-

Posts

1,116 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Valeriy V

-

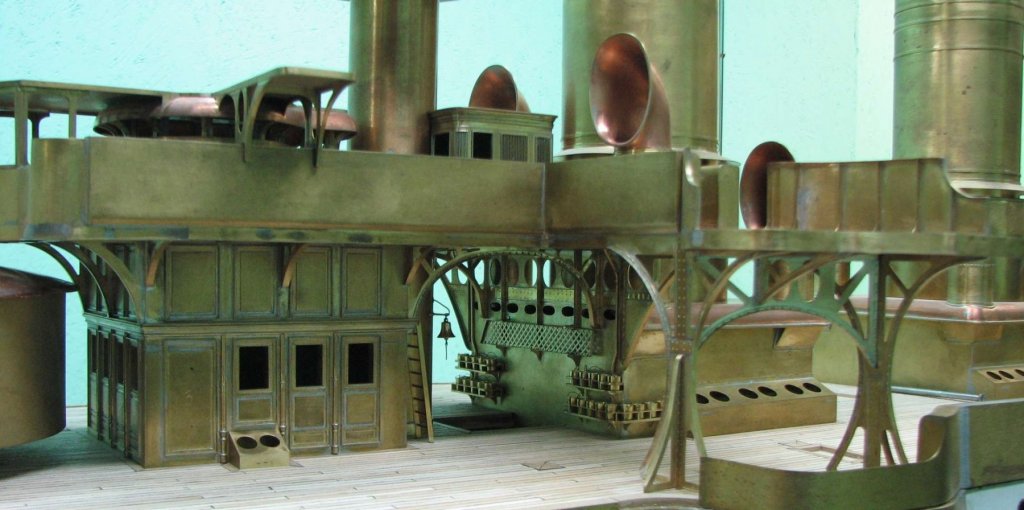

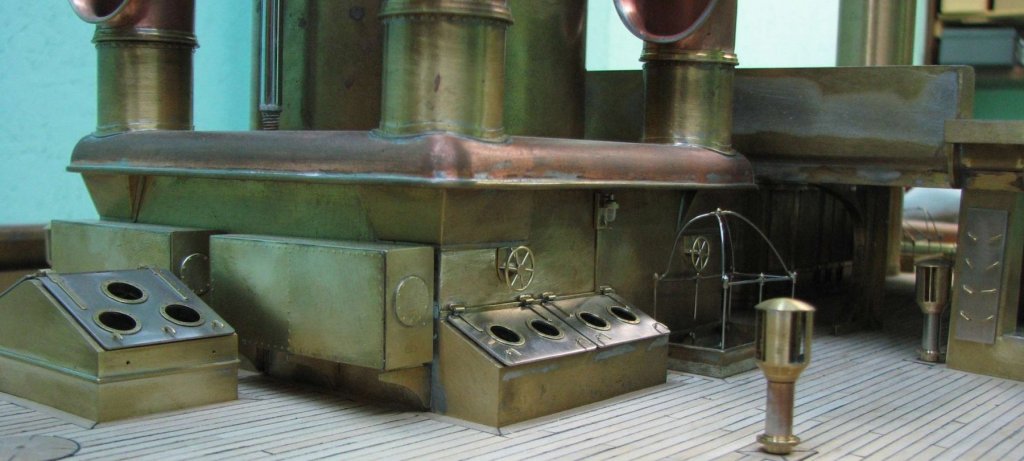

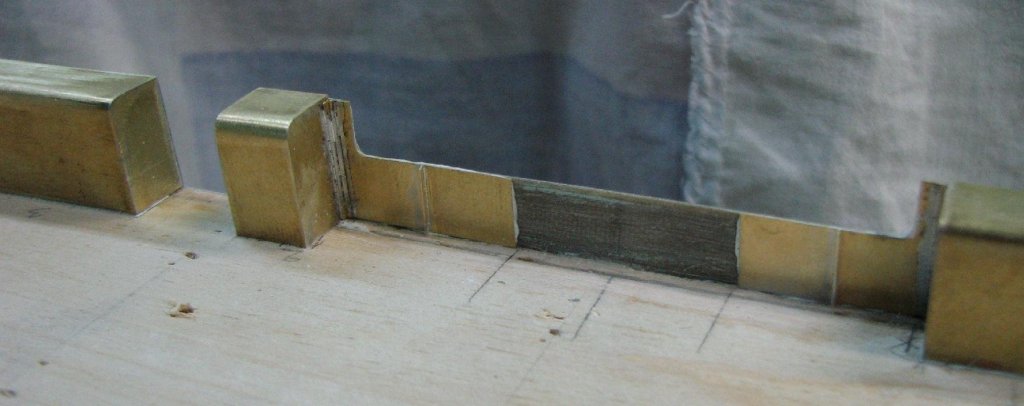

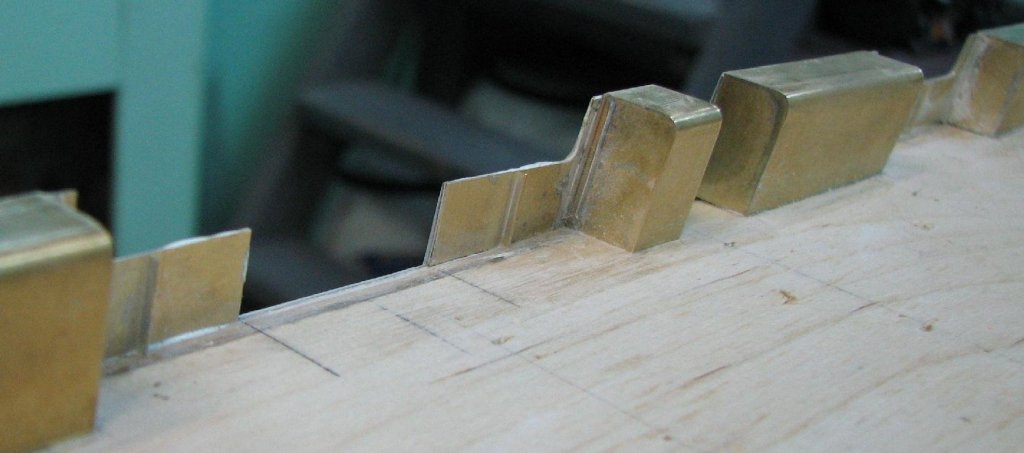

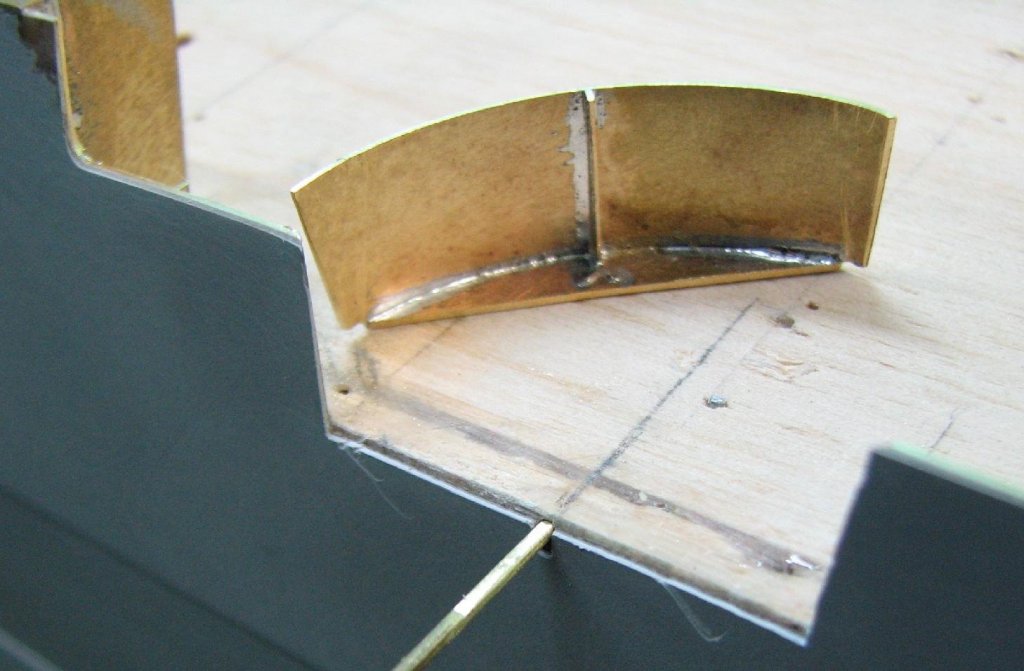

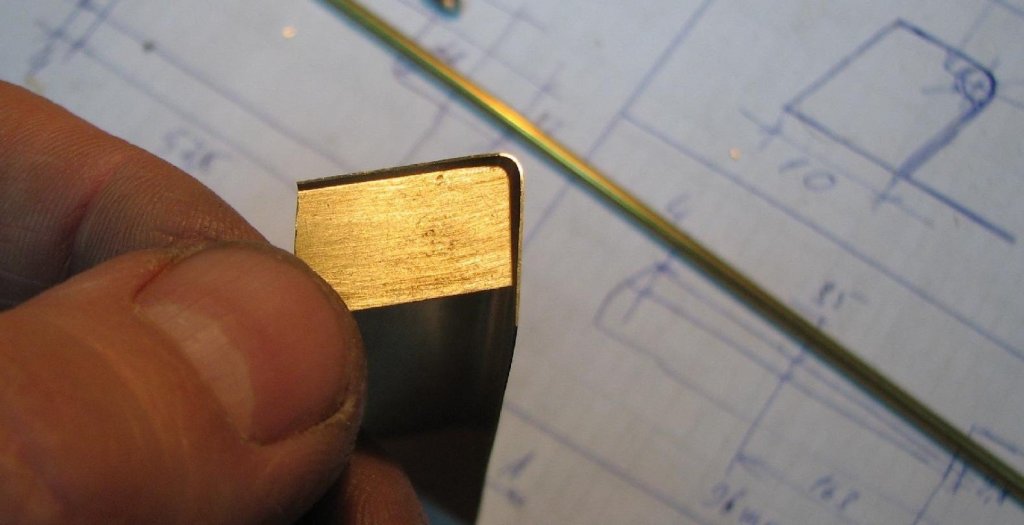

Thank you, Chris. This deflector is welded from two halves. Each half is made of copper by electroforming. At Varyag deflectors will be made by the same method of electroforming, but with whole details, without halves.

-

Colleagues, thank you all for your kind words. I hope you will also like my reports on the construction of the Varyag.

-

At the Varyag still ahead. The reasons for stopping work are temporary and undoubtedly the model will be completed.

-

Hello Joachim! I find it difficult to understand your question, since the translator does not translate the technical text very well. Please indicate with the arrow on the photo what detail you are asking.

-

Thank you all for your emotional evaluation. I am glad that I liked the model, although it is still far from complete. I often repeat the same words looking at models of sailing vessels made of wood and even paper on this forum.

