-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

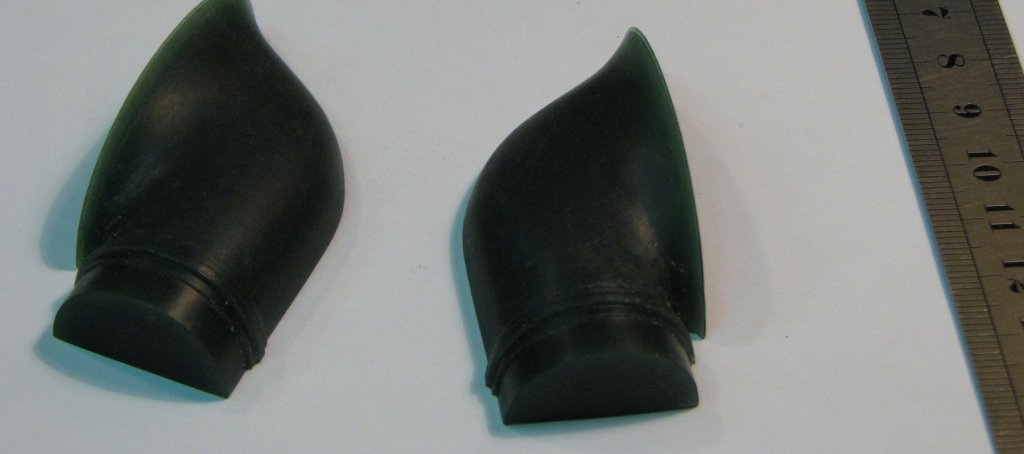

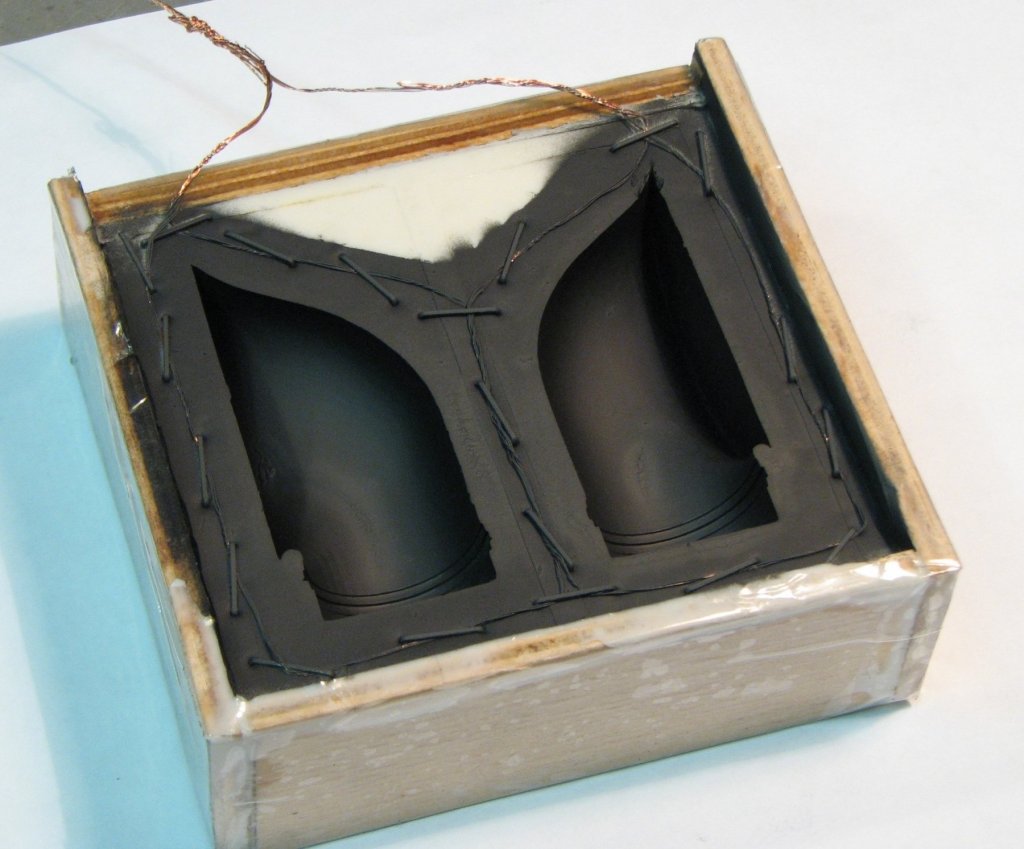

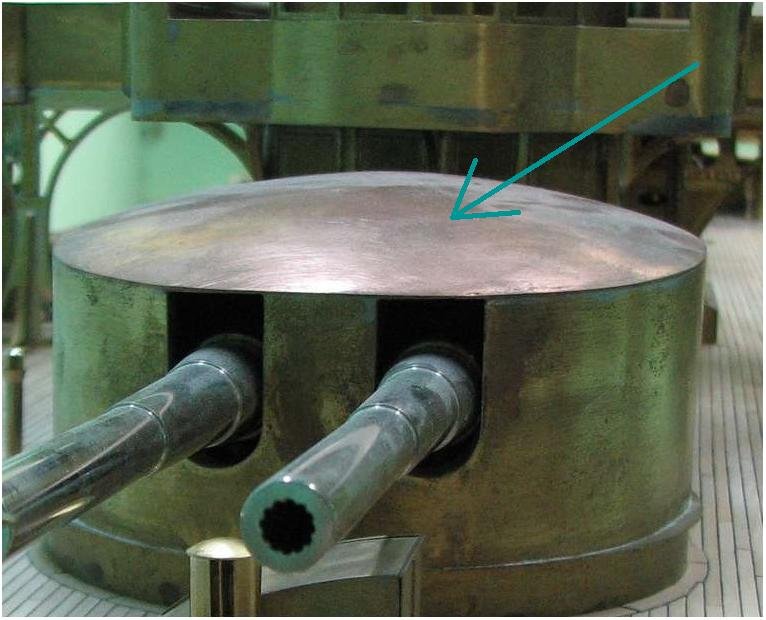

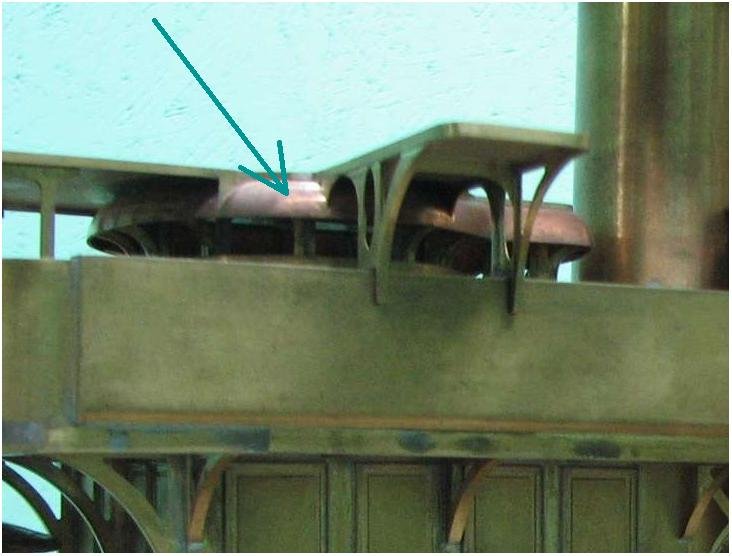

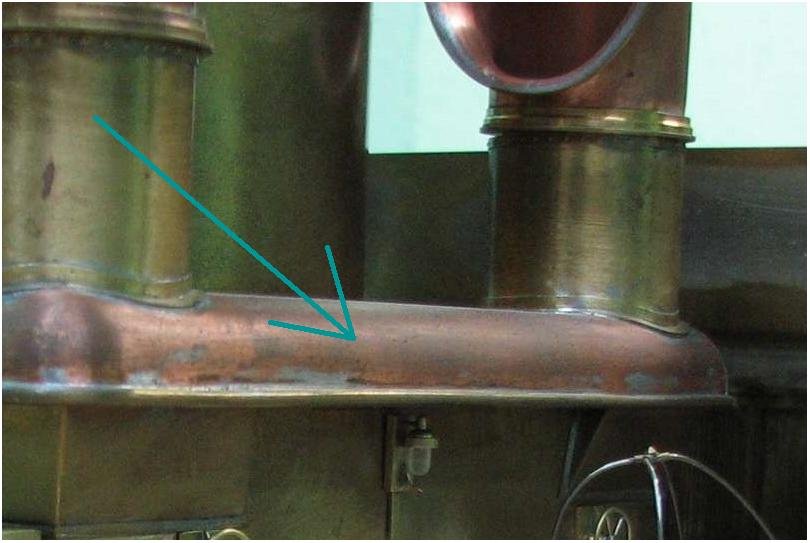

Thank you,druxey ! It's time for the portholes. The portholes on the Varyag had a visor in the upper part. This visor was cast entirely with the porthole.

-

Paper cannons! This is perhaps more abruptly than all the other amazing things on this model !!! Doris, I bow to your skill.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

