-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

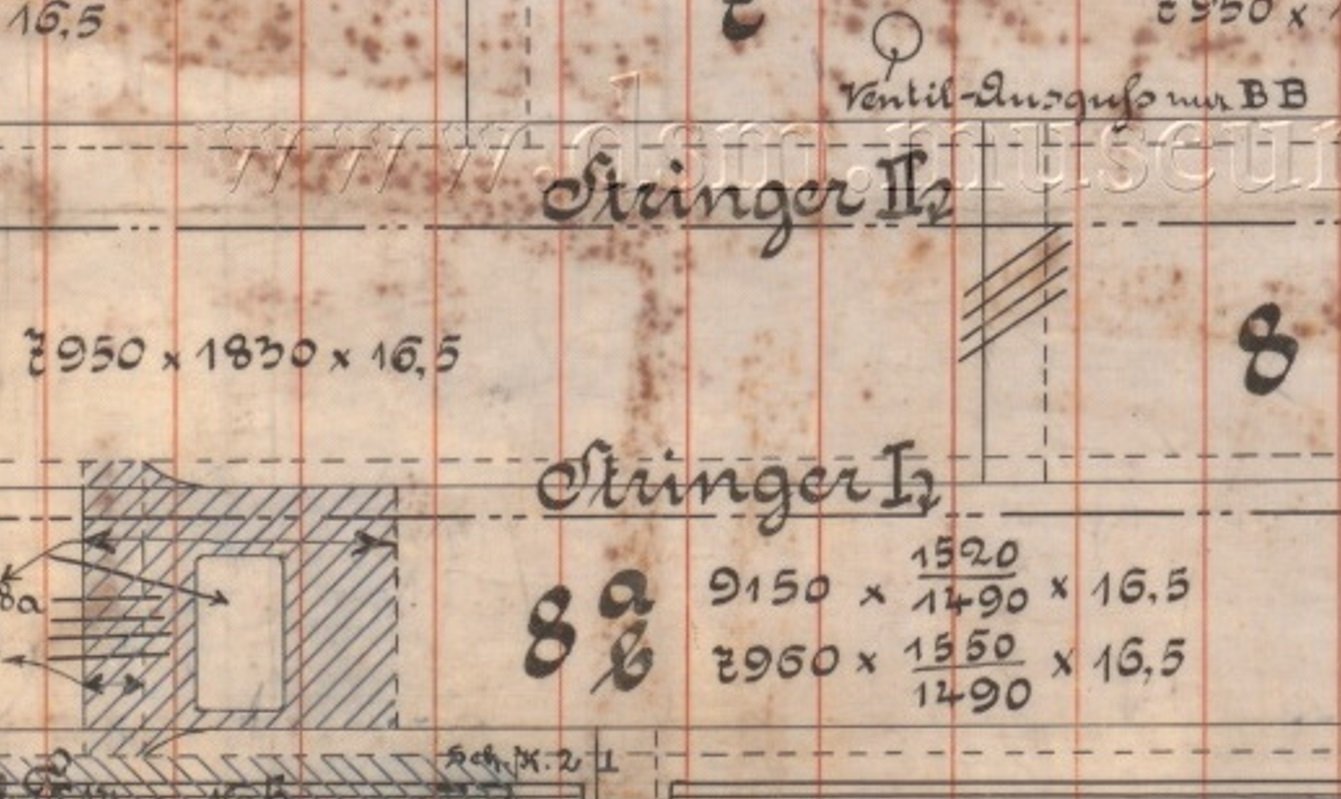

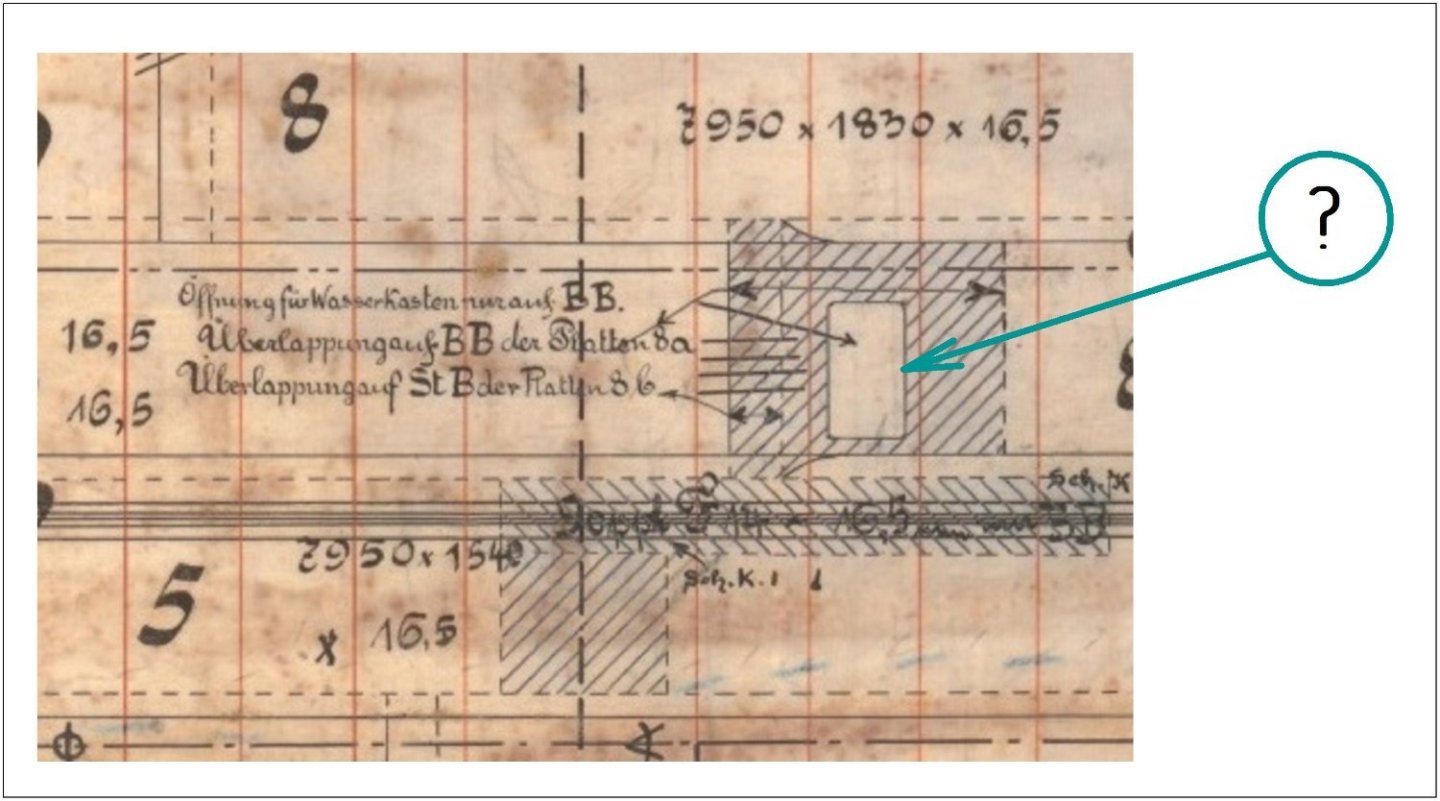

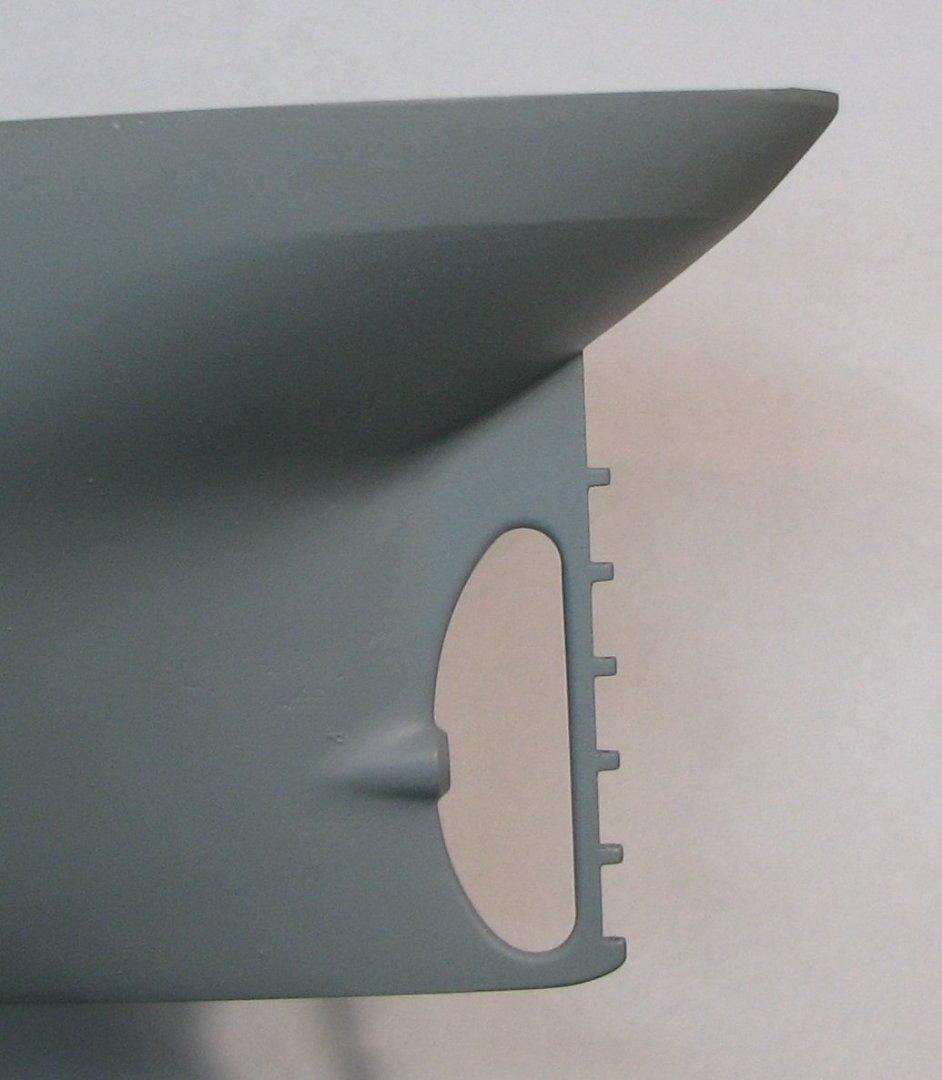

As usual, there are not enough drawings for the model, so I will use information from other ships. This is a fragment of a drawing of the outer cladding in German (ss UHENFELS ). I need your help in determining the name of this rectangular cutout, if of course there is this name on the drawing. It is located in the underwater part of the ship in the area of the engine and boiler room.

-

Sasha and Joachim, thank you for your nice reviews! By the way, I wanted to look at the work of German modelers and tried to register on the forum a couple of times. https://www.marine-modellbau-und-mehr.de/ But both times they didn’t let me go beyond the security check step. And now I’m at a loss as to whether I’m doing something wrong or whether I’m dangerous in some way (just kidding).

-

Nils! I think yes, you can work with a brush. But we must take into account that the hardening speed of this putty is greater than that of paint and you cannot hesitate. And most importantly, after mixing the two components, the putty must be diluted with acetone until it is very liquid. And you will have approximately 20-30 minutes for the entire operation.

-

Bob, I already regretted writing this phrase. We live in different conditions and I don’t have such a wide selection of hardeners as you do. And yet, with the resin that I have to work with, this is what happens. At the moment when it just begins to thicken on the hull of the model, I still have the opportunity to make it more liquid for a very short moment using a hairdryer. This technique allows me to have time to remove all excess resin from the model body and achieve an almost ideally smooth surface of fiberglass impregnated with resin, without lumps of excess resin.

