-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

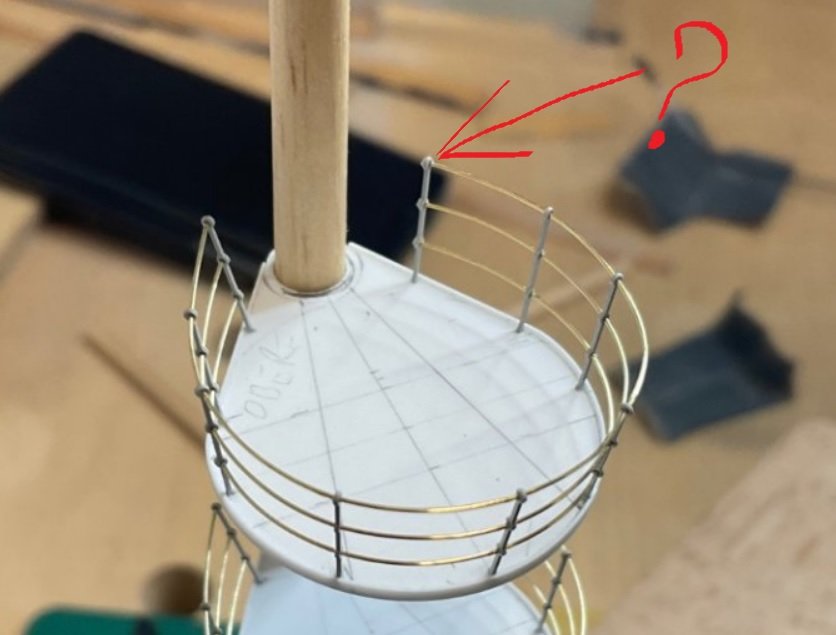

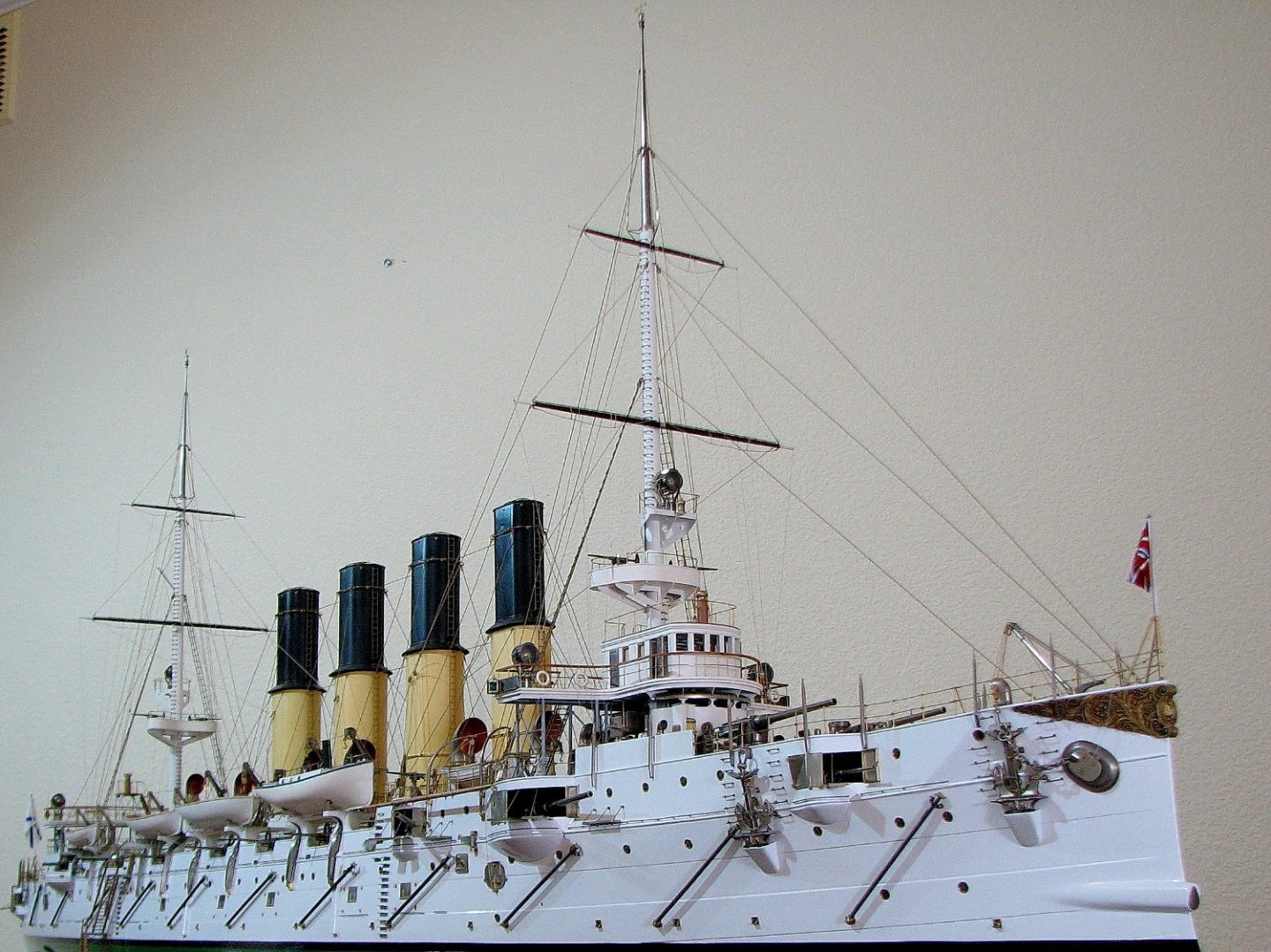

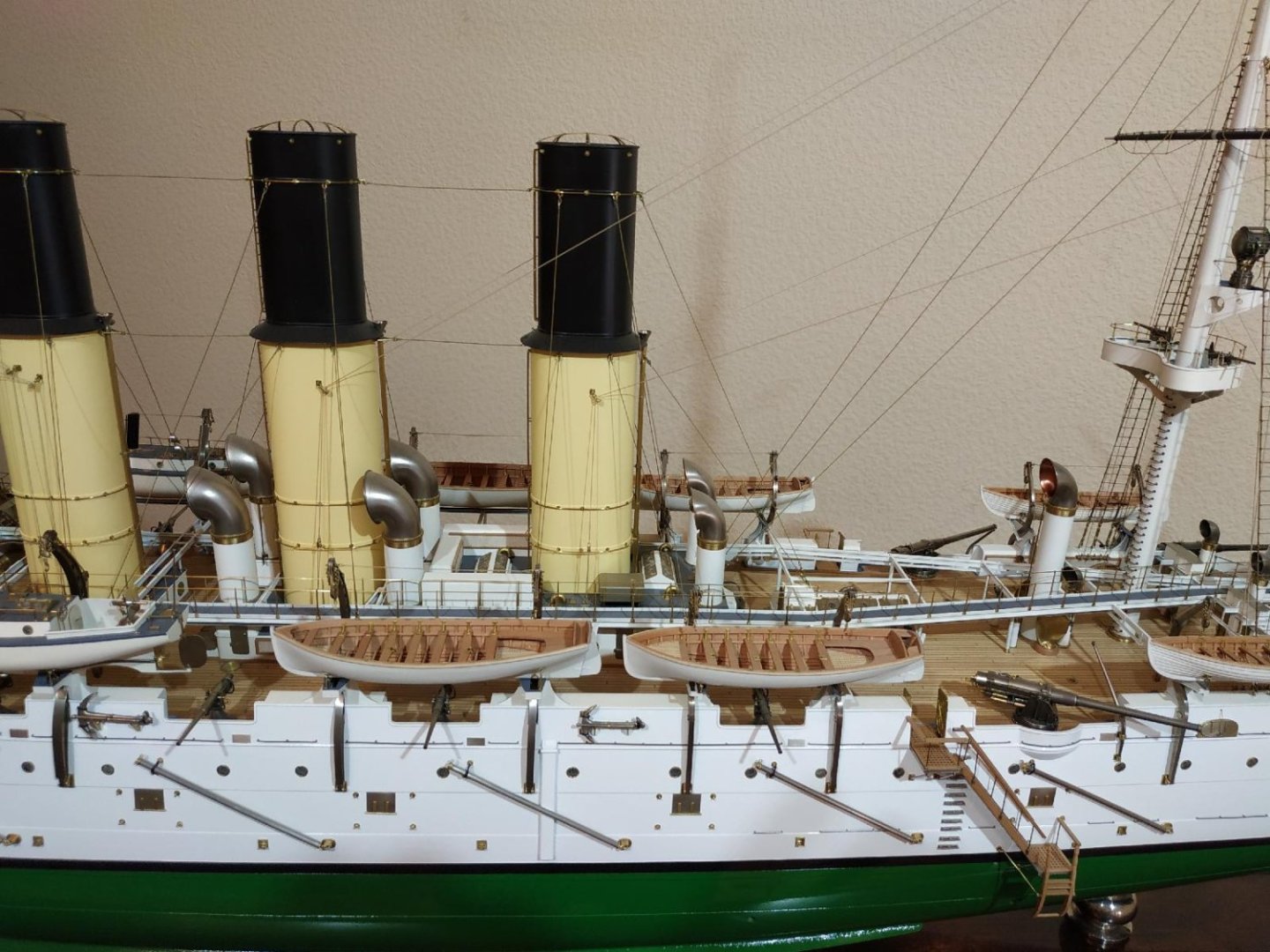

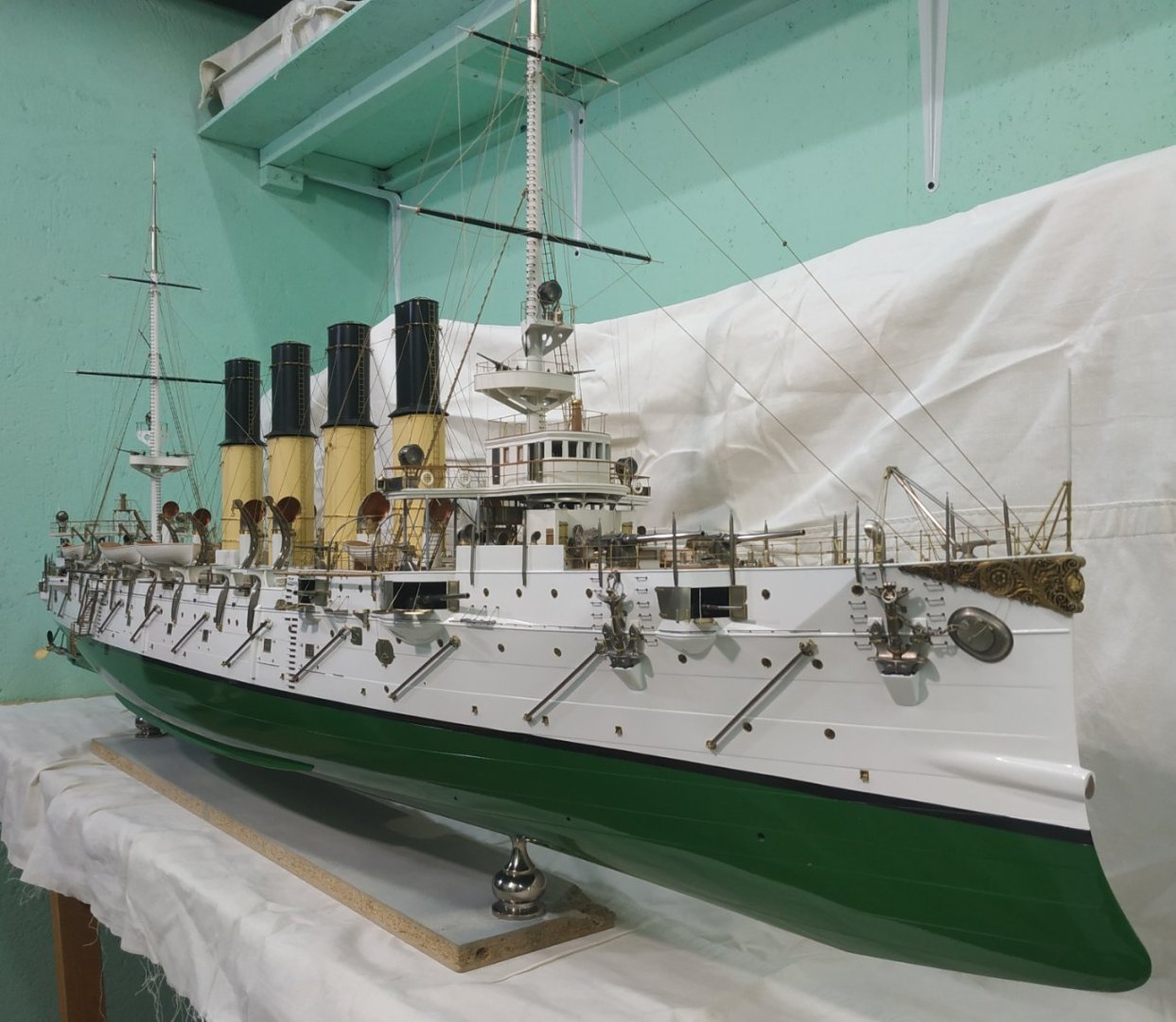

Thanks everyone! I hope that my work will justify and not disappoint your interest in it. From the point of view of ship modeling, this project is interesting in that the small length of the hull allows the use of a large scale. At the same time, the saturation of weapons and ship accessories contains a large number of small details, which, in combination with a large scale, can give an excellent result.