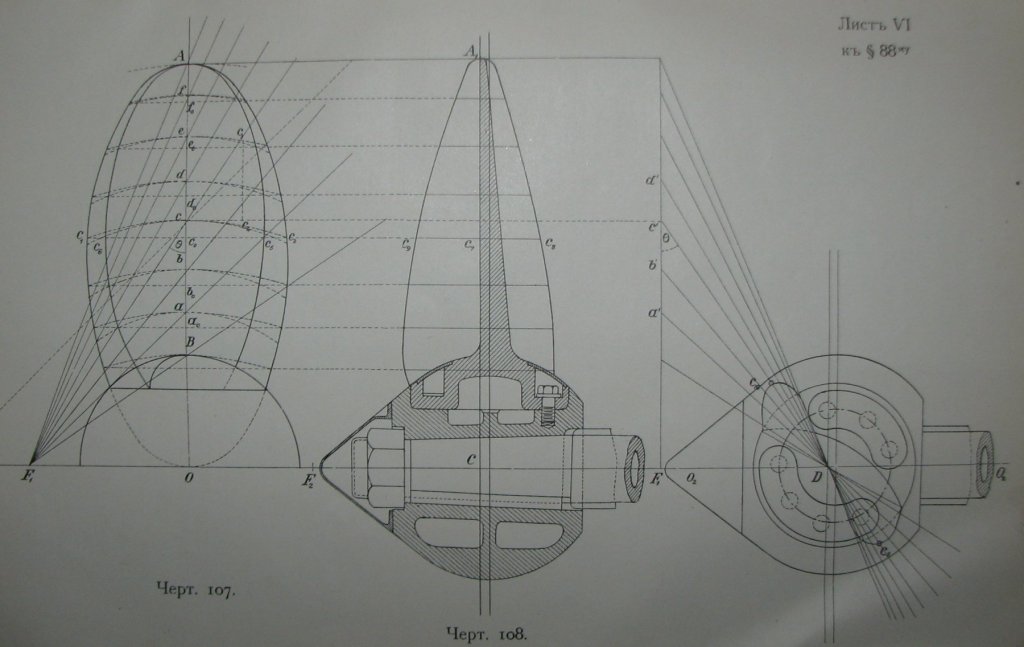

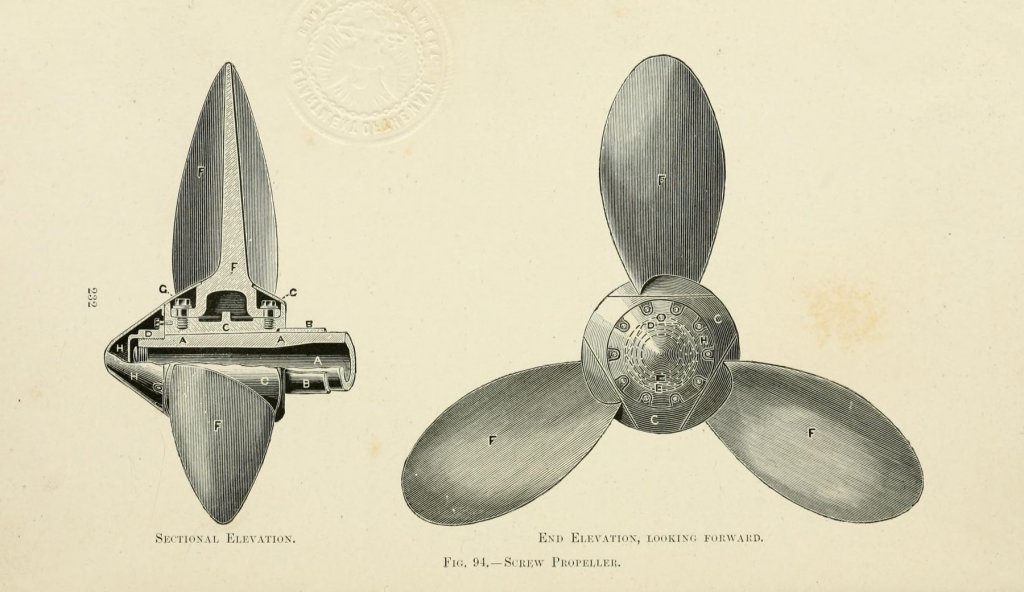

Keith, your propeller turned out to be very good, but in order to have absolutely everything correctly, it is necessary to twist each blade a little around its axis. I hope that I do not interfere too much with your process.

-

Alexander, you work very carefully. I know how difficult it is to turn small parts out of ferrous metal, you do it perfectly.

-

G.L. , I got all my knowledge of electroforming from the Internet, videos and articles. I added to this my thoughts, ideas and got the technology I needed. You can go the same way.

-

Bedford, agree with you, in Russian there is a saying - "Devil is not so black as he is painted". If you wish, soldering can be easily mastered. As a flux, I use zinc etched soldering acid. Judging by the photo, your approach to soldering is at a high level.

-

Thank you, Michael! You are a Master of your craft, and I appreciate your attention to my work. I am very pleased to follow your work. The large scale of the model confronts you with special difficulties, and you successfully overcome them. I have something to learn from you! Each item spent approximately 8-10 hours in the electroplating bath. The slower the process, the better the detail is obtained.

-

The power source operates in DC mode, so I only regulate the amperage. I set the voltage to maximum and only once, I do not regulate it later.I follow the instructions for the power source, here it is: DC POWER SUPPLY HY1500-HY1800 DC MODE 1. Turn the voltage regulator clockwise until it stops, and current control counterclockwise until it stops. 2. Power on the instrument. 3 Connect the positive and negative outputs of the device to load. 3 Turn the current dial clockwise to set the official value of the output current.