-

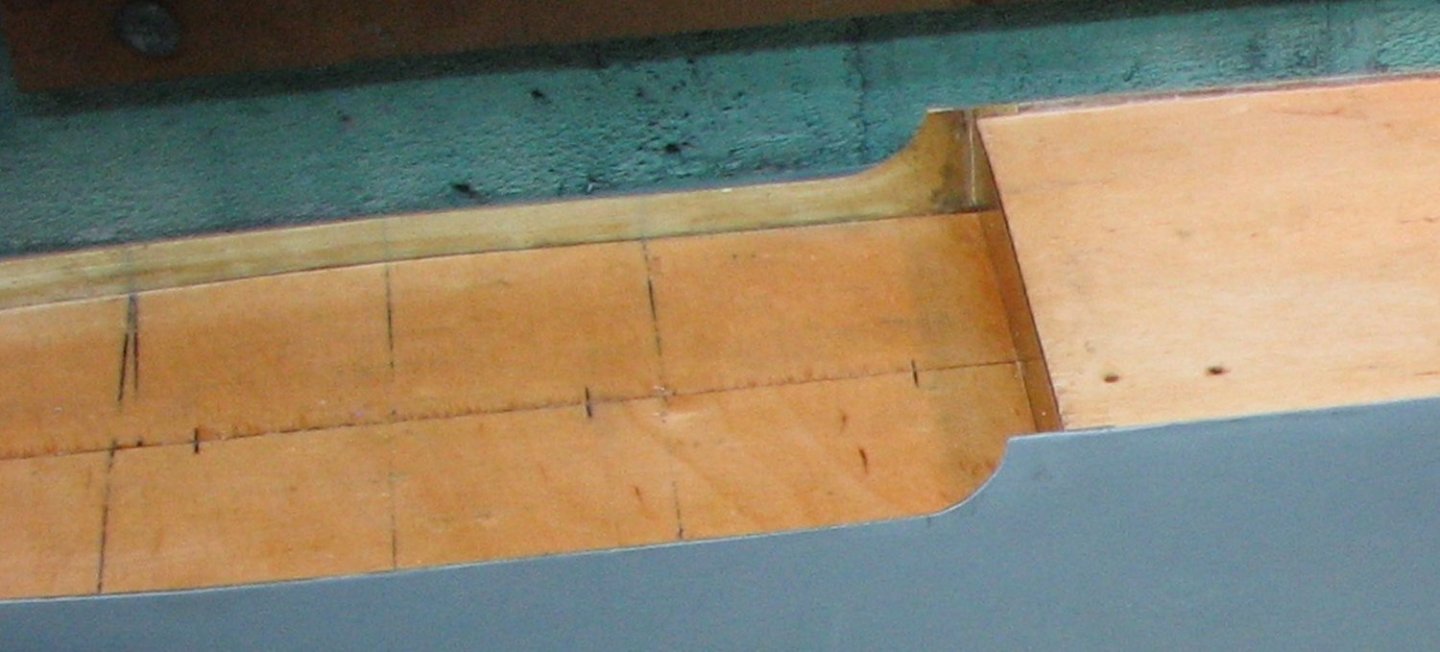

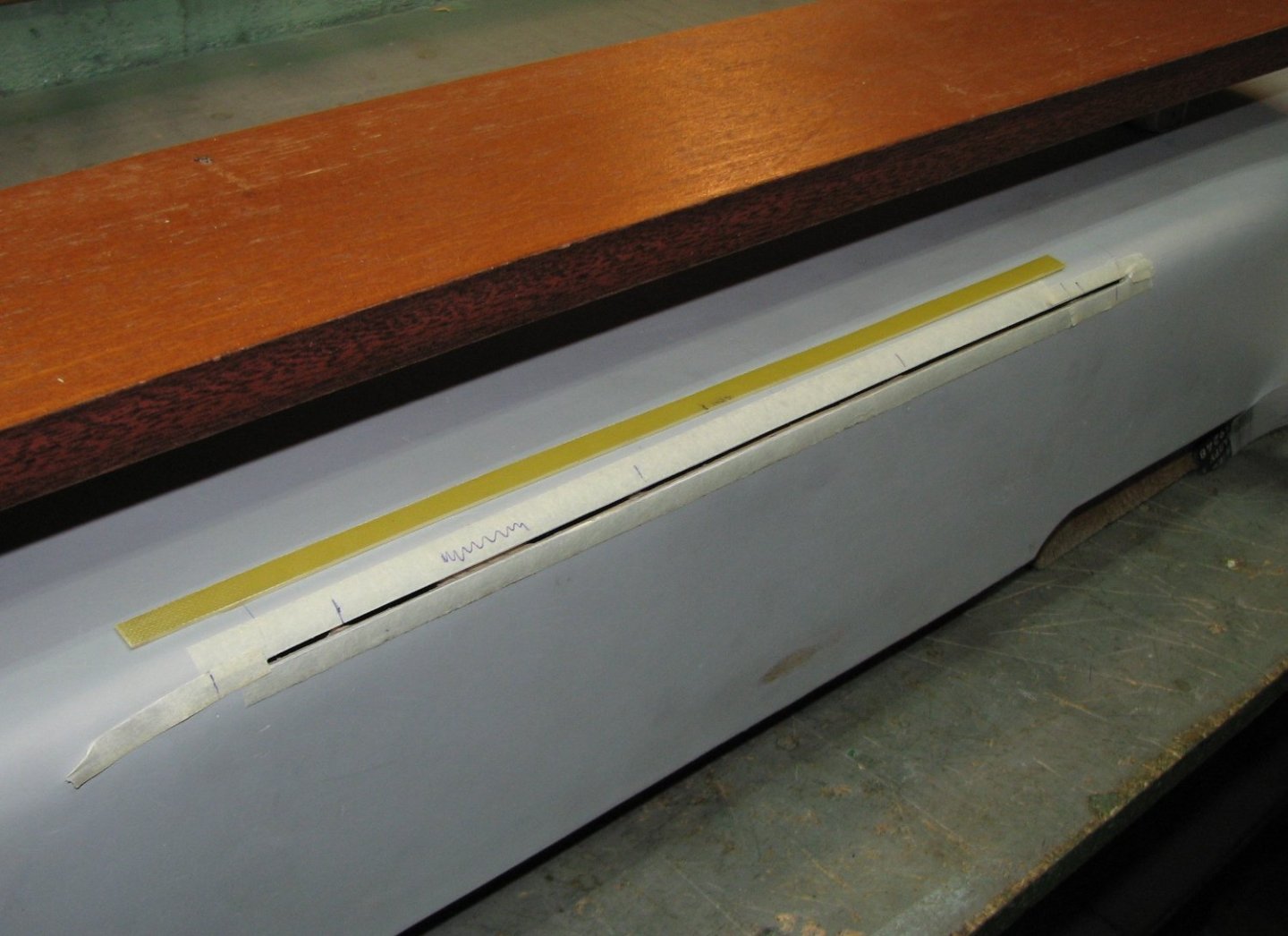

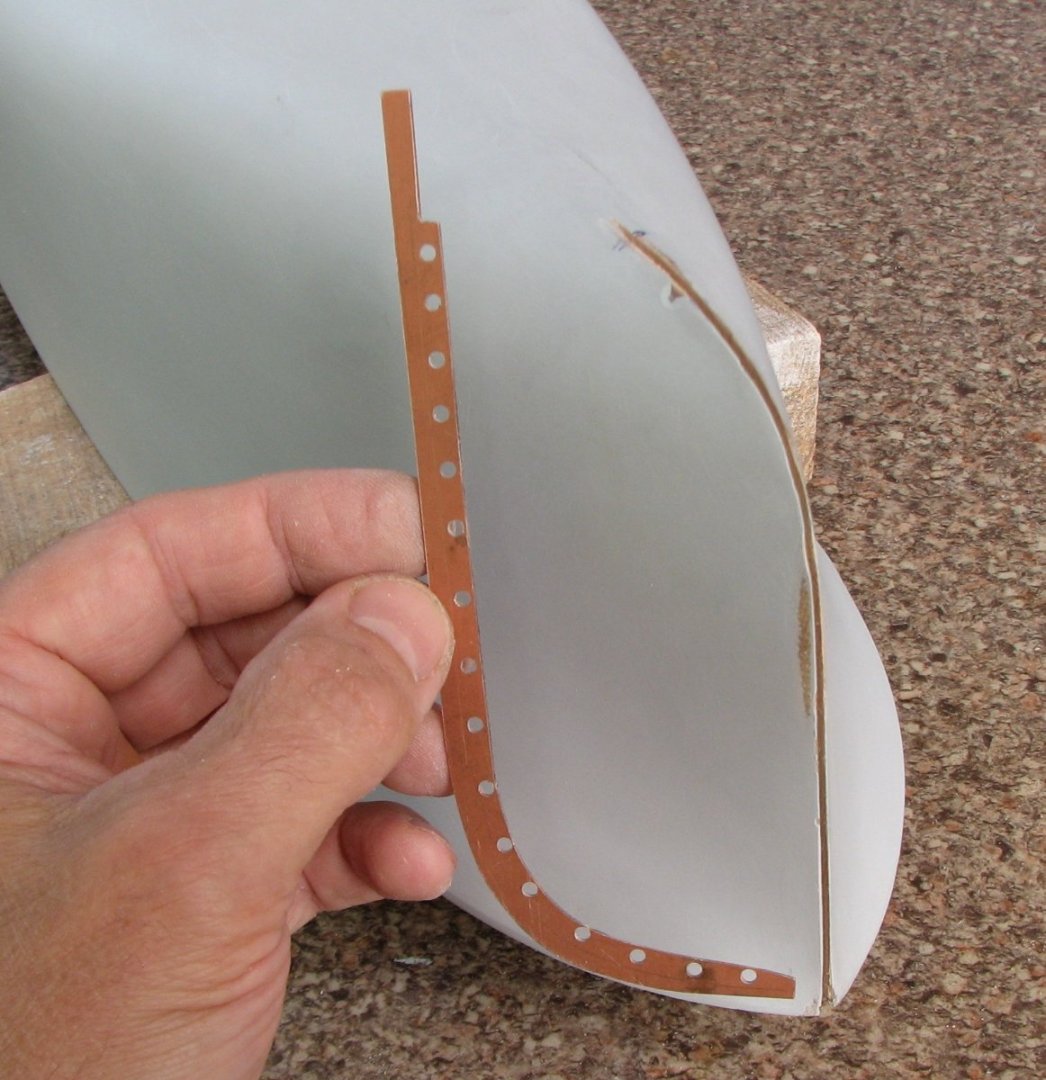

Avoiding wrinkles is not difficult: 1) I make cuts in the fiberglass fabric as shown in the photo along the green lines before applying the resin 2) after applying the resin in small portions, I smooth it along with the fiberglass with a soft rubber spatula 3) in case the resin polymerizes too