-

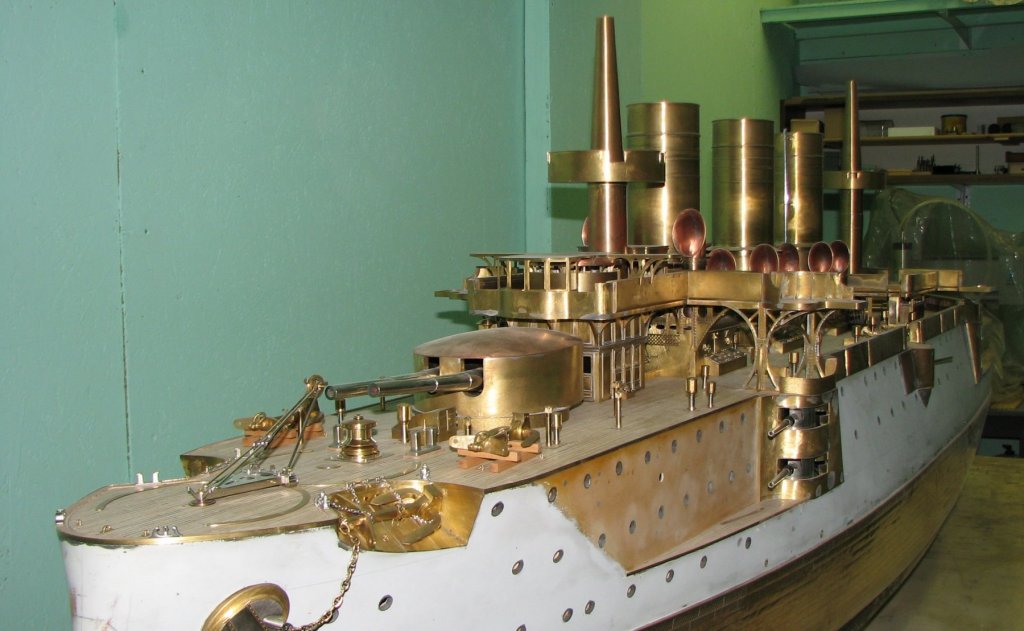

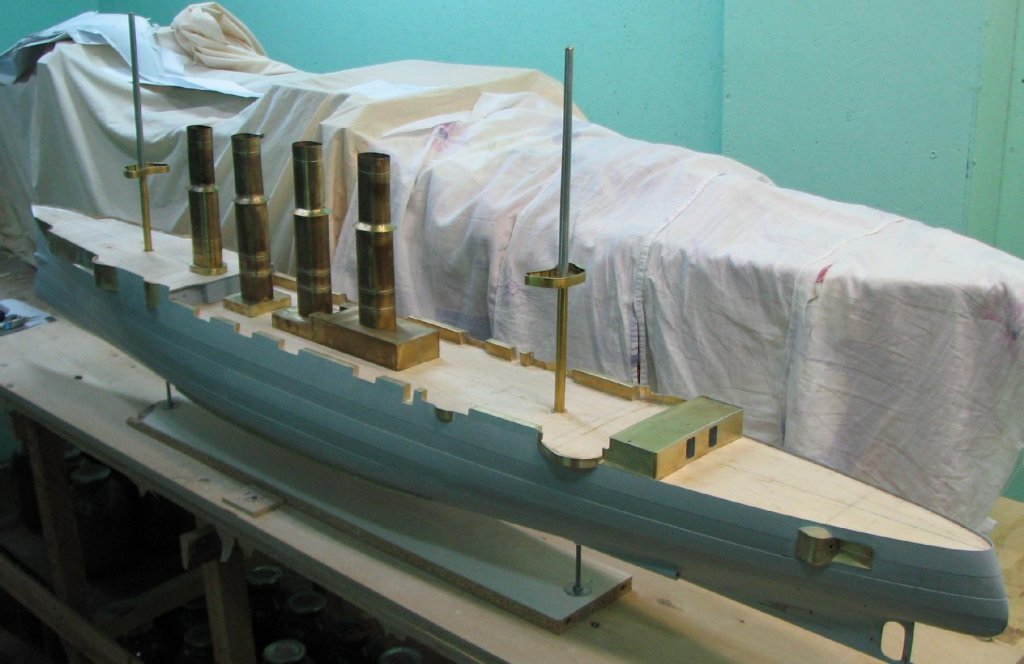

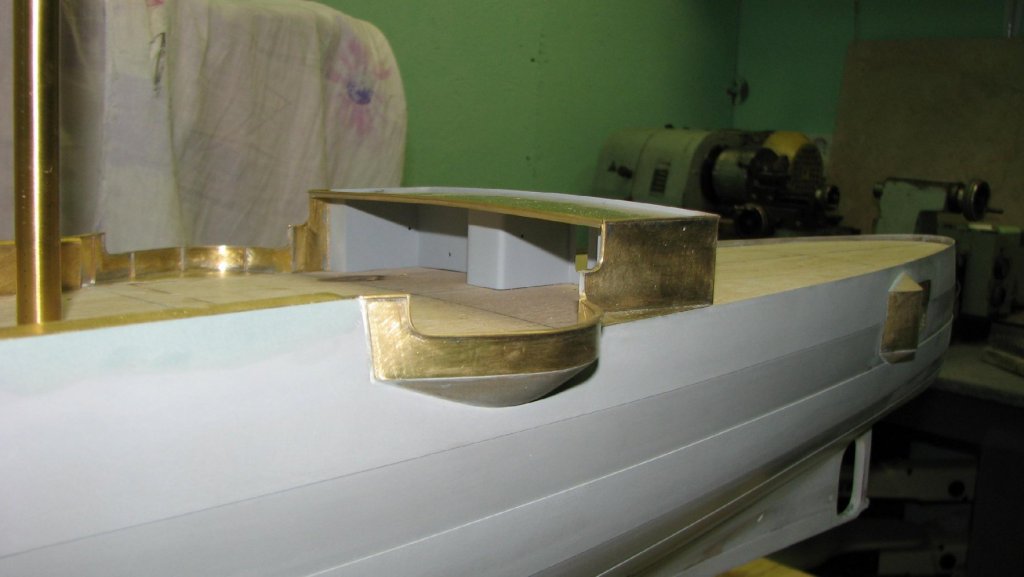

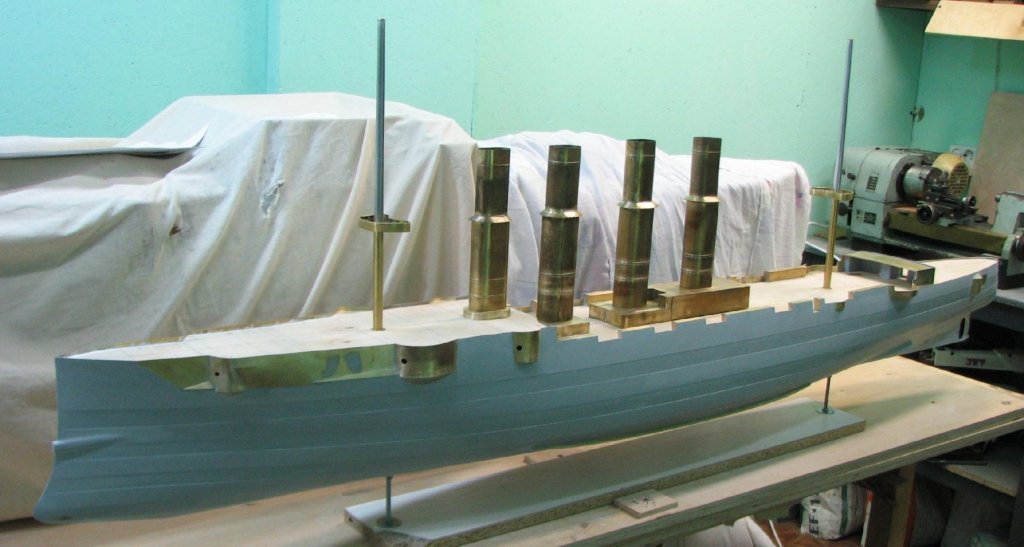

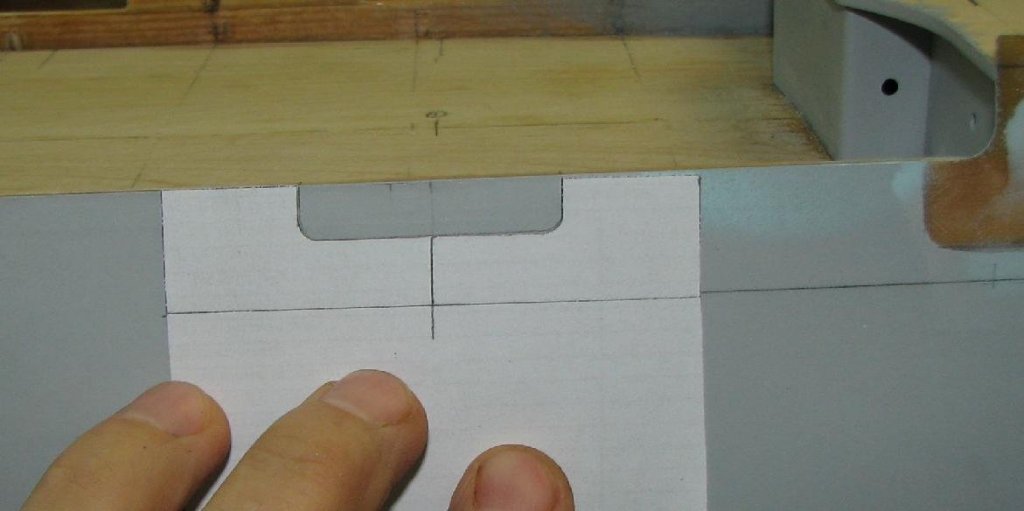

Work on this project is temporarily stopped. Ironclad "Peresvet" , scale 1:50. Under the sheet of his hull , length of 2.65 m.

-

Thanks to all who follow the construction of Varyag! Thank you for your attention to my work! Congratulations to all the masters of this wonderful forum Happy New Year !!! I wish you all a good mood and good luck in building your wonderful models !!!