-

Lou I tried to answer your question in a previous post. You need to understand that these formulas are needed to start the real process, in the course of work, you will definitely adjust these indicators as your experience becomes available.

-

I will try to answer questions as far as the translator and a small stock of my knowledge will allow me. 1) Recipe for cooking 1 l. electrolyte for electroforming: - we part 200 g of copper vitriol in 500 ml of water - we filter the resulting solution - add 134 ml. automotive electrolyte density of 1.28 - bring distilled water to 1 l. and mix well 2) Deposition Current: 15 mA * S (part coverage area) 3) To calculate the time of deposition of copper on small areas: t = (840 * m) / I time - in hours, mass - in grams, current - in milliamperes 4) Copper precipitated mass: m = (S * h) * ρ m - mass of copper in grams S - area in cm2 h - thickness in cm ρ = 8.93 g / cm3 - the proportion of copper 5) Any pure copper is used as an anode.

-

Joachim , I will show the process in pictures, if you have any questions, I will try to answer them. It will be good if the pictures do not mix up after my upload to the forum......

-

Since we are talking about shipping company models of the 1900s ... For the time being, I have been looking without success for detailed photos of two models of liners of the type "Empress of Japan" (1895). The first model is stored in Vancouver maritime museum, the second model is in the Canada Science and Technology Museum Ottawa. Perhaps one of our members of the forum will be able to photograph them in detail?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.