quickly, I have a construction hair dryer nearby with which I can heat the desired area of the resin and fiberglass to liquefy it

-

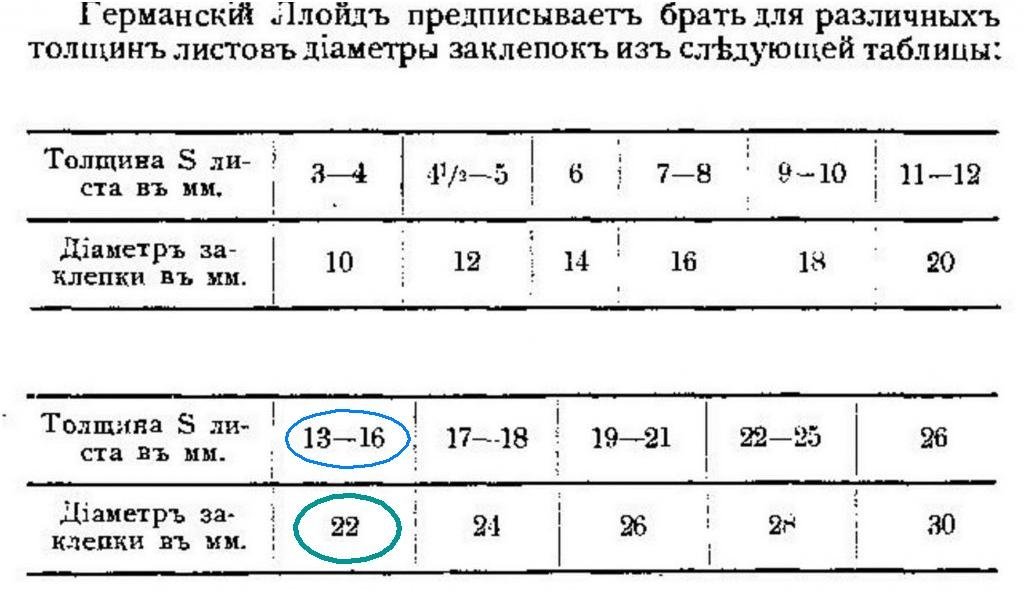

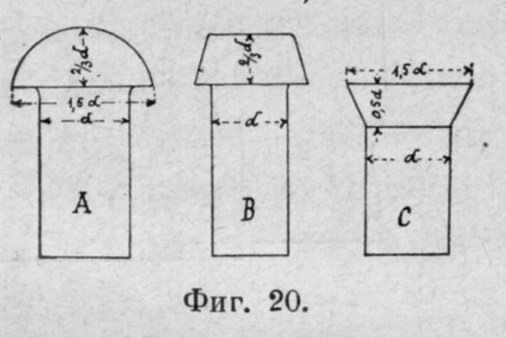

For rivet head size calculations I show the German Lloyd chart. Circled in blue is the thickness of the cooable panel sheet that I choose. Green color is the required rivet diameter. As a result of a simple calculation, I get the dimensions of the rivet head for my model on a scale of 1:100 - diameter 0.3 mm and height 0.15 mm. Even if I can make such small details on the model, after covering with primer and paint they will simply visually disappear. Therefore, it makes no sense to show rivets on this model. But the belts of the outer hull plating sheets will be shown.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.