-

Thank you, Yves, for your appreciation, but I have not yet reached a high level artist. I aim for it. This high level of metalworking is shown here: http://www.ship-model-today.de/fotoreport.htm http://www.ship-model-today.de/towa2 http://www.ship-model-today.de/aelv http://www.ship-model-today.de/balun

-

Thus, you consciously chose the risk of using black metal. Let's hope that there will be no problems. No problem, you can quickly get ahead of me in this technology.

-

Pleasure is usually at the beginning of the project and in its completion. In the middle of work - overcoming all kinds of obstacles.

-

Jean, this does not apply to the hull and large parts of the ship. I hope in the process of building a model, you will see everything.

-

Thank you Popeye! It is possible to learn how to solder in a couple of months, it is not as cool as it seems.

-

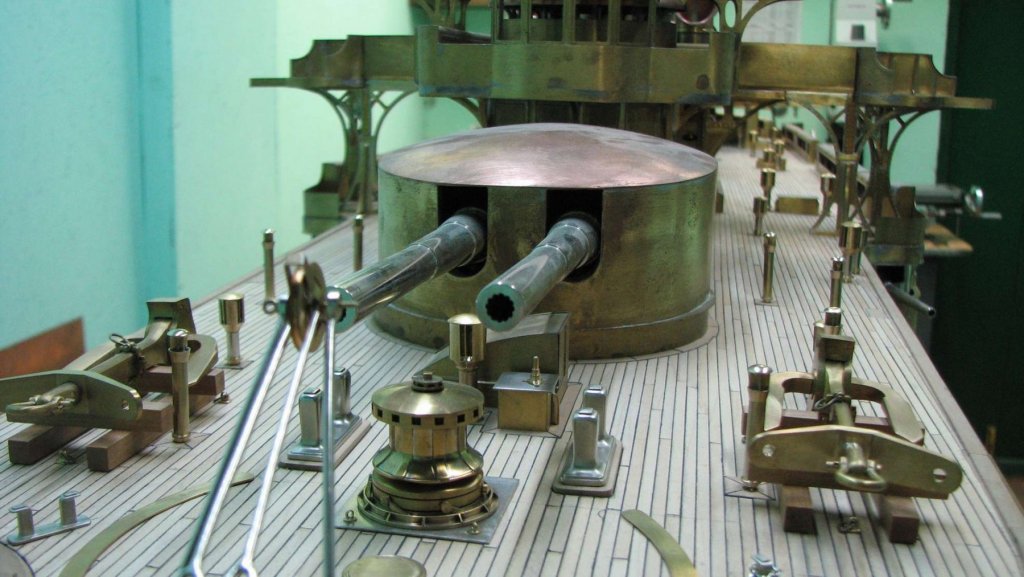

Yes Eberhard, your historical photo brushes aside all doubts about the grids. My photo was taken on the same gun as yours but later.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.