-

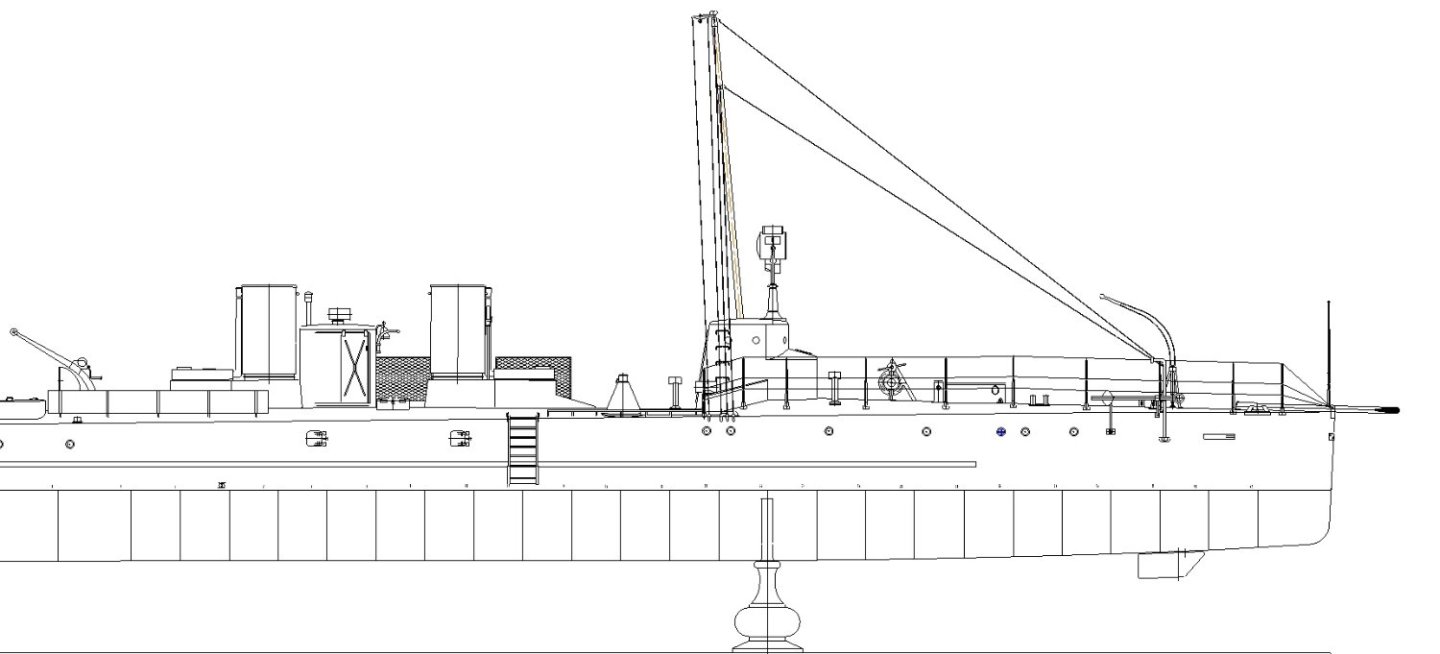

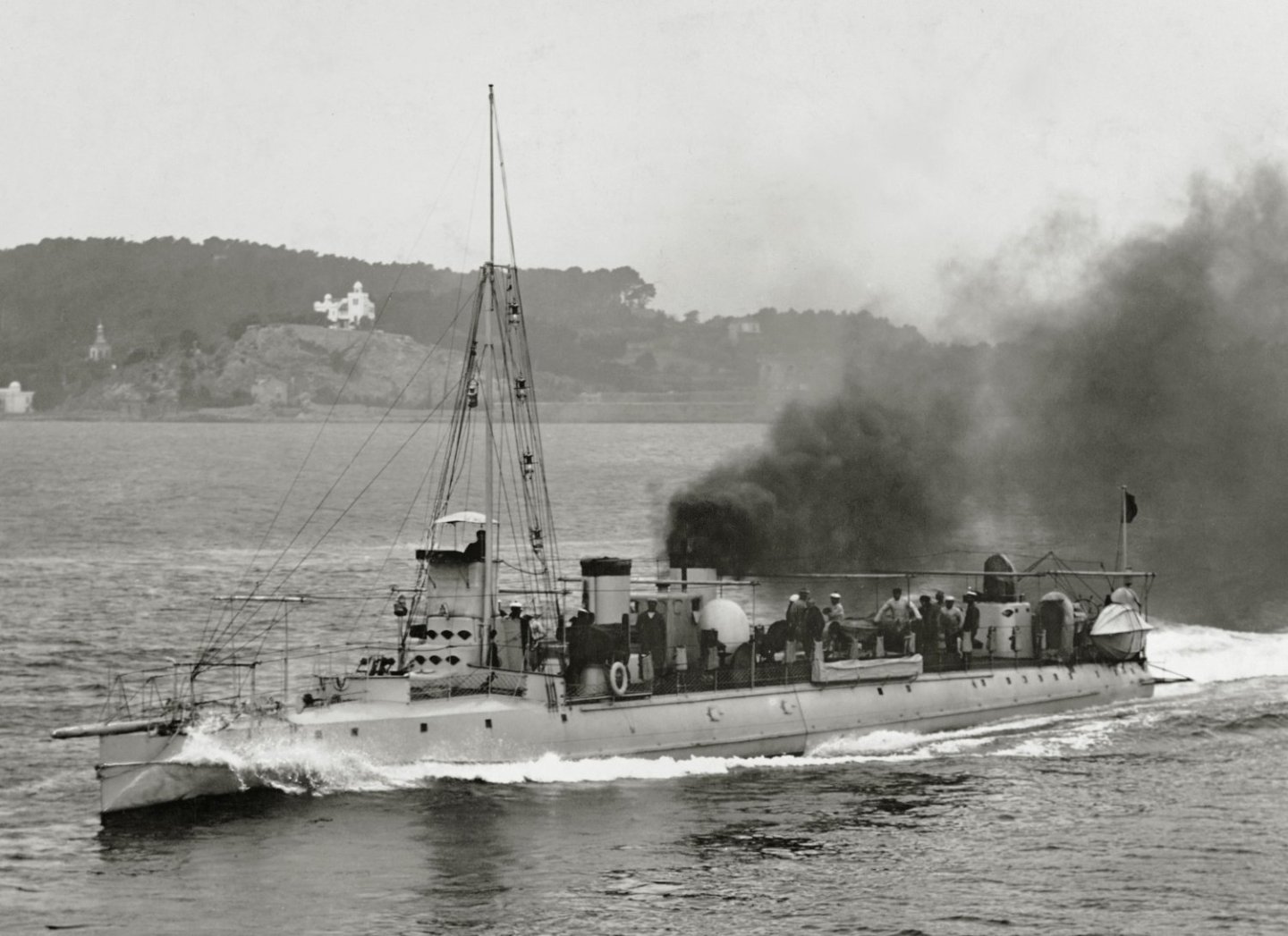

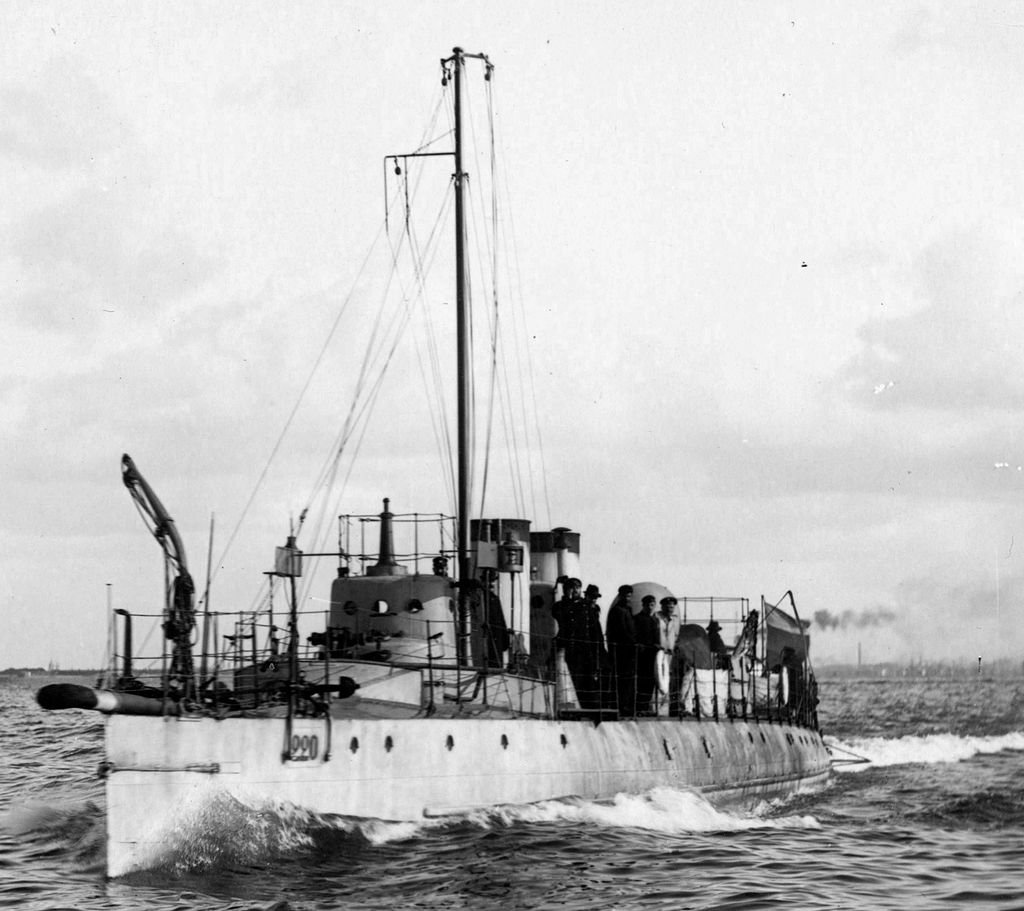

In total, 10 ships of this type were built at two Russian shipyards. The ancestor of this series was the French destroyer "Cyclone" designed and built by the company "Augustin Norman". In 1899, Russia purchased from O. Norman a complete set of drawings necessary for the construction of ships. However, before construction began, the following changes were made to the project: - reinforced steel case set - increased hull width by 0.16m to improve stability - one double-tube torpedo tube was installed instead of two single-tube ones - changed layout of living quarters. The following photo shows the French destroyer Cyclone.

-

I am glad to welcome all members of the forum again! My new topic will be dedicated to the Cyclone-class destroyer. It was built by the Nevsky Zavod in St. Petersburg in 1902. Displacement: 152.4 tons Length: 45 m Width: 4.9 m Draft aft: 2.5 m Armament: 2 - 47 mm (1.9 in) guns 1× 2 torpedo tubes 356 mm

-

Ras, congratulations on the completion of construction! I will be happy to observe how your skill improves with each subsequent work.

-

Thanks friends! I'm very impressed with your feedback and wishes! Let's hope it all goes well. Any modeler, like an actor on stage and an artist in a gallery, needs grateful spectators. I am glad that my little performance and the picture that resulted from it gave pleasure to the audience on your forum. The model of the cruiser was made to order for a private collection, but I have no right to disclose the name of its owner, sorry. The purpose of my future work has not yet been determined, but it will certainly appear and I hope that I can show it here. I wish everyone a lot of interesting models and a pleasant pastime for their construction!

-

I congratulate everyone on New Year's holidays. I wish you good models and a peaceful sky over your head!

-

Thank you Keith! Thanks to the Lord God, everything is fine with me and I am completing my project. It remains for me to install the steam boats on the model and raise the flags.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.