green Bay) per period publications. The Milwaukee Public Library, Great Lakes Marine Collection, lists the boiler as a 6 foot diameter by 12 feet long Firebox boiler. At my 1/64 scale, this is 1 1/8 by 2 ¼ - which is large enough to include some simplified detail. The 12 foot length was noted on other Ryan built boats but diameters and number of boilers varied. I used several sources to pattern the boiler. Like my Thistle build, I used Marine Iron Works of Chicago USA sales brochures and of course Bates. There are literally thousands of boiler photos in books and periodicals. I also used Keith Black’s YouTube screen shots (below) of an actual 1887 Scotch Marine boiler which was immeasurably helpful. The screen shot of the actual boiler has been heavily enhanced to show the detail. Source: YouTube Part 2:1887 Scotch Marine boiler and plant steam test and operation by A.E.Karnes I started the boiler project by drawing simplified scale plans based upon my research. The face of the boiler looks a lot like the 1887 YouTube video while the boiler itself resembles the Marine Iron Works. These are the plans with an early start on the boiler. I simulated the boiler rivets using small nails. I used a ponce wheel for the spacing, but lots of drilling. I do like what the final result was even given the work to get there. Next up, all the detail and painting.

-

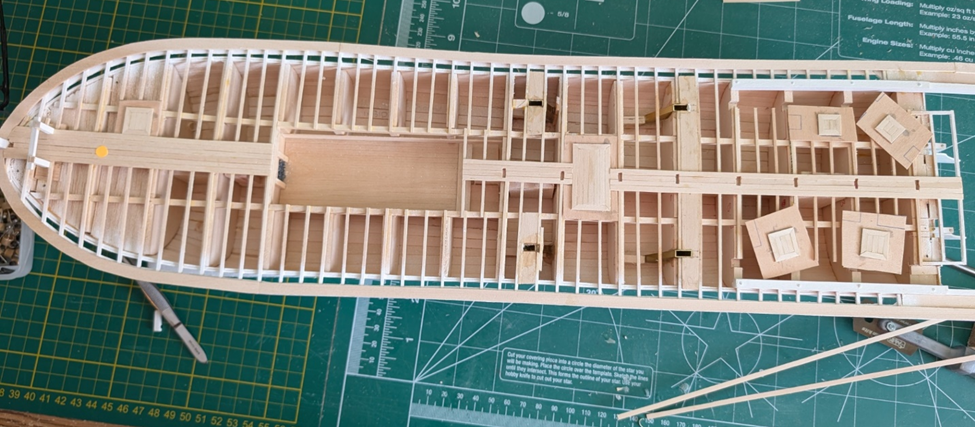

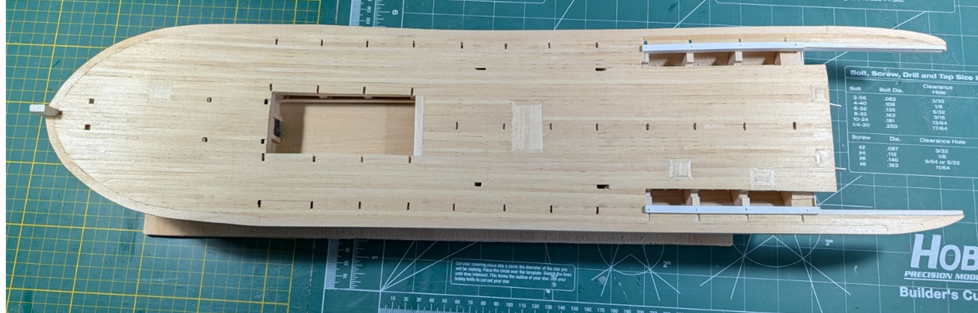

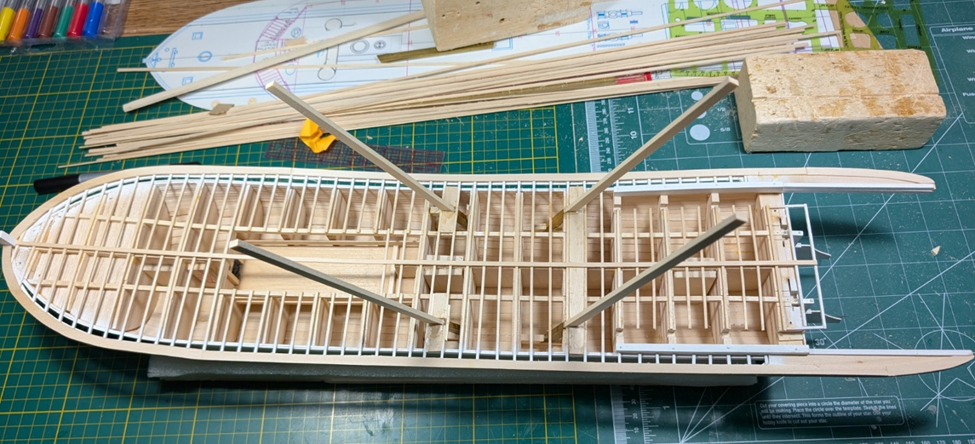

As promised, I finished planking the main deck. Earlier I had mentioned that I was uncertain if the deck at the bow had a canvas or tarpaper cover. I recently obtained a clear photo postcard of the J H Crawford’s sister boat the Paul L. The Paul L capsized in May 1910 after being unloaded of coal on only the starboard side. It may be difficult to see here but the bow is clearly planked without canvas or tarpaper. Contrast that with the canvas used on the hurricane deck This is my early process on planking. I added six access or storage hatches. I built those up on a maple veneer base and then placed them. All the planking was 1/32 by 1/8 basswood. The holes in the decking are where the mid-deck stationaries will be placed. The orange dot will place a capstan. The finished product. I included numerous slots in the deck for the stationaries, hog chain braces and bits. This will be stronger than simply gluing them to the deck like I did on Thistle. Next step is to begin building all of the “stuff” on the main deck. This includes machinery, engine room crew quarters, and of course, the Scotch Marine Boiler. Many thanks to Keith Black in his Lula build for finding a YouTube on an operating Scotch Marine boiler video. That will be a great help in building my boiler.

-

The video is incredible! Not only the detail on the boiler but the operating intricacies also. Great detail for your boiler!

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

I ended up with another step before I can begin planking the deck. As I mentioned earlier, I had problems with the hog chain braces getting in the way of later construction. So what I tried this time is epoxying 5/32 x 5/15 K&S brass tube as a guide in the hull. The 4/32 x 8/32 basswood hog chain braces are removable and just slide into the guides. It is hard to see from the photo, but the braces are all at 60 degrees. Hopefully, this will work better. I left the braces long and will cut down to length later. I also added the rudders. I needed to add these now because of the decking over the false transom. Lastly, I added the strake around the outside of the deck. I do not know what this is called – let me know if you know the correct name. On a clipper ship, the bow section is a nibbling strake – no idea what it is on a steamboat. So now I finally can begin the planking. [ I promise I will do it this time] You can also see the center plank that I laid for a reference point. It will be trimmed for the boiler pit and hatches.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.